Abstract

CO2 gas injection is one of the recommended enhanced oil recovery (EOR) methods by injecting CO2 through reservoir pores after the residual saturation is reached, since CO2 dissolves easily in oil phase as confirmed by many other researchers in pertaining field studies. An integrated system is urgently required for assessing CO2-EOR study, covering multi-disciplinary aspects as follows: geology, geophysics, reservoir, production, process and economic. Hence, those systems must be reliable in suggesting final decision for feasibility of CO2-EOR operation program, applicable either for pilot scale or for full scale. This paper is proposing an integrated system evaluation, which has the following features: (1) estimate fraction of dissolved CO2, (2) estimate viscosity reduction, (3) estimate future oil productivity index resulted, (4) forecast incremental oil production, (5) estimate surface facilities equipment design, (6) evaluate economical aspects and (7) generate final decision for feasibility of CO2-EOR operation program. Finally, as the main objective of this program, those systems will present a picture of essential reason why we need to promote or reject CO2-EOR plan program, and also some recommendations will be presented in case the CO2-EOR plan does not perform as expected.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Indonesia approximately has 998 million BOE (Barrel Oil Equivalent) of national energy demand, relying on crude oil as the main energy source (MEMRRI 2017). Furthermore, 90% of national oil production comes from depleted oil fields. If we persist in this situation without doing any exploration and discoveries, 3.6 billion of proven Indonesia’s oil reserve will completely drained within the next 11 years (SKK Migas 2016).

Pertamina as an Indonesia’s national oil and gas company has about 110 Tscf of natural gas sources, associated with large amount of CO2 content (Suarsana 2010). CO2 could reduce heating value and contribute to global warming this situation can lead to detrimental issues in economic and environmental aspect, but from another perspective we can turn these issues into new opportunity to enhance oil production by employing CO2-EOR. To raise that program, it is necessary to initiate a conceptual feasibility study of CO2-EOR, engaging essential aspect, such as thermodynamic equilibrium of CO2 dissolved in oil phase, oil recovery gain due to dissolved CO2, CO2 transport and CO2 natural gas purification facilities.

Some previous research has been greatly conducted by some researchers including feasibility study (LPPM UPN 2011; Muslim 2013; Chae and Lee 2015; Lee 2015; Abdurrahman et al. 2017), technical research (Suarsana. 2010; Rostami et al. 2017) and laboratory experiments (Abdassah et al. 2000). From those studies, we can derive some essential factors of CO2-EOR fruitfulness, such as decreased oil viscosity (Abdassah et al. 2010; Rostami et al. 2017; Miller and Jones 1981), oil expansion (Emera and Sarma 2006), oil extraction and evaporation (Abdassah 2010; Leach and Yellig 1981; Yellig 1982) and solution gas drive (Holm and Josendal 1974; Sohrabi and Emadi 2012).

This paper is tackling an integrated system of some essential aspects in CO2-EOR process, encompassing many aspects as follows: geophysics, geological, reservoir and production (GGRP) data properties, the maximum CO2 dissolved at certain pressure and injection rates to increase oil recovery, purification facilities and economics, which can be relied upon as an application to provide simple, precise and fast screening for CO2-EOR.

Research methodology

The methodology derived from essential aspects in CO2-EOR as mentioned earlier, begins with GGRP data properties followed by rate and injection pressure of CO2 design. These data will govern oil viscosity potential which affects oil recovery gain and surface facilities design. Consequently, these two outputs will govern economic evaluation used for final decision. All of these methods are presented in Fig. 1.

Geology, geophysics, reservoir, and production data (GGRP data)

As initial requisite data, geology, geophysics, reservoir and production detail data are as follows:

-

a.

Geology and geophysics data

-

Map area, topography and geology

-

Geophysical survey, contour map and isopach map (formation thickness, porosity, permeability)

-

-

b.

Reservoir data

-

Rock properties (porosity, permeability, saturation, etc.)

-

Fluid properties (specific gravity, viscosity, oil formation volume factor, etc.)

-

-

c.

Production data

Flowing well pressure (Pwf), production rate, inflow performance relationship (IPR), tubing performance relationship (TPR), bottom-hole temperature (BHT)

Oil recovery due to oil viscosity potential

To compute oil recovery gain, we use five governing equations which are solved sequentially, and detail explanations are presented below:

-

1.

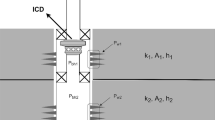

CO2 mass equilibrium is modeled under steady-state condition, determined by CO2 injection rate.

-

2.

CO2 mass equilibrium considered by thermodynamic aspects, where the fugacity of each phase is a function of Peng–Robinson’s (EOS) equation of state (EOS). By engaging EOS, this simulation can compute CO2 injection scenario whether in liquid or in gas phase. In cases of injected CO2 in undersaturated liquid phase, fugacity is ≈ 1.

-

3.

As the amount of dissolved CO2 has increased, chemical structure of oil will be changed, this process could lower oil viscosity, and the change of viscosity is described by the proposed correlation of Barclay and Mishra (2016):

-

4.

Since oil viscosity has reduced, mobility ratio also reduced, meaning oil production will increase as oil will move easier in the pore space. The oil production and oil viscosity relation is described by Vogel inflow performance relationship (IPR) equation:

where

-

5.

Percent of the amount of oil produced is described by the equation below:

where oil recovery gain is derived from the mass balance equation in an unsteady state, with oil saturation (so) is dependent variable, and time (t) is independent variable.

There is two alternatives design of CO2 purification facilities, as follows: distillation and absorption method. Distillation column is computed by three main equations: mass balance, phase balance and heat balance. These three equations are solved using a numerical program or a process simulation program, whereas in the absorption method, CO2 separation mechanism begins with: natural gas entering through the bottom of the absorption column, while absorbent liquid enters through the top of the tower, and the gas and liquid will contact each other, where the absorbent liquid will absorb the CO2, and liquid absorbent is mainly comprised of alkylamines, such as diethanolamine (DEA), monoethanolamine (MEA) and methyldiethanolamine (MDEA) (Miller et al. 1978; Gary et al. 1984; Kohl and Richard 1997; LPPM 2011). Estimation of absorber tower is calculated based on two concepts, that is concept of phase equilibrium between gas and liquid, analogously as Eq. (2) and also the concept of mass transfer between gas and liquid.

Results and discussion

The integration of CO2 gas injection simulation was started from building flowchart as shown in Fig. 1, begun with GGRP data and operating pressure, these data will generate estimation of oil recovery gain and surface facilities design, this information could be our guidance to evaluate whether this project is feasible or not, data from GGRP give essential information such as reservoir size and fluid properties, these data are delivered into three following equations, as follows: equation of mass balance under steady-state condition, CO2 phase equilibrium by Peng–Robinson equation of state and change of oil viscosity.

We are attempting to simulate a CO2 flood by injecting CO2 mixture in gas phase into reservoir with total targeted drainage volume as much as 0.5 MMCF, total injected gas is 31 MMSCFD flowing through many injection well, and injection pressure was varying from 600 up to 2400 psig. The reservoir and injection data are presented in Tables 1 and 2.

The simulation starts from computing the effects of CO2 concentration in oil phase as a function of the rate of CO2 injection. As a result, as presented in Fig. 2, we can see the intersection point between the CO2-oil absorption line due to the CO2 injection process (Eq. 1) and the inter-phase equilibrium line computed from EOS (Eq. 2). The point of intersection is the optimum CO2-oil equilibrium point.

Graph of the CO2 equilibrium in the gas-oil phase. Note: filled circle = cumulative injection day 300, filled square = cumulative injection day 600, filled triangle = cumulative injection day 1200, filled diamond = cumulative injection day 1800, straight line = phase equilibrium at P = 600 psig, straight with dotted line = phase equilibrium at P = 1200 psig, dotted line = phase equilibrium at P = 2400 psig

As a result, 0.027 CO2 fraction in crude oil phase was obtained at 600 psig of CO2 injection pressure and 1800 days cumulative, dissolved CO2 will reduce oil viscosity with respect to cumulative days injection, followed by the alteration of well IPR, and then, the oil recovery gain will be estimated as shown in Fig. 3 through Fig. 5 and Table 4, respectively.

In Fig. 3, we can see that as higher cumulative days of injection we got higher CO2, this happened due to the accumulation of CO2 in the oil phase, for example at a pressure of 600 psig and the cumulative 300 days, we obtained an equilibrium of CO2 fraction in oil (xCO2) as much as 0.01 until the cumulative 1800 days. Similarly, in other simulations we computed higher pressure and we got higher value of xCO2.

Then, the simulation is continued by entering parameters in the target field, and the target field parameter data can be seen in Tables 1 and 2. The simulation of the changes in oil viscosity due to CO2 levels in oil is presented in Fig. 3; it shows that the greater the CO2 content dissolved in oil will lower viscosity, and the longer duration of imbibition also affects the oil viscosity as shown in Fig. 4.

Simulation of inflow performance relationship improvement and cumulative oil production due to CO2 fraction in oil

In this sub-section, we computed inflow performance relationship values at various viscosity values due to accumulation of dissolved CO2 during injection process. In Fig. 5, it can be seen that the injection pressure at 600 psig gives an increase of IPR in every cumulative day of injection, which affects cumulative oil production (Eqs. 6 and 7). From Fig. 5 and Table 3, it shows that in the cumulative 300 days, CO2 injection method takes the lead in cumulative oil production compared to conventional method.

Estimated cost of CO2 purification facilities

In this section we will discuss estimation cost of CO2 purification, with baseline 31 MMSCFD of gas feed. By computing in commercial process simulation software we got results as presented in Table 4, we can see that the cost of equipment for the cryogenic distillation method is about $ 9.5 million, with 86% purity of CO2 gas product.

CO2 purification facilities are available in two options: cryogenic distillation facilities and contactor amine facilities. Cryogenic distillation is recovering CO2 by separating mixture based on boiling point differences, as shown in Fig. 6. Cryogenic distillation facilities consist of two compressors, two columns distillation and tank. Gas compressor is inflating gas pressure, gas flowing into demethanizer contactor separating gas from light hydrocarbon mixture (mainly methane), top product is send to DHU and bottom product is flowing into CO2-column, top product (mainly CO2) is flowing into injection compressor, and bottom product or condensate product is sent to liquid tank. Contactor amine facilities are to recover CO2 by absorbing CO2 through DEA/MDEA, as shown in Fig. 7. Amine facilities have three main units for processing: compressor, DEA contactor, DEA recovery column. The compressor is used to increase the pressure, then the gas is flowing into DEA contactor to dehydrated hydrocarbon gas, the bottom product of DEA contactor is flow into DEA recovery column to clean up DEA, and thus, it can be recycled into DEA contactor. Total investment for facilities is available in three options: $19.5 M for MDEA contactor, $19 M for DEA contactor and $9.5 M for cryogenic distillation as described in Table 4, whereas the process flow diagram (PFD) of purification facility can be seen in Figs. 6 and 7, respectively.

Conclusion

Based on the results of the analysis and discussion above, it can be concluded as follows:

-

1.

Evaluation of CO2-EOR feasibility can be obtained from integration of the following aspects:

-

a.

GGRP data properties, maximum CO2 dissolved and CO2 injection rates can estimate oil recovery gain.

-

b.

The needs of CO2 supply and oil recovery gain will affect design of surface facilities.

-

c.

Oil recovery gain and the need of surface facilities are used for economic consideration.

-

2.

The integration of GGRP aspects is able to provide an overview of the feasibility evaluation of CO2-EOR, quickly, simply and integrated.

-

3.

The simulation study conducted is very useful as a guide before starting the CO2-EOR study in more detail using reservoir models and EOS pressure volume temperature (PVT) regression analysis for CO2-hydrocarbons.

References

Abdassah D, Siregar S, Kristanto D (2000) The potential of carbon dioxide gas injection application in improving oil recovery. In: International oil and gas conference and exhibition in China. Society of Petroleum Engineers

Abdurrahman M et al (2017) EOR in Indonesia: past, present, and future. Int J Oil Gas Coal Technol 16(3):250–270

Barclay TH, Mishra S (2016) New correlations for CO2-oil solubility and viscosity reduction for light oils. J Petrol Explor Prod Tech 6(4):815–823

Buckley SE, Leverett MC (1942) Mechanism of fluid displacement in sands. Trans AIME 146(01):107–116

Chae K-S, Lee JW (2015) Risk analysis and simulation for geologic storage of CO2. In: Proceedings of the World congress on advances in civil, environmental, and materials research, Incheon, Korea

Emera MK, Sarma HK (2006) A genetic algorithm-based model to predict co-oil physical properties for dead and live oil. In: Canadian international petroleum conference. Petroleum Society of Canada

Gary JH, Handwerk GE, Kaiser M (1984) Refinery products. Petroleum refining: technology and economics, 2nd edn. Marcel Dekker Inc, New York, pp 5–15

Holm LW, Josendal VA (1974) Mechanisms of oil displacement by carbon dioxide. J Petrol Technol 26(12):1–427

Kohl AL, Richard N (1997) Gas purification. Gulf Professional Publishing, pp 87–132

Leach MP, Yellig WF (1981) Compositional model studies-CO2 oil-displacement mechanisms. Soc Petrol Eng J 21(01):89–97

Lee YL et al (2015) Overview of CO2-EOR operation plan in Meruap field. In: Proceedings of the World congress on advances in civil, environmental, and materials research, Incheon, Korea

LPPM UPN “Veteran” Yogyakarta (2011) Feasibility study of CO2 flooding. Lapangan Jatibarang, Pertamina EP Region Jawa, Yogyakarta

Miller JS, Jones RA (1981) A laboratory study to determine physical characteristics of heavy oil after CO2 saturation. SPE/DOE Enhanced Oil Recovery Symposium, Society of Petroleum Engineers

Miller LN, Macriss RA, Zawacki TS (1978) Process for acid gas removal from gaseous mixtures. No. US 4080424

Ministry of Energy and Mineral Resources of Republic of Indonesia (MEMRRI) (2017) Handbook of energy and economic statistics of Indonesia 2017. Pusdatin ESDM, Jakarta

Muslim A et al (2013) Opportunities and challenges of CO2 flooding implementation in Indonesia. In: SPE Asia Pacific oil and gas conference and exhibition

Rostami A et al (2017) Modeling of CO2 solubility in crude oil during carbon dioxide enhanced oil recovery using gene expression programming. Fuel 210:768–782

Satuan Kerja Khusus Pelaksana Kegiatan Usaha Hulu Minyak dan Gas Bumi (SKK Migas) (2016), Laporan Tahunan 2016, Jakarta, Indonesia

Sohrabi M, Emadi A (2012), Novel insights into the pore-scale mechanisms of enhanced oil recovery by CO2 injection. In: SPE Europec/EAGE annual conference. Society of Petroleum Engineers

Suarsana IP (2010) Producing high CO2 gas content reservoirs in Pertamina Indonesia using multi stage cryogenic process. In: SPE Asia Pacific oil and gas conference and exhibition. Society of Petroleum Engineers

Yellig WF (1982) Carbon dioxide displacement of a West Texas reservoir oil. Soc Petrol Eng J 22(06):805–815

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kristanto, D., Hermawan, Y.D., Hariyadi et al. Integrated simulation system of CO2 gas injection application for enhanced oil recovery in the oil field. J Petrol Explor Prod Technol 10, 3917–3923 (2020). https://doi.org/10.1007/s13202-020-00955-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-020-00955-9