Abstract

The existing management structure of medical supply inventory (MSI) is not sufficiently effective, and it is incompetent to solve the problems of medical supply stock control in public security emergencies. Therefore, deep learning and big data technology are employed in this work to optimize the stock control structure and enhance management efficiency, so that the optimized management structure can play an excellent role in the material supply of emergencies. After browsing copious literature, the economic ordering models with infinite/limited supply rate and without shortage are innovatively constructed to realize efficient management of emergency supplies inventory. Besides, the optimized fixed-point and quantitative ordering method of safety stock is employed to construct the MSI models for scarce emergency supplies and the time-sensitive emergency supplies, respectively. Then, an earthquake-related emergency is taken as a case and data source to evaluate the solution results of the emergency MSI model. Moreover, the stacked auto-encoders (SAE) algorithm is used to build the demand prediction model for MSI. Finally, a simulation experiment compares the SAE-based demand prediction model for MSI with a back propagation neural network (BPNN) model and radial basis function network (RBFN) model to verify the model’s performance. The experimental results demonstrate that after 150 times of training, the error between the predicted value and the actual value of each model is within 30, and the prediction accuracy is significantly improved. After 170 times of network training, the mean absolute error (MAE) values of BPNN model and RBFN model are 31.98 and 73.73, respectively. In contrast, the MAE value of the SAE-based model is 21.32, which is superior to the other two models. Evidently, the management structure of MSI is optimized by dividing the emergency MSI into three MSI models for the critical emergency supplies, scarce emergency supplies, and the time-sensitive emergency supplies. The research outcome can provide essential logistical support for dealing with public security emergencies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, continuous economic and social progress plays increasingly severe havoc with nature, resulting in the spread of natural disasters and extreme weather worldwide (Yu et al. 2018; Wang and Ye 2018). The interaction between man-made hazards and various natural disasters has constantly generated crippling large-scale emergencies worldwide in recent decades (Short et al. 2019; Rosselló et al. 2020). For example, the swine influenza (Influenza A Virus Subtype H1N1) spread out around the world in 2009, followed by the wild-type poliovirus epidemic in 2014 in Asia, Africa, and the Middle East, Ebola epidemic in Africa in 2014, Zika virus epidemic in 2016, and the epidemic of Coronavirus Disease 2019 (Yang et al. 2021). Multitudes of health emergencies play a crucial role to property and life safety of people. For a timely and effective response to international public health emergencies, the United Nations established the World Health Organization in 1948. This organization protects people around the world from harm by establishing efficient management methods of public health emergencies (Rose et al. 2017). Emergency supplies management is absolutely a primary procedure of emergency management (Khan et al. 2019). All sudden events are unpredictable, and correspondingly, the supplies used to respond to emergencies generally fail to meet the requirements for temporal and spatial accessibility. Consequently, it is usually impossible to immediately and efficiently handle public emergencies (Zhang et al. 2021). Emergency supplies management concerns multiple factors such as logistics allocation and stock control. Among them, emergency supplies stock control is particularly vital to the emergency operation (Hu et al. 2019).

Many domestic and foreign researchers have studied public emergency management, and most of them focus on how to improve the response ability to emergencies. For instance, Son et al. (2020) studied the resilience in emergency management through the method of literature review, and found out the paramount dimensions of emergency management flexibility and prevalent technical tools to enhance emergency management flexibility. Moreover, Fathi et al. (2020) performed a structured survey on the virtual operation support of the workflow of the emergency management organization. They found that data mining technologies and tools could greatly enhance the efficiency of emergency management. Kaveh et al. (2020) investigated the latest development of post-earthquake emergency management system using optimization technologies. In addition, Sun et al. (2021) employed the fuzzy multi criteria decision-making method to select emergency plans, which improved the reliability and accuracy of ranking evaluation indicators. Furthermore, Russo (2021) proposed a hybrid method of disaster and emergency management. However, few people have made efforts on the response and solutions to emergencies by establishing models to improve the ability to deal with emergencies.

The exploration reported here aims to applying the medical supply inventory (MSI) model via deep learning (DL) to provision planning scheme to public emergencies. Through the literature review and the summary of previous works, the critical emergency supplies inventory model, scarce emergency supplies inventory model, and time-sensitive emergency supplies inventory model are established, respectively, to optimize the management structure of MSI. Besides, the demand prediction model of MSI is built by using the stacked auto-encoders (SAE) algorithm of DL to provide necessary logistics support for dealing with public security emergencies. Taking an earthquake case as an example, the simulation training is performed to scientifically evaluate the effectiveness of the model. This investigation not only realizes the scientific and rational classification of medical emergency supplies, but also furnishes emergency inventory and material management with research ideas and theoretical foundation. In this work, the first section puts forward the research purpose and significance by introducing the background of emergency management of public emergencies. The second section analyzes the existing medical supply management and planning mode and problems, and expounds the classification and inventory strategy of emergency supplies to strengthen the understanding of emergency management strategy. Besides, the emergency supplies inventory model is constructed. In the third section, the experimental design and model performance evaluation are carried out, and the prediction results of emergency supplies supply based on DL are analyzed. The fourth section discusses the experimental results, and finally, the fifth section draws the experimental conclusion.

2 Methods

2.1 Existing medical supply store control and planning model and related problems

(1) MIS model

The majority of present MIS models are inspired by modern logistics management. Figure 1 reveals the primary modules of emergency supplies management and planning, principally containing the logistics hub, information management hub, and command hub. Specifically, the command hub can plan, coordinate, and control emergency supplies, involving developing specific support plans, needs analysis, comprehensive deployment, and material financing of emergency supplies, and material feedback information acquisition. The logistics center consists of four procedures, namely supplies purchasing, supplies storage, supplies transportation, and supplies distribution. The information management center is composed of the emergency supplies database, enquiry system, real-time supplies supervisory, and decision optimization system. In addition, the emergency command center can connect to the information management center and the logistics center through an information feedback module.

(2) Problems of the MIS model

The modern emergency response can be analyzed from three perspectives, namely the quantity of emergency supplies, the quality of emergency supplies, and the composition of emergency supplies. At present, the costly management of emergency supplies cannot provide high-quality services to deal with emergencies. Hence, it is crucial for scientific stock control to realize cost reduction of MSI and meanwhile the optimization of service quality of MIS.

2.2 Emergency MSI strategy

Common emergency supplies inventory strategies include deterministic and random inventory models. Deterministic inventory models include the inventory model with an infinite supply rate and without shortages for inventory, inventory model with a finite supply rate and without shortages for inventory, inventory model with an infinite supply rate and allowable shortage, and inventory model with a finite supply rate and allowable shortage. In reality, emergency supplies must be available in stock. Therefore, the deterministic emergency supplies inventory model has two categories, namely, the inventory model with an infinite supply rate and without shortages for inventory and the inventory model with a finite supply rate and without shortages for inventory, as shown in Fig. 2.

(1) For the inventory model with an infinite supply rate and without shortages for inventory, a decrease in the number of orders can reduce ordering costs. However, at the same time, it increases the average inventory, leading to a growth in inventory costs. Therefore, it is essential to balance the ordering cost and inventory cost for a reasonable order quantity. As shown in Fig. 2A, the order quantity with the minimum sum of inventory cost and ordering cost is called economic order quantity (EOQ). The purpose of this model is to solve the EOQ. The order quantity can be calculated according to:

where Q represents the order quantity, D denotes the demand for supplies in time T referring to the time interval, and N means the number of orders in T time. Besides, C1 denotes the inventory cost per unit time unit material, C3 signifies the cost of each order, Ch stands for the total inventory fee in T time, and Ca represents the total ordering cost in T time. Meanwhile, E stands for the sum of total inventory cost and total ordering cost in T time.

Then, EOQ denoted as Q* is derived as Eq. (4).

According to Q*, the minimum total cost E*, the best interval T*, and the best number of orders N* can be written as Eqs. (5)–(7).

(2) Fig. 2B describes the inventory model with a finite supply rate and without shortages for inventory. When a part of supplies is sent to the stockroom, another part of the supplies will be consumed. Therefore, the inventory order quantity will not reach the Q* value. To determine the average inventory, assume that \(F{ = }\frac{D}{T} \cdot \frac{Q}{A}\) is the number of supplies used when a new batch of supplies arrives, the maximum inventory is \(Q - F\), and the average inventory is \(\frac{1}{2}(Q - F)\). Meanwhile, the total inventory fee is denoted as \(C{\text{h = }}\frac{C1 \cdot T}{2} \cdot (Q - F)\), the total order fee as \(C{\text{a = }}C3N = C3\frac{Q}{D}\), and the total cost as \(E = \frac{C1T}{2}(Q - F) + C3\frac{Q}{D}\). Then, the EOQ Q* is expressed as Eq. (8).

Then, the minimum total cost E* can be presented as Eq. (9).

In practice, the supplement of emergency supplies is complex. Therefore, the deterministic demand of emergency supplies stock control usually occupies a minimal proportion, and it can only be determined in the short term. In this situation, inventory control methods are essential to eliminating impact of diversified uncertain factors. The fixed-point and quantitative ordering control method is often used among various random demand models, which is characterized by a fixed order point and order quantity. By this method, the next purchase demand decreases to the fixed order quantity before purchase. Therefore, the interval between orders is not certain. Figure 3 reveals the relationship between order time interval and inventory size, where the abscissa represents the time interval between orders, and the ordinate denotes the inventory size. The cycle of EOQ is calculated according to Eqs. (10), (11), and (12).

Equation (11) indicates the maximum inventory Qmax.

In view of the arrival quantity and delivery quantity, the quantity of each order is calculated according to Eq. (12).

In Eq. (12), S refers to the single ordering cost, Tk denotes the average order cycle time, C0 stands for the storage charges for unit supplies per year, and T represents the order cycle time. In addition, R denotes the average inventory demand, Qki is the physical storage of i orders, Qmax signifies the highest inventory, Qs means the safety stock, and Qni describes the arrival volume of i order points.

2.3 Emergency supplies classification

The Activity Based Classification (ABC) method is a systematic and quantitative category managerial approach on the foundation of the ratio of varieties and funds of the supplies inventory (Lu et al. 2020). The ABC method divides particular subjects into three categories in line with a specific criterion, i.e., critical supplies, scarce supplies, and time-sensitive supplies. The varieties of critical supplies account for 5% to 20%, and the funds occupy 60% to 70%, which are the core of emergency supplies. The varieties of scarce supplies account for 20% to 30%, and the funds occupy 10% to 20%, attracting general attention from stock control. The varieties of time-sensitive supplies account for 60% to 70%, and the funds occupy 5% to 10%, which are generally easy to manage. In the subsequent experiment, an MSI model is built to investigate the emergency supplies management of an earthquake. The literature Lin et al (2019), Liu et al. (2019) and Wang et al. (2020) and Emergency Supplies Classification and Product Catalog are selected for references. The emergency supplies applicable to earthquakes contain first aid items, drugs, relief devices, and recovery resources after disasters. Figure 4 illustrates the classification of emergency supplies.

2.4 Construction of emergency MSI models

(1) The MSI model for critical emergency supplies

The critical emergency supplies involve multiple types of supplies and requires some inventory space. However, in actual situations, it is difficult to balance the storage amount, tied-up funds, and storage space of different types of supplies. Therefore, the economic order model with finite storage space can be used (Sebatjane and Adetunji 2019a, b; Kumar 2016; Shekarian et al. 2016). Assume that for the stock control of critical emergency supplies with finite storage space, each kind of critical supplies occupies certain inventory space, and the inventory space allocated to critical supplies is specified. Besides, over a spell, the storage fee rate, requirements rate, and order charge for a critical supply are fixed. Then, the best order batch of critical supplies is determined as follows. First, according to the EOQ model with an infinite supply rate, the average total cost can be presented as:

The best order batch of Qi* is determined according to Eq. (15).

In practice, the stock control of critical supplies should be consistent with the constraint shown in Eq. (16).

If Qi* does not meet the constraints, it needs to be solved according to the Lagrange multiplier method, as presented in Eq. (17).

Then, Qi can be obtained by Eq. (18).

Among Eqs. (13)-(18), ωi denotes the storage space occupied by the i-th supply, Qi represents the order volume of the i-th supply, and W signifies the largest storage space allocated in the warehouse for critical supplies. Meanwhile, Di stands for the requirements rate of the i-th supply, C3i refers to the subscription charge for the i-th supply, and C1i represents the storage amount of the i-th supply. Generally, when there are less variables, the average total cost can be obtained manually or by analysis method. On the contrary, iteration methods or mathematical software like Matlab are more suitable when there are more variables.

(2) The MSI model for scarce emergency supplies

Scarce supplies often involve high funds and usually require strict management. Due to the low frequency of use and the low demand of scarce supplies, it is often essential to adjust the purchase quantity according to the market situation and realistic demand. In this case, the inventory strategy of fixed-point control method can be adopted for the stock control of scarce supplies.

(3) The MSI model for time-sensitive emergency supplies

For sudden public events, time-sensitive supply is the most vital element that affects the emergency supplies reserve mode (Guan et al. 2021). Time-sensitivity is the first issue to be considered when dealing with emergencies. Therefore, the stock control strategy for time-sensitive supplies should focus on improving service quality while minimizing management costs. Therefore, the quantitative ordering method based on EOQ can be used for the stock control of time-sensitive supplies. The key parameter Qk is calculated as follows in the implementation of quantitative ordering method. Based on requirements rate, the quantity demanded D1 of the order cycle time is presented as Eq. (19).

Given the connection between the quantity demanded D1 with order cycle time Tk and requirments rate RP, the key parameter Qk can be obtained by Eq. (20).

On the grounds of the rationale of minimum total cost, the economic order quantities can be written as Eq. (21).

In Eq. (21), C1 signifies the storage cost per unit time, C0 represents the cost per order, and Rp denotes the requirements rate.

3 Experimental design and performance evaluation

3.1 Simulation verification of emergency supplies inventory model

(1) Data collection and preprocessing

Through the query of data, the storage and management of rescue supplies in an earthquake emergency case are selected for the validation experiment of critical emergency supplies inventory model. The medical supplies for rescue are sorted out and divided into critical emergency supplies, scarce emergency supplies, and time-sensitive emergency supplies. Critical emergency supplies contain medical gauze, blood cushion, bandage, alcohol, saline, and sphygmomanometer. Scarce emergency supplies include medical gloves, goggles, disinfectant, ventilators, respirator, and protective clothing. The time-sensitive emergency supplies involve six types of medical rescue supplies, namely glucose, epinephrine, dopamine, nitroglycerin, coral amine, and Lobeline. The demand, storage cost, and cost price of the above rescue supplies are counted respectively, and the statistical data are arranged and plotted into tables.

(2) Critical emergency supplies inventory model

Critical emergency supplies in response to an earthquake contain blood pressure meter, medical gauze, bandages, saline, alcohol, and blood-sucking pads. These six types of supplies are denoted R1, R2, R3, R4, R5, and R6, respectively. Assume that the maximum size of a stockroom is 20,000 m3. Table 1 displays the stock control data of the six types of supplies according to reference.

(3) Scarce emergency supplies model

Scarce emergency supplies in this experiment are divided into goggles, protective clothing disinfectant, mask, ventilator, and medical gloves. These medical supplies are marked as G1, G2, G3, G4, G5, and G6, respectively. Assume that the arrival volume is 300 pieces, the physical holding of stock is 700 pieces, and the planned transportation volume are 280 pieces. Table 2 provides the inventory data of the six types of scarce supplies according to reference.

(4) Time-sensitive emergency supplies model

Time-sensitive emergency supplies in this experiment include Lobeline, epinephrine, coral amine nitroglycerin, dopamine, and glucose. These medical supplies are denoted as T1, T2, T3, T4, T5, and T6, respectively. Assume that the order cycle time is 8 days, and the mean consumption per day is 150 cases, and the largest consumption per day is 200 cases. Table 3 illustrates the storage details of the six kinds of time-sensitive supplies according to literature.

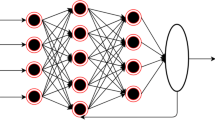

3.2 Demand prediction of medical supplies based on DL

The SAE algorithm utilizes several sparse auto-encoders, which can reduce the vector space of model data by gradually extracting data elements. In the SAE model, the initial data is input into a training set in the encoder of the initial layer. The hidden layer consists of multi-layer sparse encoders. In addition, the output of the K-type sparse encoder is the input of the K + 1-type sparse encoder, which can be used to sparsely represent the multi-layer encoder. The initial data set with 7 dimensions is denoted as [X1, X2, X3, X4, X5, X6, X7], and it enters the first hidden layer with the pre-set capacity of 5 of the SAE model, which generates the new data set [Y1, Y2, Y3, Y4, Y5] and the initial weights and parameters. Then, the output of the hidden layer is compared with the initial data. If the training accuracy is satisfied, the reconstructed data set is reduced to 5 dimensions. Otherwise, the data set is returned for compensation by analogy. The five-dimensional data set [Y1, Y2, Y3, Y4, Y5] is input into the second hidden layer as training data, and a new four-dimensional data set is obtained after debugging model’s parameters. A high-dimensional data set is finally attained by constantly adding new input and output data, which is simplified as the low-dimensional data set [Z1, Z2, Z3, Z4]. Figure 5 displays the formation process of the model after a n-dimensional vector is sent to the SAE model. The useful features of data can be obtained by processing discrete data.

Each input value can generate a unique eigenvalue through the layer-by-layer greedy algorithm. These eigenvalues are the input of the next training layer for learning. By activating the representation of the next feature, the feature of step is finally output, which is the input of the regression model. The demand prediction model reported here compares the characteristics of a given deep network with numerical regression. The last learning network in logistic regression model is different from the previous classification of results using softmax model. Here, a logistic regression model is indispensable to predicting continuous variables. The predicted value is obtained by linear superposition, and then, the true value and the error of the predicted value are calculated and used as the matrix in the sample.

3.3 Verification results of the MSI model for critical emergency supplies

Maximizing the use of storage space is of paramount importance to the stock control of critical supplies. Based on the given conditions and DL technology, the EOQ is calculated not under the constraints on the stockroom area when Q1* = 17,889, Q2* = 15,492, Q3* = 15,142, Q4* = 17,361, Q5* = 12,247, Q6* = 11,401, respectively. In this way, the occupied area of six types of critical supplies can be determined: 17,889 × 0.2 + 15,492 × 0.3 + 15,142 × 0.2 + 17,361 × 0.2 + 12,247 × 0.3 + 11,401 × 0.3 = 21,820.4 (m3). However, the best inventory quantity (21,820.4 m3) obtained by the above calculation exceed the largest storage space (20,000 m3). Obviously, it is not practicable to store critical supplies according to this schedule.

Therefore, the finite inventory space constraint model is adopted. Figure 6 reveals the results of the equation by introducing different fixed values. In Fig. 6, with the increase in the number of iterations, the quantity of different medical supplies that need to be purchased changes greatly. When ordering 11,075 pieces of bandages, 14,386 pieces of blood-sucking pads, 16,319 pieces of gauze, 13,105 pieces of sphygmomanometers, 12,072 pieces of alcohol, and 12,108 pieces of saline, the maximum inventory is 19,772.9 m3, and the maximum inventory utilization rate is 98.86%.

3.4 Verification results of the MSI model for scarce emergency supplies

It is vitally important for the MSI model for scarce emergency supplies to determine the order cycle time and the maximum inventory. According to above analysis, the EOQ cycle of scarce supplies can be determined, namely T1 = 35, T2 = 34, T3 = 33, T4 = 36, 51 = 38, T6 = 36, respectively. Figure 7 indicates the change in the maximum inventory under different demands. With the increase in demands, the maximum inventory continues to increase. In addition, when the demand quantity is 1000, the corresponding order cycle time is 35 days. Then, the order batch at this time is 630 pieces, and the maximum inventory is 1350 pieces. In concrete scenarios, for the EOQ order method, the batch size of each order is difficult to determine, and it may perform poor in operating cost and economic benefit are obvious disadvantages. Therefore, this order approach is only is only applicable to supplies that are crucial, scarce, few varieties, and high value.

3.5 Verification results of the MSI model for time-sensitive emergency supplies

It is of paramount importance for the stock control of time-sensitive emergency supplies to determine the safety inventory and order point. Based on the given prerequisite, the order quantity of time-sensitive supplies are determined, i.e., Q1* = 16,100, Q2* = 16,757, Q3* = 15,179, Q4* = 14,697, Q5* = 14,199, Q6* = 14,940, respectively. Figure 8 illustrates the changing trend of order batches of time-sensitive emergency supplies under different amounts of safety inventory. According to Fig. 8, the changes in safety inventory continue to increase as demand increases. Moreover, when the safety stock of supplies is 400 cases, the order point is 1600 cases, the order quantity is 16,100 cases, and the use effect of the model is optimal.

3.6 Prediction results of emergency supplies demand based on DL

After training the supply inventory model 50 times and 150 times, the predicted values of this model are compared with the actual values to investigate the influence of training times on the prediction accuracy of supplies inventory. The results are shown in Figs. 9 and 10, where the abscissa refers to the node of each material supply stockroom, and the ordinate denotes the size of the supply. Through Fig. 9, there is a significant gap between predicted values of the model and actual values after 50 times of training. With the increase in training times, the output value of the model is even closer to the actual value. After 150 trainings, the error between the predicted value of the model and the actual value is less than 30, indicating that the prediction accuracy is significantly improved.

Furthermore, the prediction results of the SAE algorithm model are compared with those of the traditional shallow learning model. The back propagation neural network (BPNN) and the radial basis function network (RBFN) are selected for comparison. Specifically, the same data is input into the three comparative models respectively. Each model is trained 170 times, and the mean absolute error (MAE) value is used as the evaluation index of the performance of the models. Figure 11 describes the comparison results. In Fig. 11, as the amount of training sample data enlarges, the MAE values of the three models are decreasing. However, compared with BPNN model and RBFN model, the MAE value of SAE model is significantly reduced. With the increasing amount of training sample data, the SAE algorithm model shows even more obvious advantages. After 170 times of network training, the MAE values of BPNN model and RBFN model are 31.98 and 73.73, respectively, but the MAE value of SAE algorithm model decreases to 21.32, which is significantly superior to other two models.

4 Discussion

Here, medical supplies are classified into three categories according to their characteristics, and different order control methods are adopted accordingly. Moreover, the prediction effect of the MSI model is verified through the training of DL network. A logical finite MSI model is indispensable for the rational and efficient use of supplies. Here, the EOQ method of finite inventory is employed to build the MSI model for critical emergency supplies, which can evenly assign space based on the consumption of supplies without the constraints on the stockroom area, to enhance efficiency in utilization of space. The order quantity decided in accordance with the particular condition competently meets the storage capacity of the stockroom (Fig. 4). Zhang and Wen (2020) established a multi-index pricing model for emergency supplies procurement through constraint theory, and determined the bottleneck factors of procurement pricing through simulation experiments. Jiang et al. (2020) evaluated the elementary factors affecting the reliability of emergency logistics system through multi-attribute decision-making method. He et al. (2021) studied the allocation of emergency supplies in emergencies. They adopted the improved non-dominated sorting genetic algorithm to solve the multi-objective optimization model. Although this approach solved the supply and demand matching problem of emergency supplies of public health emergencies, the emergency supplies demand workflow selected by the model was static, so it was inapplicable to the dynamic change of emergency supplies demand. In short, although these traditional methods can manage the MSI in emergency, the emergency supplies management system cannot immediately respond to adjust the supply–demand relationship in time in emergent situations. The training method based on DL is adopted to repeatedly train medical supply data, and the emergency supplies management is innovatively classified into three categories. The emergency supplies management model reported here runs fast and accurately, improving the efficiency of medical supply emergency management, and providing a new research idea for the storage and management of emergency supplies.

5 Conclusion

After reading a considerable number of works of reference for reference, MSI models for critical emergency supplies, scarce emergency supplies, and time-sensitive emergency supplies are proposed and applied to improve the stock control of emergency supplies. Among them, the MSI model for critical emergency supplies is established by the EOQ method with finite inventory. The MSI model for scarce emergency supplies is constructed via the optimized periodic order of the maximum and minimum period method. The MSI model for time-sensitive emergency supplies is built through the quantitative ordering method based on safety inventory. Besides, the present work provides the construction methods and procedures of these models. Then, an earthquake emergency is selected for the case analysis. The emergency supplies are classified into three categories, namely critical supplies, scarce supplies, and time-sensitive supplies. The MSI models reported here are more logical and workable than the existing stock control methods, dramatically enhancing the space and capital utilization, and strengthen the stock control of emergency supplies. Besides, the prediction model of emergency supplies supply based on DL has lower algorithm error and more prominent advantages than traditional shallow learning models. It realizes the cost-effective and efficient stock control of emergency supplies, and strengthens the risk management capability, which is of significant value to handling public emergencies.

However, the present work still has plenty room for improvement. On the one hand, considering that emergency supplies generally have enormous amounts and difficulty in stock control, the emergency supplies are classified into three categories in this experiment. However, the classification reported here is qualitative, and there lacks quantitative research. It is expected to utilize regression analysis and analytic hierarchy process and fuzzy comprehensive evaluation method for further analysis of the sorting of emergency supplies in the follow-up work. On the other hand, the quantitative order method, traditional EOQ method, and conventional order method are optimized and applied to construct the emergency MSI models for various medical supplies. However, the application of the model test is still at the exploration stage. For instance, the multi-variety joint order requires flexible quantitative order methods, and it is essential to find more precise methods to determine a rational scale of safety inventory. It is worth carrying out further research on diversified categories of inventory models in future.

References

Fathi R, Thom D, Koch S et al (2020) VOST: a case study in voluntary digital participation for collaborative emergency management. Inf Process Manag 57(4):102174

Guan X, Zhou H, Li M et al (2021) Multilevel coverage location model of earthquake relief material storage repository considering distribution time sequence characteristics. J Traffic Transp Eng (English Edition) 8(2):209–224

He J, Liu G, Mai THT et al (2021) Research on the allocation of 3D printing emergency supplies in public health emergencies. Front Public Health 9:263

Hu H, He J, He X et al (2019) Emergency material scheduling optimization model and algorithms: a review. J Traffic Transp Eng (English Edition) 6(5):441–454

Jiang P, Wang Y, Liu C et al (2020) Evaluating critical factors influencing the reliability of emergency logistics systems using multiple-attribute decision making. Symmetry 12(7):1115

Kaveh A, Javadi SM, Moghanni RM (2020) Emergency management systems after disastrous earthquakes using optimization methods: a comprehensive review. Adv Eng Softw 149:102885

Khan Y, Brown AD, Gagliardi AR et al (2019) Are we prepared? The development of performance indicators for public health emergency preparedness using a modified Delphi approach. PLoS ONE 14(12):e0226489

Kumar R (2016) Economic order quantity (EOQ) model. Glob J Finance Econ Manag 5(1):1–5

Lin Y, Wang T, Wang S (2019) UAV-assisted emergency communications: an extended multi-armed bandit perspective. IEEE Commun Lett 23(5):938–941

Liu M, Yang J, Gui G (2019) DSF-NOMA: UAV-assisted emergency communication technology in a heterogeneous Internet of Things. IEEE Internet Things J 6(3):5508–5519

Lu X, Pu X, Han X (2020) Sustainable smart waste classification and collection system: a bi-objective modeling and optimization approach. J Clean Prod 276:124183

Rose DA, Murthy S, Brooks J et al (2017) The evolution of public health emergency management as a field of practice. Am J Public Health 107(S2):S126–S133

Rosselló J, Becken S, Santana-Gallego M (2020) The effects of natural disasters on international tourism: a global analysis. Tour Manag 79:104080

Russo BR (2021) Mixed-methods research in disaster and emergency management. Disaster and emergency management methods. Routledge, London, pp 67–84

Sebatjane M, Adetunji O (2019a) Economic order quantity model for growing items with imperfect quality. Oper Res Perspect 6:100088

Sebatjane M, Adetunji O (2019b) Economic order quantity model for growing items with incremental quantity discounts. J Ind Eng Int 15(4):545–556

Shekarian E, Olugu EU, Abdul-Rashid SH et al (2016) An economic order quantity model considering different holding costs for imperfect quality items subject to fuzziness and learning. J Intell Fuzzy Syst 30(5):2985–2997

Short NA, Sullivan J, Soward A et al (2019) Protocol for the first large-scale emergency care-based longitudinal cohort study of recovery after sexual assault: the Women’s Health Study. BMJ Open 9(11):e031087

Son C, Sasangohar F, Neville T et al (2020) Investigating resilience in emergency management: an integrative review of literature. Appl Ergon 87:103114

Sun Y, Mi J, Chen J et al (2021) A new fuzzy multi-attribute group decision-making method with generalized maximal consistent block and its application in emergency management. Knowl Based Syst 215:106594

Wang Z, Ye X (2018) Social media analytics for natural disaster management. Int J Geogr Inf Sci 32(1):49–72

Wang B, Sun Y, Sun Z et al (2020) UAV-assisted emergency communications in social IoT: a dynamic hypergraph coloring approach. IEEE Internet Things J 7(8):7663–7677

Yang Z N, Zhao Y Y, Li L et al (2021) Evaluation of safety of two inactivated COVID-19 vaccines in a large-scale emergency use. Zhonghua liu Xing Bing xue za zhi= Zhonghua Liuxingbingxue Zazhi 42:1–6

Yu M, Yang C, Li Y (2018) Big data in natural disaster management: a review. Geosciences 8(5):165

Zhang C, Hong L, Ma N et al (2021) Logic analysis of how the emergency management legal system used to deal with public emerging infectious diseases under balancing of competing interests—the case of COVID-19. Healthcare 9(7):857

Zhang Y, Wen L (2020) A multi-index pricing model for emergency material procurement based on constraint theory. In: 2020 2nd international conference on economic management and model engineering (ICEMME). IEEE, pp 556–559

Funding

This work was supported in part by the second batch of industry-student cooperation and collaborative education project in 2021 under Grant: 202102490017. This work was supported in part by Inner Mongolia Natural Science Foundation under Grant: 2020MS06001.

Author information

Authors and Affiliations

Contributions

All authors listed have made a substantial, direct and intellectual contribution to the work, and approved it for publication.

Corresponding author

Ethics declarations

Conflict of interest

All Authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, L., Zhu, G. & Zhao, X. Application of medical supply inventory model based on deep learning and big data. Int J Syst Assur Eng Manag 13 (Suppl 3), 1216–1227 (2022). https://doi.org/10.1007/s13198-022-01669-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-022-01669-3