Abstract

Laboratory tests and column tests were carried out in a waterwoks to investigate the removal of short- and long-chain PFAS using activated carbon filtration and ion exchange treatment. For all adsorbents, the sorption affinity of short-chain per- and polyfluoroalkyl carboxylic acids (PFCA) was significantly lower than that of long-chain PFAS or short-chain per- and polyfluoroalkyl sulfonic acids (PFSA). In the PFAS-polluted groundwater matrix, the short-chain PFCA PFBA and PFPeA could only be sufficiently removed with activated carbon over short run times of 6000 and 11,000 bed volumes (BV), respectively. Longer PFCA with a chain length of C6 or more were removed over longer run times.

The removal of short-chain PFCA using ion exchange media could also only be achieved over relatively short run times of 5000 BV for PFBA, 10,000BV for PFPeA and 18,000 BV for PFHxA. These are sometimes significantly longer than those of activated carbon. Due to the higher material costs for ion exchange media, there are nevertheless no lower operating costs when the ion exchangers are used in single-use mode. However, ion exchangers can be regenerated and then reused which can result in economic advantages compared to activated carbon filtration. However, for the extensive regeneration, especially for the elution of the long-chain PFAS, the additional use of ethanol is needed in the process. In contrast, the short-chain PFBA and PFPeA can be extracted without organic solvent from a weakly basic ion exchanger.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The group of per- and polyfluoroalkyl substances (PFAS) is a large family of anthropogenic substances. They consist in part of aliphatic, acyclic hydrocarbons in which many (poly) or all (per) of the hydrogen atoms have been replaced by fluorine atoms (Buck et al. [3]). These carbon chains are connected to different functional groups. Due to their hydrophilic and hydrophobic properties, PFAS are as well oil and water repellent. PFAS show a high stability to thermal, biological and chemical processes. Thus, they have been used in a wide range of industrial and household products over several decades. One main application is their use in aqueous film forming foams (AFFF).

The group of PFAS can be subdivided into per- and polyfluoroalkyl carboxylic acids (PFCA) and per- and polyfluoroalkyl sulfonic acids (PFSA). In addition to these two subgroups, a broad variety of PFAS exist with different chemical structures at the non-fluorinated part of the molecules (Buck et al. [3]). Single perfluorinated substances, like perfluorooctane sulfonic acid (PFOS) and perfluorooctanoic acid (PFOA), have been well researched and are regulated due to their extreme resistance to degradation and their bioaccumulation potential. Owing to their very high toxicity to humans, the use of PFOS has been forbidden in the EU to a large extend since 2006 (EC [7]), based on agreements in the Stockholm Convention. The use of PFOA is also strongly restricted and in 2019 the use of firefighting foams containing PFOA has also been banned in the EU (Stockholm Convention [28]). Since over 150 countries across all inhabited continents have ratified the Stockholm Convention, the use of designated PFAS is virtually banned worldwide (Brennan et al. [2]).

Consequently, alternative PFAS are now used in many applications. These PFAS have either shorter-chain lengths or are only partly fluorinated compounds (such as the fluorotelomers) [1, 24, 26]. The non-fluorinated part of the fluorotelomers with shorter-chain lengths might be degraded microbially in the environment leading to the formation of PFCA or PFSA (Pancras et al. [21]). Short-chain PFAS are defined to have five or less carbon atoms in the case of PFSA and to have seven or less carbon atoms in the case of PFCA ([3], OECD [20]).

In general, short-chain PFAS are less toxic than long-chain PFAS; however, the short-chain PFAS have been found to be more mobile in groundwater and able to move more rapidly in the case of soil contamination [33]. This is apparent by comparing the drinking water guidance values set from the German Environmental Protection Agency for the C4 compound PFBA (perfluorobutanoic acid) of 10 µg/L and for the C8 compound PFOS of 0.1 µg/L (UBA [34]). Nevertheless, short-chain perfluoroheptanoic acid (PFHpA) has a health-oriented guidance value of 0.3 µg/L and thus exhibits a comparable toxicity like PFOS. In addition, the EC Drinking Water Directive 2020/2184 includes a drinking water limit value of 0.1 µg/L for the sum of 20 PFAS (C4 to C13 of PFCA and PFSA) (EU [8]).

Most cases of PFAS contamination of groundwater have resulted from firefighting operations using aqueous film forming foams near airports. These contaminations are often characterised by the occurrence of long-chain PFAS, like PFOS, PFHxS and PFOA. More recent groundwater contaminations are often characterised by contributions from short-chain PFAS, such as PFBA, PFPeA (perfluoropentanoic acid) or PFHxA (perfluorohexanoic acid) [12, 25, 38].

Adsorption onto granular activated carbon (GAC) is a field-proven technology for the removal of long-chain PFAS, like PFOS and PFOA, from contaminated water [14, 27]. Due to the raising concerns of emerging short-chain PFAS, new treatment technologies have recently been developed, investigated and evaluated.

Sustainable PFAS treatment technologies ensure a destruction of the substance until full degradation and mineralisation has occurred. Nevertheless, due to the very high electronegativity of fluorine and the very stable chemical bond between carbon and fluorine, destruction technologies for PFAS are very energy intensive. PFAS destruction has been investigated for electrochemical degradation, sonochemistry, plasma destruction, oxidation processes, UV radiation and incineration [15, 22, 30, 32, 35, 37]. In the case of drinking water treatment and of certain contaminant site remediation, PFAS concentrations can be rather low, and thus, these technologies are not very attractive from an economical perspective.

In general, economic benefits can be felt from treatment technologies when a PFAS liquid–liquid separation or an adsorption step is used before the PFAS destruction step. In the first case, the amount of water to be treated is significantly reduced resulting in a large energy saving for the destruction technology. In the second case, PFAS are accumulated on a solid phase and then the further destruction technology takes place via the combustion of the adsorbents with a thermal destruction of the PFAS. Effective technologies for pre-concentration of PFAS include reverse osmosis, foam fractionation, distillation and ion exchange, including resin regeneration. Adsorptive media which are effective for some PFAS include granular activated carbons (GAC), anion exchangers (IEX), amorphous aluminium hydroxide and organoclays [5, 11, 19, 31, 36].

The operation time of adsorptive media can be increased by applying a flocculation step with PFAS-specific coagulation compounds prior to adsorption to decrease the PFAS concentration in the adsorbent feed or to reduce, e.g. the concentration of natural organic substances, which compete for adsorption sites. One example of this approach is the PerfluorAd® technology [4].

Ion exchangers are utilised in a “single-use” or can be regenerated after their adsorption capacity has been exceeded. During the regeneration procedure, the functional groups on the ion exchange media are transferred back to their original form and a further cycle of sorption can be performed. Therefore, the ion exchanger can be used for a number of adsorption cycles without replacing the filter material. After the regeneration process, the removed PFAS are present in high concentrations in the liquid regenerate, which has to be further treated to mineralize the pollutants. Thus, IEX with regeneration is a liquid–liquid separation procedure that can reduce the volume of PFAS containing water that has to be treated.

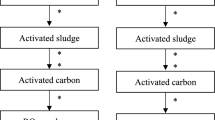

In this paper, PFAS removal from water by activated carbon adsorption and both strong base (SBA) and weak base anion exchangers (WBA) is investigated. Results are evaluated related to capacities and operating times for both long-chain and short-chain PFAS. The influence of operating parameters, such as carbon bed depth on PFAS breakthrough, is discussed. Methods for resin regeneration are shown and resulting separation factors, which indicate the volume of PFAS containing water related to the initial volume of water, are determined.

Materials and methods

Adsorption materials

For the experimental PFAS studies five GAC and six basic anion exchange media were used. An overview of the adsorbents and their characterisation parameters are given in Tables 1 and 2.

Investigated GAC types differ in raw material, supplier and origin. In water treatment processes in Germany, bituminous coal (bit)–based GAC types are mostly applied in full-scale adsorbers. In addition, lignite-based GAC and GAC of various compositions where the raw materials are unknown have been investigated. These materials have an open pored structure. More recently, new coconut shell (CC)-based GAC types with a high activation grade have been developed. In opposite to the conventional CC-based GAC, they differ in pore structure and have a higher mesopore volume.

All of the investigated IEX materials are styrene divinylbenzene-based copolymers. Both macroporous and gelular resins were investigated.

Water matrices

For the batch experiments, demineralized water or tap water was used and for the field column experiments, PFAS-contaminated groundwater was used. Concentrations of relevant parameters are listed in Table 3.

Batch experiments

IEX were pre-treated with 1 M hydrochloric acid and 1 M caustic soda to remove impurities and monomers prior to batch experiments [25]. IEX samples were taken after centrifuging at 1300 g for a time of 20 min to strip off adhering water and convert the material to a comparable state.

Sorption equilibria of PFAS on IEX were determined by equilibrating a series of resin quantities between 0.3 and 2 g with 1 L of tap water spiked with PFAS for at least 60 h. Tap water was used to simulate competitive effects. Eight different dissolved PFAS (PFBA, PFPeA, PFHxA, PFHpA, PFOA, PFBS, PFHxS and PFOS) were added to the tap water at an initial concentration of 100 µg/L each. The pH was adjusted to 7.0 ± 0.3 using an imidazole buffer (10 mM) and hydrochloric acid. For all batch experiments pyrolysed brown glass flasks were used.

After equilibration (temperature: 25 ± 2 °C), the pH values were measured and PFAS concentrations (c) were determined. PFAS were analysed by HPLC-MS/MS according to the standard method DIN 38,407–42 (DIN [6]). A HPLC system 1290 from Agilent Technologies coupled to a triple quad 6500 system from Sciex was used. Due to the elevated PFAS concentrations, no pre-concentration was needed but direct injection into the HPLC system could be applied. For quantification, isotope-labelled internal standards were added to the samples and an external calibration in tap water was used. Based on the measured PFAS concentrations, equilibrium solid phase concentrations (q) were calculated by mass balances.

Sorption equilibria for the IEX were correlated by means of the semi-empirical Langmuir approach:

The respective Langmuir equilibrium parameters KL and qmax were deduced from linearized plots (Sontheimer [29]).

For low liquid phase concentrations c, the Langmuir relationship reduces to a linear relationship because (KLc) < < 1:

If experimental equilibrium data showed a linear correlation between q and c, Eq. 2 was used to determine the respective parameters. All isotherms were plotted for individual substances.

IEX loaded with PFAS during column experiments with contaminated groundwater were regenerated in batch mode. Mean PFAS loadings (= solid phase concentrations) were calculated by integrating the experimental data of the PFAS breakthrough during column operation. This value was used to determine the efficiency of regeneration. Resin samples were taken at the top end of a filter column to obtain the part with the highest PFAS loading. 1 g of PFAS loaded and centrifuged (1300 g, 20 min) IEX material was shaken with 10 or 20 mL of the different regenerates for at least 60 h. Following this, PFAS concentrations were determined in the liquid regenerate, and based on the mean PFAS loading, the regeneration percentage was calculated.

GAC was dried and pulverised. Sorption equilibria of PFAS on GAC were determined by equilibrating a series of activated carbon quantities between 0.5 and 150 mg with 1 L of the initial solution. The contact time was 24 h when a constant concentration was achieved. The initial solution was demineralized water spiked with four PFAS (PFBA, PFPeA, PFHxA, PFOA) at an initial concentration of 6 µg/L each.

Sorption equilibria for activated carbon were determined using the Freundlich approach. Isotherms were determined for individual PFAS.

The respective equilibrium parameters KF and n were deduced from linearized plots (Sontheimer 1988).

Column experiments in the field

Column experiments with GAC and IEX were carried out in a waterworks in Southern Germany, which receives PFAS-contaminated groundwater that was caused by a soil contamination with PFAS containing paper sludge (Karlsruhe Regional Council [13]). The primary PFAS present in this raw water are the short-chain PFPeA and PFHxA at concentrations of 0.74 and 0.62 µg/L, respectively (see Table 3).

Two types of column experiments were carried out to obtain PFAS breakthrough curves. For a comparative evaluation of adsorption behaviour of different GAC the GCS test (Granular Carbon Selection Test) was used [9]. In this small column test procedure, the adsorbents are used in their original grain size. The optimal experimental set up of the GCS test was developed by taking mass transfer processes and operational feasibility into account. The filter and process parameters are given in Table 4. Due to the high filtration velocity and the low bed depth, breakthrough of PFAS is obtained after around three weeks. According to the short Empty Bed Contact Time (EBCT) the shape of the breakthrough curves differs from full-scale data. Thus, the data from GCS test should not be upscaled and only be used for adsorbents comparison.

For the evaluation of the PFAS removal efficiency of GAC based on operation time or specific throughput, a GAC pilot plant was operated. The process parameters are adapted to full-scale adsorbers for micro pollutant removal (see Table 4). In the GAC pilot plant breakthrough curves could be determined at different GAC bed depths. The filtration velocity of the pilot adsorber was 8 m/h.

The IEX column pilot investigations were performed with a volume of 8 L of resin, and fluxes between 10 and 25 BV/h (EBCT = 2.4 to 6 min) and filtration velocities varying between 10 and 25 m/h were adjusted.

The resin regeneration in column mode was carried out directly during the pilot plant filter loading using identical equipment. The first regeneration was performed using 1 M caustic soda. The second and third regenerations were done with a 1 M sodium chloride solution in 45% ethanol. The fourth regeneration was carried out with 1 M hydrochloric acid in 45% ethanol. The regenerant flux was approximately 2 BV/h in co-current flow. The amount of regenerant was 3 BV for the first three regenerations and 6 BV for the fourth regeneration. During the regeneration process, the effluent water was sampled at different time intervals for analysis.

Results

Influence of PFAS chain length and adsorbent properties

Activated carbon

Long-chain PFAS are better adsorbed by GAC than short-chain PFAS due to a decreasing polarity with chain length [11, 18, 19]. In addition, perfluorinated alkyl sulfonates (PFSA) are better adsorbable than perfluorinated carboxylic acids (PFCA) [16]. Equilibrium batch studies were carried out to compare adsorbability of the different PFAS compounds. The increasing adsorption capacity of the sorbents for PFAS with increasing chain length was confirmed for the carbonic and the sulfonic compounds in the equilibrium batch studies with demineralized water (see Fig. 1). With increasing chain length, higher Freundlich KF values and lower Freundlich n values were determined (see Table 5). The experimental investigations with activated carbon showed the following order of sorption: PFOA > PFHxA > PFPeA > PFBA.

Ion exchange

The sorption mechanism of PFAS onto anion exchange resins is a mixture of anion exchange and physical sorption, like van der Waals interaction [23, 36], that might be less dependent on substance polarity. Sorption isotherms for the eight PFAS found in the ground water (using strong base IEX K6362) are shown in Fig. 2. The experimental investigations with IEX K6362 and several other resins (Fig. 2 and Table 6) lead to the following order of adsorption of the PFAS: PFOS > PFHxS > PFBS ≈ PFOA > PFHpA > PFHxA > PFPeA > PFBA. A large difference in adsorption affinity can be seen depending on the PFAS chain length and the functional group. The C4 compound PFBA shows the lowest solid phase concentrations and thus a low adsorption affinity. For the PFCA, the isotherms become steeper with increasing chain length which implies that longer-chain PFCA are better removed from the solution than short-chain PFCA. This dependency is also observed for the PFSA.

Furthermore, sulfonated PFAS of the same chain length show a higher adsorption affinity than carboxylic acids. With regard to PFSA, the C4 substance PFBS absorbs as well as the C8 carboxylic acid PFOA. The isotherms of PFHxS and PFOS exhibit very steep straight lines which do not flatten under the selected experimental conditions.

Equilibrium parameters using the Langmuir approach according to Eqs. (1) and (2) are listed in Table 6, where short-chain PFAS are printed in italics. For IEX K6362 and the three investigated sulfonated substances and PFOA, only the product of qmax and KL (= ΠL) was determined, as the experimentally obtained equilibrium concentrations were linear under the selected test conditions. Residual concentrations were below the limit of detection for PFOS in all IEX samples meaning that the slope of the isotherm was infinite. Here, even using 0.3 g of IEX led to a complete adsorption of the 100 µg of PFOS present in the water.

Figure 3 shows the isotherms of six anion exchange media for the adsorption of the short-chain perfluorinated carboxylic acid PFPeA. The strong base anion exchanger A532E and the weak base anion exchanger D5706 show the steepest isotherms. In equilibrium with a liquid phase concentration, e.g. 1 µg/L, these IEX have a loading of 28 and 20 μg/g, respectively.

Selection of GAC

The granular carbon selection test (GCS test) was developed to compare the adsorption capacities of different types of GAC [9] in order to select the optimal GAC. Breakthrough curves for PFBA and PFOA using five different GAC types are shown in Fig. 4.

The performance of the GAC is different for PFBA and PFOA, which may be due to their adsorption in different pores. While the best removal of PFOA is observed using the GAC-lig 1, this activated carbon showed the lowest adsorption capacity for PFBA. The earliest breakthrough for PFOA was observed using the GAC-CC, whereas this activated carbon was better than the GAC-lig for PFBA removal. The GAC-bit 1 and GAC-bit 2 were equally as good for PFBA removal and performed in the middle range for PFOA.

Based on these results it seems clear that the selection of the optimal GAC for PFAS removal depends on the composition and concentrations of the PFAS mixture and the concentrations levels that the water should be cleaned up to. The results determined here can also be used to support optimization of treatment methods to reach desired threshold concentrations. For example, the 100 ng/L for 20 single PFAS that is set in the EC Drinking Water Directive can be supported by selecting an appropriate GAC by measuring breakthrough curves for all PFAS and by determining the PFAS sum concentrations.

Pilot-scale column investigations

Activated carbon

GAC column tests were used to determine the operation time of a full-scale GAC adsorber. The GAC adsorber used in the pilot-scale test received contaminated groundwater and PFAS concentrations were measured at different bed depths of the adsorber. The normalised breakthrough curves for C4 to C8 PFCA for GAC-CC at a bed depth of 1 m are shown in Fig. 5. PFBA breakthrough could be observed at 5,000 BV. At a specific throughput of 11,000 BV the effluent and initial concentration were equal, i.e. c/c0 = 1. Following this and due to chromatographic effects in the GAC bed with desorption of PFBA, the effluent concentration is higher than the influent concentration. Adsorption equilibrium for PFBA is not achieved even after a throughput of 25,000 BV.

As the PFAS chain length increases, longer operation times until initial breakthrough are achieved. A 10% breakthrough is observed at 6000 BV for PFBA, at 11,000 BV for PFPeA, at 16,000 BV for PFHxA, at 20,000 BV for PFHpA and at 23,000 BV for PFOA (initial concentrations are listed in Table 3). At these operation times, the material-specific GAC loadings are 2.4 µg/g for PFBA, 17 µg/g for PFPeA, 21 µg/g for PFHxA, 11 µg/g for PFHpA and 29 µg/g for PFOA (using a bulk density of GAC of 0.47 kg/L).

Previous investigations show that removal efficiencies of activated carbons strongly depend on the type of activated carbon used. Suitable activated carbons show incipient breakthrough for PFOS at 30,000 to 40,000 BV and for PFOA at 20,000 to 30,000 BV [16, 17]. This performance is confirmed by the test results shown here.

In general, GAC adsorbers are considered to be effective and feasible taking into account operational and economic factors so long as a specific throughput of at least 15,000 BV can be achieved. Under the given boundary conditions (especially the given initial concentrations for PFAS and a 10% breakthrough in maximum), GAC removal is effective for long-chain PFOA and short-chain PFHpA and PFHxA. However, GAC adsorption is not effective or results in short operation times of GAC adsorbers for PFBA and PFPeA and this would therefore result in high specific treatment costs.

The effectiveness of GAC adsorption for certain micro pollutant removal (e.g. pesticides) was shown to increase with increasing filter bed depth and thus increasing EBCT [10]. This effect was investigated for the removal of PFBA. Breakthrough curves were measured in different bed depths for filtration velocities of 7.5 and 3.75 m/h. With increasing EBCT (corresponding to increasing bed depth), the specific throughput to a 100% breakthrough for PFBA removal (Fig. 6) decreases. By increasing the EBCT from 8 to 24 min the specific throughput for a 100% breakthrough for PFBA decreased by 23%. This is caused by competitive adsorption in the upper filter bed with desorption of PFBA.

Ion exchange

Figure 7 shows the result of a column experiment with the WBA D5706. Normalised PFAS concentrations in the filter effluent are shown as a function of water throughput. In addition, the regeneration times of the IEX are displayed by dashed vertical lines. The throughput was initially set at 25 BV/h and after the second regeneration (after approx. 50,000 BV) it was adjusted to 10 BV/h. PFBA breakthrough of 10% was observed after approximately 4000 BV. PFPeA concentrations increased slightly with a time delay and reach a 10% breakthrough after 10,000 BV. Breakthrough of the C6 compound PFHxA was observed after 25,000 BV.

After the first regeneration with aqueous NaCl solution after almost 30,000 BV, there was no interruption in the concentrations of the individual PFAS. Thus, treatment with sodium chloride solution did not result in successful regeneration of the IEX. An analysis of the regenerate confirmed that no PFAS were removed from the exchange media.

In the following three regeneration cycles with sodium chloride solution or hydrochloric acid and ethanol, PFAS desorbed to the regeneration solution. As a consequence, in the subsequent loading cycles, the PFAS were adsorbed again onto the resin and concentration reductions were seen in the filter effluent. After the second and third regeneration, both performed with only 3 BV of regenerant, individual substances like PFPeA and PFHpA are already present in the filtrate. After the fourth regeneration, carried out with 6 BV of HCl in ethanol, the treated solution had significantly lower PFAS concentrations. In the last loading cycle, PFBA was removed at 7,000 BV and PFPeA at 12,000 BV until a 10% breakthrough occurs. This breakthrough performance is comparable to the first cycle from 0 to 25,000 BV.

SBA A532E, which showed the best adsorption performance for all PFAS in batch experiments (Fig. 3, Table 4) also had a longer operating time until breakthrough of single short-chain PFAS occurred. However, this exchanger could not be successfully regenerated, and therefore, its cyclic operation, including adsorption, regeneration and then further adsorption, was not possible.

Adsorption behaviour for the C3 substance PFPrA with different resins is shown in Fig. 8. All media showed a very fast breakthrough demonstrating their low affinity towards this polar substance. IEX A532 removed PFPrA at between 1000 and 2000 BV, and after that a regeneration is needed for successful further elimination of the substance. Furthermore, for all resins a chromatographic displacement pattern is observed in which PFPrA appears in the effluent at concentrations greater than in the feed solution.

Regeneration of IEX

Batch experiments showed that by using standard regeneration agents (NaOH, HCl, NaCl, Na2SO4, Na2CO3), both WBA and SBA can only be regenerated to a minor extend, or not at all when PFHxA, PFHpA and PFOA are being sorbed. Compared to these PFAS, PFPeA and PFBA can be extracted from WBA resins MP 62 more easily with standard regeneration agents (Fig. 9).

Using other combined regenerants, like NH4OH and NH4Cl or KCl and KOH, as described by Zaggia et al. [38] for partially successful PFAS regeneration, no sufficient regeneration could be achieved by the corresponding investigations. A complete extraction of the adsorbed PFCA from IEX A532E could be achieved by using a regenerant combination of 1 M NaCl in an ethanol/water mixture (45%/55% (v/v)). Regeneration of WBA D5706 using 0.5 M HCl in 45% ethanol resulted in the highest regeneration rates.

During regeneration in filter mode, the regeneration effluent was sampled and analysed for PFAS. The regenerated PFAS masses were compared to calculated ones based on the adsorbed masses. During the second and third regenerations of IEX D5706, percentages between 60 and 80% of each individual PFAS could be extracted. During the fourth regeneration with 6 BV of regenerant, an almost complete regeneration was achieved for all present PFCA with chain length from C4 to C8. Analysis of the total regeneration solution with a volume of 6 BV after an operation time of 22,000 BV between the third and the forth regeneration showed that the concentrations of the substances PFPeA, PFHxA, PFHpA and PFOA are higher by a factor of 3500 to 6000 than in the contaminated groundwater. A further treatment for the final PFAS destruction would therefore start with a solution in which the PFAS concentrations are 3 orders of magnitude higher than in the original raw water. These results alone show the huge promise of the method.

After IEX regeneration, PFAS are present in very high concentrations in the liquid regenerate. The volume of PFAS containing regenerate related to the initial volume of groundwater is defined as the separation factor. If a regeneration step is performed after the start of breakthrough of the substance of interest and 10 BV (instead of 6 BV) of regenerate is used, separation factors for IEX D5706 can be achieved as shown in Table 7. Separation factors of other liquid–liquid separation technologies, like reverse osmosis, are in the range of 4 (80% permeate to 20% regenerate). Compared to these values, the separation factors achieved here for ion exchange, including regeneration, are much higher again supporting the use of this method for water treatment of PFAS-contaminated water. If the amount of regenerant can be reduced, for instance to 6 BV, the separation factors will even increase.

Comparative evaluation and conclusions

Results have shown that GAC adsorption for the treatment of this groundwater (DOC = 0.7 mg/L, single PFAS < 1 µg/L) contaminated with PFAS is effective for the removal of short-chain PFAS, such as PFHpA and PFHxA, which are present in the groundwater at concentrations of several 100 ng/L. In contrast, a complete breakthrough is observed for the short-chain PFBA at a specific throughput < 10,000 BV. Owing to this, the frequency of GAC replacement for the sorption of PFBA would be high and using this treatment process is not recommended when taking into account operational and economical aspects.

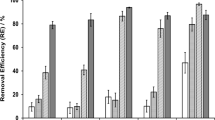

A comparison of the starting breakthroughs (10%) of each PFAS is shown for the coconut shell-based GAC as well as the IEX D5706 in Table 8.

In this study, comparable specific throughputs for (very) short-chain PFAS are achieved for both, GAC and IEX. Due to the fact that ion exchange resins are more expensive than GAC media, the use of IEX will only become the preferred method for this water quality if multiple regeneration of IEX is possible. To probe the economic efficiency of water treatment using IEX and GAC, a price of 8 €/L for ion exchangers and 2 €/L for activated carbons was assumed, which is an average price (before 2020) that was communicated to the authors by water suppliers and material providers.

If the sorption materials are not regenerated and new material has to be used after they are exhausted, the specific material costs (in €/m3 treated water) can be derived directly from the operation time. In Fig. 10, these specific material costs are shown for one IEX and one GAC for three PFAS. Figure 10 shows that despite better adsorption capacities of the IEX, higher consumable material costs result. For instance, for removing PFHxA, resin D5706 has an adsorption capacity prior to breakthrough that is more than twice that of activated carbon GAC-CC. However, the higher material costs of the exchanger result in higher specific consumable material costs (20 cent/m3 compared to 11 cent/m3). These results show that a single loading of the IEX with subsequent replacement by new material is not more cost effective than using activated carbon. In order to reduce specific material costs, regeneration of the exchangers is necessary.

If ion exchangers are regenerated, the specific consumable material costs decrease. For resin D5706, the relationship between the specific material costs and the number of loading cycles before the ion exchanger has to be replaced is shown in Fig. 11 for three short-chain PFAS. The figure also shows the specific material costs for the investigated GAC-CC which are shown as horizontal straight lines. As it can be seen, the specific material costs for the removal of PFHpA and PFHxA are already lower for resin D5706 following two adsorption and regeneration cycles when compared to GAC-CC. For the elimination of PFPeA, 5 cycles of adsorption and regeneration are needed to outperform specific consumable material costs of GAC-CC.

It must be bore in mind though that these results refer solely to material costs. The use of IEX would also incur costs for the regeneration agents and the disposal or further treatment of the regenerate containing PFAS as well as for transport and further operation. For a detailed estimation of these costs, further investigations, also including GAC reactivation, would be necessary.

Availability of data and materials

All data generated or analysed during this study are included in this published article or are available from the corresponding author on reasonable request.

References

Ahrens L, Taniyasu S, Yeung LWY, Yamashita N, Lam PKS, Ebinghaus R (2010) Distribution of polyfluoroalkyl compounds in water, suspended particulate matter and sediment from Tokyo Bay. Japan Chemosphere 79(3):266–272

Brennan NM, Evans AT, Fritz MK, Peak SA, von Holst HE (2021) Trends in the regulation of per- and polyfluoroalkyl substances (PFAS): a scoping review. Int J Environ Res Public Health 18:1–28

Buck CB, Franklin J, Berger U, Conder JM, Cousins IT, de Voogt P, Jensen AA, Kannan K, Mabury SA, van Leeuwen SPJ (2011) Perfluoroalkyl and polyfluoroalkyl substances in the environment: terminology, classification, and origins. Integr Environ Assess Manag 7(4):513–541

Cornelsen M (2015) Neues verfahren zur entfernung von per- und polyfluorierten chemikalien aus komplex belasteten wässern (new process for removing perfluorinated and polyfluorinated chemicals from complex contaminated waters). gwf-Wasser Abwasser 9:918–925

Das P, Arias VA, Kambala V, Mallavarapu M, Naidu R (2013) Remediation of perfluorooctane sulfonate in contaminated soils by modified clay adsorbent—a risk-based approach. Water Air Soil Poll 224:1714

DIN 38407-42:2011-03 German standard methods for the examination of water, waste water and sludge—jointly determinable substances (group F)—part 42: determination of selected polyfluorinated compounds (PFC) in water—method using high performance liquid chromatography and mass spectrometric detection (HPLC/MS-MS) after solid-liquid extraction (F 42)

EC: European commission 2006 directive 2006/122/EC of the European parliament and of the council of 12 December 2006 amending for the 30th time council directive 76/769/EEC on the approximation of the laws, regulations and administrative provisions of the Member States relating to restrictions on the marketing and use of certain dangerous substances and preparations (perfluorooctane sulfonates). In: Official journal of the European Union 372/32

Directive (EU) 2020/2184 of the European parliament and of the council of 16 December 2020 on the quality of water intended for human consumption (recast)

Haist-Gulde B, Baldauf G (2014) Kornaktivkohlen zur Trinkwasseraufbereitung (granular activated carbons for drinking water treatment). Energie-wasser-praxis 6:50–55

Haist-Gulde B, Baldauf G, Brauch H-J (1993) Removal of pesticides from raw waters. Water Supply 11:159–168

Hansen MC, Børresen MH, Schlabach M, Cornelissen G (2010) Sorption of perfluorinated compounds from contaminated water to activated carbon. J Soils Sediments 10(2):179–185

Janda J, Lange FT, Riegel M. 2017 Weitergehende erfassung von pfc-quellen im einzugsbereich von wasserwerken und entfernung von kurzkettigen, persistenten PFC (Further detection of PFC sources in the catchment area of waterworks and removal of short-chain, persistent PFC). Report W 07-03-14, DVGW deutscher verein des gas- und wasserfachs, Bonn, Germany.

Karlsruhe Regional Council, regierungspräsidium Karlsruhe, Überblick PFC-problematik in mittelbaden und mannheim, website, https://rp.baden-wuerttemberg.de/rpk/abt5/ref541/stabsstelle-pfc/pfc-problematik-mittelbaden-mannheim/, Accessed 04 Nov 2022

Kucharzyk KH, Darlington R, Benotti M, Deeb R, Hawley E (2017) Novel treatment technologies for PFAS compounds: a critical review. J Environ Manage 204(2):757–764

Lutze H. 2013 Sulfate radical based oxidation in water treatment. PhD thesis, Universität Duisburg-Essen, Germany

McCleaf P, Englund S, Östlund A, Lindegren K, Wiberg K, Ahrens L (2017) Removal efficiency of multiple poly- and perfluoroalkyl substances (PFASs) in drinking water using granular activated carbon (GAC) and anion exchange (AE) column tests. Water Res 120:77–87

McNamara JD, Franco R, Mimna R, Zappa L (2018) Comparison of activated carbons for removal of perfluorinated compounds from drinking water. J Am Water Works Assoc 110:E2–E14

Medina R, Pannu MW, Grieco SA, Hwang M, Pham C, Plumlee MH (2022) Pilot-scale comparison of granular activated carbons, ion exchange, and alternative adsorbents for per- and polyfluoroalkyl substances removal. AWWA Wat Sci. https://doi.org/10.1002/aws2.1308

Ochoa-Herrera V, Sierra-Alvarez R (2008) Removal of perfluorinated surfactants by sorption onto granular activated carbon, zeolite and sludge. Chemosphere 72(10):1588–1593

OECD: Organisation for Economic Co-operation and Development 2018 Toward a new comprehensive global database of per- and polyfluoroalkyl substances (PFASs): summary report on updating the OECD 2007 list of per- and polyfluoroalkyl substances (PFASs), Series on Risk Management No. 39, Paris

Pancras T, Schauwen G, Held T, Baker K, Ross I, Slenders H 2016 Environmental fate and effects of poly- and perfluoroalkyl substances (PFAS), Concawe report no. 8/16, Brussels

Park H, Vectis CD, Cheng J, Choi W, Mader BT, Hoffmann MR (2009) Reductive defluorination of aqueous perfluorinated alkyl surfactants: effects of ionic headgroup and chain length. J Phys Chem A 113(4):690–696

Rahman MF, Peldszus S, Anderson WB (2014) Behaviour and fate of perfluoroalkyl and polyfluoroalkyl substances (PFASs) in drinking water treatment: a review. Water Res 50:318–340

Renner R (2006) The long and the short of perfluorinated replacements. Environ Sci Technol 40(1):A12-13

Riegel M, Sacher F, Lange FT (2017) Aufbereitungstechnische entfernung kurzkettiger perfluorierter chemikalien (PFC) durch anionenaustauscher (removal of short-chain perfluorinated chemicals (PFC) by anion exchangers). Vom Wasser 115(2):57–61

Ritter SK (2010) Fluorochemicals go short shorter perfluoroalkyl chain lengths improve environmental profile of versatile stain-, grease-, and water-repelling chemicals. Chem Eng News 88(5):12–17

Ross I, McDonough J, Miles J, Stroch P, Kochunarayanan PT et al (2018) A review of emerging technologies for remediation of PFASs. Remediation 28:101–126

Stockholm convention. Ninth meeting of the conference of the parties to the stockholm convention. Joint press release with the Ministry of the Environment, 14 May 2019. https://www.meti.go.jp/english/press/2019/0514_001.html

Sontheimer H, Crittenden JC, Summers RS (1988) Activated carbon for water treatment. DVGW-Forschungstelle, Karlsruhe

Stratton GR, Dai F, Bellona CL, Holsen TM, Dickenson ERV, Thagard SM (2017) Plasma-based water treatment: efficient transformation of perfluoroalkyl substances in prepared solutions and contaminated groundwater. Environ Sci Technol 51(3):1643–1648

Szabo J, Hall J, Magnuson M, Panguluri S, Meiners G (2017) Treatment of perfluorinated alkyl substances in wash water using granular acitvated carbon and mixed-media, report EPA/600/R-17/175. US-EPA, Cincinnati, USA

Trautmann AM, Schell H, Schmidt KR, Mangold K-M, Tiehm A (2015) Electrochemical degradation of perfluoroalkyl and polyfluoroalkyl substances (PFASs) in groundwater. Water Sci Technol 71(10):1569–1575

Trenkle A (2015) Transfer von poly- und perfluorierten Chemikalien (PFC) aus kontaminierten Böden in Nutzpflanzen (Transfer of polyfluorinated and perfluorinated chemicals (PFC) from contaminated soils to crop plants). VDLUFA-Schriftenreihe 71:727–744

UBA Umweltbundesamt (2017) Fortschreibung der vorläufigen Bewertung von per- und polyfluorierten Chemikalien (PFC) im Trinkwasser: Empfehlung des Umweltbundesamtes nach Anhörung der Trinkwasserkommission, (Update of the Preliminary Assessment of Perfluorinated and Polyfluorinated Chemicals (PFCs) in Drinking Water). Bundesgesundheitsblatt Gesundheitsforschung Gesundheitsschutz 60(3):350–352

Vecitis CD, Park H, Cheng J, Mader BT, Hoffmann MR (2008) Enhancement of perfluorooctanoate and perfluorooctanesulfonate activity at acoustic cavitation bubble interfaces. J Phys Chem C 112(43):16850–16857

Woodard S, Berry J, Newman B (2017) Ion exchange resin for PFAS removal and pilot test comparison to GAC. Remediation 27:19–27

Yamada T, Taylor PH 2003 Laboratory scale thermal degradation of perfluoro-octanyl sulfonate and related precursors Report UDR-TR-03-00044. university of dayton research institute, environmental science and engineering group. Dayton, USA.

Zaggia A, Conte L, Falletti L, Fant M, Chiorboli A (2016) Use of strong anion exchange resins for the removal of perfluoroalkylated substances from contaminated drinking water in batch and continuous pilot plants. Water Res 91:137–146

Acknowledgements

The authors gratefully acknowledge the support of the work by the German Association of Gas and Water (DVGW) and the EU Interreg. Furthermore, they would like to thank Purolite, LANXESS, Donaucarbon, Chemviron, Cabot Norit and Jacobi carbons for providing the adsorbents. This publication was made as part of a project funded by the European Union's Horizon 2020 research and innovation programme under grant agreement No. 101036756.

Funding

Open Access funding enabled and organized by Projekt DEAL. Parts of the ion exchanger investigations were funded by the German Association of Gas and Water (DVGW). Parts of the activated carbon investigations were funded by the EU Interreg. Manuscript writing was funded by the European Union's Horizon 2020 research and innovation programme under grant agreement No. 101036756.

Author information

Authors and Affiliations

Contributions

MR organised the work on the use of ion exchangers. BHG organised the work on the use of activated carbon. MR and BHG wrote the main manuscript text. BHG prepared Figs. 1 and 4–6. MR prepared Figs. 2, 3 and 7–11. All the authors reviewed the manuscript. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Riegel, M., Haist-Gulde, B. & Sacher, F. Sorptive removal of short-chain perfluoroalkyl substances (PFAS) during drinking water treatment using activated carbon and anion exchanger. Environ Sci Eur 35, 12 (2023). https://doi.org/10.1186/s12302-023-00716-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12302-023-00716-5