Abstract

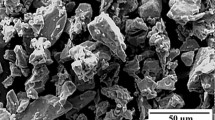

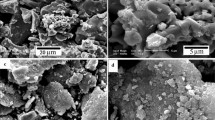

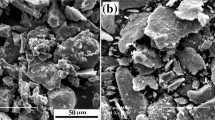

In this study, Al-TiAl3 nanocomposites were produced by applying annealing treatment (AT) before and after the accumulative roll bonding (ARB). First, the sandwich of two Al sheets containing pure Ti powder was subjected to cold roll bonding (CRB) and then underwent AT-ARB and ARB-AT processes. Annealing conditions were used to form the intermetallic compound at 590 °C for 2 h, and the ARB process was performed for a maximum of five cycles. The chemical and microstructural revolutions were evaluated using field emission scanning electron microscopy (FESEM) equipped with an elemental analyzer (EDS) and electron backscatter diffraction (EBSD) analysis. The results showed that through annealing after CRB, TiAl3 intermetallic compound was formed in the Al matrix, and then, the obtained Al-TiAl3 composite was subjected to the ARB process. Finally, a composite containing a uniform distribution of TiAl3 particles of larger than 200 nm in the Al matrix was obtained. Microstructural changes showed that with an increase in strain due to the development of continuous recrystallization, a structure containing grains smaller than 500 nm was obtained. The microstructural evaluation of the ARB-AT composite showed that the grain size of Al and particle size of TiAl3, in this case, were in micrometer and larger.

Graphic Abstract

Similar content being viewed by others

References

Rana R S, Purohit R, and Das S, Int. J. Eng. Res.3 (2012) 1-16.

Clyne T W, in Metal matrix composites: Matrices and processing, (ed) Mortensen A, Elsevier, 2001.

Heathcote J, Odette G, Lucas G, Rowe R, and Skelly D, Acta Mater.44 (1996) 2489.

Lesuer D, and Syn. C, in Metallic laminates for engine applications, 8th CIMTEC World Ceramics Congress & Forum on New Materials, Italy, (1994).

Massalski T, binary alloy phase diagrams, American society for metals, (1986).

Saito Y, Tsuji N, Utsunomiya H, Sakai T, and Hong R G, Scr. Mater.39 (1998) 1221–1227.

Saito Y, Utsunomiya H, Tsuji N, and Sakai T, Acta Mater.47 (1999) 579–583.

Tsuji N, Ito Y, Saito Y, and Minamino Y, Scr. Mater.47 (2002) 893-899.

Oh J, Pyo S G, Lee S, and Kim N J, J. Mater. Sci.38 (2003) 3647 – 3651.

Luo J G, and Acoff V L, Mater. Sci. Eng. A379 (2004) 164–172.

Chaudhari G P, Acoff V L, Intermetallics18 (2010) 472–478.

Sieber H, and Perepezko J H, in Intermetallic Phase Formation in Bulk Multilayered Structures, (Eds.) Morris D G, Naka S, and Caron P, WILEY-VCH Verlag GmbH, Weinheim. (2000) pp. 324–329.

Yang D K, Hodgson P, and Cui E W, Intermetallics17 (2009) 727–732.

Liu C Y, Jing R, Wang Q, Zhang B, Jia Y Z, Ma M Z, and Liu R P, Mater. Sci. Eng. A558 (2012) 510-516.

Yazdani Z, Toroghinejad M R, Edris H, and Ngan A H W, J. Alloys Compd.747 (2018) 217-226.

Loo F V, and Rieck G, Acta Metall. Mater.21 (1973) 61-71.

Yazdani Z, Toroghinejad M R, Edris H, and Ngan A H W, Trans. Indian Inst. Met.71 (2018) 2497–2504.

Azushima A, Kopp R, Korhonen A, Yang D Y, Micari F, Lahoti G D, Groche P, Yanagimoto J, Tsuji N, Rosochowski A, and Yanagida A, CIRP Ann Manuf Technol57 (2008) 716–735.

Smallman R E, and Westmacott K H, Philos. Mag.2 (1957) 669-683.

Loo F V, and Rieck G, Acta Metall. Mater.21 (1973) 73.

Xu L, Cui Y, Hao Y L, and Yang R, Mater. Sci. Eng. A435–436 (2006) 638–647.

Chianeh V A, Hosseini H M, and Nofar M, J. Alloys Compd.473 (2009) 127-132.

Jamaati R, and Toroghinejad M R, Mater. Des.31 (2010) 4816–4822.

Guan R, and Tie D, Acta Metall. Sin. (Engl. Lett.)30 (2017) 409-432.

Lin H R, Tian Y Z, and Sun S J, Acta Metall. Sin. (Engl. Lett.)34 (2021) 925–931.

Muhammad W, Brahme A P, Sabat R K, Mishra R K, and Inal K, Mater. Sci. Eng. A759 (2019) 613–623.

Fukutomi H, Nakamura M, Suzuki T, Takagi S, and Kikuchi S, Mater. Trans.41 (2000) 1244.

Rahmatabadi D, Hashemi R, Mohammadi B, and Shojaee T, Mater. Sci. Eng. A708 (2017) 301–310.

Tsuji N, Ueji R, and Minamino Y, Scr. Mater.47 (2002) 69-76.

Kim H W, Kang S B, Tsuji N, and Minamino Y, Metall. Mater. Trans. A36 (2005) 3151–3163

[31] Li Z G, Li N, Jiang H W, Xiong Y, and Liu L, J. Alloys Compd.589 (2014) 164–173.

Tesuji N, Lee Y, and Minamino Y, Adv. Eng. Mater.5 (2003) 338-344.

Tsuji N, Minamino Y, and Hansen N, in Science of metastable and nanocrystalline alloys. Structure, properties and modelling, (edn) Dinesen A.R., Eldrup M, Jensen D J, Linderoth S, Pedersen T B, Pryds N H, Pedersen A S, and Wert J A, Proceedings, Roskilde (2001) pp. 255–262.

Bay B, Hansen N, Hughes D A, and Kuhlmann-Wilsdorf D, Acta Metall. Mater.40 (1992) 205-219.

Jaehyung C, Hyung-Wook K, and Cha-Yong L, Texture and Microstructure Evolution of AA1100 during Accumulative Roll Bonding, Proceedings of the 12th International Conference on Aluminium Alloys, Yokohama, Japan (2010) pp. 143–148.

Humphreys F J, and Hatherly M, Recrystallization and related annealing phenomena, Elsevier, Oxford (2004).

Yang D K, Cizek P, Hodgson P, and Cui E W, Scr. Mater.62 (2010) 321–324.

Mackenzie J K, Acta Metall. Mater.12 (1964) 223-225.

Sabat R K, Sahoo S K, Panda D, Mohanty U K, and Suwas S, Mater. Charact.132 (2017) 388–396.

Takata N, Yamada K, Ikeda K, Yoshida F, Nakashima H, Tsuji N, Mater. Trans.48 (2007) 2043-2048.

Singh P B, Sabat R K, Kumaran S, J. Mater. Eng. Perform27 (2018).

Jamaati R, Toroghinejad M R, Dutkiewicz J, Szpunar J A, Mater. Des.35 (2012) 37–42.

Ivanov K V, Structure, AIP Conf. Proc., (2016) pp. 20–76.

Sabat R K, Pavan M V S S D S S, Aakash D S, Kumar M, Sahoo S K, Philos. Mag. (2018) 2562–2581.

Zhang L, Wang Y, Yang X, Li K, Ni S, Du Y, and Song M, Mater. Res.20 (2017) 1360-1368.

Zhao Q, Liu Z, Huang T, Mater. Charact.119 (2016) 47-54.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Mohammad Reza Toroghinejad and Hossein Edris are Co-authors.

Rights and permissions

About this article

Cite this article

Yazdani, Z., Toroghinejad, M.R. & Edris, H. EBSD Evaluation of Al- TiAl3 Composites Manufactured Through CRB-Annealing-ARB and CRB-ARB-Annealing Methods. Trans Indian Inst Met 75, 113–131 (2022). https://doi.org/10.1007/s12666-021-02408-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02408-1