Abstract

Oil has extensively been extracted from oil-bearing crops and traded globally as a major food commodity. There is always a huge demand from the fats and oils industries to increase oil yield because of profitability benefits. If extraction is conducted under mild operating conditions to preserve and improve the oil quality, then it would be an added value. Ultrasound that works on the cavitational action helps to fulfil the gap. Ultrasound is gaining tremendous interest as an alternative to replace the current conventional extractions approach because of its multiple benefits. Cavitation generated by ultrasound eases the release of oil from cell matrices, thereby allowing the extraction to be carried out under mild processing conditions. The effect enhances the oil yield whilst preserving the quality of the oil. In ultrasound, green solvents can be used to replace toxic organic solvents. Recent up-to-date approaches utilised a combination of ultrasound with enzyme, microwave and supercritical technology to further enhance the oil extraction. This review highlights a comprehensive work of the impact of ultrasound and ultrasound in combination with other technologies on oil extraction, which emphasises the extraction yield and physicochemical properties of the oil, such as fatty acid composition, oxidative stability with the retention of the lipophilic phytochemicals and iodine, saponification values and colour parameters. Understanding of ultrasonication techniques for oil extraction served to be essential and useful information for the fats and oils scientists from academia and industries to explore the possibility of employing a sustainable and mild approaches for extracting oil from various crops.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Presently, several crops, including seeds of vegetables, fruits, flowers and oil seeds, are extensively grown to extract its oil that can be used for edible purposes as food ingredients. According to the United States Department of Agriculture (2021), global oilseed production in 2020/2021 stands at 600 million tons. Seed oils are used widely in different food applications such as cooking or salad oils and confectionery fats. In cases where the extracted oil is rich in essential fatty acids like omega 3, 6 and any phytochemicals, it will be a competitive advantage and profitable to the industries as they can be used as nutraceuticals and sold at a higher price (Putnik et al. 2018).

Until recently, extraction of oil from oilseeds was performed using conventional methods via solvent, steam distillation or mechanical pressing. Of these extraction techniques, solvent extraction techniques are highly dependent on the diffusion of solvent to the plant cell wall (Rodrigues and Fernande 2017). In fact, it is technically and scientifically challenging to handle. Solvent extractions require massive consumption of non-environmental friendly and toxic organic solvents that lead to waste generation. It is also complex and requires long operating hours to operate, which is energy-intensive. Furthermore, extra purification steps are needed to remove the solvent and purify the final product to ensure it is safe for consumption. More intently, the prolonged operating conditions may degrade some of the lipophilic bioactive compounds or unsaturated fatty acid in oil, negatively affecting the quality of the extracted oil. Thus, the shortcomings of existing classical separation methods have forced the industries to search for green extraction techniques that can reduce energy consumption and wastes as well as to replace organic solvents with alternative green solvents whilst improving the yield and quality of the oil (Putnik et al. 2018).

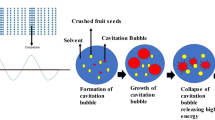

One such green technique that is becoming popular in the industries today is ultrasound assisted extraction (UAE). Ultrasound application works on the principle of cavitation or oscillation phenomenon via either using ultrasound probe or ultrasound bath that operates at 20 kHz and 40 kHz frequencies, respectively (Fig. 1). Ultrasonic waves generate vibrations that can create voids that transfer energy to solid particles immersed in the extraction. In addition, cavitation bubbles grow closer to the solid surface and collapse at a higher amplitude forcing the cell wall to rupture, further accelerating the transfer of desired compounds trapped inside into the solvent medium (Senrayan and Venkatachalam 2019). Chemat et al (2017) described in detail the effect generates through independent or combined mechanisms in between fragmentation, erosion, sono-capillarity, sonoporation, shear forces, and detexturation. Cavitation created by ultrasound outperformed conventional extraction approaches (Senrayan and Venkatachalam 2020).

Schematic diagrams of ultrasound extraction methods, ultrasonic bath where transducers are fixed A vertically B horizontally and, C ultrasonic probe. The ultrasonic probe is directly immersed in the sample and solvent mixture while samples are immersed in a steel tank equipped with one or more transducers in the ultrasound bath, resulting in lesser intensity. The intensity given by the probe tip is relatively high due to the small surface area, and probe diameter, length, and shape of the tip directly influence the extraction. Generally, the probe system is preferable over the bath in the extraction industry due to its high efficiency. Either way, ultrasound can be combined with enzymatic, microwave, and supercritical extractions to improve its productivity

In fats and oils application, ultrasound technology has been employed to extract oil from oilseeds and other promising crops. It was shown to be able to increase oil extraction yield as well as promote the extraction of phytochemicals (Jalili et al. 2018; Rojo-Gutiérrez et al. 2021; Senrayan and Venkatachalam 2019, 2020; Stevanato and Silva 2019). UAE offers several benefits as compared to the conventional methods. It requires a simple and easy instrumental setup. UAE is also environmentally friendly and economically feasible to be adopted. It requires less amount of solvent for the extraction, low energy throughput, and is highly efficient in extracting oil (Rodrigues and Fernandes 2017). More importantly, the mild operational conditions enable retention of minor lipophilic compounds such as phytochemicals, thus, adding value to the oil besides improving its stability. With its mild operating conditions, UAE can also help to prevent the deterioration of the oil. In a more advanced situation, ultrasound can be combined with other technologies like microwave, enzymatic and supercritical fluid extractions to be used directly in the process or could be used as a pre-treatment process. These hybrid techniques are useful in increasing the extraction efficiency of oil (Hu et al. 2020; Goula et al. 2018; Liu et al. 2020).

Looking at the several advantages offered by the ultrasound technology, it is important to understand the use of ultrasound for oil extraction purposes that outperforms other conventional extraction methods. Thus, this review aims to provide a comprehensive insight into the potential of adopting ultrasound application along with ultrasound assisted technologies and oil quality compared to other traditional extraction techniques in major oil seeds and some other promising crops. Therefore, this review is useful to harness the knowledge of UAE applied for oilseed extraction to address the current limitations of traditional extraction approaches used in the fats and oils industries.

The effect of ultrasound assisted extraction on the oil yield

Multiple studies have been conducted on using UAE for seed oil extraction. Table 1 shows the optimum UAE conditions for the extraction of different types of seed oil such as canola, commonly used vegetables, fruits and flower seed oils with oil yield ranging from 8 to 83% (Table 1).

Mechanism of the ultrasound for oil extraction could be influenced by parameters such as extraction time, temperature, sample to solvent ratio, ultrasound power, and type of the solvent. A table to summarise the influence of these parameters is tabulated in Table 2. Apparently, each parameter is cumulatively affecting the ultrasound where it acts positively to increase oil yield and seldom negatively. In addition, literature profoundly emphasizes a considerable extent for each parameter where prolonged action is undesirable on cavitation.

A recent study by Senrayan and Venkatachalam (2020) compared UAE with traditional solvent extraction (SE) in an orbital shaker and Soxhlet extraction (SXE) for the extraction Kapok seed oil. The study revealed a 92.29% of oil recovery within 10 min using UAE, which is significantly shorter than SE and SXE that required 5.7 h and 8 h, respectively. The energy consumption by UAE is 80 fold lower than SXE and 50 fold less than SE. A yield of 70.93% of castor oil within a 9 min of extraction time using a solvent containing mixture of isopropanol: methanol (1:3 w/w) was reported by Naveenkumar and Baskar (2019). Similarly, around 27.02% of safflower seed oil was extracted using UAE whilst, classical method resulted in 25% yield. Despite the almost similar oil yield obtained, UAE was conducted under mild condition of 35 °C and liquid–solid ratio of 5/1 (w/w) within 30 min whereas the traditional approach was performed under elevated conditions of 50 °C and liquid–solid ratio of 6/1 (w/w) for 60 min (Hu et al. 2012). Also, Moringa Oleifera seed oil extracted with UAE showed comparable yield as SE which is around 35.78 and 35.26%, respectively. However, extraction time of UAE was 20 min while conventional approach spent around 50 min (Zhong et al. 2018). Contradictorily, oil extraction of cactus pear seeds favoured the soxhelt extraction with a yield of 9.3–9.5% whilst UAE acquired only 5.4–5.6% (Loizzo et al. 2019). However, a majority of studies clearly verify that UAE is able to increase the oil yield using a considerably shorter extraction time, milder conditions and lower energy consumption than conventional oil extraction method.

The effect of ultrasound assisted enzymatic extraction (UAEE) on the oil yield

Enzymatic extraction is combined with ultrasound extraction in UAEE. Enzymatic extraction is manifested by mechanical crushing, and use enzymes to degrade complexes composed of lipoproteins, lipopolysaccharides, and cell wall to release oil. Non-oil components separated from complex partition into the extractant and oil forms another phase (Song et al. 2019). Since enzymes need more time to break cell wall and this time lapse can be overcome by ultrasound. Thus, it can be seen that enzymes in the medium act to soften and promote the degradation of seed tissues which enhances the solvent permeability. Ultrasonic waves create bubble cavitation, and altogether, enzymes and ultrasound work to improve the oil extractability.

The operating and optimized conditions of UAEE of different types of seeds are illustrated in the Table 3. Typically, the ultrasound probe is immersed in the solvent bath containing enzymes (cellulase, pectinase and hemicellulase) and oilseeds. Also, mixture of enzymes is more effective than using them individually. In this regard, UAEE was employed for extraction of pomegranate seed oil (Goula et al. 2018), date seed oil (Amigh and Dinani 2020), and pine kernel oil (Chen et al. 2016). Significantly, Goula et al. (2018) emphasised the positive impact of the ultrasonication in aiding the enzymatic oil recovery. The study revealed that ultrasound increased the enzymatic extraction of pomegranate seed oil by 18.4% and decreased the extraction time by 91.7%. Furthermore, with the aid of ultrasound, the enzyme–substrate interaction was improved mainly because of the demolishment of the tissues created by ultrasound that increased in the mass transfer of solvent-enzyme into the cellular structure and the elevated contact surface area between the tissue’s enzyme-aqueous solution and the seed powder. In addition, Amigh and Dinani (2020) highlight that besides the effect of ultrasound, having a cooking process of seed powder before extraction could enhance the extraction yield.

Apart from that, UAEE can also be performed by incubating seed powder with an enzyme and subsequently submerging the mixture in the ultrasonic bath. Although the ultrasound is applied indirectly, the physical effect of ultrasonic waves effectively enhances enzyme–substrate reaction. Following that, oil extracted from Sapindus mukorossi seed kernel oil could reach up to 82.67% in the enzyme mixture of neutral protease, cellulase and pectinase (Liu et al. 2019). However, the long incubation time needed for enzymes to react with seed powder which may take around 8–12 h, is the major drawback of this method.

Alternatively, ultrasound was used as a pretreatment prior to applying the enzymatic hydrolysis method for the extraction of peanut, perilla seeds, and walnut oil (Haji Heidari and Taghian Dinani 2018; Li et al. 2014; Zahra et al. 2018). Pretreatment works to disrupt the cell wall of the solid matrix and to reach the oil bodies before enzymatic extraction. Usually, ultrasound pretreatment time ranges from 30 to 50 min. Subsequent enzymatic extraction can extend up until 120 min. Nevertheless, the duration of extraction time is still far lesser than the extraction time used in convectional enzymatic extraction.

In general, UAEE can be considered as a cost-effective and environmentally friendly approach for oil extraction. However, sufficient data is yet available to fairly compare all the types of UAEE.

The effect of ultrasound assisted supercritical extraction (UASE) on the oil yield

Supercritical fluid extraction (SFE) is a sophisticated method using supercritical fluid for oil extraction. The supercritical fluid is a specific liquid or gas formed as a homogeneous fluid when the temperature and pressure increased above the critical point. The demarcation surface between liquid and gas is disappeared under supercritical conditions and the infusibility, and the density of the fluid lies between gas and liquid. Therefore, a slight increase in pressure drastically improves the supercritical fluid's infusibility and solvating power, which result in high extractability (Salinas et al. 2020).

However, the extraction efficiency of SFE is always hindered by the low solubility of the oil in CO2 fluid because of deviation of the polarity. As a remedy, SFE can be assisted with ultrasound. Cavitation generated from ultrasound resulted in micro jetting of supercritical fluid into the cell wall matrix which enhances the penetration of CO2 fluid. The assistance of the ultrasound reduces the SFE operating parameters such as temperature, pressure, CO2 flow rate, and time. The operating and optimized conditions of UASE of different types of seeds are represented in Table 4. UASE performed on passion fruit seed oil produced an oil yield of 20.6% compared to SFE that only yields 12.3% at 40 °C of temperature and 16 MPa of pressure (Barrales et al. 2015). The authors suggest that a lower combination of pressure and temperature enables formation of CO2 gas bubbles inside the extracting bed under the ultrasound vibrations resulting in cavitation. Also, using ultrasound as a pretreatment for hemp seeds (Da. Porto et al. 2015) and Iberis amara seeds (Liu et al. 2020) have shown a similar effect in oil increment. The studies indicate that nearly 10 min of ultrasound pretreatment is sufficient rather than prolong treatment in order to get maximum oil yields. Noticeably, Dias et al (2019) followed ultrasonication of umbu seed powder after treating with SFE first and achieved the highest oil yield compared to SFE or ultrasound extraction alone. The authors assume that the breaking of non-polar materials like waxes and resins with subsequent matrix modification will lead to enhance the extraction. In as much as the ability of ultrasound to increase the yield while reducing the severity of operating parameters is significant, integrating ultrasound with other extractions is useful.

The effect of ultrasound assisted microwave extraction (UAME) on the oil yield

Microwave irradiation is an advanced technology used to enhance the extraction process. Microwaves are generated at a frequency range of 300 MHz to 300 GHz, and these electromagnetic radiations penetrate the oil bodies converting energy into heat. The resultant intra-cellular pressure causes the swelling of the cell and ruptures the cell wall as well as the lipoprotein membrane surrounded by the individual lipid body. Thus, the release of oil is depending upon the heating rate (Fouad et al. 2018).

As for UAME, the effect generated by microwaves is localised in plant cells and its driving force is combined with the acoustic cavitation produced by ultrasonic voids. The resulted larger surface area due to small particle size caused by the implosion of the cell wall helps to enhance the mass transfer rate and intraparticle diffusion, boosting the oil extractability. UAME showed a promising result in reducing energy consumption. A summarized data of operating and optimized conditions employed to extract different seed oils by ultrasound assisted microwave extraction is shown in Table 5.

UAME utilised 38 min whilst SE needed 6 h to extract a similar amount of tea seed (Camelia sinensis) oil (Hu et al. 2019a, b). Chen et al. (2020) developed a UMAE technique to extract 10.58% of green coffee bean oil. The study further demonstrated that elevation of temperature from 40 to 70 °C induces the emanation oil from coffee beans. Nevertheless, evidence on the break-down of constituents in the oil by microwave and ultrasound have been reported (Hosseini et al. 2015). The hybrid method studied by Quaisie et al. (2021) confirmed a higher oil yield of 64.15% and extraction efficiency of 92.16% for Allanblackia parvifora seed oil with a 33.33% reduction in extraction time over the conventional method. The synergetic effect of both technologies again ensured by Sánchez et al. (2019) as the yield of canola oil increased when seeds are pretreated with microwaves followed by ultrasound extraction. In another study, around 85.23% of tiger nut (Cyperus esculentus L.) oil was extracted using UAME in combination with aqueous enzymatic extraction using cellulase, pectinase and hemicellulose at dosage of 1/1/1, (w/w/w) (Hu et al. 2020).

The effect of ultrasound technology on fatty acid composition (FAC), oxidative stability and physiochemical properties of extracted oil

Apart from improving extraction yield, the quality of oil extracted remains a critical and utmost important parameter for the fats and oils industries regardless of any of the extraction processes being employed. Therefore, the extraction techniques that can preserve or improve oil quality will be of much preference. In this regard, the influence of ultrasound treatment on the quality of extracted oil was reviewed in this section which is mainly based on the evaluation on changes of the FAC and oxidative stability, which is indicated by the peroxide value (PV), p-anisidine (AV), acid value, Totox value (TV) and induction time. Oil with low acidity, PV (primary oxidation), AV (secondary oxidation) confer better oxidative and hydrolytic stability. In addition, other physiochemical properties such as iodine value, saponification value and colour parameters are also compared with convectional extraction.

In terms of FAC, the majority of the studies demonstrated that the UAE has slight effect on the fatty acid profile of the oil extracted (de Mello et al. 2017; Hernández-santos et al. 2016; Senrayan and Venkatachalam 2019; Sicaire et al. 2016). Interestingly, sunflower and kiwi seed oils extracted by UAE showed a significant increment in linolenic acid (ω-3) acid (Moradi et al. 2018; Cravotto et al. 2011).

On the other hand, pumpkin seed oil extracted from the UAE had a high oxidative stability with a low PV, AV and TV (Hernández-santos et al. 2016). Samaram et al (2014, 2015) and Zhang et al. (2019) confirmed the same finding on the high oxidative stability of papaya seed oil extracted from UAE. The promising results may be due to the mild conditions (lower temperature and shorter extraction time) used in UAE than conventional SE. In addition, it prevents the degradation of oil, particularly those with unsaturated fatty acid and deterioration of antioxidants, thereby protecting the oil from undergoing auto-oxidation. Also, the partial destruction of cell membrane promotes the release of more oil inherent bioactive compounds. Another rationale behind improving the oil stability may be due to the mechanical and thermal inactivation of oxidative enzymes such as peroxidase and lipase generated by ultrasound voids. A recent study by Stevanato and Silva (2019) demonstrated the longest oxidative induction time of 72.5 min for radish seed oil extracted by UAE, while classical extraction presented with the oxidative stability of only 27.5 min. Traditional means may have caused thermal degradation of oil due to an extended period of exposing the oil under elevated temperature. In contrast, Sicaire et al. (2016) stated that the UAE extracted rapeseed oil showed a slight increase in peroxide value (0.53 meq O2 / kg oil) and conjugated dienes. The authors further suggested performing the UAE under a modified inert atmosphere in the absence of oxygen or in the presence of argon to prevent oxidation of oil.

Ultrasound combined with other technologies also shows similar results. A study of pine kernel oil extracted via UAEE also reported similar FAC compared to SE except for a slight increment in acid value, but is still under the edible range (F. Chen et al. 2016). Additionally, slight differences in FAC were reported for kenaf seed oil when differentiating the type of solvent in the ethanol, hexane, and aqueous mediums for UAEE (Zhang et al. 2020). Similarly, the FAC of Cumbaru oil extracted using supercritical fluid in the presence or absence of ultrasound showed to have no significant difference (Dos Santos et al. 2016). Liu et al. (2020) found that Iberis amara seed oil extracted using ultrasound as a pretreatment for supercritical extraction had a better FAC profile with a slight increase in MUFA and a small decrease in SFA. The PV of oil extracted with enzymes in the presence and absence of ultrasound pre-treatment reported for peanuts did not vary significantly (Haji Heidari and Taghian Dinani 2018). Contradictorily, Zahra et al (2018) imply that ultrasound pretreatment increases the PV of walnut seed oil.

A comparison of iodine value, saponification value, acid value and colour parameters of different seed oils extracted based on ultrasound and ultrasound assisted other technologies are represented in Table 6. Regardless the ultrasound assisted extraction mechanism, iodine, saponification, and colour values are not influenced by the ultrasound treatment frequently. However, acid and peroxide values have been significantly affected as discussed above. Often, ultrasonication operated at mild conditions (summarized in Table 2) have resulted in lowering acidity and generation of peroxides compared to conventional methods conducted at elevated levels. From the authors point of view the influence of ultrasound on FAC, PV, AV, TV including other physiochemical parameters is more prominent when combined with other extraction technologies. This is merely because, when ultrasound voids are used along with another approach, the resulting force is more effective than used alone. However, more comparative research data is essential to confirm the effect.

The effect of ultrasound on the polyphenolic content of extracted oil

Ultrasound technology promotes the extraction of lipophilic antioxidants and pigments. Porto et al (2013) found that grape seed oil extracted using UAE under a nitrogen atmosphere had higher polyphenols, total tannins, total anthocyanins, cinnamic acids, flavanols and antioxidant activity. Again, ultrasound extracted pumpkin peel/seed oil has more antioxidants (tocopherols, phytosterols, and β-carotene) than SE (Bovo et al. 2019). The high polyphenolic compounds extracted was attributed by the acoustic cavitation where the mechanical effect of ultrasound increased the release of active compounds. In contrast, the antioxidant activity of Moringa oleifera seed oil extracted by ultrasound and conventional extraction methodologies did not show any appreciable differences (Zhong et al. 2018). Also, when grape seed powder is treated with ultrasound twice, the total polyphenol content of the oil decreases (Porto et al. 2013). It was suggested that the double ultrasound treatment for UAE is not desirable for recovery of phenolic compounds as prolonged application may reason for the degradation of active compounds. Similarly, virgin olive oil extracted under sonication demonstrated an increment of tocopherols by 60%, carotenoids and chlorophylls by 30% whilst the total polyphenols decreased by 30% for Coratina type of olive (Clodoveo et al. 2013). The authors assumed that the polyphenols decrement can be ascribed by activity of enzymes like peroxidase that is still preserved during the sonication time in Coratina type of olive. This is because ultrasound waves can influence both enzyme activation and inactivation during the extraction process. Suggesting the same behaviour, due to the effect of ultrasound, grape seed oil shows a higher phenolic compound content and antioxidant capacity by the free radical method, but a lower ability to scavenge DPPH radical than the control (Böger et al. 2018). Conversely, the milder processing parameters of UAE, together with a controlled atmosphere are favourable to enhance the extraction of bioactive compounds in the extracted oil.

Moreover, high contents of total tocopherol (830.51 mg/kg), carotenoids (57.06 mg/kg), phenols (104.22 mg GAE/kg), sterols (1.77 g/kg) and Trolox equivalent antioxidant capacity (1.38 µmol Trolox/g) were obtained when ultrasound is employed for supercritical fluid extraction of Iberis amara seed oil (Liu et al. 2020). Further, microwave extraction assisted with ultrasound promotes the extraction of carotenoids and chlorophyll to produce a phenolic rich olive oil (Tamborrino et al. 2019). Interestingly, H. Li et al (2017) revealed that the best antioxidant capacity for perilla seed oil using UAEE compared to SE, occupying 615.25 and 410.5 mg GAE/kg of total phenols, respectively.

Industrial potential and future trends

The application of ultrasonication on an industrial scale is currently restricted due to the need of large capital to install high power/amplitude units. Lack of technical know-how immensely impacts small and medium scale oil industries. Even though many studies have been conducted on the laboratory scale, the findings disclose via pilot plants to scale up are limited. Despite these challenges, ultrasound outperforms the existing conventional methods in the industry. For instance, the organic solvents used in soxhlet extractors can be replaced with green solvents, where in cases when the green solvents are used in conventional approach that it may resulted in low oil yield. However, to work ultrasound properly, seeds have to be ground into a smaller size, where at an industrial scale, it would be disadvantageous due to additional processing steps. Nevertheless, refining the extracted oil is a significant process conducted in the oil industry to meet the desired quality parameters. However, there is considerable time and energy consumption behind this complex treatment. Advances of ultrasound suggest that impurities of the extracted oil can be minimized based on the reduction of pigments and colour parameters in the extracted oil (Samaram et al. 2014; Hosseini et al. 2015). More research is essential to link refining of oil with UAE where there is no reported data. As the oil industry is always looking forward to advanced extraction techniques with high efficiency, low cost, fewer impurities, and sustainable development, UAE for edible oil is a better solution. As the newest trend, ultrasound coupled with both microwave and enzymatic aqueous extraction of cherry and tiger nut seed oil has given oil recovery greater than 80% with superior oil quality than soxhelt extraction (Hu et al. 2019a, b; Hu et al. 2020). The results ensure the effect of ultrasonication hybrid with other technologies is more significant, even to replace solvents with an aqueous medium for oil extraction. Recently, the sequential effect of ultrasonication and microwave extractions studied by Quaisie et al (2021) suggest that there is a significant effect when applying ultrasonication first, followed by microwave extraction. Thus, a new research area is open to considering the sequence of combining ultrasonication with other seed oil extraction methods. In the future, most industries will embrace sustainability, and conventional methods will fail to compete with the market where advanced technologies like ultrasound are used.

Conclusion

UAE is an efficient and recent extraction technique that can be used either directly or combined with other novel methods such as enzymatic, supercritical, and microwave to replace the conventional oil extraction methods. UAE can replace organic solvents with green solvents or reduce solvent usage and operate under mild operational conditions. Ultrasound cavitation generated by the transducer directly influences the extractability of oil. The intensity and propagation of the cavitation highly depend on extraction time, temperature, ultrasound power, and solvent/sample ratio. Despite few exceptions, the overall increment of oil yield at reduced energy consumption is solid enough to conclude the efficacy of ultrasound application for oil extraction. Remarkably, the quality of the extracted oil remained unchanged in terms of the fatty acid profile and thermal-oxidative stability. Also, UAE can be a promising approach to improve the extraction of lipophilic phytochemical composition.

Abbreviations

- AV:

-

P-anisidine value

- FAC:

-

Fatty acid composition

- PV:

-

Peroxide value

- TV:

-

Totox value

- SE:

-

Solvent extraction

- SXE:

-

Soxhlet extraction

- SFE:

-

Supercritical fluid extraction

- UAE:

-

Ultrasound assisted extraction

- UAEE:

-

Ultrasound assisted enzymatic extraction

- UAME:

-

Ultrasound assisted microwave extraction

- UASE:

-

Ultrasound assisted supercritical extraction

References

Amigh S, Dinani ST (2020) Combination of ultrasound-assisted aqueous enzymatic extraction and cooking pretreatment for date seed oil recovery. Heat Mass Transf 56(8):2345–2354. https://doi.org/10.1007/s00231-020-02865-2

Barrales FM, Rezende CA, Martínez J (2015) Supercritical CO2 extraction of passion fruit (Passiflora edulis sp.) seed oil assisted by ultrasound. J Supercrit Fluids 104:183–192. https://doi.org/10.1016/j.supflu.2015.06.006

Böger BR, Salviato A, Valezi DF, Di Mauro E, Georgetti SR, Kurozawa LE (2018) Optimization of ultrasound-assisted extraction of grape-seed oil to enhance process yield and minimize free radical formation. J Sci Food Agric 98(13):5019–5026. https://doi.org/10.1002/jsfa.9036

Bovo T, Natália M, Lúcio S, Camila C (2019) Pumpkin (Cucurbita maxima) by-products: obtaining seed oil enriched with active compounds from the peel by ultrasonic-assisted extraction. J Food Process Eng. https://doi.org/10.1111/jfpe.13125

Chemat F, Rombaut N, Sicaire AG, Meullemiestre A, Fabiano-Tixier AS, Abert-Vian M (2017) Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason Sonochem 34:540–560. https://doi.org/10.1016/j.ultsonch.2016.06.035

Chen F, Zhang Q, Gu H, Yang L (2016) An approach for extraction of kernel oil from Pinus pumila using homogenate-circulating ultrasound in combination with an aqueous enzymatic process and evaluation of its antioxidant activity. J Chromatogr A 1471:68–79. https://doi.org/10.1016/j.chroma.2016.10.037

Chen Q, Dong W, Wei C, Hu R, Long Y (2020) Industrial Crops & products combining integrated ultrasonic-microwave technique with ethanol to maximise extraction of green coffee oil from Arabica coffee beans. Ind Crops Prod 151:112405. https://doi.org/10.1016/j.indcrop.2020.112405

Clodoveo ML, Durante V, Notte DL, Punzi R, Gambacorta G (2013) Ultrasound - assisted extraction of virgin olive oil to improve the process efficiency. Eur J Lipid Sci Technol. https://doi.org/10.1002/ejlt.201200426

Cravotto G, Bicchi C, Mantegna S, Binello A, Tomao V, Chemat F, Tomao V (2011) Natural product research extraction of kiwi seed oil: Soxhlet versus four different non-conventional techniques. Nat Prod Res 25(10):974–981. https://doi.org/10.1080/14786419.2010.524162

Dias JL, Mazzutti S, de Souza JAL, Ferreira SRS, Soares LAL, Stragevitch L, Danielski L (2019) Extraction of umbu (Spondias tuberosa) seed oil using CO2, ultrasound and conventional methods: evaluations of composition profiles and antioxidant activities. J Supercrit Fluids 145:10–18. https://doi.org/10.1016/j.supflu.2018.11.011

Dos Santos P, De Aguiar AC, Viganó J, Boeing JS, Visentainer JV, Martínez J (2016) Supercritical CO2 extraction of cumbaru oil (Dipteryx alata Vogel) assisted by ultrasound: global yield, kinetics and fatty acid composition. J Supercrit Fluids 107:75–83. https://doi.org/10.1016/j.supflu.2015.08.018

Fouad MA, Gaber M, Tujillo FJ, Mansour MP, Juliano P (2018) Improving Oil extraction from canola seeds by conventional and advanced methods. Food Eng Rev 10:198–210. https://doi.org/10.1007/s12393-018-9182-1

Fuad FM, Karim KA, Don MM (2016) Ultrasound-assisted extraction of oil from Calophyllum inophyllum seeds: statistical optimisation using Box-Behnken design. J Phys Sci 27(2):103–121

Goula AM, Papatheodorou A, Karasavva S, Kaderides K (2018) Ultrasound-assisted aqueous enzymatic extraction of oil from pomegranate seeds. Waste Biomass Valoriz. https://doi.org/10.1007/s12649-016-9740-9

Haji Heidari S, Taghian Dinani S (2018) The study of ultrasound-assisted enzymatic extraction of oil from peanut seeds using response surface methodology. Eur J Lipid Sci Technol 120(3):1–13. https://doi.org/10.1002/ejlt.201700252

Hernández-santos B, Rodríguez-miranda J, Herman-lara E, Torruco-uco JG, Carmona-garcía R, Juárez-barrientos JM, Chávez-zamudio R, Martínez-sánchez CE (2016) Ultrasonics Sonochemistry effect of oil extraction assisted by ultrasound on the physicochemical properties and fatty acid profile of pumpkin seed oil (Cucurbita pepo). Ultrason Sonochem 31:429–436. https://doi.org/10.1016/j.ultsonch.2016.01.029

Hosseini S, Gharachorloo M, Ghiassi B (2015) Effects of ultrasound amplitude on the physicochemical properties of some edible oils. J Am Oil Chem Soc. https://doi.org/10.1007/s11746-015-2733-1

Hu AJ, Feng QQ, Zheng J, Hu XH, Wu C, Liu CY (2012) Kinetic model and technology of ultrasound extraction of safflower seed oil. J Food Process Eng 35(2):278–294. https://doi.org/10.1111/j.1745-4530.2010.00589.x

Hu B, Wang H, He L, Li Y, Li C, Zhang Z, Liu Y, Zhou K, Zhang Q, Liu A, Liu S, Zhu Y, Luo Q (2019b) A method for extracting oil from cherry seed by ultrasonic-microwave assisted aqueous enzymatic process and evaluation of its quality. J Chromatogr A 1587:50–60. https://doi.org/10.1016/j.chroma.2018.12.027

Hu B, Li C, Qin W, Zhang Z, Liu Y, Zhang Q, Liu A, Jia R, Yin Z, Han X, Zhu Y, Luo Q, Liu S (2019) A method for extracting oil from tea (Camelia sinensis) seed by microwave in combination with ultrasonic and evaluation of its quality. Ind Crops Prod 131:234–242. https://doi.org/10.1016/j.indcrop.2019.01.068

Hu B, Li Y, Song J, Li H, Zhou Q, Li C, Zhang Z, Liu Y, Liu A, Zhang Q, Liu S, Luo Q (2020) Oil extraction from tiger nut (Cyperus esculentus L.) using the combination of microwave-ultrasonic assisted aqueous enzymatic method - design, optimization and quality evaluation. J Chromatogr A. https://doi.org/10.1016/j.chroma.2020.461380

Jalili F, Jafari SM, Emam-djomeh Z, Malekjani N (2018) Optimization of ultrasound-assisted extraction of oil from canola seeds with the use of response surface methodology. Food Anal Methods 11(2):598–612. https://doi.org/10.1007/s12161-017-1030-z

Li H, Zhang Z, He D, Xia Y, Liu Q, Li X (2017) Ultrasound-assisted aqueous enzymatic extraction of oil from perilla seeds and determination of its physicochemical properties, fatty acid composition and antioxidant activity. Food Sci Technol 37:71–77. https://doi.org/10.1590/1678-457X.29116

Li Y, Zhang Y, Sui X, Zhang Y, Feng H, Jiang L (2014) Ultrasound-assisted aqueous enzymatic extraction of oil from perilla (Perilla frutescens L.) seeds. CYTA J Food 12(1):16–21. https://doi.org/10.1080/19476337.2013.782070

Liu X, Ou H, Xiang Z, Gregersen H (2020) Ultrasound pretreatment combined with supercritical CO2 extraction of Iberis amara seed oil. J Appl Res Med Aromat Plants 18:100265. https://doi.org/10.1016/j.jarmap.2020.100265

Liu Z, Gui M, Xu T, Zhang L, Kong L, Qin L, Zou Z (2019) Efficient aqueous enzymatic-ultrasonication extraction of oil from Sapindus mukorossi seed kernels. Ind Crops Prod 134:124–133. https://doi.org/10.1016/j.indcrop.2019.03.065

Loizzo MR, Bruno M, Balzano M, Giardinieri A, Pacetti D, Frega NG, Sicari V, Leporini M, Tundis R (2019) Comparative chemical composition and bioactivity of opuntia ficus-indica sanguigna and surfarina seed oils obtained by traditional and ultrasound-assisted extraction procedures. Eur J Lipid Sci Technol 121(1):1–7. https://doi.org/10.1002/ejlt.201800283

Ma Y, Wu X, Zhao L, Wang Y, Liao X (2019) Comparison of the compounds and characteristics of pepper seed oil by pressure-assisted, ultrasound-assisted and conventional solvent extraction. Innov Food Sci Emerg Technol 54:78–86. https://doi.org/10.1016/j.ifset.2019.03.011

de Mello BTF, dos Santos Garcia VA, da Silva C (2017) Ultrasound-assisted extraction of oil from chia (Salvia hispânica L.) seeds: optimization extraction and fatty acid profile. J Food Process Eng 40(1):1–8. https://doi.org/10.1111/jfpe.12298

Mohammadpour H, Sadrameli SM, Eslami F, Asoodeh A (2019) Optimization of ultrasound-assisted extraction of Moringa peregrina oil with response surface methodology and comparison with Soxhlet method. Ind Crops Prod 131:106–116. https://doi.org/10.1016/j.indcrop.2019.01.030

Moradi N, Rahimi M, Moeini A, Parsamoghadam MA (2018) Impact of ultrasound on oil yield and content of functional food ingredients at the oil extraction from sunflower. Sep Sci Technol philadelphia 53(2):261–276. https://doi.org/10.1080/01496395.2017.1384016

Mushtaq A, Roobab U, Denoya GI, Beatriz MI, Jose G, Lorenzo M, Barba FJ, Asif XZ, Rana W, Aadil M (2020) Advances in green processing of seed oils using ultrasound-assisted extraction: a review. J Food Proces Preserv. https://doi.org/10.1111/jfpp.14740

Naveenkumar R, Baskar G (2019) Ultrasonic assisted extraction of oil from castor seeds: optimization using response surface methodology, extraction kinetics and characterization. Energy Sources Part a: Recov Util Environ Effects. https://doi.org/10.1080/15567036.2019.1650136

Perrier A, Delsart C, Boussetta N, Grimi N, Citeau M, Vorobiev E (2017) Effect of ultrasound and green solvents addition on the oil extraction efficiency from rapeseed flakes. Ultrason Sonochem. https://doi.org/10.1016/j.ultsonch.2017.04.003

da Porto C, Porretto E, Decorti D (2013) Comparison of ultrasound-assisted extraction with conventional extraction methods of oil and polyphenols from grape (Vitis vinifera L.) seeds. Ultrason Sonochem 20(4):1076–1080. https://doi.org/10.1016/j.ultsonch.2012.12.002

Da Porto C, Natolino A, Decorti D (2015) Effect of ultrasound pre-treatment of hemp (Cannabis sativa L.) seed on supercritical CO 2 extraction of oil. J Food Sci Technol 52(3):1748–1753. https://doi.org/10.1007/s13197-013-1143-3

Putnik P, Lorenzo JM, Barba FJ, Roohinejad S, Jambrak AR, Granato D, Montesano D, Kovačević DB (2018) Novel food processing and extraction technologies of high-added value compounds from plant materials. Foods 7(7):1–16. https://doi.org/10.3390/foods7070106

Quaisie J, Ma H, Golly MK, Tuly JA, Amaglo NK, Jiaqi Z (2021) Effect of ultrasound-microwave irradiation hybrid technique on extraction, physicochemical, antioxidative, and structural properties of stearic acid-rich Allanblackia parviflora seed oil. Chem Pap. https://doi.org/10.1007/s11696-021-01666-z

Riera E, Blanco A, García J, Benedito J, Mulet A, Gallego-Juárez JA, Blasco M (2010) High-power ultrasonic system for the enhancement of mass transfer in supercritical CO2 extraction processes. Phys Proc 3(1):141–146. https://doi.org/10.1016/j.phpro.2010.01.020

Rodrigues S, Fernandes FAN (2017) Extraction processes assisted by ultrasound. In Epigenetic biomarkers and diagnostics. Elsevier Inc. https://doi.org/10.1016/B978-0-12-804581-7.00014-2

Rojo-Gutiérrez E, Carrasco-Molinar O, Tirado-Gallegos JM, Levario-Gómez A, Chávez-González ML, Baeza-Jiménez R, Buenrostro-Figueroa JJ (2021) Evaluation of green extraction processes, lipid composition and antioxidant activity of pomegranate seed oil. J Food Meas Charact 15(2):2098–2107. https://doi.org/10.1007/s11694-020-00804-7

Salinas F, Vardanega R, Espinosa-Álvarez C, Jimenéz D, Muñoz WB, Ruiz-Domínguez MC, Meireles MAA, Cerezal- Mezquita P (2020) Supercritical fluid extraction of chañar (Geoffroea decorticans) almond oil: global yield, kinetics and oil characterization. J Supercrit Fluids. https://doi.org/10.1016/j.supflu.2020.104824

Samaram S, Mirhosseini H, Ping C, Mohd H (2014) Ultrasound-assisted extraction and solvent extraction of papaya seed oil: crystallization and thermal behavior, saturation degree, color and oxidative stability. Ind Crops Prod 52:702–708. https://doi.org/10.1016/j.indcrop.2013.11.047

Samaram S, Mirhosseini H, Ping C, Mohd H, Bordbar S (2015) Optimisation of ultrasound-assisted extraction of oil from papaya seed by response surface methodology: Oil recovery, radical scavenging antioxidant activity, and oxidation stability. Food Chem 172:7–17. https://doi.org/10.1016/j.foodchem.2014.08.068

Sánchez RJ, Fernández MB, Nolasco SM (2019) Canola oil with high antioxidant content obtained by combining emerging technologies: microwave, ultrasound, and a green solvent. Eur J Lipid Sci Technol 121(11):1–9. https://doi.org/10.1002/ejlt.201900152

Santos KA, da Silva EA, da Silva C (2021) Ultrasound-assisted extraction of favela (Cnidoscolus quercifolius) seed oil using ethanol as a solvent. J Food Process Preserv 45(6):1–13. https://doi.org/10.1111/jfpp.15497

Senrayan J, Venkatachalam S (2019) A short extraction time of vegetable oil from Carica papaya L. seeds using continuous ultrasound acoustic cavitation: analysis of fatty acid profile and thermal behavior. J Food Process Eng 42(1):1–9. https://doi.org/10.1111/jfpe.12950

Senrayan J, Venkatachalam S (2020) Ultrasonic acoustic-cavitation as a novel and emerging energy efficient technique for oil extraction from kapok seeds. Innov Food Sci Emerg Technol 62(April):102347. https://doi.org/10.1016/j.ifset.2020.102347

Sicaire A, Vian MA, Fine F, Carré P, Tostain S, Chemat F (2016) Ultrasound induced green solvent extraction of oil from oleaginous seeds. Ultrason Sonochem. https://doi.org/10.1016/j.ultsonch.2016.01.011

Song Y, Zhang W, Wu J, Admassu H, Liu J, Zhao W, Yang R (2019) Ethanol-assisted aqueous enzymatic extraction of peony seed oil. JAOCS J Am Oil Chem Soc 96(5):595–606. https://doi.org/10.1002/aocs.12204

Stevanato N, da Silva C (2019) Ultrasound-assisted extraction using ethanol as solvent and assessment of its potential for ester production. Ind Crops Prod 132:283–291. https://doi.org/10.1016/j.indcrop.2019.02.032

Tamborrino A, Romaniello R, Caponio F, Squeo G, Leone A (2019) Combined industrial olive oil extraction plant using ultrasounds microwave and heat exchange: Impact on olive oil quality and yield. J Food Eng 245:124–130. https://doi.org/10.1016/j.jfoodeng.2018.10.019

Teng H, Chen L, Huang Q, Wang J, Lin Q, Liu M (2016) Ultrasonic-assisted extraction of raspberry seed oil and evaluation of its physicochemical properties. Fatty Acid Compos Antioxid Act. https://doi.org/10.6084/m9.figshare.3100867

Thirugnanasambandham K (2018) Ultrasound-assisted extraction of oil from Moringa oleifera Lam. seed using various solvents. Energy Sources Part A: Recov Util Environ Effects 40(3):343–350. https://doi.org/10.1080/15567036.2017.1416708

United States Department of Agriculture (2021) Oilseeds: world markets and trade. Foreign Agri Serv. https://doi.org/10.1016/j.ultsonch.2018.07.18

Zahra Y, Somayeh G, Dinani T (2018) Optimization of ultrasound-assisted enzymatic extraction of walnut kernel oil using response surface methodology. J Food Process Eng. https://doi.org/10.1111/jfpe.12696

Zhang L, Zhou C, Wang B, Yagoub AEA, Ma H (2016) Study of ultrasonic cavitation during extraction of the peanut oil at varying frequencies. Ultrason Sonochem. https://doi.org/10.1016/j.ultsonch.2016.12.034

Zhang ZS, Xie QF, Che L (2020) Synergistic effects of ultrasound and extraction solvent on the bioactive compound in kenaf seed oil. J Food Sci Technol. https://doi.org/10.1007/s13197-020-04247-2

Zhang W, Gui Y, Wuyang P, Haiming H (2019) Optimized ultrasonic - assisted extraction of papaya seed oil from Hainan / Eksotika variety. Food Sci Nutr. https://doi.org/10.1002/fsn3.1125

Zhong J, Wang Y, Yang R, Liu X, Yang Q, Qin X (2018) The application of ultrasound and microwave to increase oil extraction from Moringa oleifera seeds. Ind Crops Prod 120:1–10. https://doi.org/10.1016/j.indcrop.2018.04.028

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. This study was funded by School of Science, Monash University Malaysia.

Author information

Authors and Affiliations

Contributions

RCNT Original drafting preparation; LFS Review and editing, supervision; TKT Review and editing, supervision; YYL Manuscript writing, review and editing, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they do not have any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Thilakarathna, R.C.N., Siow, L.F., Tang, TK. et al. A review on application of ultrasound and ultrasound assisted technology for seed oil extraction. J Food Sci Technol 60, 1222–1236 (2023). https://doi.org/10.1007/s13197-022-05359-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05359-7