Abstract

The use of mixed culture in the fermentation industry requires more complicated equipment, processes, and monitoring systems; therefore, a single culture may be preferable. This study aimed to investigate the correlation between chemical and microbiological properties and sensory characteristics. In addition, this study aimed to determine the different characteristics of cheese made using single probiotic cultures of Lactobacillus plantarum Dad-13 and Lactobacillus plantarum Kita-3 and mixed culture. The obtained results showed that the chemical characteristics of cream cheese made using single cultures were similar to those of cream cheese made using mixed cultures. The viability of the cells remained high after 35 days of storage for the single culture, which was not the case for the mixed culture. In terms of sensory analysis, cream cheese made using the single culture L. plantarum Kita-3 showed higher overall liking score among the samples, which might correlate with the high ester and ketone content. In addition, there was a strong relationship between the ethyl octanoate and methyl butanol contents and the overall liking score. The results of this study showed that the use of a single culture of L. plantarum Kita-3 could improve the sensory characteristics of cream cheese with probiotic properties. This study also contributed to the development of cream cheese production, particularly in the screening of potential starters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently, there is an increasing concern about probiotic fermented food, particularly in the COVID-19 pandemic era, because functional foods have a strong correlation with maintaining the immune system (Adnan and Pramaningtyas 2020). Probiotics can modulate the immune system to prevent viral infections through modulation in the intestinal mucosa (Kanauchi et al. 2018). Probiotics are defined as live microorganisms that can provide health effects by supporting the balance of microbiota growth in the gut when consumed in sufficient quantities, such that during the processing and storage, the number of living cells is 107–109 CFU/g or CFU/ml (FAO/WHO 2002).

Lactic acid bacteria (LAB) have been widely used as probiotics in the food industry, because they hold a generally recognized as safe (GRAS) status. They are not only beneficial for health but can also improve the texture, taste, aroma, and nutritional value of the resulting product. L. plantarum is a probiotic that is widely found in nature, including the strain L. plantarum Dad-13 that is isolated from curd, which is traditional fermented buffalo milk from West Sumatra, Indonesia (Rahayu et al. 2016), and the strain L. plantarum Kita-3 is isolated from Halloumi cheese. A previous study showed that a single culture of L. plantarum Dad-13 can be used as a starter culture to form curds in cheese (Meidistria et al. 2020), and in the yogurt fermentation process, the number of viable cells of L. plantarum Dad-13 can be maintained up to 109 CFU/g during 4 weeks of storage at 4 °C (Utami et al. 2016). In a previous study, these LAB have been proven to be probiotic compounds (Rahayu et al. 2016) and has ability to inhibit the growth of pathogenic Escherichia Coli in vitro (Sumaryati et al. 2009). Thus, these LAB can be used to make probiotic fermented food.

One of the most consumed fermented dairy foods globally is cheese. Cheese has been consumed throughout the world, and its use has continuously increased in recent years in most of the selected countries and worldwide (Mikkelsen 2020). Several studies on probiotic cheeses have been conducted such as on cheddar cheese (Wang et al. 2018), kalari cheese (Mushtaq et al. 2019) and mozzarella cheese (Mukhtar et al. 2020). However, these types of cheese are usually used for cooking, which may reduce the number of probiotic living cells. On the other hand, fresh cheese, such as cream cheese, is consumed as bread spreads, which may provide better protection to the cells. In addition, cream cheese has a soft, creamy white, spreadable texture, a smooth consistency, and a slightly acidic taste, which makes this product sensorially attractive. A study on probiotic living cells from cream cheese was performed by Ningtyas et al. (2019b). The study reported that the addition of L. rhamnosus increased the sensory properties of the cheese and that the viability of the cells remained high during storage.

The commercial culture for cheese production is currently dominated by a mixed culture. However, the production of a mixed starter culture is more complicated than that of a single culture and requires special equipment and optimization of fermentation conditions for the growth of the microorganisms (Wilkinson and Lapointe 2020). Therefore, the use of a single culture may be more desirable. However, there is scarce information on the effect of using a mixed and single culture on the characteristics of fermented products. Therefore, this study aimed to investigate the effect of using a mixed and single culture of L. plantarum Dad-13 and L. plantarum Kita-3 on the chemical, microbiological and sensory properties of probiotic cream cheese.

Materials and methods

Microorganisms

Freeze-dried cultures of probiotic Lactobacillus plantarum Dad-13 and Lactobacillus plantarum Kita-3 were obtained from the FNCC (Food Nutrition Culture Collection), Center for Food and Nutrition Studies, Gadjah Mada University, Yogyakarta, Indonesia. Preparation of probiotic starter cultures is based on the method previously reported by Utami et al. (2020). The isolates were grown in halal media for 24 h at 30 °C. The halal media consisted of 3% sucrose, 25% meat peptone, 40% mung bean sprout extract, 2% tomato extract, and 30% fresh young coconut water. Meat peptone was prepared by hydrolysis of halal meat using crude bromelain (Utami et al. 2019). The culture suspension was centrifuged using a refrigerated centrifuge (Beckman J-6B, Germany) to harvest the cells. To produce freeze-dried starter cultures, pellets that were resuspended in 10% skim milk and 1% sucrose mixture were frozen overnight (at −20 °C), followed by freeze-drying for 3 h. For comparison, the commercial starter was from Chr. Hansen (Bayswater, Australia) and consisted of Lactococcus lactis ssp. cremoris, Leuconostoc mesenteroides ssp. cremoris, Lactococcus lactis ssp. lactis, and Lactococcus lactis ssp. lactis biovar diacetylactis was also used.

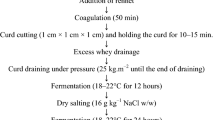

Cream cheese production

Cream cheese was prepared by pasteurizing 1 L of fresh milk mixed with 1 L of cream. The mixture of milk and cream with a ratio of 1:1 requires 8 L of fresh milk to make 1 L of cream. Pasteurization of milk and cream was performed at 63 °C for 15 min, after which the mixture was cooled at 37 °C. Then, the starter culture and rennet were added in a proportion of 2% (w/v) and 0.01% (w/v), respectively (Tologana 2022). The inoculum amount of the single starter cultures and mixed cultures added to milk was estimated at population levels of approximately 7 log CFU/ml and 5 log CFU/ml, respectively. The acidification process was performed until the pH of cream cheese was 4.7 at 37 °C, and then cream cheese was drained for 12 h at 3–4 °C to separate the whey. After the draining process, the cream cheese was transferred to a stainless steel container for the salting process, followed by packing in small containers with lids.

Proximate analysis

The pH values were measured with a digital pH meter (TPS WP80Z) by inserting the electrode directly into the samples. The proximate composition (moisture, fat and protein) was determined using traditional methods (Ningtyas et al. 2019b). Moisture was determined by drying a 2 g sample at 105 °C for 24 h. Fat was quantified by the Gerber method, and protein was determined by the Kjeldahl method by multiplying the nitrogen content by a factor of 6.38. Physicochemical analysis was performed on triplicate samples.

Microbiological analysis

The viability of Lactobacillus plantarum Dad-13 and Lactobacillus plantarum Kita-3 was monitored during the fermentation process and storage at 4 °C for 35 days. Five grams of cream cheese was put into a sterile plastic seal, filled with 45 mL of 0.85% NaCl solution, and then crushed with a stomacher (Bagmixer 400, Model VW, Interscience). The solution was serially diluted to 10–8 with the same diluent. The total count of microorganisms with potential probiotics was performed using pour plates with 100 μL of inoculum on MRS agar (Oxoid, Basingstoke, UK). Colonies were counted after 48 h at 37 °C, and the obtained results were expressed as colony-forming units log per gram of cream cheese (log CFU/g).

Volatile compound detection by SPME GC/MS

The volatile compounds in cream cheese were measured using solid phase microextraction gas chromatography (SPME-GC/MS). The method was adopted from Ningtyas et al. (2019a) with modification. Two grams of cream cheese sample were weighed, placed in a 22 mL glass vial and sealed with a septum and aluminum cap. The flavor compound extraction was performed by automated injection of a 50/30 μm vivinylbenzene/carboxene/polydimethylsiloxane SPME fiber (Supelco, Bellefonte, PA, USA) into the vial and exposing it to the headspace at 60 °C for 40 min. After extraction, the SPME fiber was automatically inserted into the GC injection port and desorbed at 250 °C for 1.5 min. The separation was performed using a DB-WAX capillary column (30 m × 250 μm × 0.25 μm) (Phenomenex, Torrance, CA, USA) and helium as the carrier gas at a flow rate of 0.8 mL/min. The following temperature program was used: 8 min at 40 °C, followed by an increase at 4 °C/min to 160 °C, then by an increase to 240 °C at a rate of 7 °C/min; the final temperature was maintained for 5 min. The mass spectrometer (MS) was operated in electron impact mode with a source temperature of 230 °C, a capillary interface at 280 °C, an ionization voltage at 70 eV and a scan mass range of m/z 29-550. Identification of the compounds was based on the comparison of their mass spectra with the spectra from the National Institute of Standards and Technology (NIST) 14 library. The internal standard used in this study was 3-heptanone (Sigma‒Aldrich). The relative percentage of the compounds was calculated by peak area normalization.

Sensory evaluation

All resulting cream cheese products were subjected to a hedonic test based on the method previously reported by Utami et al. (2020). The hedonic test was performed with 45 untrained panelists who were asked to evaluate sensory characteristics including appearance, texture, odor, taste and overall liking. In the overall liking, a 7-point hedonic scale ranging from 1 “extremely dislike” to 7 for “extremely like” was used.

Statistical analysis

The experiments were performed in triplicate. The obtained results are presented as the means ± standard deviations. One-way ANOVA followed by Duncan's multiple range test with a significance level of p < 0.05 was performed using SPSS software (version 17.0, SPSS Inc., Chicago, IL). The relationship between variables was assessed using principal component analysis (PCA). PCA was performed using XLStat (Addinsoft, New York, MA, USA). Loading plots were also created to visualize the relationship among variables with the peak area of volatile compounds (GC‒MS). Correlations between the microbiological, chemical composition and volatile compound with sensory characteristics were determined using Pearson’s test for correlation.

Results and discussion

During cheese processing, various chemical and biochemical reactions co-occur, such as glycolysis, lipolysis, and proteolysis, followed by fatty acid and amino acid metabolism, which play an essential role in the production flavor of cream cheese. The type of starter culture in cheese making may affect the volatile compounds of cheese produced. Therefore, this study aimed to evaluate probiotic strains L. plantarum Dad-13 and L. plantarum Kita-3 as a single starter culture in cream cheese production and their effect on the chemical properties, viability of probiotics during fermentation and storage, volatile compounds of cream cheese and sensory properties.

Viability of the cells during fermentation and storage

The type of starter culture affected the growth rate of bacteria during fermentation (Fig. 1). Figure 1 shows that the number of LAB reached 7.19, 8.67 and 8.73 for a mixed culture, L. plantarum Dad-13 and L. plantarum Kita-3, at the end of fermentation. This implied that a single culture could meet the requirements for probiotic cream cheese. The growth rate of the mixed culture was higher than that of the single culture during cream cheese fermentation. This could be because the mixed culture has a symbiotic relationship among the different species, which shortens the lag phase (Park et al. 2017). Another reason could be that the fermentation temperature is more favorable for the mixed culture than for the single culture. In this study, the temperature was set to 27–30 °C, while the optimum growth temperature of L. plantarum Dad-13 was 37 °C (Wardani et al. 2017).

The viability of LAB in cream cheese with different starter cultures during storage at 4 °C for 35 days is shown in Table 1. The number of living cells decreased below 7 log CFU/g at the end of storage for the cream cheese made using a mixed culture. On the other hand, the number of living cells for the cream cheese made using L. plantarum Dad-13 and L. plantarum Kita-3 remained high (above 8 log CFU/g) after 35 days of storage. This indicated that the cream cheese made using a single culture has the potential to be developed as probiotic cream cheese because the number of living cells was above the threshold value to confer probiotic benefits. The number of living cells slightly increased at the beginning of fermentation and decreased after two weeks. This revealed that both L. plantarum Dad-13 and L. plantarum Kita-3 were able to grow under psychrophilic conditions.

Proximate of cream cheese

The proximate analysis of cream cheese produced with mixed and single cultures is presented in Table 2. In general, the obtained results showed that the proximate values of cream cheese made using a single and mixed cultures were similar. This indicated that the type of culture did not affect the proximate composition. During fermentation, lactose is metabolized into lactic acid, which acidifies the products. The moisture content of cream cheese using a mixed culture was higher than that of the single culture. One explanation could be the slower acidification in single culture fermentation, which prolongs the coagulation process. The milk starts to coagulate at pH 5.3–5.5 (Corredig and Salvatore 2016). The long coagulation process increased syneresis so that the water content decreased (Rani et al. 2012). Syneresis occurs because the bonds between casein form a strong curd, which causes a large amount of water to be pulled out into whey. The water content of cream cheese in this study is in compliance with United States Department of Agriculture (USDA) requirements, which specify that cream cheese must have a maximum moisture level of 55%.

The use of mixed cultures in cream cheese production resulted in higher fat content compared with that in cream cheese produced using single cultures. The high fat content of cream cheese with mixed cultures may be associated with shorter coagulation. During fermentation, LAB degrade lactose to glucose and galactose, which are then converted into lactic acid. Lactic acid decreases the pH until it reaches 4.7 and causes curd formation. The decrease in pH using mixed and single cultures is presented in Fig. 1. The milk reached pH for coagulation at 10, 18 and 20 h for a mixed culture, L. plantarum Dad-13 and L. plantarum Kita-3. The faster is the coagulation process, the more fat globules are trapped in the solid curd. The fat content resulting from this study met the standard fat content of cream cheese, which is a minimum of 33% (Phadungath, 2005). In addition, Brighenti et al. (2018) also reported that the fat content of cream cheese produced was 33.59% and 33.68%. This result implied that cream cheese made using a single culture had the potential to make probiotic cream cheese.

Figure 1 shows that cream cheese made using a mixed culture required a shorter time (10 h) to reach the targeted pH of 4.7 than that made using a single culture (18–20 h). This becomes the reason for terminating the fermentation at 10 h. This may be due to the different types of LAB. A mixed culture contained Lactococcus lactis subsp. cremoris, Leuconostoc mesenteroides subsp. cremoris, Lactococcus lactis subsp. lactis, and Lactococcus lactis subsp. lactis biovar diacetylactis. Mixed culture has the advantage that 90% of the bacteria present in the mixed culture play a role in the acidification process, while the other 10% play a role in flavor formation; thus, it can lower pH more quickly than single cultures or single strains (Park et al. 2017). In addition, Lactocucus lactis quickly metabolizes lactose into lactic acid, even though it is added at lower amounts during milk fermentation. Gutsal et al. (2018) reported that the addition of 0.02% (v/v) commercial starter culture was able to reduce the pH from 6.5 to 5.8 in approximately 4 h, whereas it took more than 18 h for cream cheese made using a single culture, according to Utami et al. (2016).

Volatile compound of cream cheese made from mixed and single cultures

Volatile compounds influence the final quality of cream cheese and its acceptance during consumption. A total of thirty-six major volatile compounds were identified in cream cheese made from mixed and single cultures. The volatile compounds of cream cheese made using mixed and single cultures are represented in Table 3.

Previous studies have reported that the main aroma-active compounds in cheese are diacetyl and acetoin (Phadungath 2005; Ningtyas et al. 2019a). Diacetyl and acetoin are ketone compounds that contribute to consumer perceptions of cream cheese, especially the aroma of butter in cheese (Clark and Winter 2015). These compounds are mainly derived from the metabolism of lactose and lactic acid by the starter culture Lactobacillus or by the enzymatic oxidation of fatty acids. In this study, the use of the probiotics L. plantarum Dad-13 and L. plantarum Kita-3 as single starter cultures produced higher amounts of diacetyl and acetoin than mixed cultures. These results are similar to the results of Ningtyas et al. (2019a), who showed that using the probiotic L. rhamnosus significantly increased the amount of diacetyl. According to Corsetti et al. (2022), L. plantarum species can produce various secondary end products, such as diacetyl, acetoin, and 2,3-butanediol, through glucose and citrate metabolism via a-acetolactate. These findings indicate the potential of L. plantarum Dad-13 and L. plantarum Kita-3 as single cultures for use in cream cheese production.

One of the most important volatile compounds responsible for aromatic cheese characteristics is esters and lactones. In general, esters are most desirable among volatiles because they have low threshold values, conferring an important impact even at low concentrations. At the same time, they usually provide floral or fruity notes, which smoothens other undesirable odors (Ningtyas et al. 2019a). In this study, ethyl hexanoate, pentyl pentanoate, propyl hexanoate, and ethyl 2-hexanoate were identified in cream cheese samples with the starter culture of L. plantarum Kita-3, which are known for their fruity notes such as pineapple, banana, melon, and apricot. However, cream cheese produced with mixed culture and L. plantarum Dad-13 produced low levels of heptil acetate and ethyl octanoate compounds. Ethyl octanoate is known to impart a pleasant, fruity, floral, fresh, or even sweet essence in cheese products. In cream cheese produced with mixed culture, fewer ester compounds were produced because the microorganism Lactococcus lactis only had one enzyme with esterase activity (Fernadez et al. 2000). Apart from their fruity contribution, esters are also considered essential compounds because of their ability to reduce the effect of compounds with unpleasant aromas, such as short-chain FAs and phenolic compounds. Lactones are known to have a similar impact on esters because they also have very low threshold values and are characterized by fruity, creamy, and buttery attributes. In general, cream cheeses produced by the probiotic L. plantarum Dad-13 and L. plantarum Kita-3 as single cultures were reported to be most abundant regarding lactone formation. Based on these results, the probiotic starter culture L. plantarum Kita-3 can provide a cheese product enhanced with a sweet floral or fruity aroma with a smoother texture and unique taste.

Nine fatty acids were identified at varying levels in all the cream cheese samples. The highest volatile fatty acid content was observed in cream cheese with L. plantarum Dad-13 and L. plantarum Kita-3. The dominant compounds were decanoic and hexanoic acids. The different volatile compound profiles are associated with different lipolytic activities and amino acid breakdowns, which are essential for flavor formation in cheese (Delgado et al. 2010). Alcohols are another important aroma in cheese. Several different metabolic pathways to produce alcohols include lactose and amino acid metabolism as well as fatty acid degradation (Delgado et al. 2010). In this study, 3-methyl-1-butanol was detected in all cream cheese samples, with the highest concentration obtained in cream cheese using L. plantarum Dad-13. This compound gives a floral aroma. In particular, 3-methyl 1-butanol is considered responsible for the faint odor of bovine Mozzarella, and it imparts a pleasant aroma to fresh cheese (Jia et al., 2021).

Sensory properties of cream cheese made using different cultures

The obtained results of the sensory properties are presented in Table 4. The obtained results showed that the appearance of the samples was similar. Meanwhile, for texture and spreadability, cream cheese produced with mixed culture was more preferable compared to those produced using single cultures. This may be due to the higher moisture content of the cream cheese produced using mixed culture. The higher is the moisture content of the cream cheese, the softer is the texture of the cream cheese and the greater is the spreadability (Li et al. 2013). On the other hand, with regard to aroma and taste, cream cheese made using a single culture of L. plantarum Kita-3 obtained the highest score compared to those made using mixed culture and L. plantarum Dad-13 starter. This is attributed to the presence of high levels of acetoin and diacetyl compounds in cream cheese using L. plantarum Kita-3 (Table 3), which are responsible for butter aroma and taste. In terms of overall liking, cream cheese made using a single culture of L. plantarum Kita-3 obtained the highest score among the samples. This may be due to the ability of this strain to produce more ester and lactone compounds that contribute to a floral or fruity aroma, which masks other undesirable odors. Based on the sensory test, the obtained results indicate that L. plantarum Dad-13 and L. plantarum Kita-3 have the potential to be further developed to become industrial starter cultures.

Principal component analysis (PCA)

A principal component analysis was performed to assess the correlations between the type of starter and the volatile compounds of the cream cheese. Two components were extracted from the PCA results, which accounted for 100% of the variability in the original data (Fig. 2). The obtained results showed that the different types of strains produced different volatile profiles. The volatile profiles of cream cheese made using mixed culture are dominated by acetic acid and pentanol acid, whereas the key flavors of cream cheese made with L. plantarum Dad-13 are δ-decalactone, 2-heptanone and δ-octalactone. Meanwhile, L. plantarum Kita-3 has many volatile compounds, including acid compounds, alcohols, ketones and ester compounds, which are dominated by ketone and ester compounds, especially propyl hexanoate, pentyl pentanoate, heptyl acetate, and 2-hexanone. The most preferred cream cheese flavors are dominated by ester and ketone compounds (Ningtyas et al., 2019a). This may be the reason why cream cheese made using L. plantarum Kita-3 achieved the highest overall liking score in the hedonic test.

Correlation between chemical properties and sensory characteristics of cream cheese

This study investigated the correlation between chemical properties and different sensory attributes using Pearson’s correlation to determine the most important factors contributing to the overall liking of the samples. The obtained results showed that the overall liking had a strong correlation with ethyl octanoate (0.997) and methyl butanol (0.989) content. Ethyl octanoate is known to impart a pleasant, fruity, floral, fresh and sweet aroma. Meanwhile, methyl butanol contributes to fresh aroma. Other chemical and sensory correlations were obtained from fat and moisture content with texture (0.99) and spreadability (0.99) of cream cheese. In addition, the taste of cream cheese had a strong correlation with different volatile compounds including pentanoic acid (0.995), methyl butanole (0.994), 2-hexanone (0.997), 2-octanone (0.998), heptyl acetate (0.994), ethyl hexanoate (0.998), propyl pentanoate (0.998), -octalactone (0.998) and -caprolactone (0.998).

Conclusion

This study successfully produced probiotic cream cheese that complied with the United States Department of Agriculture’s standard for cream cheese. The sensory characteristics of cream cheese made using a single culture of L. plantarum Kita-3 are preferred by the panelists. There was a strong correlation between ethyl octanoate and methyl butanol with the overall liking. The use of a single culture may improve not only the viability of the cells but also the sensory properties, particularly the taste and aroma, of the cream cheese. The use of a single culture may reduce the complexity of the inoculum development process compared to a mixed culture in industrial applications. The findings of this study indicate that chemical analysis, i.e., ethyl octanoate and methyl butanol, can be used to predict the overall likeness of the cream cheese.

Availability of data and materials

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

Abbreviations

- LAB:

-

Lactic acid bacteria

- GRAS:

-

Generally recognized as safe

References

Adnan ML, Pramaningtyas MD (2020) Probiotics as promising immunomodulatory agents to prevent COVID-19 Infection : a narrative review. Int J Med Stud 8(2):121–125. https://doi.org/10.5195/ijms/2020.486

Brighenti M, Jaeggi JJ, Johnson ME, Lucey JA (2018) Effects of processing conditions on the texture and rheological properties of model acid gels and cream cheese. J Dairy Sci 101(8):6762–6775. https://doi.org/10.3168/jds.2018-14391

Clark S, Winter CK (2015) Diacetyl in foods: a review of safety and sensory characteristics. Compr Rev Food Sci Food Saf 14(5):634–643. https://doi.org/10.1111/1541-4337.12150

Corredig M, Salvatore E (2016) Enzymatic coagulation of milk. Adv Dairy Chem, 287–307M. https://doi.org/10.1007/978-1-4939-2800-2

Corsetti A, Ciarrocchi A, Prete R (2022) Lactic Acid Bacteria: Lactobacillus plantarum. Ref Module Food Sci. https://doi.org/10.1016/b978-0-08-100596-5.00856-8

Delgado FJ, González-crespo J, Cava R, García-Parra J, Ramírez R (2010) Characterisation by SPME-GC-MS of the volatile profile of a Spanish soft. Food Chem 118(1):182–189. https://doi.org/10.1016/j.foodchem.2009.04.081

FAO/WHO (2002) Guidelines for the evaluation of probiotics in food

Fernadez L, Beerthuyzen MM, Brown J, Siezen RJ (2000) Cloning, characterization, controlled overexpression, and inactivation of the major tributyrin esterase gene of Lactococcus lactis. Appl Environ Microbiol 66(4):1360–1368. https://doi.org/10.1128/AEM.66.4.1360-1368.2000

Gutsal V, Sieuwerts S, Bibiloni R (2018) High-throughput pH monitoring method for application in dairy fermentations. J Dairy Res 365(20):1–7. https://doi.org/10.1017/S0022029918000717

Jia R, Zhang F, Song Y, Lou Y, Zhao A, Liu Y, Peng H, Hui Y, Ren R, Wang B (2021) Physicochemical and textural characteristics and volatile compounds of semihard goat cheese as affected by starter cultures. J Dairy Sci 104(1):270–280. https://doi.org/10.3168/jds.2020-18884

Kanauchi O, Andoh A, Abubakar S, Yamamoto N (2018) Probiotics and paraprobiotics in viral infection: clinical application and effects on the innate and acquired immune systems. Curr Pharm Des 24:710–717. https://doi.org/10.2174/1381612824666180116163411

Li Q, Xia Y, Zhou L, Xie J (2013) Food and bioproducts processing evaluation of the rheological, textural, microstructural and sensory properties of soy cheese spreads. Food Bioprod Process 91(4):429–439. https://doi.org/10.1016/j.fbp.2013.03.001

Meidistria TR, Sembiring L, Rahayu ES, Haedar N, Dwyana Z (2020) Survival of Lactobacillus plantarum dad 13 in probiotic cheese making. IOP Conf Ser: Earth Environ Sci 575(1). https://doi.org/10.1088/1755-1315/575/1/012020

Mikkelsen P (2020) World cheese production. In: New World Cheese Market Report 2000–2020

Mukhtar H, Yaqub S, Haq I (2020) Production of probiotic mozzarella cheese by incorporating locally isolated Lactobacillus Acidophilus. Ann Microbiol 5:70–56. https://doi.org/10.1186/s13213-020-01592-7

Mushtaq M, Gani A, Masoodi FA (2019) Himalayan cheese (Kalari/Kradi) fermented with different probiotic strains: in vitro investigation of nutraceutical properties. Lwt 104(January):53–60. https://doi.org/10.1016/j.lwt.2019.01.024

Ningtyas DW, Bhandari B, Bansal N, Prakash S (2019a) Flavour profiles of functional reduced-fat cream cheese : effects of β -glucan, phytosterols , and probiotic L. rhamnosus. LWT - Food Sci Technol, 105(January):16–22. https://doi.org/10.1016/j.lwt.2019.01.063

Ningtyas DW, Bhandari B, Bansal N, Prakash S (2019b) The viability of probiotic Lactobacillus rhamnosus (non-encapsulated and encapsulated) in functional reduced-fat cream cheese and its textural properties during storage. Food Control 100(November 2018):8–16. https://doi.org/10.1016/j.foodcont.2018.12.048

Park S, Yoo M, Paik H, Lim S (2017) Production of benzoic acid as a natural compound in fermented skim milk using commercial cheese starter. J Dairy Sci 100(6):4269–4275. https://doi.org/10.3168/jds.2016-12399

Phadungath C (2005) Cream cheese products: a review. J Sci Technol 1:191–199

Rahayu ES, Yogeswara A, Windiarti L, Utami T, Watanabe K (2016) Molecular characteristics of indigenous probiotic strains from Indonesia. Int J Probiotics Prebiotics 11(2):109–116

Rani R, Unnikrishnan VNC, Singh B (2012) Factors affecting syneresis in yoghurt : a review. Indian J Dairy Biosci, 23

Sumaryati BT, Utami T, Suparmo S (2009) PENGARUH INFEKSI Escherichia coli DAN PEMBERIAN Lactobacillus plantarum Dad 13 TERHADAP MIKROBIOTA FESES TIKUS WISTAR. AgriTECH 29(4):165–170

Tologana RD (2022) Probiotik Lokal sebagai Starter pada Pembuatan Keju Krim. Tesis. Universitas Gadjah Mada, Yogyakarta

Utami T, Cindarbhumi A, Khuangga MC, Rahayu ES, Cahyanto MN (2020) Preparation of indigenous lactic acid bacteria starter cultures for large scale production of fermented milk. Digital Press Life Sciences

Utami T, Harmayani E, Rahayu ES (2016) Survival of Lactobacillus plantarum Dad 13 during spray drying and its application for Yoghurt Fermentation. Int Res J Biol Sci 5(2):16–22

Utami T, Kusuma EN, Satiti R, Rahayu ES, Cahyanto M (2019) Hydrolyses of meat and soybean proteins using crude bromelain to produce halal peptone as a complex nitrogen source for the growth of lactic acid bacteria. Int Food Res J 26(1):117–122

Wang Ji, Fang X, Tong Wu, Min W, Yang Z (2018) Exopolysaccharide producing lactobacillus plantarum SKT109 as adjunct culture in Cheddar cheese production. Lwt 97(11):419–426. https://doi.org/10.1016/j.lwt.2018.07.011

Wardani S, Cahyanto M, Rahayu E, Utami T (2017) The effect of inoculum size and incubation temperature on cell growth, acid production and curd formation during milk fermentation by Lactobacillus plantarum Dad 13. Int Food Res J 24(3):921–926

Wilkinson MG, Lapointe G (2020) Invited review: Starter lactic acid bacteria survival in cheese: new perspectives on cheese microbiology. J Dairy Sci 103(12):10963–10985. https://doi.org/10.3168/jds.2020-18960

Funding

This research was funded by The Ministry of Research and Technology/National Agency for Research and Innovation of the Republic of Indonesia (RISTEK-BRIN). Trough The Higher Education of Research and Development research scheme (PPUPT) with contract number 2164/UN1/DITLIT/DIT-LIT/PT/2021 as well as Center of Excellence for Research and Application on Integrated Probiotic Industry, Universitas Gadjah Mada with contract number 1256/E3/PKS.04/KL/2021 and 1078/UN1.P.III/DIT-LIT/PT/2021.

Author information

Authors and Affiliations

Contributions

RDT, ESR, TU designed the study. RD carried out the laboratory work. RD, DA, ESR, TU, RW analyzed the data. RD, RW wrote the manuscript. All authors read and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to research, authorship, and/or publication of this article.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Ethics approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tologana, R.D., Wikandari, R., Rahayu, E.S. et al. Correlation between the chemical, microbiological and sensory characteristics of cream cheese using a mixed and single probiotic culture. J Food Sci Technol 60, 181–189 (2023). https://doi.org/10.1007/s13197-022-05603-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05603-0