Abstract

In the current investigation, the removal of Levafix Fast Red CA (LFR) and Levafix Amber CA (LA) azo-dyes from aqueous media using the Fenton/adsorption processes has been carried out. The water treatment by-product, namely alum sludge (AS), was successfully collected and calcined to various temperatures, i.e., 400, 600 and 800 °C, then tested for use as a catalyst in the Fenton/adsorption processes. Fourier transform infrared (FT-IR) transmittance spectrum analysis and Transmission electron microscopy techniques (TEM) were applied to investigate the structural and morphological properties of such a catalyst. The results displayed that the calcined AS at 400 °C (AS400) showed the best photocatalytic activity under ultraviolet illumination and sunlight irradiation. The results indicated that the adsorption/Fenton’s oxidation systems are efficient for treatment and eliminating such types of reactive dyes. The oxidation reaction using Fenton’s reagent reached 99.9 and 86% removal for LFR and LA dyes, respectively. The operating conditions revealed that the reaction was maximized at the operational parameters of 1 g/L and 800 mg/L for AS400 and H2O2 at acidic pH (3.0). The process of single dyes was studied either from thermodynamic and kinetic viewpoints and the data exhibited that the reaction is followed a pseudo-second- order kinetic model and an exothermic reaction nature. The practical application of such byproduct waste used as a photocatalyst source through using natural solar radiation introduces an industrial ecology approach in treating dye effluents for safer environment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Every day, toxic organic and inorganic compounds are released into soil, air and water severely polluting the ecosystem. Dyes are signified as frequent pollutants emitted in large quantities by industries such as textile, leather, paper, rubber, foodstuffs and plastics. Such dyes generate massive amounts of dye-containing wastewater when released to the ecosystem. This colored wastewater is also produced as a byproduct of dye manufacture and thus also employed widely as chemical intermediates in the manufacturing of pharmaceuticals and cosmetics. Consumption of colorful textiles, which is one of the key technologies in human civilization, is gradually expanding globally, paralleling the increase in the world population. Textile dyeing and finishing processes, being one of the most chemically demanding sectors on the planet, has caused severe environmental concerns and is the second largest pollutant of pure water, behind only agriculture (Tony 2020a; Tony and Mansour 2020b; Yao et al. 2021). Dyes can cause severe toxicity, chronic, sensitization effects with repeated use, as well as carcinogenic and mutagenic consequences in humans. They can be ecotoxic and have an impact on the transparency and gas solubility of water bodies. By absorbing sunlight that enters the water, they change the growth of aquatic organisms and impede photosynthesis, disrupting natural ecosystems (Golka et al. 2004). The annual output of textile dyes is projected to be 700,000 ton, with nearly half of this amount spent on dyeing cotton and cellulosic fibers (Robinson et al. 2001; Hao et al. 2021). For cellulose-based material, many dye classes are utilized. Today, reactive dyes are the most significant class, accounting for over half of the dyes used in cellulosic fibres’ dyeing (Tony 2021a; Vigo 2013; Liang et al. 2021).

Among many other technologies, Advanced Oxidation Processes (AOPs) are categorized as one of the supreme wastewater treatment techniques due to its sustainability, ability to remove organic contaminants, high removal capacity, ease of operation and the availability of their catalyst to be recovered, recycled and reused (Tony and Lin 2021; Yu et al. 2021). They use chemical processes, ultrasonic pulses, or UV light to achieve high oxidation rates by generating highly oxidants free radicals (mainly hydroxyl radicals). Indeed, powerful oxidizing hydroxyl radicals (HO•) have long been assumed to be the primary active species responsible for oxidizing pollutants. Such radicals have the ability to oxidize nearly all organic molecules to non-toxic end products, carbon dioxide and water (Tony and Lin 2020b). Lately, in the last several decades, previous researchers (Chu 2001; Exley 2004; Grassi et al. 2020; Laib et al. 2021; Nguyen et al. 2021; Yang et al. 2021) proved the use of an aluminum-based Fenton reaction is a good candidate to substitute the classical Fenton’s reaction catalyst to overcome the disadvantages of the Fenton reaction. Aluminum, Al, is well known as one of the most common metals in the earth's crust capable of forming a wide range of powerful complexes. Aluminum has favorable pro-oxidation reactivity. Previous research revealed that the generation of the Al-superoxide, O2.− radical is linked to metal oxidant activity (Yang et al. 2021; Qiu et al. 2022).

The use of solar energy to activate the Fenton’s reaction as an alternative to the auxiliary artificial UV source is a possible long-term solution to the problems associated with the artificial UV radiation (Tony 2021c). Significant attempts have recently been made to create solar-powered water treatment technology. Recent findings indicate that the existing potential for merging solar technology with photochemical processes for wastewater treatment plays only a limited role (Tony 2021b). Currently, the majority of industrial solar wastewater treatment is still under research, with few real-world applications (Malato et al. 2002). The main factors influencing process application are scaling up and commercialization (Tony 2021d; Zhang et al. 2018). The most frequently used and researched solar/AOPs is solar heterogeneous photocatalysis based on Fenton processes. Current dyestuff oxidation research has mostly focused on demonstrating the technology at various reactive dye representations as chemical models to evaluate the procedure. A treatment procedure for reactive dye-containing wastewater may accomplish oxidation of a spectrum of relevant dyes, which is necessary to establish a color gamut of coloristic value in order to achieve technical relevance. Furthermore, such a procedure must perform successful oxidation at relatively low dyestuff concentrations, which are commonly found in leftover dyebaths produced at the conclusion of the dyeing process (Carneiro et al. 2005).

On the other hand, the processing of drinking water treatment plants creates a pronounced tones of sludge. It is estimated in a daily volume that it is exhibited 3,300 m3/day (Dahhou et al. 2012). Thus, nowadays, the disposal of water treatment sludge remains a challenge. It might be utilized in the cement industry as a construction material (Pan et al. 2004; Tony 2021a) or in brick production (Anderson et al. 2003). Also, various research dealt with land applications such as agriculture (Aamir et al. 2019) and as a substrate in created wetland (Zhao et al. 2011). Further, it could be reused as a coagulant (Mazari et al. 2018), adsorbent material for eliminating organic pollutants (Tony 2020b, 2022) or heavy metal (Abo-El-Enein et al. 2017) and as photo-catalyst (Laib et al. 2021) in wastewater treatment. However, it is not applied so much as a source of solar/Fenton oxidation reaction. To the best of the authors’ knowledge, this research first introduces the evaluation of the photocatalytic activity of alum sludge for oxidizing various commercial reactive dyes supplied. Two hetero-bifunctional reactive dyes having a vinyl sulfone and difluoropyrimidine groups, were chosen as the basic constituents of a reactive dye gamut, Levafix Fast Red CA (LR) and Levafix Amber CA (LA) (Santos et al. 2009). The photocatalytic activity of calcined alum sludge was examined to treat these reactive dyes using both solar and ultraviolet irradiation as oxidation initiation sources.

Experimental investigation

Wastewater

Two individual stock solutions (1000 ppm) for bifunctional reactive dyes (acid dyes), Levafix Fast Red CA (LR) and Levafix Amber CA (LA)—CA (combined anchor), referring to the use of chlorine-free tri-fluoropyrimidine, mono-fluorotriazine and new vinyl sulfone anchor groups (Körbahti 2007; Santos et al. 2009) supplied by DyStar Ltd., Egyptian branch were prepared by dissolving 1 g of every dye in 1000 mL of distilled water. The dye solution is diluted according to the working dye solutions required. Certain mixtures of dyestuffs were selected for this study due to their stability and solubility in water, and they are mainly used as colorants in foodstuffs and textiles and the chemical structures of two commercially available Levafix CA reactive dyes are not revealed.

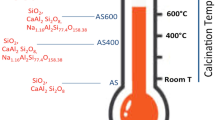

Preparation of alum sludge catalyst

Sludge (Al2(SO4)3 sludge) was collected from the sedimentation tanks of Geziret El-Dahab Drinking Water treatment Plant in Giza government. The sludge sample was air-dried in a clean place for 48 h, washed with distilled water, oven-dried at 105 °C for 24 h., and then ground into fine particles. Afterward, it calcined to 400 °C in an electrical furnace at a rate of 10 °C/min for 2 h. The detailed preparation process is illustrated elsewhere (Tony 2020b); Tony, 2020a, b).

Experimental technique

Lab-scale photo-reactor

To perform the photo-Fenton test, a volume of 100 mL of LFR at 100 ppm concentration and 100 mL of LA at 50 ppm concentration were treated to the simulated photocatalytic system includes a UV lamp (254 nm wavelength) emerged in a dye solution and a magnetic stirrer to ensure the homogeneity of the treated solution. After the AS400/H2O2 (30 percent w/w) are introduced into the solution where the pH is adjusted, if necessary, using analytical grade sulfuric acid and sodium hydroxide. Then, at frequent time intervals, 5 mL of treated samples was withdrawn from the reactor using an injector and analyzed spectrophotometrically to determine the residual dye concentrations in the solution. The samples were filtered using a micro-filter prior to spectrophotometrically analyzing.

Pilot scale solar-reactor

An aqueous solution of 2 L of dye-containing wastewater was used and the prepared Fenton reagent was added to the system of a real natural sun activation pilot scale solar reactor assembled at city of Shebin El-Kom which is located 75 kms north of Cairo. The coordinates of the place are 30°58′N and 31°01′E, with an elevation of 11 m above sea level (Farahat et al. 2016; Tony and Mansour 2020b). The solar reactor system is consists of: (i) tubular silica glass tube that are completely transparent to acquire the sun-light; (ii) a parabolic trough-concentrating collector made of stainless-steel reflecting sheet; (iii) Peristaltic pump (Shenchen, model LABN6) with a maximum flow rate of 2280 mL min−1 that provides circulation; (iv) 1/2-inch rubber tubes are employed to link a feed/discharge beaker to the solar reactor and (v) magnetic stirrer (DLAB model Ms-H280) to guarantee that the solution and the catalyst within the container is completely homogenized. The full schematic representation of the treatment steps is displayed in Fig. 1.

Analytical determination

A digital pH-meter was used to determine the pH of the wastewater samples (AD1030, Adwa instrument, Hungary). The spectrophotometric study of wastewater concentrations before and after treatment was performed using a spectrophotometer (UV–visible spectrophotometer, model Unico UV-2100 spectrophotometer, USA). During the sun illumination experiment, an ISO 9060 s class pyranometer from Kipp & Zonen® (Model, CMP3) was utilized to investigate solar intensity. During the months of testing, this sensor was adopted at the AMSEES laboratory in Shebin El-Kom city, the location of study.

Results and discussions:

Characterization of alum sludge catalyst:

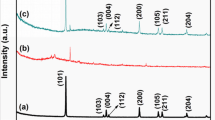

Fourier transform infrared spectroscopy

Fourier transform infrared (FTIR) transmittance spectrum analysis could detect the different types of bonding found in alum sludge and calcined sludge. FTIR method was applied to investigate the four types of AS, AS400, AS600, and AS800 and the results are displayed in Fig. 2a, b, c and d. Despite the fact that there are primary absorption intense bands for all AS samples, coupled vibrations are noticeable due to the existence of diverse elements. The absorption band at 3439.42, 3440.38, 3416.28 and 3440.38 cm−1 is assigned for the O–H stretching vibration of structural water. The Si–HO–HSi stretching vibrations (silanol) are identified at 1089.58, 1090.55, 1091.51 and 1094.41 that representing the presence of quartz in four samples (Bukalo et al. 2017; van der Marel and Beutelspacher 1976). Additionally, the appearance of O–HSi–HO band at 467.65, 467.65, 463.79 and 465.72 cm−1 also confirms the presence of quartz (Bukalo et al. 2017). The position and intensity of Si–HO–HSi stretching band gives an indication of the nature of silicate network. For amorphous silica, this peak occurs at approximately 1089.58 cm−1 as in the case of raw alum sludge sample (Fig. 2a) (Rees et al. 2007; Zholobenko et al. 1997). Raising temperature of calcination for alum sludge shifted the Si–HO–HSi stretching band to higher wave numbers (Fig. 3b–d) that giving an indication of the changes in bonding structure of silicate network that could accompany crystallization of silica (Rees et al. 2007). The deformation of Si–HO–HAl and Al–HO–Al observed at 3846.33, 3743.1 and 3822.2 cm−1. According to AS400, the absorption bands of silica appear at 1090.55, 789.7, and 467.65 cm−1, which attributed to asymmetric stretching vibration of Si–HO–HSi, symmetric stretching vibration of Si–HO–HSi and bending vibration of O–HSi–HO, respectively (Tantawy 2015). The absorption bands at 539.97, 1644.2, and 3440.38 cm −1 are corresponding with the Al–H–HO stretching vibration, bending vibration H–O–H angular deformation and OH stretching, respectively (Tantawy 2015). The absorption band of carbonate appears at 1425.14 cm−1 (Gadsden 1975). The bands at 467.65 cm−1 are reflecting the indication of presence Si–O–Fe (Ahangaran et al. 2013). In addition, AS400 spectra show bands at 539.97 and 789.7 cm−1 related to the stretching vibrations of Si–O–Al group (Ashour and Tony 2020), which may demonstrate the presence of zeolite. Table 1 summarizes the prominent absorption wavenumbers obtained from FTIR analysis of the sludge samples.

Transmission electron microscopy (TEM)

The TEM examination depicts the shape of the calcined sludge material (AS400). Figure 3 confirms the porous nature of the prepared sludge. The representative products’ TEM images clearly demonstrated that some of the images are mixed of phases rod-like, with a diameter of 2 nm and a length of 12–30 nm. Moreover, the borders of the AS400 layers are very clearly visible with irregular sheets with diameters of 30–60 nm with rough crystalline surfaces.

Application of alum sludge as a photocatalyst:

Effect of AS calcination temperature on the catalytic activity

The change in C/C0 value of both dyes, i.e., LFR and LA versus irradiation time is displayed in Fig. 4a and b for various AS samples, (AS, AS400, AS600 and AS800). Interestingly, it is noted from Fig. 4 that the AS400 has the highest catalytic activity compared to other samples in oxidizing the two studied dyes. According to the FT-IR results (Fig. 2), this might be attributed to the presence of aluminosilicate (Zeolite) and quartz in AS400 in addition to the Si–O–Fe link. Such materials are effective in dye adsorption and photocatalytic activity due to the ion exchange features. Furthermore, zeolite is regarded as an essential adsorbent material due to its large surface area, charged structure with amphoteric characteristics, and adsorption ability (Yahya et al. 2018). In addition, the presence of Al–O units in zeolite framework can minimize electron electron–hole recombination, making it a suitable choice for hybrid adsorbent/photocatalyst applications. Further, the adsorptive potential of zeolites’ material could attain a good interaction between the organic molecules and nanoparticles. Such investigation was previously emphasized by-Lizama et al. (2002) and Tony (2020b) on dye oxidation. As a result, when AS400 is used as a Fenton catalyst, it has a greater impact due to its greater surface area compared to other alum sludge samples, which allows the catalyst to have more accessible active sites, resulting in more hydroxyl radicals species in the medium that are the main horsepower of the oxidation reaction. Furthermore, the presence of aluminum on the AS400 positively affects its photocatalytic behavior (Wang et al. 2019).

Further, it is noteworthy to mention that since the Levafix dye types are formed of aromatic rings (Hossain et al. 2016), OH radicals react with substituted benzene ion. The OH radicals attack such aromatic rings and hydroxylated them. Moreover, the hydroxyl radical attack on aromatic compounds is electrophilic in nature; hence, its attack on the meta-position of aromatic compounds carrying orthopara directing substituents. OH radicals are noncharged species. It might be suggested that the OH radicals that attack the aromatic are compounds is corresponding to an electrophilic substitution. Such suggestion is in accordance with the assumption that in most cases of electrophilic attacks on aromatic compounds the rate-determining step involves the addition of the electrophilic reactant to the aromatic ring. Moreover, the electrophilic behavior of the noncharged hydroxyl radicals species is possessing high electron affinity (Melander 1960; Hochanadel 1962; Matheson 1964).

Based on the above results and analysis, a catalytic mechanism for dye with the AS catalysts was suggested. According to the FTIR results, the catalyst includes C element, the catalyst generates a photogenerated charge under light excitation. The conduction band electrons react with O2 in the water, reducing O2 to hydrogen peroxide. The holes in the valence band contribute in the oxidation process of water, releasing oxygen. O2 reduction produces H2O2 in the same way, but the reaction of water oxidation depletion holes is partially replaced by catalyst self-sacrifice. Also, due to the presence of the self-sacrificial reaction, the H2O2 generation upsurges significantly (Hong et al. 2022). Moreover, as AS is rich in aluminum the displacement of a water molecule is signified a favorable process. Contrary, the displacement of a hydroxide molecule is categorized as endergonic in nature, and consequently will not occur. Hence, the co-existence of the Al3+ in a liquate solution is leading to suggestive stabilization of a superoxide via the development of Al3+ superoxide complex. Thus, just the Al3+-superoxide complex contained in the medium might affect the oxidation reaction. Such advantages including increasing the availability of the reactive oxygen species that promotes the Fenton-based reaction and the thus oxidizing process is accelerated (Thabet et al. 2022a, b).

Effect of H 2 O 2 concentration

Figure 4a, b displays the decolorization of two reactive dyes, LFR dye and LA dye, taken individually, in the presence of AS400/H2O2 system. The oxidation was monitored in the presence of different H2O2 doses, i.e., 200, 400, 800 and 1600 mg/L. Individual LFR dye (Fig. 5a), oxidation rates were shown an elevation with increasing the H2O2 concentrations from 200 to 800 mg/L until reaching practically complete dye oxidation within 30 min of reaction time using the optimal value of 800 mg/L of H2O2, 1 g/L AS400, and the solution pH of 3.0. This increase is related to the creation of more peroxide species and OH radicals in the reaction medium, which are the main responsible on the dye oxidation. Furthermore, increasing the H2O2 concentration to 1600 mg/L above the optimal limit of 800 mg/L renders the oxidation reaction. However, although the same trend is attained of higher oxidation yield is given at the maximal OH radicals production that is associated with the optimal presence of H2O2, the optimal amount differs from one dye to another. To verify, the LA dye oxidation (Fig. 5b) achieved 85% within 60 min of irradiance illumination at the optimal dose of 200 mg/L H2O2 while the other parameters are the same as of LFR dye. However, increasing the concentration above this limit, the rate of dye oxidation was also reduced. It is probably associated with the concentration of ion pairs on the surface that could reduce the availability of the AS400 sites to react with the excess H2O2. In this situation, extra H2O2 may be detrimental because scavenging of OH radicals occurs at higher H2O2 concentrations, as stated by Eqs. (1–4). In general, dye chromophore groups are promptly destroyed by direct and indirect oxidation; nonetheless, subsequent intermediates and other organics may be subjected to further oxidation at a much slower pace (Turcanu and Bechtold 2017). Therefore, the dye molecules behavior affects the reaction intermediates species generation.

Effect of catalyst dose

Oxidation of 100 ppm solution of LFR azo-dye and 50 ppm of LA azo-dye by Fenton’s reagent was conducted separately using the optimal H2O2 doses of the two dyes, 800 mg/L H2O2 for LFR dye and 200 mg/L H2O2 for LA dye at a solution of pH 3.0. In the presence of various concentrations of AS400 (1–2.5 g/L) as a Fenton’s catalyst. Oxidation extent of the LFR azo-dye is 99.3, 99.9, 95 and 98.8% for 1, 1.5, 2 and 2.5 g/L, respectively after 30 min of irradiance time and the corresponding for LA azo-dye is 83, 73, 79, and 71%, respectively, but after 50 min of irradiance time in the presence of AS400-(the results displayed in Fig. 6a, b). The data revealed that for two investigated dyes, the optimal dose of AS400 is 1 g/L. Moreover, the oxidation of the two investigated azo dyes was decreasing on increasing the concentration of AS400 up to a critical concentration (1 g/L). The explanation for this might be that when the AS400 dosage was raised, the Fe, Al, and Si concentrations in the solution were elevated as well. The presence of such ions in excess in the heterogeneous Fenton process could operate as scavengers rather than an enhancer, limiting further increase in oxidation efficiency when present in excess more than 1 g/L.

Also, increasing in the catalyst load resulted in Fenton’s oxidation deficiency due to the reduction in the active sites since the particles could aggregate and that hinders the surface area of the catalyst being subjected to UV irradiation and thus the photocatalytic activity efficiency is declined (Tony and Mansour 2020a). To investigate the intrinsic photoactivity of the material under consideration for pollution removal, it is also necessary to investigate its adsorption capacity by studying the contacts between the model molecule and the catalyst interface (Tony 2020b). This reason confirms the fact that increasing the AS400 dose, the Fe, Al and Si concentrations were also increased in the solution. The excess of iron ions in the heterogeneous Fenton process could act as scavengers, which may hinder further improvement in oxidation efficiency beyond 1 g/L.

Effect of initial pH

For real scale applications, solution pH is an important parameter that affects oxidation of the dye molecules. The effect of initial solution pH on the oxidation of LFR and LA with Fenton reagent (AS400/H2O2) was assessed in the pH range of 2.0–9.0 in batch tests. The variation of dye removal efficiency at different pH values for LFR and LA is shown in Fig. 7a, b. The initial concentration of LFR dye, catalyst dosage and H2O2 concentration was set constant at 100 mg/L, 1.5 g/L and 800 mg/L, respectively, for all batch tests, While, the initial concentration of LA dye, catalyst dosage and H2O2 concentration was set at 50 mg/L, 1 g/L and 200 mg/L respectively. The LFR removal efficiency was observed according to Fig. 7a to increase with the decrease in solution pH to 2.0. Also, the same trend is observable for the effect of the solution pH on the oxidation of LA dye likewise LFR dye.

The effect of solution pH on the oxidation of LFR and LA could be explained that, at lower pH levels, the •OH radicals are severely scavenged by H+ (Neyens and Baeyens 2003). As a result, H2O2 is unstable in the alkaline solutions and thus it rapidly decomposes to oxygen and water at neutral and higher pH levels. Hence, it loses its capacity to oxidize (Thabet et al. 2020; Tony and Mansour 2019). Consequently, the current Fenton's oxidation tests were carried out in both acidic and basic solutions with pH values ranging from 2.0 to 9.0. Separate oxidation of the two dyes, LFR and LA, was achieved. Using various solution pHs of 2.0, 3.0, 7.0 and 9.0 (LFR dye), the oxidation reached 99, 100, 94, and 58 percent, respectively, within 30 min of illumination time. The solutions pH- of 2.0, 3.0, 7.0, and 8.0 of LA dye the removal reached 73, 82, 59, and 57%, respectively, within 40 min of illumination time. Consequently, the results indicated that the extent of investigated azo-dyes oxidation was much more effective at pH 3.0. Therefore, pH 3.0 was adjusted as the optimal value in the rest of the present study. Previous research study (Stawiński et al. 2017) also confirmed that lower pH levels increase LA dye adsorption. Additionally, Hossain et al. (2016) assume that the optimal pH of the LFR dye removal is 3.0.

Effect of initial dye loading

From the practical point of view, various solutions’ concentration is essential to study since its loading is varied according to the industrial discharge. From such regard, oxidation of solutions of various concentrations of each azo-dyes was carried out by Fenton’s reagents under the reaction conditions (800 mg/L of H2O2, 1 g/L of AS400 and pH 3.0) on LFR solution and (200 mg/L H2O2, AS400 1 g/L and pH 3.0) on LA are shown in Fig. 8a, b. Dye concentrations were varied from 50 to 300 mg/L for LFR and from 25 to 200 mg/L for LA. It is observed that the oxidation reaction for the both dyes, LFR and LA dyes decreased with increasing the initial dye concentrations. As attained by the data displayed in Fig, 8, the oxidation is higher at low concentrations of two dyes than at higher dye concentrations. LFR dye oxidation removal within 30 min of photo-Fenton reaction time reached 99% for 50 ppm and increasing the dye loading results in a decline in the oxidation that reached 91% at 100 ppm. While further increase in the dye load, the oxidation reaction reached 51% at 200 ppm and decreased to 33% at 300 ppm. In case of LA dye efficiency of removal in 50 min reaction time reached 66% for 25 ppm, while using 50 ppm the removal reached 61% and declined to 59 and 58% for 100 and 200 ppm, respectively. This could be illustrated by although increasing the dye initial loading, the hydroxyl radical concentration stayed constant for all dye molecules, causing the removal rendered. Consequently, oxidation takes a longer time to proceed. Hence, overall, the percentage conversion is higher at low dyes concentrations compared to higher concentrations. Such investigation is in accordance with the previous data cited in the literature (Tony and Ali 2021; Tony and Eltabey 2022).

Temperature effects on kinetics and thermodynamic parameters

As textile wastewater discharge could be disposed at various temperatures, the effect of various temperatures was also evaluated and is shown in Fig. 9a and b. As recorded in Fig. 9, the high temperature reduced the oxidiation yield of the studied LFR and LA dyes. As a result, the optimal temperature for removing the two dyes was found to be 23 °C. At temperatures above this value, certain OH radicals could not possess enough chance to react with contaminants since the rate limiting of radical is reached. This declines in the OH radicals due to the temperature rising is associated with the Arrhenius equation, and the result is a decrease in the treatment efficiency. Furthermore, H2O2 might be degraded into water and oxygen (i.e., radical formation reduces) (Dindar 2019), reducing oxidation yield. Because the major aim of the Fenton’s process is the formation of hydroxyl radicals, it might be argued that the high temperature is unsuitable for these operating circumstances, which are stronger oxidants. However, at higher temperatures, adsorption was reduced due to an increase in interval pores, which stimulate diffusion and limit dye retention. (Hossain et al. 2016).

Variation of concentration for each of the azo-dyes (LFR) and (LA) with time t of the Fenton’s oxidation reaction is analyzed in order to investigate the kinetics of the reaction. The general elementary rate law for reaction of a target two dyes compounds can be written as follows:

where C is concentration of dye, and k0, k1, and k2 express the kinetic rate constants for zero-, first-, and second-order reaction kinetics, respectively. After integrating and plotting (plots are not shown) Eqs. (5–7) for the obtained concentration-time data, the most acceptable reaction kinetics order and corresponding reaction constant were evaluated, with the greatest R2 values referring to the best model fit. From data analysis in Table 2, the behavior indicated that the oxidation process obeyed second-order reaction for LFR dye and LA.

The apparent second order rate constants (k2) obtained for each of the investigated LFR and LA dyes were found to be 0.105, 0.0338, 0.0002 and 0.00006 L mg−1 min−1 and 0.048, 0.0008, 0.0003 and 0.0001 L mg−1 min−1, respectively. This drop in the value of the apparent second-order rate constant with rising azo-dye concentration may be owing to the larger amount of interactions between •OH radicals and oxidation by-products than those involving the azo-dyes, resulting in faster decay kinetics. And this finding is in agreement with Stawiński et al. (2017) and Hossain et al. (2016) who used LA and LFR dyes, respectively. The estimated half reaction time (t1/2) is mentioned also in Table 2 and is further confirming such findings.

To well understand the oxidation reaction, analysis of the azo-dye oxidation thermodynamic parameters was calculated in order to further clarify the oxidation of the dye molecules onto the AS400. The thermodynamic parameters for the two dyes, such as entropy, enthalpy and Gibbs free energy changes, were investigated and the values are displayed in Table 3. The van’t Hoff equation was used to compute the values of entropy (ΔS) and enthalpy (ΔH) given by Eq. (8). Since the equilibrium constant (K2) can be used to investigate the thermodynamic parameters, the change in Gibbs free energy of oxidation is given by Eq. (9) (Fayoud et al. 2016).

where R is a gas constant (8.314 J/mol K) and T is the absolute temperature (K). As shown in Table 3, the calculated positive Gibbs free energy and negative enthalpy values across all temperatures specify that the oxidation of each studied dyes is nonspontaneous and exothermic in nature. Furthermore, negative entropy change values indicate a reduction in the degree of randomness at the reaction interface. Such results are in agreement with that mentioned previously in literature (Thabet et al. 2022a, b; Tony and Lin 2020a).

Solar/Alum-Fenton system treatment

After checking the effectiveness of AS400 on the photo-Fenton reaction system under UV light using LFR and LA as an industrial contamination effluent, relevant information on photocatalytic degradation was obtained, and the optimal reaction parameters were manipulated. LFR dye (800 mg/L H2O2, AS400 1 g/L, and pH 3.0) and LA dye (200 mg/L H2O2, AS400 1 g/L, and pH 3.0). The sun photocatalytic tests were carried out separately for two dyes using those optimal values and a continuous dye solution flow rate of 350 mL/min. Experiments in the sun were carried out on sunny days in September 2021, around the midday where the sun shines around the place. During the period spent on the experiments, the average intensity of solar radiation was measured to be between 1014 and 998 W/m2. The results showed a photocatalytic oxidation reached 81 and 66% for LFR and LA, respectively after 50 min of sunlight irradiation time as seen in Fig. 9. Such results confirms that the two analyzed azo dyes may be eliminated by photo-Fenton oxidation under artificial UV irradiation, with higher activity than when was employed as a source of incident sun-light for the photo-Fenton decontamination process in the analyzed Fenton system. According to the findings, the photo-Fenton reaction system was operated in the presence of sun radiation, and the incident energy may have raised the temperature of the dyes solutions throughout treatment. This could be illustrated by, at high temperatures, the reaction follows exothermic nature and becomes unfavorable at high temperature and tends to be a rate-limiting phase, resulting in lower activity (Malato et al. 2009; Tony and Lin 2021). Consequently, a drop in the reaction rate is attained. Also, the dissolved oxygen content in the medium is similarly lowered, and affects in hindering the oxidation process (Borges et al. 2017; Tony and Lin 2020c). However, it is noteworthy to mention that reaching to reasonable treatment via a cost-efficient, solar energy source is reliable for real application. However, further work is still needed to control the aqueous solution temperature (Fig. 10).

It is important to compare such an investigation with the other data cited in the literature to show the importance of the current study. Table 4 summarizes a comparison of different low-cost sludges’ derived from industrial and municipal wastes for the removal of various types of aqueous pollutants. Tony (2020a, b) concentrated on the use of drinking water sludge as an adsorbent material for dye removal, whereas Meerbergen et al. (2017) and Rio et al. (2005) employed the sludge for biological and adsorption wastewater treatments, respectively. Furthermore, Kishimoto et al. (2013) employed the principle of reusability of iron sludge as an iron supply for the Fenton-type process. Further, Tony and Lin, (2020a, b, c) adopted a natural iron supply derived from acid mine drainage sludge for municipal wastewater treatment. Generally, the use of waste sludge as low-cost materials for eliminating different contaminants from water and wastewater has several appealing aspects, including their contribution to waste disposal cost reduction, which contributes to environmental protection. It is worthy to mention that the current study revealed 99.9% almost complete dye removal compared to the other studies. However, other studies are based on the adsorption and current investigation is dual treatment based on adsorption and oxidation reaction. However, when the solar radiation is used as the source of UV radiation, the process is more economical.

Catalyst stability and reusability

The recyclability of the AS catalyst was investigated to achieve and confirm the meaning of sustainability. Four treatment cycles were performed using Levafix blue dye as pollutant model pollutant and after each cycle the catalyst is recovered and collected through filtration and then regenerated via washing by distilled water prior to drying at 105 °C for 1 h. Afterward, the catalyst was subjected for successive treatment and the process is repeatedly conducted and after each cycle the remaining catalyst is collected. The catalytic activity of the oxidation process is reduced from 100% when the fresh catalyst is used to 63% after the fourth cycle use within minutes of irradiance time. When the wastewater treatment experiment is conducted, the remaining catalyst was filtered then dried drying time. This reduction in the catalytic activity of the catalyst could be attributed by some of Levafix blue dye molecule occupying the composite active sites. Moreover, the weight of the catalyst loss after each cycle is monitored in and it is recorded about 30% losses.

As above-mentioned, the chemical stability of the alum sludge as a photocatalyst was also examined and the Al element release was determined in the aqueous effluent. After using1 g/L of AS400 catalyst in treatment, the quantity of soluble Al has been monitored in the treated effluent and the concentration of aluminum release was recorded 0.85 mg/L. Such low value recorded as Al release onto the treated effluent is an indication to the stability of Al in the AS400 material. It is noteworthy to mention that, according to the World Health Organization (WHO, 2003), the average levels of the aluminum monitoring in public water supplies in different regions differ according to the facilities using aluminum sulfate coagulation and it is ranged in median level was 0.1 mg/L, with a maximum of 2.7 mg/L at different countries and regions. Thus, the reasonable release of alumnium from AS catalyst is introducing it for real and industrial applications.

Conclusion

Calcined alum sludge powder can be effectively used as a photo-catalyst for oxidation of Levafix Fast Red CA (LFR) and Levafix Amber CA (LA) azo-dyes. The dual adsorption/Fenton of two dyes was studied using artificial UV source and with solar radiation. It was found that the solution pH, the initial H2O2 concentration and the initial AS400 concentration, are the main factors that possess the strong influence on the oxidation process. The optimal operation parameters for the Fenton oxidation of LFR dye were 800 mg/L for H2O2 and 1 g/L for AS400 at an initial pH of 2.0 with 99.9% removal within 30 min reaction time and for LA dye were 100 mg/L for H2O2 and 1 g/L for AS400 at an initial pH of 2.0 with 80% oxidation efficiency within 50 min reaction time. By using a pilot-scale photo-reactor, solar photo-Fenton demonstrated an effective treatment solution contaminated with such dyes. It was proposed that the process be carried out around solar noon since raising the sun intensity enhances the degradation percentages close to 81and 66% for LFR and LA, respectively, after 50 min of sunlight irradiation. As a result, the procedure offers a potential technology for treating textile dyeing effluent wastewater in a cost-effective manner utilizing renewable energy.

References

Aamir M, Mahmood Z, Nisar A, Farid A, Ahmed Khan T, Abbas M, Ismaeel M, Shah SAR, Waseem M (2019) Performance evaluation of sustainable soil stabilization process using waste materials. Processes 7:378

Abo-El-Enein SA, Shebl A, El-Dahab SAA (2017) Drinking water treatment sludge as an efficient adsorbent for heavy metals removal. Appl Clay Sci 146:343–349

Ahangaran F, Hassanzadeh A, Nouri S (2013) Surface modification of Fe3O4@ SiO2 microsphere by silane coupling agent. Int Nano Lett 3:1–5

Anderson M, Biggs A, Winters C (2003) Use of two blended water industry by-product wastes as a composite substitute for traditional raw materials used in clay brick manufacture. In: Recycling and Reuse of Waste Materials. Thomas Telford Publishing, London, pp 417–426

Ashour EA, Tony MA (2020) Eco-friendly removal of hexavalent chromium from aqueous solution using natural clay mineral: activation and modification effects. SN App Sci 2:1–13

Borges ME, Sierra M, Esparza P (2017) Solar photocatalysis at semi-pilot scale: wastewater decontamination in a packed-bed photocatalytic reactor system with a visible-solar-light-driven photocatalyst. Clean Technol Environ Policy 19:1239–1245

Bukalo NN, Ekosse G-IE, Odiyo JO, Ogola JS (2017) Fourier transform infrared spectroscopy of clay size fraction of cretaceous-tertiary kaolins in the Douala Sub-Basin, Cameroon. Open Geosci 9:407–418

Carneiro PA, Osugi ME, ClS F, Boralle N, Furlan M, Zanoni MVB (2005) Evaluation of different electrochemical methods on the oxidation and degradation of Reactive Blue 4 in aqueous solution. Chemosphere 59:431–439

Chu W (2001) Dye removal from textile dye wastewater using recycled alum sludge. Water Res 35:3147–3152

Dahhou M, El Moussaouiti M, Khachani N, Assafi M, Ait Hsain L, Mostahsine S, Bouqallaba K (2012) Caractérisation physico-chimique de boues d’unité de production d’eau potable. MATEC Web Conf 2:01017

Dindar N (2019) Implementation of advanced treatment processes in textile industry wastewaters for organic substance removal.

Exley C (2004) The pro-oxidant activity of aluminum. Free Radical Biol Med 36:380–387

Farahat M, Mousa M, Mahmoud N (2016) Solar distiller with flat plate collector and thermal storage. Int Conf Appl Mech Mech Eng 17(17):1–11. https://doi.org/10.21608/amme.2016.35260

Fayoud N, Tahiri S, Alami Younssi S, Albizane A, Gallart-Mateu D, Cervera ML, De la Guardia M (2016) Kinetic, isotherm and thermodynamic studies of the adsorption of methylene blue dye onto agro-based cellulosic materials. Desalin Water Treat 57:16611–16625

Gadsden JA (1975) Infrared spectra of minerals and related inorganic c ompounds

Golka K, Kopps S, Myslak ZW (2004) Carcinogenicity of azo colorants: influence of solubility and bioavailability. Toxicol Lett 151:203–210

Grassi P, Drumm FC, Georgin J, Franco DSP, Foletto EL, Dotto GL, Jahn SL (2020) Water treatment plant sludge as iron source to catalyze a heterogeneous photo-Fenton reaction. Environ Technol Innov 17:100544

Hao M, Qiu M, Yang H, Hu B, Wang X (2021) Recent advances on preparation and environmental applications of MOF-derived carbons in catalysis. Sci Total Environ 760:143333

Hochanadel CJ (1962) Photolysis of dilute hydrogen peroxide solution in the presence of dissolved hydrogen and oxygen: evidence relating to the nature of the hydroxyl radical and the hydrogen atom produced in the radiolysis of water. Radiat Res 17:286–301

Hong Q, Wu Q, Wu Z, Liu Y, Li Y, Huang H, Liu Y, Kang Z (2022) Diverse catalytic behavior of a dye-based polymer metal-free catalyst for hydrogen peroxide photoproduction. Mater Adv 3(10):4243–4251

Hossain R, Rahman MA, Ara NJ, Alam AMS (2016) Removal of levafix red from aqueous solution with treated jute stick and its relevance to pharmaceutical field. Bangladesh Pharm J 19:75–84

Kishimoto N, Kitamura T, Kato M, Otsu H (2013) Reusability of iron sludge as an iron source for the electrochemical Fenton-type process using Fe2+/HOCl system. Water Res 47:1919–1927

Körbahti BK (2007) Response surface optimization of electrochemical treatment of textile dye wastewater. J Hazard Mater 145:277–286

Laib S, Rezzaz-Yazid H, Yatmaz HC, Sadaoui Z (2021) Low cost effective heterogeneous photo-Fenton catalyst from drinking water treatment residuals for reactive blue 19 degradation: preparation and characterization. Water Environ Res 93(7):1097–1106

Liang L, Xi F, Tan W, Meng X, Hu B, Wang X (2021) Review of organic and inorganic pollutants removal by biochar and biochar-based composites. Biochar 3:255–281

Lizama C, Freer J, Baeza J, Mansilla HD (2002) Optimized photodegradation of reactive Blue 19 on TiO2 and ZnO suspensions. Catal Today 76:235–246

Malato S, Blanco J, Cáceres J, Fernández-Alba AR, Agüera A, Rodrıguez A (2002) Photocatalytic treatment of water-soluble pesticides by photo-Fenton and TiO2 using solar energy. Catal Today 76:209–220

Malato S, Fernández-Ibáñez P, Maldonado MI, Blanco J, Gernjak W (2009) Decontamination and disinfection of water by solar photocatalysis: recent overview and trends. Catal Today 147:1–59

Matheson MS (1964) The formation and detection of intermediates in water radiolysis. Radiat Res Suppl 4:1–23

Mazari L, Abdessemed D, Szymczyk A (2018) Evaluating reuse of alum sludge as coagulant for tertiary wastewater treatment. J Environ Eng 144:04018119

Meerbergen K, Crauwels S, Willems KA, Dewil R, Van Impe J, Appels L, Lievens B (2017) Decolorization of reactive azo dyes using a sequential chemical and activated sludge treatment. J Biosci Bioeng 124:668–673

Melander L (1960) Isotope Effects on Reaction Rates. The Ronald Press Co, New York, NY, p 107

Neyens E, Baeyens J (2003) A review of classic Fenton’s peroxidation as an advanced oxidation technique. J Hazard Mater 98:33–50

Nguyen DDD, Quang HHP, Nguyen XH, Nguyen TP (2021) The treatment of real dyeing wastewater by the electro-Fenton process using drinking water treatment sludge as a catalyst. RSC Adv 11:27443–27452

Pan JR, Huang C, Lin S (2004) Reuse of fresh water sludge in cement making. Water Sci Technol 50:183–188

Qiu M, Liu L, Ling Q, Cai Y, Yu S, Wang S, Fu D, Hu B, Wang X (2022) Biochar for the removal of contaminants from soil and water: a review. Biochar 4:1–25

Rees CA, Provis JL, Lukey GC, van Deventer JSJ (2007) Attenuated total reflectance fourier transform infrared analysis of fly ash geopolymer gel aging. Langmuir 23:8170–8179

Rio S, Faur-Brasquet C, Le Coq L, Courcoux P, Le Cloirec P (2005) Experimental design methodology for the preparation of carbonaceous sorbents from sewage sludge by chemical activation–application to air and water treatments. Chemosphere 58:423–437

Rio S, Le Coq L, Faur C, Lecomte D, Le Cloirec P (2006) Preparation of adsorbents from sewage sludge by steam activation for industrial emission treatment. Process Saf Environ Prot 84:258–264

Robinson T, McMullan G, Marchant R, Nigam P (2001) Remediation of dyes in textile effluent: a critical review on current treatment technologies with a proposed alternative. Biores Technol 77:247–255

Santos SCR, Vilar VJP, Boaventura RAR (2008) Waste metal hydroxide sludge as adsorbent for a reactive dye. J Hazard Mater 153:999–1008

Santos JG, Soares GM, Hrdina R, Oliveira-Campos AM, Gomes JINR (2009) A study on the spectral changes of reactive textile dyes and their implications for online control of dyeing processes. Colo TechnoL 125(1):8–13

Stawiński W, Węgrzyn A, Freitas O, Chmielarz L, Figueiredo S (2017) Dual-function hydrotalcite-derived adsorbents with sulfur storage properties: dyes and hydrotalcite fate in adsorption-regeneration cycles. Microporous Mesoporous Mater 250:72–87

Tantawy MA (2015) Characterization and pozzolanic properties of calcined alum sludge. Mater Res Bull 61:415–421

Thabet RH, Tony MA, El Sherbiny SA, Ali IA, Fouad MK (2020) Catalytic oxidation over nanostructured heterogeneous process as an effective tool for environmental remediation. IOP Conf Series Mater Sci Eng 975:012004

Thabet RH, Fouad MK, Sherbiny SAE, Tony MA (2022a) Zero-waste approach: assessment of aluminum-based waste as a photocatalyst for industrial wastewater treatment ecology. Int J Environ Res 16:1–19

Thabet RH, Fouad MK, El Sherbiney SA, Tony MA (2022b) Solar assisted green photocatalysis for deducing carbamate insecticide from agriculture stream into water reclaiming opportunity. Int J Environ Anal Chem, pp 1–23

Tony MA (2020a) Central composite design optimization of bismarck dye oxidation from textile effluent with fenton’s reagent. Appl Water Sci 10:1–9

Tony MA (2020b) Zeolite-based adsorbent from alum sludge residue for textile wastewater treatment. Int J Environ Sci Technol 17(5):2485–2498. https://doi.org/10.1007/s13762-020-02646-8

Tony MA (2021d) An industrial ecology approach: green cellulose-based bio-adsorbent from sugar industry residue for treating textile industry wastewater effluent. Int J Environ Anal Chem 101:167–183

Tony MA (2022) Valorization of undervalued aluminum-based waterworks sludge waste for the science of “The 5 Rs’ criteria”. Appl Water Sci 12:1–30

Tony MA, Eltabey MM (2022) End-of-life waste criteria: synthesis and utilization of Mn–Zn ferrite nanoparticles as a superparamagnetic photocatalyst for synergistic wastewater remediation. Appl Water Sci 12:1–17

Tony MA, Lin LS (2020a) Iron recovery from acid mine drainage sludge as Fenton source for municipal wastewater treatment. Int J Environ Anal Chem 102(6):1245–1260

Tony MA, Lin LS (2020b) Attenuation of organics contamination in polymers processing effluent using iron-based sludge: process optimization and oxidation mechanism. Environ Technol 43(5):718–727

Tony MA, Lin LS (2020c) Performance of acid mine drainage sludge as an innovative catalytic oxidation source for treating vehicle-washing wastewater. J Dispers Sci Technol 43(1):50–60

Tony MA, Lin LS (2021) Iron coated-sand from acid mine drainage waste for being a catalytic oxidant towards municipal wastewater remediation. Int J Environ Res 15(1):191–201

Tony MA, Mansour SA (2019) Removal of the commercial reactive dye Procion Blue MX-7RX from real textile wastewater using the synthesized Fe 2 O 3 nanoparticles at different particle sizes as a source of Fenton’s reagent. Nanoscale Adv 1:1362–1371

Tony MA, Mansour SA (2020a) Microwave-assisted catalytic oxidation of methomyl pesticide by Cu/Cu 2 O/CuO hybrid nanoparticles as a Fenton-like source. Int J Environ Sci Technol 17:161–174

Tony MA, Mansour SA (2020b) Solar photo-Fenton reagent with nanostructured iron oxide for Bismarck dye oxidation: an Egyptian apparel case study. Int J Environ Sci Technol 17:1337–1350

Tony MA, Ali IA (2021) Mechanistic implications of redox cycles solar reactions of recyclable layered double hydroxides nanoparticles for remazol brilliant abatement. Int J Environ Sci Technol, pp 1–18

Tony MA (2021a) Low-cost adsorbents for environmental pollution control: a concise systematic review from the prospective of principles, mechanism and their applications. J Dispers Sci Technol, pp 1–23

Tony MA (2021b) Paradigms of homo/heterogonous fenton systems incorporating 'solar energy' based on 'emerging pollutants' removal-challenges, advancements and visualized bibliometric analysis. Int J Environ Anal Chem, pp 1–32

Tony MA (2021c) Solar concentration for green environmental remediation opportunity-international review: advances, constraints and their practice in wastewater treatment. Int J Environ Anal Chem, pp 1–33

Turcanu A, Bechtold T (2017) Cathodic decolourisation of reactive dyes in model effluents released from textile dyeing. J Clean Prod 142:1397–1405

van der Marel HW, Beutelspacher H (1976) Atlas of infrared spectroscopy of clay minerals and their admixtures. Elsevier

Vigo TL (2013) Textile processing and properties: Preparation, dyeing, finishing and performance. Elsevier

Wang L, Wang W, Liu M, Ge H, Zha W, Wei Y, Fei E, Zhang Z, Long J, Sa R (2019) Understanding structure-function relationships in HZSM-5 zeolite catalysts for photocatalytic oxidation of isopropyl alcohol. J Catal 377:322–331

WHO (2003) Guidelines for drinking-water quality, 2nd ed. Addendum to Vol. 2. Health criteria and other supporting information. In: World Health Organization, (Geneva, 1998). https://apps.who.int/iris/bitstream/handle/10665/75362/WHO_SDE_WSH_03.04_53_eng.pdf, Accessed at (16 June 2022)

Yahya N, Aziz F, Jamaludin NA, Mutalib MA, Ismail AF, Salleh WNW, Jaafar J, Yusof N, Ludin NA (2018) A review of integrated photocatalyst adsorbents for wastewater treatment. J Environ Chem Eng 6:7411–7425

Yang Y, Ma C, He X, Li J, Li M, Wang J (2021) Calcined aluminum sludge as a heterogeneous fenton-Like catalyst for methylene blue degradation by three-dimensional electrochemical system. Electrocatalysis 12(6):698–714

Yao L, Yang H, Chen Z, Qiu M, Hu B, Wang X (2021) Bismuth oxychloride-based materials for the removal of organic pollutants in wastewater. Chemosphere 273:128576

Yu S, Tang H, Zhang D, Wang S, Qiu M, Song G, Fu D, Hu B, Wang X (2021) MXenes as emerging nanomaterials in water purification and environmental remediation. Sci Total Environ, p 152280

Zhang Y, Sivakumar M, Yang S, Enever K, Ramezanianpour M (2018) Application of solar energy in water treatment processes: a review. Desalination 428:116–145

Zhao YQ, Babatunde AO, Hu YS, Kumar JLG, Zhao XH (2011) Pilot field-scale demonstration of a novel alum sludge-based constructed wetland system for enhanced wastewater treatment. Process Biochem 46:278–283

Zholobenko VL, Holmes SM, Cundy CS, Dwyer J (1997) Synthesis of MCM-41 materials: an in situ FTIR study. Microporous Mater 11:83–86

Acknowledgements

The authors are sincerely acknowledging the Geziret El Dahab drinking water treatment plant, Giza governorate, Egypt, for providing the alum sludge samples used in this study.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The author(s) received no specific funding for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Thabet, R.H., Fouad, M.K., El Sherbiny, S.A. et al. Identifying optimized conditions for developing dewatered alum sludge-based photocatalyst to immobilize a wide range of dye contamination. Appl Water Sci 12, 210 (2022). https://doi.org/10.1007/s13201-022-01739-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-022-01739-8