Abstract

Perfluoroalkyl acids (PFAAs) are widespread in the aquatic environment and also measurable in ground and drinking water. Because of the insufficient PFAA elimination in conventional water treatment processes, e. g. active carbon based methods, consumers in areas with contaminated water supplies are exposed to an elevated health hazard. For this purpose, the applicability of five differentially fluorinated silica-based adsorbents (HSU00107954-958) to remove the potentially human toxic perfluoroalkyl sulfonic acids(PFSAs) perfluorooctane sulfonic acid (PFOS), perfluorohexane sulfonic acid (PFHxS), and perfluorobutane sulfonic acid (PFBS) from water was investigated with regard to removal efficiencies (REs) and equilibrium loadings. During the adsorbent screening at nanomolar concentrations (20.0–33.4 nmol L−1) maximum REs of 46.9% for PFBS (HSU00107954), 79.4% for PFHxS (HSU00107954), and between 86.5 to 96.7% for PFOS (HSU00107956, and HSU00107954, respectively) have been achieved. Even at picomolar concentrations (< 400 pmol L−1) HSU00107954 was still able to eliminate PFBS and PFHxS with an efficiency of 46.3–51.2% and 79.1–88.2%, respectively. Analyses of the equilibrium loadings of the functionalized adsorbents in the concentration range 40.1 pmol to 3.34 nmol L−1 resulted in appropriate linearized Freundlich isotherms for all investigated PFSA. Compared to literature-based Freundlich adsorption coefficients (KF) for granular activated carbon (GAC), the determined KF values (nmol(1−n) Ln m−2) of the most efficient adsorbents HSU00107956 and HSU00107954 for each PFSA were significantly 8–10 and 50–60 times higher, respectively. These proven increased adsorption capacities relative to activated carbon possibly indicate specific PFSA selectivities of the functionalized macroporous silica adsorbents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Perfluoroalkyl acids (PFAAs), also referred to as perfluorinated tensides (PFTs), are an industrially extensively used class of chemical compounds. Due to their hydro and oleophobic properties as well as their surface activity they find versatile application, for example in electroplating and semiconductor production, and as additives in medical and cosmetic products or aqueous film-forming foams (AFFFs) for firefighting (Hu et al. 2016).

They consist of a completely fluorinated carbon chain and a terminal functional group (e. g. carboxylate or sulfonate). Notably the high number of strong bonds between the carbon and fluorine atoms is responsible for the exceptional stability of PFAAs to chemical and thermal (Buck et al. 2011) as well as biological degradation processes, making them extremely persistent in the environment (Giesy and Kannan 2002; Liou et al. 2010; Scheringer et al. 2014; Ochoa-Herrera et al. 2016). Most widely produced representatives of this group of chemicals in the past have been perfluorooctane sulfonic acid (PFOS) and perfluorooctanoic acid (PFOA) (USEPA 2016c).

PFAAs are released into the environment for several decades and since then globally detectable in diverse environmental compartments, for example soils, sediments, water bodies such as rivers and lakes, and even in seas and oceans (Senthilkumar et al. 2007; Ahrens et al. 2009b, 2009a; Naile et al. 2010; Wang et al. 2011; Llorca et al. 2012; Theobald et al. 2012; Pignotti et al. 2017; Joerss et al. 2019; Muir and Miaz 2021). Furthermore, these toxic and bio accumulating compounds are also provable worldwide in a variety of aquatic and terrestrial animal species, including humans (Giesy and Kannan 2002; Sinclair et al. 2006; Fromme et al. 2007; Zhao et al. 2012; Bossi et al. 2015; Riebe et al. 2016; Koch et al. 2019). They have various harmful effects on human health with correlations to kidney, bladder, testicular, and liver cancer (Alexander et al. 2003; Steenland and Woskie 2012; Barry et al. 2013; Vieira et al. 2013; Mastrantonio et al. 2018; Li et al. 2022; Goodrich et al. 2022; Messmer et al. 2022), thyroid disease (Melzer et al. 2010), female fecundity disorder (Fei et al. 2009; Di Nisio et al. 2020; Velez et al. 2015), decreased sperm quality (Vested et al. 2013; Louis et al. 2015; Sabovic et al. 2020), and a lower immune response after vaccination (Grandjean et al. 2012; Porter et al. 2022). Besides that, bioassays with mammalian species demonstrated their potential for an induction of pancreatic and also liver and testicular tumors in rats (Biegel et al. 2001), as well as an adverse immunomodulation in mice (DeWitt et al. 2008, 2012).

The proven high mobility of perfluorinated surfactants in the hydrosphere, especially that of short-chain PFAAs, lead to a prevalent contamination of drinking water supplies (Skutlarek et al. 2006; Thompson et al. 2011; Boiteux et al. 2012; Eschauzier et al. 2013b; Banzhaf et al. 2017; Kabore et al. 2018) which in view of an impending water scarcity pose a problem for the delivery of clean potable water. In addition to PFOA and PFOS, perfluorobutane sulfonic acid (PFBS) and perfluorohexane sulfonic acid (PFHxS) are among the most frequently detected PFAAs in drinking water of industrialized countries (Ateia et al. 2019; Boston et al. 2019) and it is well known that tap water is a not negligible source for the daily uptake of PFAAs through diet (Ericson et al. 2008; Hoffman et al. 2011; Noorlander et al. 2011; Eschauzier et al. 2013a; Zhang et al. 2019; Hu et al. 2019). Monitoring studies demonstrated that residents of areas with contaminated drinking water more likely show enhanced body burdens (Bruton and Blum 2017) indicated by increased serum or plasma levels (Hölzer et al. 2008; Brede et al. 2010; Pinney et al. 2014; Hurley et al. 2016; Gyllenhammar et al. 2019; Glynn et al. 2020).

In 2016, the US Environmental Protection Agency (USEPA) therefore first issued drinking water health advisories (HAs) of 70 ppt (70 ng L−1) for PFOS and PFOA in order to ensure a protection from health effects throughout a lifetime exposure (USEPA 2016b, a). Based on new studies, USEPA (2022a, b) recently published a preliminary lifetime HA for PFOS, which has been drastically reduced to 20 ppq, and for the first time a HA value of 2.0 ppb for the short-chain perfluorobutane sulfonic acid (PFBS) (USEPA 2022b, a). The European parliament and council (EUCO) passed a recasted directive on the quality of water intended for human consumption in 2020, that regulate the maximum drinking water level to in sum 100 ppt for 20 PFAAs of concern, including PFSA with a perfluoroalkyl moiety of four to 13 carbons (Directive 2020/2184, Annex III, Part B, 3) (EUCO 2022).

Today, public water suppliers have to utilize sophisticated techniques for the removal of very low concentrated organic pollutants like PFAAs from contaminated drinking water resources, among them membrane separation methods, e.g. pervaporation, reverse osmosis or nano filtration, as well as anion-exchange, and adsorption, usually with activated carbon (AC) (Izák et al. 2006; Appleman et al. 2014; Crone et al. 2019; Belkouteb et al. 2020). Sorption based technologies are generally efficient and economic processes for the elimination of a multitude of hazardous organic compounds of lowest concentration from the water phase (Nassi et al. 2014). For the generation of a clean and safe drinking water supply, drinking water treatment plants thus widely apply water purification processes with integrated AC separation stages for the removal of organic contaminants, pharmaceuticals, flame retardants or PFAAs (Takagi et al. 2011; Delgado et al. 2012; Sim et al. 2021). However, long-chain PFAAs and notably those with shorter carbon chains (C4–C6) at concentration levels < 0.5 µg L−1 are only partially or not removed by AC, respectively (Eschauzier et al. 2012; Flores et al. 2013; Rahman et al. 2014; Boone et al. 2019).

This study is part of a project that aims on the development of an adsorptive drinking water treatment method for the elimination of very low concentrated PFAAs on the basis of reuseable fluorinated silica adsorbents. For this purpose, the putative high fluorophilicity of the newly synthesized adsorbents due to specific and potentially selective non-covalent interactions between PFAAs and fluorinated ligands on the functionalized silica surface (Marchetti et al. 2015) should be exploited. The main objectives beside the synthesis of suitable adsorbents were the subsequent investigation of their adsorption efficiency and behavior with regard to PFBS, PFHxS, and PFOS. We present data on the synthesis of a set of five silica gel-based adsorbents, functionalized with different polyfluorinated ligands and degrees of functionalization, as well as their subsequent characterization in terms of maximum removal efficiencies and equilibrium loads (isotherms) with respect to the individual PFSAs. Evaluated higher adsorption capacities at relevant drinking water concentrations compared to that of granular activated carbon are also discussed.

Materials and methods

Chemicals

A macroporous spherical silica (pore size 1000 Å, particle size distribution 200–500 µm, specific surface 25 m2 g−1) was applied as base material for the synthesis of functionalized adsorbents and obtained from SiliCycle (Québec, Canada). For silica functionalization, a polyfluorinated N-(alkoxysilylalkyl)alkanamide and four polyfluorinated alkylalkoxysilanes with different alkoxy moieties and chain lengths were purchased from abcr (Karlsruhe, Germany) and internally encoded as HSU54 and HSU55-HSU58, respectively. Acetonitrile (LiChrosolv, hypergrade), ethanol (LiChrosolv, gradient grade), methanol (Lichrosolv, hypergrade), n-octane (for synthesis), 2-propanol (p. A.), xylene (p. A.) and ammonium acetate (p. A.) have been procured from Merck Millipore (Darmstadt, Germany), as well as acetone (Rotipuran, p. A) from Carl Roth (Karlsruhe, Germany).

Certified methanolic standard stock solutions (c = 50 μg mL−1) of potassium perfluoro-1- butanesulfonate, sodium perfluoro-1-hexanesulfonate, perfluoro-n-nonanoic acid, sodium perfluoro-1-octanesulfonate) and isotopically labeled sodium perfluoro-1-[2,3,4-13C3] butanesulfonate, sodium perfluoro-1-[1,2,3-13C3] hexanesulfonate, perfluoro-n-[1,2,3,4,5-13C5] nonanoic acid, sodium perfluoro-1-[1,2,3,4-13C4] octanesulfonate for analytical purpose as well as analytical grade (> 98%) perfluorobutane-1-sulfonic acid, perfluorohexane-1-sulfonic acid (potassium salt), perfluorooctane-1-sulfonic acid (potassium salt), perfluorononanoic acid (as reference substance) for the preparation of acetonitrile working solutions were purchased from Wellington Laboratories (Guelph, Canada), and Sigma-Aldrich (Munich, Germany), respectively. All stock and working solutions were stored in amber glass vials at − 18 °C, and 5 °C, respectively. Ultrapure water (conductivity 0.055 µS cm−1), produced by a water purification system (AQUAlab, Höhr-Grenzhausen, Germany), was employed for the production of reagents and throughout the adsorption experiments. Pure oxygen (99.998%) and nitrogen (99.999%) for the operation of the thermobalance were obtained from Air Liquide (Düsseldorf, Germany).

Synthesis of functionalized silica adsorbents

Initially, 10 g of silica per functionalization were dried for 24 h in 250 mL round-bottomed flasks and closed with a glass stopper after drying. Calculated amounts of each silane were then thoroughly dissolved in beakers in 60 mL organic solvent (xylene) and organic solvent mixtures, consisting of n-octane and xylene of different compositions, and subsequently added to a dried silica. For synthesis, the resulting reaction mixtures were attached to a water-cooled rotary evaporator that operated at normal pressure and a cooling water temperature of T = 6 °C. Depending on the individual boiling temperatures of the silanes, the various reaction mixtures were heated to a maximum of T = 120 °C for 4 h under reflux and constant rotation (120 rpm) and the resulting reaction products are then purified sequentially with different solvents of increasing hydrophilicity in a five-stage wash cycle at 30 mL per stage, respectively. After transfer to a Buchner funnel and a final washing step with 10 mL acetone the drying of each product took place at T = 60 °C overnight in a drying cabinet. For sample archival, all synthesized adsorbents received an internal code based on the described ligand coding system (see section "Chemicals"), namely HSU00107954, HSU00107955, HSU00107956, HSU00107957, and HSU00107958, respectively. These are also used throughout the manuscript as the corresponding adsorbent designation. Beside the specific ligand the respective code additionally contains precise information on the type, manufacturer as well as particle, and pore size of the base material used.

Thermogravimetric analysis (TGA) of functionalized silica adsorbents

Prior to each thermogravimetric analysis on an STA 449 F3 thermobalance (Netzsch, Selb, Germany) in pure oxygen atmosphere, a second drying of the adsorbent at T = 60 °C under vacuum was performed for 24 h in order to evaporate any residual solvent. During TGA, aluminum oxide (Al2O3) pans, loaded with 100 mg of adsorbent were heated from room temperature to T = 800 °C at a rate of 5 °C min−1 and held at 800 °C for 1 h. In order to compensate the influences of possible water losses, e.g. humidity, on the results, each thermogravimetric measurement was corrected throughout the analysis of an adsorbent sample, that is, automatically adjusted with stored data from a previous analysis of the non-functionalized silica.

Individual analysis was executed in triplicate (n = 3) and subsequently evaluated with the Proteus 6.1 software tool (Netzsch, Selb, Germany). The resulting mass changes formed the basis for the calculation of surface coverages (µmol ligand molecules m−2), and functionalization degrees (FD, expressed as µmol ligand molecules per µmol−1 silanol (SiOH) groups × 100%) of the individual adsorbents.

Adsorption experiments

All adsorption experiments preceded a three-step purification procedure of the utilized 8 mL poly-propylene (PP) cartridges (Chromabond Flash DL, Macherey–Nagel, Germany) with equal volumes (4 mL) of acetone, ethanol, and ultrapure water, respectively. After drying, 100 mg of the macroporous adsorbent was weighed into a cleaned PP cartridge for each experiment and carefully conditioned with 2 × 1 mL of acetonitrile without the adsorbent running dry. Although the macroporosity of each adsorbent favors a rapid adjustment of the adsorption equilibrium, which is advantageous for further process development, its hence small surface area, i.e., low adsorption capacity, had to be compensated by the comparatively high adsorbent dosage. Subsequently, 4 mL ultrapure water was pipetted into the cartridge and spiked with a defined volume of a corresponding PFAA working solution in order to adjust a specific initial PFAA concentration level (20–1,000 ng L−1 for equilibrium loading experiments and 10,000 ng L−1 for adsorbent screening). Because of the reduction of the specified theoretical concentrations caused by self-adsorption of the PP cartridges, a corresponding number of cartridges without adsorbent were spiked in parallel for each PFAA concentration, allowing then the determination of the real initial concentrations (c0). Each concentration level was executed in triplicate (n = 3). After sample preparation, the cartridges were sealed with PP caps and mixed for 24 h at 45 rpm in an overhead mixer (Sunlab, Aschaffenburg, Germany).

Instrumental analysis of aqueous PFAA samples by LC–ESI–MS/MS

Analysis of PFBS, PFHxS, PFOS and PFNA in the aqueous samples was performed on a PFC-free 1290 Infinity II high performance liquid chromatography system (Agilent, Waldbronn, Germany) hyphenated to an Agilent 6495 triple quadrupole mass spectrometer. At first, sample aliquots of 100 µL were mixed in 2 mL PP vials with 250 µL PP micro inserts and PP caps (Agilent, Waldbronn, Germany) with 2 µL internal standard working solution (c13C-PFAA = 0.025 ng µL−1) on a vortex mixer (VWR International, Darmstadt, Germany).

Subsequently, sample volumes of 5 µL were injected into the chromatographic system and then analyzed on a Triart C18 ExRS HPLC column (3 µm, 8 nm, 50 × 3.0 mm) with guard column (10 × 3.0 mm) from YMC Europe (Dinslaken, Germany) at a constant flow rate of 0.5 mL min−1 and a temperature of T = 40 °C. Elution of the PFAAs occurred with an initial isocratic step at 10% mobile phase B (acetonitrile/1 mM ammonium acetate) for 0.5 min followed by a linear gradient from 10% B to 70% B in 3.5 min and an additional isocratic step at 70% B for another 4 min (mobile phase A: ultrapure water/1 mM ammonium acetate). According to Kaupmees and Rebane (2017) an Agilent PFC delay column (InfinityLab, 30 × 4.6 mm) was additionally installed inline between pump and auto sampler so that PFAA contaminants from the system eluted with a retardation of roughly 0.5 min in comparison to the corresponding analytes (Kaupmees and Rebane 2017).

Ionization of the PFAAs took place in the jet stream electrospray ionization (ESI) source of the 6495 mass spectrometer in the negative ion mode (capillary voltage 2.4 kV, drying gas temperature T = 185 °C, drying gas flow rate 15 L min−1, nebulizer gas pressure p = 40 psi (2.8 bar), sheath gas temperature T = 350 °C, sheath gas flow rate 11 L min−1). Multiple Reaction Monitoring (MRM) parameters for precursor ion ([M-H]−) transmission and fragmentation were optimized automatically for each analyte with the optimization tools of the Agilent Mass Hunter software (Version 10.0.142). For PFAA quantification, MRM transitions for the native and corresponding isotopically labeled compounds were utilized as follows: 299 → 80 (PFBS), 399 → 80 (PFHxS), 463 → 419 (PFNA), 499 → 80 (PFOS), and 302 → 80 (13C3-PFBS), 402 → 80 (13C3-PFHxS), 468 → 372 (13C5- PFNA), 503 → 80 (13C4-PFOS), respectively. Individual limits of quantification (LOQ) of the investigated PFAAs (LOQPFBS 19 pmol L−1 [5.8 ng L−1], LOQPFHxS 20 pmol L−1 [8.1 ng L−1], LOQPFNA 14 pmol L−1 [6.3 ng L−1], LOQPFOS 14 pmol L−1 [6.9 ng L−1]) were determined with the calibration curve method according to DIN 32645 (DIN 2008).

Results and discussion

3.1 Surface coverage and functionalization degree of the silica adsorbents

First silica functionalizations with each ligand at a reaction temperature of T = 100 °C in pure xylene, except the xylene-insoluble ligand HSU54, led to synthesis products with maximum surface coverages (SC) between 0.06 (HSU00107957) and 0.80 (HSU00107956) µmol ligands m−2 adsorbent. Individual SC were calculated as the product of the respective normalized mass changes (µg m−2) from TGA measurements and the molar masses (µg µmol−1) of the corresponding split-off fluoroalkyl groups. Through variation of solvent composition from xylene to n-octane/xylene mixtures, the corresponding SC values could be significantly increased by 1.7 to 6 times, resulting in enhanced values of 0.37 to 1.36 µmol ligands m−2 adsorbent for HSU00107957, and HSU00107956, respectively. With regard to ligands HSU54 and HSU55, functionalization in a solvent mixture of n-octane/xylene (1:1, v/v) at modified reaction temperatures of T = 120 °C, and T = 83 °C, respectively proved to be the optimal synthesis conditions.

Additionally, the determined SC was converted into appropriate functionalization degrees (FD/%) on the basis of the Zhuravlev constant (2000), i.e., the maximum number of SiOH groups per unit surface area (α = 4.90 SiOH nm−2, and 8.14 μmol m−2, respectively). Assuming that a maximum of two leaving groups of a silane molecule (ligand) react with two SiOH groups on the silica surface, the maximum achievable surface coverage (SCmax) of the silica with ligand molecules is 4.07 µmol m−2 (namely 0.5α). Individual FDs were then calculated according to the following equation:

Individual surface coverages, functionalization degrees as well as specific surfaces of the silica-based adsorbents are summarized in Table 1.

The 2.5- to fourfold higher functionalization degrees obtained for the adsorbents HSU00107955 (36.6%) and HSU00107956 (33.5%) compared to HSU00107954 (14.6%), HSU00107957 (9.00%), and HSU00107958, respectively, were possibly due to a generally higher rate of hydrolysis of the applied alkoxysilanes (HSU55, HSU56) (Brochier Salon and Belgacem 2011) and steric hindrance.

Synthesis of fluorinated silica by silanization with fluorinated silanes has been carried out since the early 1980s. Berendsen et al. (1980) investigated the suitability of a (heptadeca-fluorodecyl)dimethylsilyl-bonded silica as material for the separation of fluorine-containing compounds in the liquid phase (Berendsen et al. 1980). In the following years, several applications employing fluorinated silica as stationary phases for the liquid chromatographic separation of proteins, peptides, biogenic amines as well as perfluoroalkyl compounds were described (Xindu and Carr 1983; Brittain et al. 2005; Hayama et al. 2012; Marchetti et al. 2012). Compared to the macroporous adsorbents investigated in this study, those fluorous reversed phase materials typically consist of smaller mesoporous particles with a particle size and pore size distribution of 5–60 µm and 60–300 Å, respectively (Marchetti et al. 2015). When applying such small particles in form of a packed separation column, working with aqueous media, especially at elevated flow rates, usually produces high back pressures that must be overcome with help of high pressure pumps. A flow experiment with an aqueous PFOS solution (feed volume: 0.05 L, feed concentration: 56 nmol L−1) and HSU00107956 as adsorbent in a miniaturized fixed-bed adsorber (2 g adsorbent, bed length 40 mm, bed diameter 12.4 mm) resulted in an only gravity-induced average flow rate of 0.35 L h−1, with a simultaneous 97% reduction of the PFOS concentration in the effluent to 1.7 nmol L−1. By virtue of the exemplary but promising flow properties of the investigated HSU00107956 such functionalized macroporous silica adsorbents could be useful materials for a PFAA elimination process of drinking water at necessarily high volume flows but manageable back pressures.

Screening of the silica adsorbents: PFAA removal efficiency

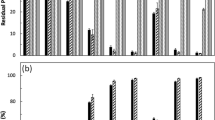

In order to prove the principle, the five newly functionalized adsorbents (HSU00107954-58) were first screened regarding their removal efficiencies at high, but realistic environmental PFAA concentrations as found in European surface and wastewaters (Skutlarek et al. 2006; Mazzoni et al. 2015). Removal efficiencies \(\left( {{\text{RE}} = \frac{{C_{0} - C_{{\text{e}}} }}{{C_{0} }} \times 100 } \right)\) for each individual PFAA were determined at initial concentration (c0) of 10 µg L−1 corresponding to molar concentrations of 20.0 to 33.4 nmol L−1. The results are demonstrated in Fig. 1.

Removal efficiencies (RE/%) of the functionalized silica adsorbents HSU00107954, HSU00107955, HSU00107956, HSU00107957, and HSU00107958 for perfluorobutane sulfonic acid (PFBS), perfluorohexane sulfonic acid (PFHxS), perfluorooctane sulfonic acid (PFOS), and perfluorononanoic acid (PFNA) after 24 h; initial PFAA concentrations (c0) 20.0–33.4 nmol L−1

HSU00107957 reached REs for the investigated PFAA between 8.70 to 83.4% (PFBS 8.70%, PFHxS 9.80%, PFOS 40.8%, PFNA 83.4%) comparable to those achieved with HSU00107958 (PFBS 9.50%, PFHxS 16.2%, PFOS 38.5%, PFNA 78.9%). Attainable REs with HSU00107955 and HSU00107956 for PFBS (10.1 and 18.0%), PFHxS (22.2 and 15.3%), and PFNA (86.8 and 93.8%) exhibited the same magnitude as the corresponding RE values for HSU00107957 and HSU00107958 with exception of PFOS, which was eliminated about two times more effective by HSU00107955 and HSU00107956.

Although the carbon chains of the ligands bound to HSU00107957 and HSU00107958 are elongated by two to six fluorinated carbon moieties compared to those bound to HSU00107955 and HSU00107956, theoretically leading to stronger fluorine-fluorine (F-F) interactions with PFOS, the resulting twofold lower PFOS-REs of about 40% for HSU00107957 and HSU00107958 as opposed to approximately 80% for HSU00107955 and HSU00107956, respectively, were probably due to their three to four times lower degrees of functionalization (refer to Table 1). The associated higher hydrophilicity of the adsorbent surface was thus disadvantageous for the adsorption of the rather hydrophobic and nonpolar PFOS with a high log P value of 5.43 (Park et al. 2020). Octanol–water partition coefficient P is a measure for the hydrophobicity (log P > 1) and hydrophilicity (log P < 1) of a given molecular species and also reflects its polarity. In order to compare: PFNA with the same number of perfluorinated carbons (C8) as PFOS but a different functional group, showed a similar but significantly lower negative adsorption tendency from HSU00107956 to HSU00107958 because the higher hydrophobicity of PFNA (log P = 5.81) (Park et al. 2020) probably compensates the higher hydrophilicity of the lower-functionalized adsorbents HSU00107957 and HSU00107958. Overall, the determined REs for the more hydrophilic PFBS (log P = 2.63) (Park et al. 2020) and PFHxS (log P = 4.03) (Park et al. 2020) of the four adsorbents HSU00107955-58 were significantly lower (8.70–22.2%) and in fact almost independent of the adsorbent`s FD and the particular chain length of the immobilized ligand.

Of all adsorbents, HSU00107954 yielded the highest REs for the investigated PFSA, namely 46.3%, 79.1%, and 96.7% for PFBS, PFHxS, and PFOS, respectively. In comparison to HSU00107956, the RE for the examined long-chain PFAS could be improved by 10% for PFOS (86.5–96.7%) and more than 60% for PFHxS (15.3–79.4%) as well as for the short-chain PFBS remarkably by around 30% (18.0–46.9%). The enhanced adsorption performance of HSU00107954 possibly caused by the secondary carboxamide group (formally R1–(C=O)–NH–R2) of ligand HSU54. Because of the mesomeric stabilization of carboxamides, zwitterionic boundary structures are formed with positive charged nitrogen atoms probably capable of additional ionic interactions with the negatively charged PFSA molecules.

Investigation of the equilibrium loadings: Adsorption isotherms

Subsequently, further investigations of the equilibrium loadings of three of the five adsorbents (HSU00107954, HSU00107955, and HSU00107956) with the researched PFSAs were conducted in a concentration range from 0.04 (PFOS) to 3.34 (PFBS) nmol L−1, corresponding to concentrations of 20–1000 ng L−1. The applied concentration range was chosen taking into account the recommended drinking water standard of the German Federal Environment Agency (Umweltbundesamt) for PFHxS (0.25 nmol L−1) as well as PFOS (0.20 nmol L−1) (Umweltbundesamt 2017) and representative literature levels for PFSAs in ground and drinking water. Boone et al. (2019) recently studied 25 drinking water treatment plants across the United States and reported PFBS, PFHxS, and PFOS concentrations in treated drinking water up to 0.04, 0.05, and 0.07 nmol L−1, respectively (Boone et al. 2019).

Experimental data were then fitted to the linear forms of the Langmuir model, the Scatchard linearization (Eq. 2), and the Freundlich model (Eq. 3):

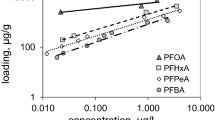

These models describe the adsorption of solved compounds (adsorbates) to solid surfaces (adsorbents), where qe is defined as the equilibrium loading of an adsorbent with an adsorbate and qm (in Eq. 2) as the maximum monolayer adsorption capacity of an adsorbent. ce represents the adsorbate concentration in solution at the equilibrium and KL as well as KF represents the Langmuir, and Freundlich coefficients, respectively. n (in Eq. 3) denotes the dimensionless Freundlich exponent, that specifies the extent of surface heterogeneity of an adsorbent (Tran et al. 2017). A linear correlation (coefficient of determination r2 > 0.7) indicates a good fit between the experimental results and the corresponding model. Within the examined low concentration range including the elevated screening level, all experimental derived PFSA isotherms for the three investigated adsorbents strictly followed the linearized Freundlich model (r2 > 0.95), depicted in Figs. 2, 3 and 4.

Linearized Freundlich isotherms for PFSA adsorption onto HSU00107954 (filled square perfluorooctane sulfonic acid [PFOS, r2 = 0.95], filled triangle perfluorohexane sulfonic acid [PFHxS, r2 = 0.98], filled circle perfluorobutane sulfonic acid [PFBS, r2 = 0.99]; initial concentrations (c0) 0.04–33.4 nmol L−1). Resulting PFOS and PFHxS equilibrium concentrations (ce) for c0,PFOS < 0.40 nmol L−1 and c0,PFHxS = 0.05 nmol L−1 were below the corresponding limits of quantification (LOQ) and therefore excluded from the linear regressions

Linearized Freundlich isotherms for PFSA adsorption onto HSU00107955 (filled square perfluorooctane sulfonic acid [PFOS, r2 = 0.98], filled triangle perfluorohexane sulfonic acid [PFHxS, r2 = 0.97], filled circle perfluorobutane sulfonic acid [PFBS, r2 = 0.96]; initial concentrations (c0) 0.04–33.4 nmol L−1)

Linearized Freundlich isotherms for PFSA adsorption onto HSU00107956 (filled square perfluorooctane sulfonic acid [PFOS, r2 = 0.99], filled triangle perfluorohexane sulfonic acid [PFHxS, r2 = 0.96], filled circle perfluorobutane sulfonic acid [PFBS, r2 = 0.98]; initial concentrations (c0) 0.04–33.4 nmol L−1). Resulting PFOS equilibrium concentrations (ce) for c0,PFOS < 0.20 nmol L−1 were below the corresponding limit of quantification (LOQ) and therefore excluded in the linear regression

Deduced KF values from the ordinate intercepts (= log KF, see Figs. 2, 3 and 4) and the n values from the slopes of the calculated linear equations, respectively, varied between KF = 0.33–52.4 × 10–3 nmol(1−n) Ln m−2 and n = 0.82–1.08, where n = 1 signifies adsorption linearity (Tran et al. 2017). Nonlinearity (n < 1) may results from adsorption site heterogeneities or adsorbate–adsorbate interactions (Yu et al. 2009) such as molecular aggregations, that here are rather unlikely due to the low PFSA concentrations used (Cheng et al. 2009). In terms of the surface-bound ligands, the demonstrated virtual adsorption linearities (n > 0.8) of the PFSAs possibly indicate an approximate surface homogeneity of the three functionalized adsorbents analyzed. According to the type of PFSA, a detailed summary of the calculated KF and n values for each silica adsorbent is provided in Table 2.

Exemplary Scatchard plots (qe ce−1 vs. qe) of the Langmuir isotherms for the adsorption of PFHxS, and PFBS onto HSU00107954 (Fig. 5), and HSU00107955 (Fig. 6), respectively, clarify the poor agreement between the experimental data and the Langmuir model for all adsorbents and becomes evident due to the calculated low r2 values of 0.28, and 0.35, respectively. However, it must be taken into account that the correlation (r) between qe and qe ce−1 is often underestimated in the Scatchard linearization, i.e., Eq. 2 may simulate a poor fit to data even though they actually correspond to the Langmuir model (Tran et al. 2017).

Overall, the calculated Freundlich coefficients (KF) as a measure of the adsorption capacities (Tran et al. 2017; Yu et al. 2009) of HSU00107954, HSU00107955, and HSU00107956 for PFOS were higher than for PFHxS and PFBS (refer to Table 2). These results were in agreement with the results of the screening experiments (refer to Fig. 1), confirming that in general the fluorinated silicas adsorb PFOS roughly two to eight times more efficiently from the aqueous samples (RE = 76.0–96.7%) as PFHxS (RE = 15.3–79.4%) and PFBS (RE = 10.1–46.9%). However, comparing the KF values of the functionalized adsorbents with high FDs (see Table 1) for each individual PFSA, notably adsorbent HSU00107956 (FD = 33.5%) exhibited a 20 times higher capacity for PFOS (KF = 7.23 × 10–3 nmol(1−n) Ln m−2) than for PFHxS (KF = 0.38 × 10–3 nmol(1−n) Ln m−2) and PFBS (KF = 0.33 × 10–3 nmol(1−n) Ln m−2) while the adsorption capacities of HSU00107955 (FD = 36.6%) were 5 and 7 times higher for PFHxS (KF = 0.53 × 10–3 nmol(1−n) Ln m−2) and PFBS (KF = 0.33 × 10–3 nmol(1−n) Ln m−2), respectively, compared to that of PFOS (KF = 2.49 × 10–3 nmol(1−n) Ln m−2). Regarding PFOS, the distinct KF difference between HSU00107956 and HSU00107955 (~ 200%; refer to Table 2) at approximately same FDs most likely reflected a strongly increased fluorous affinity of HSU00107956 for long-chain PFSA, possibly due to the extended fluorinated carbon chain of its immobilized ligand HSU56 (C8) in contrast to that of HSU00107955 (ligand HSU55).

Although HSU00107954 showed a twofold lower FD (14.6%) to that of HSU00107956 (33.5%), here the additional ionic interaction of the amide group with the anionic PFSA (see section "Screening of the silica adsorbents: PFAA removal efficiency") provoked five to 20-fold higher KF values in particular for the short-chain PFBS and PFHxS, respectively (refer to Table 2). This can be explained by a usually higher adsorption enthalpy of ionic bonds compared to the enthalpy of instantaneous dipole–dipole bonds that are described as the cause of the specific fluorine interaction (Xu and Oleschuk 2014). HSU00107954 demonstrated the best adsorption performance over all PFSAs. Its high removal efficiencies (REs) reached for PFSA during the screening experiments (46.9–96.7%) were reproducible also in the investigated low nano to picomolar concentration range, illustrated in Fig. 7. Missing REs for PFOS and PFHxS at the lowest initial concentrations in Fig. 7 are due to the fact that the corresponding equilibrium concentrations (ce) laid below their LODs and therefore were not considered in the calculation of the REs. Nevertheless, defining of the respective LODs for PFHxS (0.02 nmol L−1) and PFOS (0.014 nmol L−1) as the maximum achievable equilibrium concentrations (ce = LOD) and using them for RE calculations, results in values of the same order of magnitude, namely 60% for PFHxS and between 65 and 93% for PFOS. Maximum standard deviations of the triple determined REs (n = 3) at the highest initial concentrations studied (2.00–3.34 nmol L−1) were 10% and 14% for PFBS and PFHxS, respectively and for PFOS only 1% over the entire depicted concentration range.

Resulting Freundlich coefficients of the three examined adsorbents were finally matched to modeled KF values for GAC derived by Hansen et al. (2010) from experimental data of corresponding PFSAs (Hansen et al. 2010). In that study, natural PFAA contaminated well water at concentration levels very similar to our study was treated with an activated material originated from anthracite coal (average particle size 226 µm, specific surface 1200 m2 g−1). We converted their published KF values (released in ng(1−n) Ln g−1) for the individual PFSA to amounts of substance (nmol) and normalized to the GAC surface area (m2) in order to obtain values comparable to ours in nmol(1−n) Ln m−2. In sum, individual determined Freundlich coefficients for the adsorption of the investigated PFSA onto HSU00107954, HSU00107955, and HSU00107956 showed much higher values as corresponding KF values for GAC adsorption of PFHxS, and PFOS in the Hansen study (Hansen et al. 2010) and published (Crone et al. 2019) and also converted values for PFBS adsorption in deionized water (refer to Table 2). In particular, the KF values for the adsorption of PFBS (1.60 × 10–3 nmol(1−n) Ln m−2), PFHxS (7.43 × 10–3 nmol(1−n) Ln m−2), and PFOS (52.4 × 10–3 nmol(1−n) Ln m−2) onto HSU00107954 were remarkably 50–60 times higher to those for GAC adsorption (0.03 (Crone et al. 2019), 0.13 (Hansen et al. 2010), and 0.90 (Hansen et al. 2010) × 10–3 nmol(1−n) Ln m−2, respectively) and also three to 10 times higher in case of HSU00107955 and HSU00107956. With respect to the individual PFSA investigated, our findings confirm significantly increased adsorption capacities of the three newly developed functionalized silica adsorbents compared to granular activated carbon (GAC).

The results prove that the newly developed adsorbent HSU0010954 is able to reduce nanomolar as well as picomolar PFSA concentrations below actual drinking water regulation values. For PFBS at an initial concentration range of 0.07–3.34 nmol L−1 (corresponding to 21–1,000 ng L−1) and REs of around 50%, equilibrium concentrations of 10–500 ng L−1 were obtained and are therefore significantly below the USEPA regulation value for PFBS of 6.7 nmol L−1 (corresponding to 2,000 ng L−1) (USEPA 2022a). For PFHxS at an initial concentration range of 0.05–2.51 nmol L−1 (corresponding to 20–1,000 ng L−1) and REs of at least 80%, equilibrium concentrations of 4–200 ng L−1 were detected and therefore predominantly below the regulation value of the German Federal Environment Agency for PFHxS of 0.25 nmol L−1 (corresponding to 100 ng L−1) (Umweltbundesamt 2017).

However, our experiments were carried out in ultrapure water with single PFSA, while Hansen et al. utilized natural well water for their investigations that was natively contaminated with a mixture of PFAA. In more complex samples/matrices the contained compounds compete for adsorption sites, leading to a reduced adsorption of individual substances.

Conclusion

Highly efficient adsorbents for drinking water purification help to achieve the worldwide recommended drinking water limits for perfluorosulfonic as well as carboxylic acids (PFSAs, PFCAs). The herein presented functionalized macroporous silica adsorbents (HSU00107954, HSU00107955, HSU00107956) demonstrate up to 60 times higher PFSA adsorption capacities compared to granular activated carbon (GAC), especially at sub-nanomolar concentrations that are common for raw and drinking water.

Furthermore, our study demonstrates the high efficiency of the novel fluorinated macroporous silica adsorbent (HSU00107954) especially for the removal of short-chain perfluorobutane sulfonic acid (PFBS) as well as the long-chain PFSAs perfluorohexane sulfonic acid (PFHxS), and perfluorooctane sulfonic acid (PFOS) from aqueous solutions at concentration levels also relevant for drinking water. In batch experiments, HSU00107954 was able to reduce picomolar PFSA concentrations by 56.4%, 88.2%, and 97.4% for PFBS, PFHxS, and PFOS, respectively. Determined adsorption capacities of HSU00107954 for each PFSA in the investigated very low concentration range were significantly higher compared to corresponding literature values for granular activated carbon (GAC). Due to the similar particle size distribution and macroporosity to that of GAC, which is commonly employed for drinking water treatment, HSU00107954 performed as an effective adsorbent material for PFSA removal in laboratory experiments and thus could be highly efficient in flow-through systems of drinking water treatment plants.

Nevertheless, extensive further research of adsorption kinetics and dynamics of the new adsorbents are necessary for the development and design of a sufficient adsorbent-based water treatment process under real conditions, e.g., investigations in suitable fixed-bed adsorber arrangements using technically conventional flow rates (from L to m3 h−1) as well as natural water matrices like groundwater.

References

Ahrens L, Barber JL, Xie ZY, Ebinghaus R (2009a) Longitudinal and latitudinal distribution of perfluoroalkyl compounds in the surface water of the Atlantic Ocean. Environ Sci Technol 43(9):3122–3127. https://doi.org/10.1021/es803507p

Ahrens L, Plassmann M, Xie ZY, Ebinghaus R (2009b) Determination of polyfluoroalkyl compounds in water and suspended particulate matter in the river Elbe and North Sea, Germany. Front Environ Sci Eng 3(2):152–170. https://doi.org/10.1007/s11783-009-0021-8

Alexander BH, Olsen GW, Burris JM, Mandel JH, Mandel JS (2003) Mortality of employees of a perfluorooctanesulphonyl fluoride manufacturing facility. Occup Environ Med 60(10):722–729. https://doi.org/10.1136/oem.60.10.722

Appleman TD, Higgins CP, Quinones O, Vanderford BJ, Kolstad C, Zeigler-Holady JC, Dickenson ERV (2014) Treatment of poly- and perfluoroalkyl substances in US full-scale water treatment systems. Water Res 51:246–255. https://doi.org/10.1016/j.watres.2013.10.067

Ateia M, Maroli A, Tharayil N, Karanfil T (2019) The overlooked short- and ultrashort-chain poly- and perfluorinated substances: A review. Chemosphere 220:866–882. https://doi.org/10.1016/j.chemosphere.2018.12.186

Banzhaf S, Filipovic M, Lewis J, Sparrenbom CJ, Barthel R (2017) A review of contamination of surface-, ground-, and drinking water in Sweden by perfluoroalkyl and polyfluoroalkyl substances (PFASs). Ambio 46(3):335–346. https://doi.org/10.1007/s13280-016-0848-8

Barry V, Winquist A, Steenland K (2013) Perfluorooctanoic acid (PFOA) exposures and incident cancers among adults living near a chemical plant. Environ Health Perspect 121(11–12):1313–1318. https://doi.org/10.1289/ehp.1306615

Belkouteb N, Franke V, McCleaf P, Kohler S, Ahrens L (2020) Removal of per- and polyfluoroalkyl substances (PFASs) in a full-scale drinking water treatment plant: Long-term performance of granular activated carbon (GAC) and influence of flow-rate. Water Res. https://doi.org/10.1016/j.watres.2020.115913

Berendsen GE, Pikaart KA, De Galan L (1980) (Heptadecafluorodecyl)dimethylsilyl bonded phase for reversed-phase liquid chromatography. Anal Chem 52(12):1990–1993

Biegel LB, Hurtt ME, Frame SR, O’Connor JC, Cook JC (2001) Mechanisms of extrahepatic tumor induction by peroxisome proliferators in male CD rats. Toxicol Sci 60(1):44–55. https://doi.org/10.1093/toxsci/60.1.44

Boiteux V, Dauchy X, Rosin C, Munoz JF (2012) National screening study on 10 perfluorinated compounds in raw and treated tap water in France. Arch Environ Contam Toxicol 63(1):1–12. https://doi.org/10.1007/s00244-012-9754-7

Boone JS, Vigo C, Boone T, Byrne C, Ferrario J, Benson R, Donohue J, Simmons JE, Kolpin DW, Furlong ET, Glassmeyer ST (2019) Per- and polyfluoroalkyl substances in source and treated drinking waters of the United States. Sci Total Environ 653:359–369. https://doi.org/10.1016/j.scitotenv.2018.10.245

Bossi R, Dam M, Riget FF (2015) Perfluorinated alkyl substances (PFAS) in terrestrial environments in Greenland and Faroe Islands. Chemosphere 129:164–169. https://doi.org/10.1016/j.chemosphere.2014.11.044

Boston CM, Banacos N, Heiger-Bernays W (2019) Per- and polyfluoroalkyl substances: A national priority for safe drinking water. Public Health Rep 134(2):112–117. https://doi.org/10.1177/0033354919826567

Brede E, Wilhelm M, Goen T, Muller J, Rauchfuss K, Kraft M, Holzer J (2010) Two-year follow-up biomonitoring pilot study of residents’ and controls’ PFC plasma levels after PFOA reduction in public water system in Arnsberg, Germany. Int J Hyg Environ Health 213(3):217–223. https://doi.org/10.1016/j.ijheh.2010.03.007

Brittain SM, Ficarro SB, Brock A, Peters EC (2005) Enrichment and analysis of peptide subsets using fluorous affinity tags and mass spectrometry. Nat Biotechnol 23(4):463–468. https://doi.org/10.1038/nbt1076

Brochier Salon MC, Belgacem MN (2011) Hydrolysis-condensation kinetics of different silane coupling agents. Phosphorus, sulfur, and silicon and the related elements, vol 186. Taylor & Francis, London, pp 240–254

Bruton TA, Blum A (2017) Proposal for coordinated health research in PFAS-contaminated communities in the United States. Environ Health 16:120. https://doi.org/10.1186/s12940-017-0321-6

Buck R, Franklin J, Berger U, Conder J, Cousins I, de Vogt P, Jensen A, Kannan K, Mabury S, van Leeuwen S (2011) Perfluoroalkyl and polyfluoroalkyl substances in the environment: Terminology, classification, and origins. Integr Environ Assess Manag 7(4):513–541

Cheng J, Psillakis E, Hoffmann MR, Colussi AJ (2009) Acid dissociation versus molecular association of perfluoroalkyl oxoacids: environmental implications. J Phys Chem A 113(29):8152–8156. https://doi.org/10.1021/jp9051352

Crone BC, Speth TF, Wahman DG, Smith SJ, Abulikemu G, Kleiner EJ, Pressman JG (2019) Occurrence of per- and polyfluoroalkyl substances (PFAS) in source water and their treatment in drinking water. Crit Rev Environ Sci Technol 49(24):2359–2396. https://doi.org/10.1080/10643389.2019.1614848

Delgado LF, Charles P, Glucina K, Morlay C (2012) The removal of endocrine disrupting compounds, pharmaceutically activated compounds and cyanobacterial toxins during drinking water preparation using activated carbon-A review. Sci Total Environ 435:509–525. https://doi.org/10.1016/j.scitotenv.2012.07.046

DeWitt JC, Copeland CB, Strynar MJ, Luebke RW (2008) Perfluorooctanoic acid-induced immunomodulation in adult C57BL/6J or C57BL/6N female mice. Environ Health Perspect 116(5):644–650. https://doi.org/10.1289/ehp.10896

DeWitt JC, Peden-Adams MM, Keller JM, Germolec DR (2012) Immunotoxicity of perfluorinated compounds: Recent developments. Toxicol Pathol 40(2):300–311. https://doi.org/10.1177/0192623311428473

Di Nisio A, Rocca MS, Sabovic I, Ponce MD, Corsini C, Guidolin D, Zanon C, Acquasaliente L, Carosso AR, De Toni L, Foresta C (2020) Perfluorooctanoic acid alters progesterone activity in human endometrial cells and induces reproductive alterations in young women. Chemosphere. https://doi.org/10.1016/j.chemosphere.2019.125208

DIN (2008) Chemical analysis: Decision limit, detection limit and determination limit under repeatability conditions: Terms, methods, evaluation. Beuth-Verlag, Berlin

Ericson I, Nadal M, van Bavel B, Lindstrom G, Domingo JL (2008) Levels of perfluorochemicals in water samples from Catalonia, Spain: Is drinking water a significant contribution to human exposure? Environ Sci Pollut Res 15(7):614–619. https://doi.org/10.1007/s11356-008-0040-1

Eschauzier C, Beerendonk E, Scholte-Veenendaal P, De Voogt P (2012) Impact of treatment processes on the removal of perfluoroalkyl acids from the drinking water production chain. Environ Sci Technol 46(3):1708–1715. https://doi.org/10.1021/es201662b

Eschauzier C, Hoppe M, Schlummer M, de Voogt P (2013a) Presence and sources of anthropogenic perfluoroalkyl acids in high-consumption tap-water based beverages. Chemosphere 90(1):36–41. https://doi.org/10.1016/j.chemosphere.2012.06.070

Eschauzier C, Raat KJ, Stuyfzand PJ, De Voogt P (2013b) Perfluorinated alkylated acids in groundwater and drinking water: identification, origin and mobility. Sci Total Environ 458:477–485. https://doi.org/10.1016/j.scitotenv.2013.04.066

EUCO (2022) Directive (EU) 2020/2184 of the European Parliament and of the Council of 16 December 2020 on the quality of water intended for human consumption (recast). Off J Eur Union

Fei CY, McLaughlin JK, Lipworth L, Olsen J (2009) Maternal levels of perfluorinated chemicals and subfecundity. Hum Reprod 24(5):1200–1205. https://doi.org/10.1093/humrep/den490

Flores C, Ventura F, Martin-Alonso J, Caixach J (2013) Occurrence of perfluorooctane sulfonate (PFOS) and perfluorooctanoate (PFOA) in NE Spanish surface waters and their removal in a drinking water treatment plant that combines conventional and advanced treatments in parallel lines. Sci Total Environ 461:618–626. https://doi.org/10.1016/j.scitotenv.2013.05.026

Fromme H, Midasch O, Twardella D, Angerer J, Boehmer S, Liebl B (2007) Occurrence of perfluorinated substances in an adult German population in southern Bavaria. Int Arch Occup Environ Health 80(4):313–319. https://doi.org/10.1007/s00420-006-0136-1

Giesy JP, Kannan K (2002) Perfluorochemical surfactants in the environment. Environ Sci Technol 36(7):146A-152A. https://doi.org/10.1021/es022253t

Glynn A, Kotova N, Dahlgren E, Lindh C, Jakobsson K, Gyllenhammar I, Lignell S, Nalsen C (2020) Determinants of serum concentrations of perfluoroalkyl acids (PFAAs) in school children and the contribution of low-level PFAA-contaminated drinking water. Environ Sci: Process Impacts 22(4):930–944. https://doi.org/10.1039/c9em00497a

Goodrich JA, Walker D, Lin XP, Wang HX, Lim T, McConnell R, Conti DV, Chatzi L, Setiawan VW (2022) Exposure to perfluoroalkyl substances and risk of hepatocellular carcinoma in a multiethnic cohort. JHEP Rep 4(10):100550. https://doi.org/10.1016/j.jhepr.2022.100550

Grandjean P, Andersen EW, Budtz-Jorgensen E, Nielsen F, Molbak K, Weihe P, Heilmann C (2012) Serum vaccine antibody concentrations in children exposed to perfluorinated compounds. J Am Med Assoc 307(4):391–397. https://doi.org/10.1001/jama.2011.2034

Gyllenhammar I, Benskin JP, Sandblom O, Berger U, Ahrens L, Lignell S, Wiberg K, Glynn A (2019) Perfluoroalkyl acids (PFAAs) in children’s serum and contribution from PFAA-contaminated drinking water. Environ Sci Technol 53(19):11447–11457. https://doi.org/10.1021/acs.est.9b01746

Hansen MC, Borresen MH, Schlabach M, Cornelissen G (2010) Sorption of perfluorinated compounds from contaminated water to activated carbon. J Soils Sediments 10(2):179–185. https://doi.org/10.1007/s11368-009-0172-z

Hayama T, Sakaguchi Y, Yoshida H, Itoyama M, Todoroki K, Yamaguchi M, Nohta H (2012) Binary fluorous alkylation of biogenic primary amines with perfluorinated aldehyde followed by fluorous liquid chromatography-tandem mass spectrometry analysis. Anal Chem 84(19):8407–8414. https://doi.org/10.1021/ac3020092

Hoffman K, Webster TF, Bartell SM, Weisskopf MG, Fletcher T, Vieira VM (2011) Private drinking water wells as a source of exposure to perfluorooctanoic acid (PFOA) in communities surrounding a fluoropolymer production facility. Environ Health Perspect 119(1):92–97. https://doi.org/10.1289/ehp.1002503

Holzer J, Midasch O, Rauchfuss K, Kraft M, Reupert R, Angerer J, Kleeschulte P, Marschall N, Wilhelm M (2008) Biomonitoring of perfluorinated compounds in children and adults exposed to perfluorooctanoate-contaminated drinking water. Environ Health Perspect 116(5):651–657. https://doi.org/10.1289/ehp.11064

Hu XDC, Andrews DQ, Lindstrom AB, Bruton TA, Schaider LA, Grandjean P, Lohmann R, Carignan CC, Blum A, Balan SA, Higgins CP, Sunderland EM (2016) Detection of poly- and perfluoroalkyl substances (PFASs) in US drinking water linked to industrial sites, military fire training areas, and wastewater treatment plants. Environ Sci Technol Lett 3(10):344–350. https://doi.org/10.1021/acs.estlett.6b00260

Hu XDC, Tokranov AK, Liddie J, Zhang XM, Grandjean P, Hart JE, Laden F, Sun Q, Yeung LWY, Sunderland EM (2019) Tap water contributions to plasma concentrations of poly- and perfluoroalkyl substances (PFAS) in a nationwide prospective cohort of US women. Environ Health Perspect. https://doi.org/10.1289/ehp4093

Hurley S, Houtz E, Goldberg D, Wang MM, Park JS, Nelson DO, Reynolds P, Bernstein L, Anton-Culver H, Horn-Ross P, Petreas M (2016) Preliminary associations between the detection of perfluoroalkyl acids (PFAAs) in drinking water and serum concentrations in a sample of California women. Environ Sci Technol Lett 3(7):264–269. https://doi.org/10.1021/acs.estlett.6b00154

Izák P, Koekerling A, Kragl U (2006) Solute transport from aqueous mixture throught supported ionic liquid membrane by pervaporation. Desalination 199(1–3):96–98. https://doi.org/10.1016/j.desal.2006.03.151

Joerss H, Apel C, Ebinghaus R (2019) Emerging per- and polyfluoroalkyl substances (PFASs) in surface water and sediment of the North and Baltic Seas. Sci Total Environ 686:360–369. https://doi.org/10.1016/j.scitotenv.2019.05.363

Kabore HA, Duy SV, Munoz G, Meite L, Desrosiers M, Liu JX, Sory TK, Sauve S (2018) Worldwide drinking water occurrence and levels of newly-identified perfluoroalkyl and polyfluoroalkyl substances. Sci Total Environ 616:1089–1100. https://doi.org/10.1016/j.scitotenv.2017.10.210

Kaupmees S, Rebane R (2017) Analysis and validation of perfluorinated compounds in water, sediment and fish with LC-ESI-MS/MS. Int J Environ Anal Chem 97(8):695–709. https://doi.org/10.1080/03067319.2017.1356922

Koch A, Kärrman A, Yeung LWY, Jonsson M, Ahrens L, Wang T (2019) Point source characterization of per- and polyfluoroalkyl substances (PFASs) and extractable organofluorine (EOF) in freshwater and aquatic invertebrates. Environ Sci: Process Impacts 21(11):1887–1898

Li HQ, Hammarstrand S, Midberg B, Xu YY, Li Y, Olsson DS, Fletcher T, Jakobsson K, Andersson EM (2022) Cancer incidence in a Swedish cohort with high exposure to perfluoroalkyl substances in drinking water. Environ Res. https://doi.org/10.1016/j.envres.2021.112217

Liou JSC, Szostek B, DeRito CM, Madsen EL (2010) Investigating the biodegradability of perfluorooctanoic acid. Chemosphere 80(2):176–183. https://doi.org/10.1016/j.chemosphere.2010.03.009

Llorca M, Farre M, Tavano MS, Alonso B, Koremblit G, Barcelo D (2012) Fate of a broad spectrum of perfluorinated compounds in soils and biota from Tierra del Fuego and Antarctica. Environ Pollut 163:158–166. https://doi.org/10.1016/j.envpol.2011.10.027

Louis GMB, Chen Z, Schisterman EF, Kim S, Sweeney AM, Sundaram R, Lynch CD, Gore-Langton RE, Barr DB (2015) Perfluorochemicals and human semen quality: The LIFE study. Environ Health Perspect 123(1):57–63. https://doi.org/10.1289/ehp.1307621

Marchetti N, Caciolli L, Lagana A, Gasparrini F, Pasti L, Dondi F, Cavazzini A (2012) Fluorous affinity chromatography for enrichment and determination of perfluoroalkyl substances. Anal Chem 84(16):7138–7145. https://doi.org/10.1021/ac301442m

Marchetti N, Guzzinati R, Catani M, Massi A, Pasti L, Cavazzini A (2015) New insights into perfluorinated adsorbents for analytical and bioanalytical applications. Anal Bioanal Chem 407(1):17–21. https://doi.org/10.1007/s00216-014-8198-5

Mastrantonio M, Bai E, Uccelli R, Cordiano V, Screpanti A, Crosignani P (2018) Drinking water contamination from perfluoroalkyl substances (PFAS): an ecological mortality study in the Veneto Region, Italy. Eur J Public Health 28(1):180–185. https://doi.org/10.1093/eurpub/ckx066

Mazzoni M, Rusconi M, Valsecchi S, Martins CPB, Polesello S (2015) An on-line solid phase extraction-liquid chromatography-tandem mass spectrometry method for the determination of perfluoroalkyl acids in drinking and surface waters. J Anal Methods Chem. https://doi.org/10.1155/2015/942016

Melzer D, Rice N, Depledge MH, Henley WE, Galloway TS (2010) Association between serum perfluorooctanoic acid (PFOA) and thyroid disease in the US National Health and Nutrition Examination Survey. Environ Health Perspect 118(5):686–692. https://doi.org/10.1289/ehp.0901584

Messmer MF, Salloway J, Shara N, Locwin B, Harvey MW, Traviss N (2022) Risk of cancer in a community exposed to per- and poly-fluoroalkyl substances. Environ Health Insights 16:1–16. https://doi.org/10.1177/11786302221076707

Muir D, Miaz LT (2021) Spatial and temporal trends of perfluoroalkyl substances in global ocean and coastal waters. Environ Sci Technol 55(14):9527–9537. https://doi.org/10.1021/acs.est.0c08035

Naile JE, Khim JS, Wang TY, Chen CL, Luo W, Kwon BO, Park J, Koh CH, Jones PD, Lu YL, Giesy JP (2010) Perfluorinated compounds in water, sediment, soil and biota from estuarine and coastal areas of Korea. Environ Pollut 158(5):1237–1244. https://doi.org/10.1016/j.envpol.2010.01.023

Nassi M, Sarti E, Pasti L, Martucci A, Marchetti N, Cavazzini A, Di Renzo F, Galarneau A (2014) Removal of perfluorooctanoic acid from water by adsorption on high surface area mesoporous materials. J Porous Mater 21(4):423–432. https://doi.org/10.1007/s10934-014-9788-5

Noorlander CW, van Leeuwen SPJ, Biesebeek JDT, Mengelers MJB, Zeilmaker MJ (2011) Levels of perfluorinated compounds in food and dietary intake of PFOS and PFOA in The Netherlands. J Agric Food Chem 59(13):7496–7505. https://doi.org/10.1021/jf104943p

Ochoa-Herrera V, Field JA, Luna-Velasco A, Sierra-Alvarez R (2016) Microbial toxicity and biodegradability of perfluorooctane sulfonate (PFOS) and shorter chain perfluoroalkyl and polyfluoroalkyl substances (PFASs). Environ Sci: Process Impacts 18(9):1236–1246. https://doi.org/10.1039/c6em00366d

Park M, Wu SM, Lopez IJ, Chang JY, Karanfil T, Snyder SA (2020) Adsorption of perfluoroalkyl substances (PFAS) in groundwater by granular activated carbons: Roles of hydrophobicity of PFAS and carbon characteristics. Water Res. https://doi.org/10.1016/j.watres.2019.115364

Pignotti E, Casas G, Llorca M, Tellbuscher A, Almeida D, Dinelli E, Farre M, Barcelo D (2017) Seasonal variations in the occurrence of perfluoroalkyl substances in water, sediment and fish samples from Ebro Delta (Catalonia, Spain). Sci Total Environ 607:933–943. https://doi.org/10.1016/j.scitotenv.2017.07.025

Pinney SM, Biro FM, Windham GC, Herrick RL, Yaghjyan L, Calafat AM, Succop P, Sucharew H, Ball KM, Kato K, Kushi LH, Bornschein R (2014) Serum biomarkers of polyfluoroalkyl compound exposure in young girls in Greater Cincinnati and the San Francisco Bay Area, USA. Environ Pollut 184:327–334. https://doi.org/10.1016/j.envpol.2013.09.008

Porter AK, Kleinschmidt SE, Andres KL, Reusch CN, Krisko RM, Taiwo OA, Olsen GW, Longnecker MP (2022) Antibody response to COVID-19 vaccines among workers with a wide range of exposure to per- and polyfluoroalkyl substances. Environ Int. https://doi.org/10.1016/j.envint.2022.107537

Rahman MF, Peldszus S, Anderson WB (2014) Behaviour and fate of perfluoroalkyl and polyfluoroalkyl substances (PFASs) in drinking water treatment: A review. Water Res 50:318–340. https://doi.org/10.1016/j.watres.2013.10.045

Riebe RA, Falk S, Georgii S, Brunn H, Failing K, Stahl T (2016) Perfluoroalkyl acid concentrations in livers of fox (Vulpes vulpes) and chamois (Rupicapra rupicapra) from Germany and Austria. Arch Environ Contam Toxicol 71(1):7–15. https://doi.org/10.1007/s00244-015-0250-8

Sabovic I, Cosci I, De Toni L, Ferramosca A, Stornaiuolo M, Di Nisio A, Dall’Acqua S, Garolla A, Foresta C (2020) Perfluoro-octanoic acid impairs sperm motility through the alteration of plasma membrane. J Endocrinol Invest 43(5):641–652. https://doi.org/10.1007/s40618-019-01152-0

Scheringer M, Trier X, Cousins IT, de Voogt P, Fletcher T, Wang ZY, Webster TF (2014) Helsingor Statement on poly- and perfluorinated alkyl substances (PFASs). Chemosphere 114:337–339. https://doi.org/10.1016/j.chemosphere.2014.05.044

Senthilkumar K, Ohi E, Sajwan K, Takasuga T, Kannan K (2007) Perfluorinated compounds in river water, river sediment, market fish, and wildlife samples from Japan. Bull Environ Contam Toxicol 79(4):427–431. https://doi.org/10.1007/s00128-007-9243-2

Sim W, Choi S, Choo G, Yang M, Park JH, Oh JE (2021) Organophosphate flame retardants and perfluoroalkyl substances in drinking water treatment plants from Korea: Occurrence and human exposure. Int J Environ Res Public Health 18(5):2645. https://doi.org/10.3390/ijerph18052645

Sinclair E, Mayack DT, Roblee K, Yamashita N, Kannan K (2006) Occurrence of perfluoroalkyl surfactants in water, fish, and birds from New York State. Arch Environ Contam Toxicol 50(3):398–410. https://doi.org/10.1007/s00244-005-1188-z

Skutlarek D, Exner M, Farber H (2006) Perfluorinated surfactants in surface and drinking water. Environ Sci Pollut Res 13(5):299–307. https://doi.org/10.1065/espr2006.07.326

Steenland K, Woskie S (2012) Cohort mortality study of workers exposed to perfluorooctanoic acid. Am J Epidemol 176(10):909–917. https://doi.org/10.1093/aje/kws171

Takagi S, Adachi F, Miyano K, Koizumi Y, Tanaka H, Watanabe I, Tanabe S, Kannan K (2011) Fate of perfluorooctanesulfonate and perfluorooctanoate in drinking water treatment processes. Water Res 45(13):3925–3932. https://doi.org/10.1016/j.watres.2011.04.052

Theobald N, Caliebe C, Gerwinski W, Hühnerfuss H, Lepom P (2012) Occurrence of perfluorinated organic acids in the North and Baltic Seas. Part 2: Distribution in sediments. Environ Sci Pollut Res 19(2):313–324. https://doi.org/10.1007/s11356-011-0559-4

Thompson J, Eaglesham G, Mueller J (2011) Concentrations of PFOS, PFOA and other perfluorinated alkyl acids in Australian drinking water. Chemosphere 83(10):1320–1325. https://doi.org/10.1016/j.chemosphere.2011.04.017

Tran HN, You SJ, Hosseini-Bandegharaei A, Chao HP (2017) Mistakes and inconsistencies regarding adsorption of contaminants from aqueous solutions: A critical review. Water Res 120:88–116. https://doi.org/10.1016/j.watres.2017.04.014

Umweltbundesamt, (2017) Fortschreibung der vorläufigen Bewertung von per- und polyfluorierten Chemikalien (PFC) im Trinkwasser: Empfehlung des Umweltbundesamtes nach Anhörung der Trinkwasserkommission (in German). Bundesgesundheitsblatt 60(3):350–352. https://doi.org/10.1007/s00103-016-2508-3

USEPA (2016c) PFOA & PFOS Drinking Water Health Advisories. EPA 800-F-16-003. Washington D.C., USA

USEPA (2016a) Drinking Water Health Advisory for perfluorooctane sulfonate (PFOS). EPA 822-R-16-004 Washington D.C., USA

USEPA (2016b) Drinking Water Health Advisory for perfluorooctanoic acid (PFOA). EPA 822-R-16–005. Wahington D.C., USA

USEPA (2022a) Drinking Water Health Advisory: Perfluorobutane sulfonic acid and related compound potassium perfluorobutane sulfonate. EPA 822-R-22-006. Washington D.C., USA

USEPA (2022b) Interim Drinking Water Health Advisory: Perfluorooctane sulfonic acid (PFOS). EPA 822-R-22–004. Washington D.C., USA

Velez MP, Arbuckle TE, Fraser WD (2015) Maternal exposure to perfluorinated chemicals and reduced fecundity: The MIREC study. Hum Reprod 30(3):701–709. https://doi.org/10.1093/humrep/deu350

Vested A, Ramlau-Hansen CH, Olsen SF, Bonde JP, Kristensen SL, Halldorsson TI, Becher G, Haug LS, Ernst EH, Toft G (2013) Associations of in utero exposure to perfluorinated alkyl acids with human semen quality and reproductive hormones in adult men. Environ Health Perspect 121(4):453–458. https://doi.org/10.1289/ehp.1205118

Vieira VM, Hoffman K, Shin HM, Weinberg JM, Webster TF, Fletcher T (2013) Perfluorooctanoic acid exposure and cancer outcomes in a contaminated community: A geographic analysis. Environ Health Perspect 121(3):318–323. https://doi.org/10.1289/ehp.1205829

Wang TY, Chen CL, Naile JE, Khim JS, Giesy JP, Lu YL (2011) Perfluorinated compounds in water, sediment and soil from Guanting Reservoir. China Bull Environ Contam Toxicol 87(1):74–79. https://doi.org/10.1007/s00128-011-0307-y

Xindu G, Carr PW (1983) Use of fluorinated bonded phases in reversed-phase high-performance liquid chromatography of proteins. J Chromatogr 269:96–102

Xu ZP, Oleschuk RD (2014) A study of the methylene/perfluormethylene selectivity of porous polymer monolithic stationary phases exhibiting different fluorous/hydrophobic content. J Chromatogr A 1329:61–70. https://doi.org/10.1016/j.chroma.2013.12.032

Yu Q, Zhang RQ, Deng SB, Huang J, Yu G (2009) Sorption of perfluorooctane sulfonate and perfluorooctanoate on activated carbons and resin: Kinetic and isotherm study. Water Res 43(4):1150–1158. https://doi.org/10.1016/j.watres.2008.12.001

Zhang SY, Kang QY, Peng H, Ding MY, Zhao FR, Zhou YY, Dong ZM, Zhang HF, Yang M, Tao S, Hu JY (2019) Relationship between perfluorooctanoate and perfluorooctane sulfonate blood concentrations in the general population and routine drinking water exposure. Environ Int 126:54–60. https://doi.org/10.1016/j.envint.2019.02.009

Zhao YG, Wong CKC, Wong MH (2012) Environmental contamination, human exposure and body loadings of perfluorooctane sulfonate (PFOS), focusing on Asian countries. Chemosphere 89(4):355–368. https://doi.org/10.1016/j.chemosphere.2012.05.043

Zhuravlev LT (2000) The surface chemistry of amorphous silica. Zhuravlev model. Colloids Surf A: Physicochem Eng Asp 173(1–3):1–38. https://doi.org/10.1016/s0927-7757(00)00556-2

Acknowledgements

The authors would like to thank Pascal Fuge, Markus Kren, Lena Schmidt, and Mathias Werner for their extensive experimental work, high level of commitment and thus essential contribution to this research topic.

Funding

Open Access funding enabled and organized by Projekt DEAL. This study was funded by the Helmut-Schmidt-University/University of the Bundeswehr Hamburg.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lassen, S., Niemeyer, B. New silica-based adsorbents for water purification: Removal of short- and long-chain perfluoroalkyl sulfonic acids (PFSA) at sub-nanomolar concentrations. Appl Water Sci 14, 183 (2024). https://doi.org/10.1007/s13201-024-02245-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-024-02245-9