Abstract

Emulsions are extensively prevalent in the oil industry in both advantageous and disadvantageous ways. In the literature, conventional water flooding in high permeability oil reservoirs has confronted with water channeling and poor sweep efficiency. In this paper, the remedial application of O/W emulsions as an EOR method in improving water performance is discussed. To this purpose, a series of flooding experiments were carried out in one of the Iranian oil reservoirs in reservoir condition of 75 C and 2000 psi. Then, visual stability measurements were conducted to inspect the stability characterization of the emulsion. Sodium dodecyl sulfate was applied helping simple dispersion of the gasoil into the water phase, and emulsions with water percentage of 90, 80, 70 and 60 were developed to introduce into the porous media. It was found out from flooding experiments that emulsion injection after conventional water flooding can lead to additional oil recovery (up to 20%). Besides, the emulsion with 80% water cut was determined as the optimum emulsion for injection in this reservoir considering financial aspects. Moreover, results of the stability test revealed that the aqueous phase with one wt% surfactant or higher had formed emulsions which have been stable during a long period of 6 months.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Technically speaking, primary production from oil reservoirs cannot recover more than 30% of IOIP. Moreover, with recent growing demand for more energy resources, the role of implementation of secondary and tertiary oil recovery methods has been highlighted. To fulfill this, many researches have been conducted to propose sufficient ways to extract more crude oil from the underground (Policy 2012). In the secondary oil production, water flooding is considered as the primary method, bringing in several advantages including lower operation cost which was performed for the first time in an oilfield of northeast America in the late eighteenth century (Craig 1993; Sheng 2014).

In the last decades, injection of water with varieties of dissolved compositions into the oil reservoirs by the mean of improving oil recovery has been the subject matter of many scientific works (Craig 1993; Willhite 1986). To be more precise, low-salinity water flooding is one of the most promising methods of oil recovery improvement that has gotten several attentions lately (Sheng 2014). Although this method has led to few increases in oil recovery by raising capillary number subsequently after reduction in oil–water interfacial, its poor sweep efficiency and unfavorable mobility ratio as a result of early breakthrough and water channeling still are regarded as some of its principal drawbacks which may get severe in reservoirs with vertical heterogeneity (Liu et al. 2006, 2010; Sheng 2014; Sydansk and Romero-Zeron 2011). On the other hand, from a financial standpoint, water treatment procedures possess cost in the range from 5 to more than 50 cents per water barrel to oil companies which turn out to be $40 billion to deal with unwanted water in aggregate (Crabtree and Romano 2000). Unfortunately, some portions of this produced water are related to the inefficiency of water flooding which bypasses from injection to production well leaving a massive amount of reservoir oil intact (Dong et al. 2007; Liu et al. 2010). Therefore, the utilization of useful water control technology can bring out a significant reduction in expenditures and improve oil recovery (Crabtree and Romano 2000). One of these water control technologies is the application of emulsions for the injection in the reservoirs (Bai et al. 2000; Taylor et al. 2015). Emulsions are usually defined as a combination of two different immiscible liquids that are dispersed in each other consisting of two distinct phases, the dispersed or internal phase, and the continuous or external phase (Bande et al. 2008; Gewers 1968; Maaref et al. 2017; Pietrangeli et al. 2014). Generally, two types of emulsions are used in this technique, which are O/W and W/O emulsions (Winsor 1948). Between these two, O/W emulsions have shown a better performance and higher oil recovery in the literature (Gogarty 1967). These emulsions can improve water injection profile through the selective plugging process. This means that they can prevent water from passing through areas with lower moveable oil saturation and reduce water cut, while the oil recovery factor is increasing (Arastoo and Zohoorparvaz 2015; Bai et al. 2000; Breston 1957; Moradi et al. 2014; Yu et al. 2018). In the 1970s, McAuliffe was the first who investigated in O/W emulsions flooding as an EOR method. He introduced emulsion into two parallel cores and stated that emulsions drops have been trapped in high-perm layers and formed a barrier against water flow. He attributed this fact to the larger diameter of emulsion oil drops compared to the pore throat diameter.

Emulsions aside, there are a plethora of studies worked on various selective plugging agents such as gels, cement and polymers to control water cut in production wells (Bai and Zhang 2011; Breston 1957; Liu et al. 2017; Stavland et al. 2006; Wang et al. 2003). Among these, although emulsion is not capable as much as the others in permeability reduction of formations, it has its unique distinctions (Seright and Liang 1995). In Bai et al. investigation, it is shown that more recovery factor has been obtained from emulsion injection over gel injection due to the formation damage it induced on target areas and lack of the incident of selective plugging process during the gel injection. They created an emulsion with a high percentage of water content and introduced it in one of the oil reservoirs in the North Sea to diminish water cut up to 30% in their oilfield study (Bai et al. 2000). Furthermore, the other advantages of O/W of emulsion flooding are its accessibility and lower cost of transportation as well as its more in-depth coverage into the formation and so its undemanding injectivity (Hasan et al. 2010; Kumar and Mahto 2016; Mcauliffe 1973a, b; Romero et al. 1996; Yu et al. 2018). Romero et al. studied on the effect of fracture plugging of in situ O/W emulsions by injection of an optimum amount of water/oil ratio in sandpacks and observed a massive reduction of 90% in water relative permeability as well as injectivity. This matter even was more evident in the initial part of their model (Romero et al. 1996). According to Starvland et al. (2006), the amount of this permeability reduction varies from zone to zones, with regard to the fluids saturations. Demikhova et al. (2018) attributed this matter to retention of dispersed oleic droplets of O/W emulsions in the pore throat as a consequence of two mechanisms: (1) size exclusion and (2) droplets/pore walls interactions in porous media. Yu et al. (2018) declared that permeability reduction of their sandpack models was a function of the volume of emulsion slug, oil and water fraction in emulsions, injection flow rate and the absolute permeability of the models. Zohoorparvaz and Arastoo in their experimental work evaluated the ability of inverse water in oil emulsions in water cut control after water flooding in both homogeneous and heterogonous reservoirs and concluded that the reductions of effective permeability of water in high-perm layers have led to almost 30% improvement in oil recovery (Arastoo and Zohoorparvaz 2015; Taylor et al. 2015). Mandal et al. used O/W emulsions with different oil contents of 5, 10, 20 and 30%, made by gear oil and injected them into sandpack models. The result of their flooding experiments illustrated that in the emulsion with the oil content of 10 percent, a significant amount of oil recovery has been obtained and after that with the increase in oil percentage, only slight growth in oil production is observed (Mandal et al. 2010). Later on, Pei et al. enforced O/W emulsions by using few quantities of HPAM and noticed more stable emulsions with higher shear viscosity. They experienced improved sweep efficiencies and more than 30% enhancement in oil recovery when they injected them in sandpack models (Pei et al. 2017).

Typically, using one or several surface active agents play a significant role in the formation of stable emulsions. In Romero et al. (1996), experiments emulsions had been formed as a result of alkaline injection. Torrealba and Hoteit observed the in situ generation of thermodynamically stable microemulsions in their reservoir model based on the injection of cyclical surfactant slugs after mixing with existed oil in the reservoir using a chemical flooding simulator (UTCHEM 2000). They found the successful treatment of conformance problems as a result of the formation of the high viscosity microemulsions in the high-perm zones inducing a crossflow into the low permeability zones. In their research, the viscosity of the injected fluids was typically low which preserved injectivity and ensured the invasion of the conformance agent toward the thief zones leading to plugging of thief layers (Torrealba et al. 2018). Bai et al. (2000) synthesized a new emulsifier and created stable emulsions even with 80% of water content. Long Yu et al. characterized the properties of the O/W emulsions which have been formed from heavy crude oil information brine. According to their observations, heavy crude oil could be emulsified in formation brine using surfactants (Span 60 and Tween 80) and NaOH. In their work emulsions with oil/water IFTs, less than 1 mN/m exhibited high stability and a highly effective plugging performance in sandpack (Yu et al. 2018).

In this study, we attempt to evaluate the efficiency of O/W emulsion in an Iranian onshore oil reservoir conditions that suffer from high produced water cut after water flooding. To cut down the operation costs, the emulsions were formed from gasoil and SDS as an emulsifier in the distilled water. Through this study, the optimum amount of the surfactant is gained, and the best water/oil ratio is nominated to perform in the oilfield aiming to reduce water cut production in the future.

Experimental section

Materials

In this experimental work, the intermediate crude oil was collected from one of the Iranian oil fields in the south of Iran. The oil had the API of 26.3 and viscosity of 3.8 cp at reservoir temperature of 75 C and 69.4 cp at surface temperature. Also, the asphaltene content of the oil was measured as 7.5 wt% (IP-143). The composition of formation brine with the salinity of 75,000 ppm used to saturate the porous media is shown in Table 1 which has a density of 1.055 g/cm3. In the experiments, the synthesized sea water was composed by dissolving different salts with specific concentrations in distilled water. Table 1 also shows the precise composition of the synthesized sea water with a density of 1.034 g/cc and total dissolved solids of 38,670 ppm. For emulsification, an ionic surfactant of sodium dodecyl sulfate (sodium lauryl sulfate) was used provided by Sigma-Aldrich Chemicals Company, USA. This creamy-white powder has a great potential to form O/W emulsions due to its excellent solubility in water (soluble 1 g in 10 ml) and high HLB value of 40 (Wu et al. 2014). Besides, for the oleic phase of the emulsion, gasoil with the density of 0.887 g/cc was used which is a combination of hydrocarbons with the carbon number of 10–15 consisting of saturated and aromatic hydrocarbons (Date 2011; Services 1995). Gasoil is regarded as an inexpensive fuel in Iran. Therefore, it justifies its application for making emulsions.

Emulsions preparation

In this section, O/W emulsions with different volume ratios of water to oil of 90/10, 80/20, 70/30 and 60/40 were created. Gasoil and double-distilled water were used as internal and external phase, respectively. Minimizing IFT between gasoil and distilled water is the main necessity for dispersing oil drops in the water and making stable emulsions. To achieve this, the surfactant of SDS was dissolved in the water at a specific concentration before adding the oil phase. The surfactant concentration in the emulsions has been chosen around twice the critical micelle concentration of SDS. Regarding this fact that SDS is an ionic emulsifier, the conductivity measurements method was applied for the determination of CMC (Domínguez et al. 1997; Miura and Kodama 1972). Hence, the electrical conductivity of the different dissolved weight percent of the surfactant was measured by Benchtop PH/Conductivity Meter AZ-86505 (Fig. 1) at room temperature, and Fig. 2 is obtained. According to this figure, the graph has experienced a break at the SDS concentration of 0.251 weight percent and the capacity of solutions for ionization has been reduced after that. This point is construed as critical micelle concentration. Basically, below the CMC, the dissolved molecules are arranged in monomer structures, while the molecules are assembled and structured in almost spherical shapes called micelles over this point. Since micelles are more enormous than the monomers, the diffusion of the molecules into the solvent has become slowed down, and the figure features a declination in this spot (Zana 1996; Zana et al. 1992). The mixing process of the surfactant solutions and gasoil was conducted by using ultrasonic homogenizer SONOPULS HD 2070 made by Bandelin Company, Germany, for three periods of five-minute length with the frequency of 20 kHz and maximum power. Between the periods’ intervals, for more desirable blending, the samples were stirred on the magnetic stirrer hot plate in a rate equal to 400 rpm for 5 min, either. To confirm that the formed emulsions were precisely oil in water, Bancroft’s rule (Bancroft 1913) was employed by mixing prepared samples in both gasoil and water. As reported by him, if the formed emulsions dissolve in an oleic phase, then the emulsion type is W/O. Otherwise, the emulsion should be O/W. Since all samples were dispersed in the gasoil, we assured that the emulsion type was O/W.

Sandpack flooding experiments

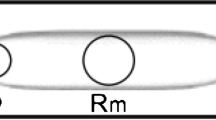

An experimental flooding setup was utilized to conduct HP-HT sandpack flooding tests. The system contains one HPLC pump, three accumulators, one back pressure regulator and a sandpack holder which has been held in an entirely horizontal situation inside an oven at 75 centigrade. As it is evident in Fig. 3, the accumulators are located outside of the oven. HPLC pump injects the prepared fluids and oil into the model with employed flow rates. The differential pressure between the inlet and outlet of the model is recorded by Siemens SITRANS P DS III differential pressure transmitter. The reservoir pressure is exerted by supplying a back pressure regulator adjusted at 2000 psi at the outlet line before. The effluent fluids pass through the regulator and are collected inside a measuring cylinder. The diameter of the sandpack models is 5 cm with the length of 16 cm, and the maximum working pressure and temperature of the apparatus are 400 bar and 200 centigrade, respectively. For measuring some of the petrophysical properties, firstly, a laboratory mechanical shaker was used, and sand with the size of 40–70 mesh was chosen for preparing a quite homogeneous porous media. After that, the prepared sandpack was saturated by flooding formation brine at the slow rate of 0.1 cc/min and the porosity of the models is calculated by subtraction of the dry weight from the saturated weight of the models. The range of porosity was from 36.7 to 38.3%. In the next step, absolute permeability was calculated by formation brine injection at different flow rates using Darcy equation. To avoid the non-Darcy condition, we examined several flow rates of 0.1, 0.2, 0.3 and 0.5 cc/min and ∆p was determined by the differential pressure transmitter, and the absolute permeabilities were from 1283 to 1392 mD. Subsequently, the dead oil of the reservoir was injected again with the flow rate of 0.1 cc/min to simulate the oil migration into the formation until the water is observed in effluent fluid. At this step, back pressure was adjusted at 2000 psi, and the injection was continued until no water is observed in the outlet. Afterward, the percentage of IOIP and connate water is estimated by measuring the volume of the water which has been collected into the cylinder. The previously prepared sea water and emulsions were introduced into the porous media at a constant flow rate of 0.5 cc/min. Each flooding test was performed up to 2.5 PV. Table 2 indicates the summary of all test and their porous media properties.

Results and discussions

Sandpack flooding experiments

At the beginning of the flooding test, with the intention of having a yardstick, synthesized sea water was flooded into the porous media for 2.8 PV in a horizontal orientation. Figure 4 demonstrates the amount of cumulative recovery factor and water cut percentage during this run. Having observed that, it is obvious that the amount of water cut has reached 90% in 1.1 PV. In many cases, this number is taken as the end of the oil field production. For instance, in an oil well with water cut production of less than 90%, the cost of water treatment can approximately be as costly as more than $4 per barrel of oil (Crabtree and Romano 2000). By realizing this, this point was nominated for the outset of the subsequent emulsion flooding tests. The breakthrough time of the water happened nearly at 0.22 PV, and it has recovered 42% of IOIP. Also, it is worth mentioning that no oil was experienced in the outlet in the pore volumes higher than 2.5. To investigate the enrichment of water flooding performance through emulsion flooding, four different emulsions were flooded during four flooding. In these experiments, all the operation conditions such as temperature, pressure, injection flow rate and slug volume were identical, and only the water/oil ratio has been altered. The emulsion slug has been thrown in the porous media from 1.1 to 1.6 PV. Figures 5, 6, 7 and 8 represent the water cut percentage and cumulative oil recovery factor of these experiments. Comparing the flooding data is a significant contribution to get to a comprehensive deduction. To aim this, Fig. 9 is plotted. This figure shows the amount of water cut produced from the experiments, all together. The trends of all tests had been almost indistinguishable before the emulsions have been introduced to the system. No water was observed before the 0.2 PV, and the water breakthrough time of all runs was between 0.21 and 0.23 PV. At the same time with appearing of injected water at the outlet, the water cut curves have experienced a sharp rise continuing until 1 PV almost in all cases. Although 0.5 PV of emulsion entered into the system in 1.1 PV, the system has undergone a time lag, and minimum water cut has occurred in around 1.8–2 PV. This happening is associated with the required time of emulsions to act as a selective plugging agent and plug the pore throats appropriately (Fig. 11). Also, it is quite clear that emulsion 90/10 was not as successful as the others in the reduction of water production. To be quantitative, in their best shots, the emulsion 90/10 has diminished the amount of water cut to merely 69.3%, while this parameter in the injection of emulsions 80/20, 70/30 and 60/40 is 48, 45.5 and 40.1%, respectively.

Besides, for having a quantifiable examination of oil recoveries, Fig. 10 is depicted. Even though only sea water was injected until 1.1 PV for test 2–5, the secondary recoveries are unequal by the end of this time which can be ascribed as differences in petrophysical properties of the sandpacks, including pore volume, permeabilities and IOIP. However, as it can be observed that tertiary injection of all emulsions has entailed in significant improvement in oil produced. This phenomenon can be explained with two arguments. Naturally, water tends to pass through the areas with fewer blockades. After flooding emulsion, emulsion oil drops are trapped in these areas and jam the flow passage, and so the injection fluid flow is conducted to the regions with higher oil saturations. Hence, the volume sweep efficiency is improved. The second argument is attributed to the higher viscosity of O/W emulsion rather than the sea water which comes to direct contact with displacing fluid mobility and higher recovery improvement (Ali et al. 1979; Dong et al. 2007; Mandal et al. 2010). In fact, in O/W emulsions, by few increments in oil content, the viscosity of the system increases automatically, and with crossing over the inversion point, the viscosity is correlated reversely with the amount of oil content (Bera and Mandal 2014). This matter can be seen in Fig. 12 which shows significant increase in differential pressure of the models during emulsion injections. It is also quite evident that the differential pressure curve has experienced a sudden jump at the beginning of emulsions injections due to its higher viscosity which naturally affects the injectivity. By looking back at Fig. 10, it is elusive that the tertiary injection of emulsion 60/40 is the best option rather than the others enhancing the recovery factor by 22.6%. However, on the other hand, the preparation of this emulsion costs remarkably higher because of the need for gasoil and also SDS to stabilize this system. When the oil content goes high, there are much more needs for molecules of surfactant to shape in micelle structure to disperse the oil drop inside the aqueous phase. Also, another visible feature of the figure is that the recovery factor of the emulsion 80/20 has encountered a considerable increase than the oil recovery of emulsion 90/10 and it is close to the 70/10’s. To conclude, although the injection of the emulsion has led to higher oil recovery in all cases, it is vital to mention that the injection of conventional emulsion sustained an extensive effect on differential pressure and so the injectivity as was mentioned before. Thus, it could be an ideal choice for implementing in the oil field if the emulsion was formed inside the porous media since many researches have confirmed the better operation of microemulsion than conventional emulsions due to its better injectivity (Santanna et al. 2009; Torrealba et al. 2018). However, the feasibility of this matter should be assessed in the studied reservoir in the future projects.

Determination of emulsion stability in surfactant concentrations

In the previous section, it was concluded that the water/oil ratio of 80/20 is an optimum one for the emulsion to reduce water production. In this time, the optimum concentration of SDS in this emulsion is determined. Even though it is clear that greater amount of surfactant is able to make more homogeneous dispersion of oil drops and higher stability, this matter in addition to extravagant fees it sustains can reduce the emulsion plugging efficiency by lowering capillary resistance factor (Jamin 1860; Yu et al. 2018). To this purpose, 8 different concentrations, including 0.1, 0.3, 0.5, 0.7, 1, 1.5, 2 and 3 weight percent, as well as zero percent dissolved in distilled water and 9 emulsions were prepared. Just a few minutes after the preparation, it was noticed that emulsions with SDS concentrations of zero and 0.1 wt% became unstable and some amount of gasoil was seen on top and emulsions with concentrations of 0.3 wt% or higher did not meet any changes. As mentioned earlier, CMC of SDS is 0.25 wt% which is placed between 0.1 and 0.3 wt%, so it can be realized that for having a stable emulsion, a minimum amount of CMC is needed to be dissolved into the aqueous phase to make the oil phase disperse into the water. Then, the samples were kept in the oven in the temperature of 75 C equal to reservoir temperature for 1, 5 and 15 days and also the stability of the samples was examined visually (Fig. 13) using creaming index method. This method is an acceptable way for the characterization of emulsion stability within a specific time span (Li et al. 2009; Rocha et al. 2016; Yu et al. 2018). This index is defined as the division of the volume of the creamed phase by the total emulsion volume, and creamed phase is the internal phase of emulsion which is migrated under the influence of buoyancy (Demetriades et al. 1997). Figure 14 represents the creaming index with respect to the concentration and spent days. It indicates that the stability of the emulsion varied upon the time and its intensity in the first days (1 and 5) was more drastic than the last day (15). For further investigation, the samples were retained up to 6 months, and it was comprehended that emulsions formed by 1 wt% ≤ were still sufficiently stable. Therefore, 1 wt% is regarded as the optimum SDS concentration for forming stable emulsion over a long period (Fig. 15).

Conclusions

-

It was determined by electrical conductivity measurement that critical micelle concentration of sodium dodecyl sulfate occurs in 2510 ppm or 8.7 × 10−3 mol/L in double-distilled water at room temperature.

-

It was inferred from the flooding tests that utilization of O/W could significantly enhance the water flooding performance by improving sweep efficiency, recovery enhancement (up to 22%) and water cut reduction. Besides, the water/oil ratio of 80/20 was determined as the sufficient emulsion to inject into the studied reservoir.

-

Visual characterization of the emulsion stability showed that having a surfactant concentration beyond the CMC improves the stability of the emulsion significantly.

-

It was also obtained that for a long period (over 6 months) 1 wt% was regarded as an optimum concentration of SDS when the ultrasonic homogenizer along with the magnetic stirrer was used for making emulsions.

Abbreviations

- IOIP:

-

Initial oil in place

- O/W:

-

Oil-in-water

- W/O:

-

Water-in-oil

- IFT:

-

Interfacial tension

- SDS:

-

Sodium dodecyl sulfate

- API:

-

American Petroleum Institute

- HLB:

-

Hydrophilic–lipophilic balance

- CMC:

-

Critical micelle concentration

- HP–HT:

-

High pressure–high temperature

- SW:

-

Sea water

- FB:

-

Formation brine

- WC:

-

Water cut

- HPLC:

-

High-performance liquid chromatography

References

Ali SM, Figueroa JM, Azuaje EA, Farquharson RG (1979) Recovery of Lloydminster and Morichal crudes by caustic, acid and emulsion floods. J Can Pet Technol Pet Soc Can 18:1

Arastoo A, Zohoorparvaz A (2015) Petroleum science and technology the applicability of inverse water-in-oil emulsion as a selective plugging agent. Pet Sci Technol 2014:37–41

Bai B, Zhang H (2011) Preformed-particle-gel transport through open fractures and its effect on water flow. SPE J Soc Pet Eng 16(02):388–400

Bai B, Han M, Li Y, Wei M, Gao Y, Coste JP (2000) Selective water shutoff technology study and application of W/O emulsions. In: SPE improved oil recovery symposium, Society of Petroleum Engineers

Bancroft WD (1913) The theory of emulsification. J Phys Chem ACS Publ 17(6):501–519

Bande RM, Prasad B, Mishra IM, Wasewar KL (2008) Oil field effluent water treatment for safe disposal by electroflotation. Chem Eng J Elsevier 137(3):503–509

Bera A, Mandal A (2014) Microemulsions: a novel approach to enhanced oil recovery: a review. J Pet Explor Prod Technol 5:255–268

Breston JN (1957) Selective plugging of waterflood input wells theory, methods and results. J Pet Technol Soc Pet Eng 9(03):26–31

Crabtree M, Romano C (2000) Today, oil companies produce an average of three barrels. Oilfield Rev 12:30–51

Craig FF Jr (1993) The reservoir engineering aspects of waterflooding monograph, vol 3, Society of Petroleum Engineers of AIME, Texas

Date AW (2011) Analytic combustion: with thermodynamics, chemical kinetics and mass transfer. Cambridge University Press, Cambridge

Demetriades K, Coupland JN, McClements DJ (1997) Physicochemical properties of whey protein-stabilized emulsions as affected by heating and ionic strength. J Food Sci 62(3):462–467

Demikhova II, Likhanova NV, Perez JRH, Lopez DA, Olivares-xometl O, Andres E (2018) Author’s accepted manuscript emulsion flooding for enhanced oil recovery: filtration model and numerical simulation. J Pet Sci Eng. https://doi.org/10.1016/j.petrol.2016.02.018

Domínguez A, Fernández A, González N, Iglesias E, Montenegro L (1997) Determination of critical micelle concentration of some surfactants by three techniques. J Chem Educ ACS Publ 74(10):1227

Dong M, Liu Q, Li A (2007) Micromodel study of the displacement mechanisms of enhanced oil recovery by alkaline flooding. In: International symposium of the society of core analysts, Calgary, AB, Canada, pp 10–12

Gewers CWW (1968) Colloid and surface chemical problems in non-conventional heavy oil recovery. J Can Pet Technol Pet Soc Can 7(02):85–89

Gogarty WB (1967) Rheological properties of pseudoplastic fluids in porous media. Soc Pet Eng J Soc Pet Eng 7(02):149–160

Hasan SW, Ghannam MT, Esmail N (2010) Heavy crude oil viscosity reduction and rheology for pipeline transportation. Fuel Elsevier 89(5):1095–1100

Jamin J (1860) Notes about equilibrium and flow of fluids in porous body. Acad Sci 50:172

Kumar S, Mahto V (2016) Emulsification of Indian heavy crude oil in water for its efficient transportation through offshore pipelines. Chem Eng Res Des Elsevier 115:34–43

Li C, Liu Q, Mei Z, Wang J, Xu J, Sun D (2009) Pickering emulsions stabilized by paraffin wax and Laponite clay particles. J. Colloid Interface Sci Elsevier 336(1):314–321

Liu Y, Bai B, Shuler PJ (2006) Application and development of chemical-based conformance control treatments in China oilfields. In: SPE/DOE improved oil recovery symposium, Society of Petroleum Engineers

Liu Y, Bai B, Wang Y (2010) Applied technologies and prospects of conformance control treatments in China. Oil Gas Sci Technol 65(6):859–878

Liu Z, Li Y, Lv J, Li B, Chen Y (2017) Optimization of polymer flooding design in conglomerate reservoirs. J Pet Sci Eng Elsevier 152:267–274

Maaref S, Ayatollahi S, Rezaei N, Masihi M (2017) The effect of dispersed phase salinity on water-in- oil emulsion flow performance: a micromodel study the effect of dispersed phase salinity on water-in-oil emulsion flow performance: a micromodel study. Ind Eng Chem Res 56:4549–4561

Mandal A, Samanta A, Bera A, Ojha K (2010) Characterization of Oil–water emulsion and its use in enhanced oil recovery. Ind Eng Chem Res 49:12756–12761

Mcauliffe CD (1973a) Oil-in-water emulsions and their flow properties in porous media. J Pet Technol 25:727–733

McAuliffe CD (1973b) Crude-oil-water emulsions to improve fluid flow in an oil reservoir. J Pet Technol 25(06):721–726. https://doi.org/10.2118/4370-PA

Miura M, Kodama M (1972) The second CMC of the aqueous solution of sodium dodecyl sulfate. I. Conductivity. Bull Chem Soc Jpn 45(2):428–431

Moradi M, Kazempour M, French JT, Alvarado V (2014) Dynamic flow response of crude oil-in-water emulsion during flow through porous media. Fuel 135:38–45. https://doi.org/10.1016/j.fuel.2014.06.025

Pei H, Zhang G, Ge J, Jiang P, Zhang J, Zh, Zhong Y (2017) Study of polymer-enhanced emulsion flooding to improve viscous oil recovery in water flooded heavy oil reservoirs. Colloids Surfces A Phys Eng Asp. https://doi.org/10.1016/j.colsurfa.2017.06.039

Pietrangeli GA, Quintero L, Jones TA, Darugar Q (2014) Treatment of water in heavy crude oil emulsions with innovative microemulsion fluids. In: SPE heavy and extra heavy oil conference: Latin America, Society of Petroleum Engineers

Policy US (2012) Carbon dioxide enhanced oil recovery: a critical domestic energy, economic, and environmental opportunity

Rocha JA, Baydak EN, Yarranton HW, Sztukowski DM, Ali-Marcano V, Gong L et al (2016) Role of aqueous phase chemistry, interfacial film properties, and surface coverage in stabilizing water-in-bitumen emulsions. Energy Fuels 30(7):5240–5252

Romero L, Ziritt JL, Marin A, Rojas F, Mogollón JL, Paz EMF (1996) Plugging of high permeability-fractured zones using emulsions. In: SPE improved oil recovery symposium, Society of Petroleum Engineers

Santanna VC, Curbelo FDS, Castro Dantas TN, Dantas Neto AA, Albuquerque HS, Garnica AIC (2009) Microemulsion flooding for enhanced oil recovery. J Pet Sci Eng 66(3–4):117–120

Seright RS, Liang J (1995) A comparison of different types of blocking agents. In: The SPE European formation damage conference, Society of Petroleum Engineers

Services USD of H and H (1995) Agency for toxic substances and disease registry. Toxicol Profile Polycycl Aromat Hydrocarb PB/95/264370, Atlanta U.S. Department of Health and Human Services

Sheng JJ (2014) Critical review of low-salinity waterflooding. J Pet Sci Eng 120:216–224

Stavland A, Andersen KI, Sandoey B, Tjomsland T, Mebratu AA (2006) How to apply a blocking gel system for bullhead selective water shutoff: from laboratory to field. In: SPE improved oil recovery symposium, Society of Petroleum Engineers

Sydansk RD, Romero-Zeron L (2011) Reservoir conformance improvement. Society of Petroleum Engineers, Richardson

Taylor P, Zohoorparvaz A, Arastoo A, Sahraei E (2015) Petroleum science and technology the evaluation of water-in-oil emulsions to use as a water control agent in waterflooding. Pet Sci Technol 31:37–41

Torrealba VA, Hoteit H, Abdullah K (2018) Conformance improvement in oil reservoirs by use of microemulsions. In: SPE reservoir evaluation and engineering, pp 23–26

Wang D, Zhao L, Cheng J, Wu J (2003) Actual field data show that production costs of polymer flooding can be lower than water flooding. In: SPE international improved oil recovery conference, Asia Pacific. Society of Petroleum Engineers

Willhite GP (1986) Waterflooding (SPE textbook series). SPE, Richardson, p 326

Winsor PA (1948) Hydrotropy, solubilisation and related emulsification processes. Trans Faraday Soc R Soc Chem 44:376–398

Wu Z-M, Zhai W-Z, He Y-F, Song P-F, Wang R-M (2014) Silicylacrylate copolymer core–shell emulsion for humidity coatings. Prog Org Coat 77(11):1841–1847

Yu L, Dong M, Ding B, Yuan Y (2018) Emulsification of heavy crude oil in brine and its plugging performance in porous media. Chem Eng Sci 178:335–347. https://doi.org/10.1016/j.ces.2017.12.043

Zana R (1996) Critical micellization concentration of surfactants in aqueous solution and free energy of micellization. Langmuir 12(5):1208–1211

Zana R, Binana-Limbelé W, Kamenka N, Lindman B (1992) Ethyl (hydroxyethyl) cellulose-cationic surfactant interactions: electrical conductivity, self-diffusion and time-resolved fluorescence quenching investigations. J Phys Chem 96(13):5461–5465

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Yazdani Sadati, E., Sahraei, E. An experimental investigation on enhancing water flooding performance using oil-in-water emulsions in an Iranian oil reservoir. J Petrol Explor Prod Technol 9, 2613–2624 (2019). https://doi.org/10.1007/s13202-019-0679-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-019-0679-9