Abstract

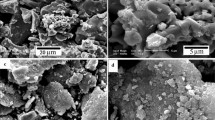

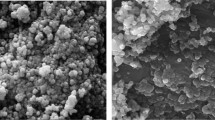

This paper investigates the texture of Al–TiAl3 nanocomposites prepared by two different processes. First, a sandwich of two Al sheets with Ti powder underwent CRB. Subsequently, two groups of annealed-ARB and ARB-annealed samples were prepared. Microstructural texture was investigated by TEM, EBSD, and ODF analysis. Results showed a decrease in intensity of the cube component because of formation of nano shear bands in the fifth cycle of ARB. It was found that the presence of large particles of intermetallic compounds completely changes the annealing texture by affecting the movement of boundaries. With increase in the number of ARB cycles after annealing, the recrystallization texture components were completely eliminated. Only the deformation texture components, including strong Goss, Copper, Dillamore, Brass, and S components, were present. A remarkable point was the elimination of the cube texture component in the structure after the third cycle of ARB due to the development of shear bands.

Similar content being viewed by others

References

Chaudhari GP, Acoff VL (2010) Titanium aluminide sheets made using roll bonding and reaction annealing. Intermetallics 18:472–478

Heathcote J, Odette G, Lucas G, Rowe R, Skelly D (1996) On the micromechanics of low temperature strength and toughness of intermetallic/metallic microlaminate composites. Acta Mater 44:2489

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena. Elsevier, Oxford

Hutchinson B (2012) The cube texture revisited. Mater Sci Forum 702–703:3–10

Jamaati R, Toroghinejad MR (2010) High-strength and highly-uniform composite produced by anodizing and accumulative roll bonding processes. Mater Design 31:4816–4822

Jamaati R, Toroghinejad MR, Hoseini M, Szpunar JA (2011) Texture development in Al/Al2O3 MMCs produced by anodizing and ARB processes. Mater Sci Eng A 528:3573–3580

Lee DN, Han HN (2014) The cube recrystallization-texture related component in the β-fiber rolling-texture FCC metals. Mater Sci Forum 783–786:51–56

Lesuer D, Syn C (1994) Metallic laminates for engine applications, June–July 1994

Liu CY, Jing R, Wang Q, Zhang B, Jia YZ, Ma MZ, Liu RP (2012) Fabrication of Al/Al3Mg2 composite by vacuum annealing and accumulative roll-bonding process. Mater Sci Eng A 558:510–516

Loo FV, Rieck G (1973) Diffusion in the titanium-aluminum system-interdiffusion between solid al and ti or ti-al alloys. Acta Metall 21:61–71

Lucke K, Engler O (1990) Effects of particles on development of microstructure and texture during rolling and recrystallisation in fcc alloys. Mater Sci Technol 6:1113–1130

Luo JG, Acoff VL (2004) Using cold roll bonding and annealing to process Ti/Al multi-layered composites from elemental foils. Mater Sci Eng A 379:164–172

Oh J, Pyo SG, Lee S, Kim NJ (2003) Fabrication of multilayered titanium aluminide sheets by self-propagating high-temperature synthesis reaction using hot rolling and heat treatment. J Mater Sci 38:3647–3651

Quadir MZ, Ferry M, Al-Buhamad O, Munroe PR (2009) Shear banding and recrystallization texture development in a multilayered Al alloy sheet produced by accumulative roll bonding. Acta Mater 57:29–40

Raei M, Toroghinejad MR, Jamaati R, Szpunar JA (2010) Effect of ARB process on textural evolution of AA1100 aluminum alloy. Mater Sci Eng A 527:7068–7073

Rana RS, Purohit R, Das S (2012) Review of recent studies in Al matrix composites. Int J Sci Eng Res 3:1–16

Roy S, Singh S, Suwas DS, Kumar S, Chattopadhyay K (2011) Microstructure and texture evolution during accumulative roll bonding of aluminium alloy AA5086. Mater Sci Eng A 528:8469–8478

Saito Y, Tsuji N, Utsunomiya H, Sakai T, Hong RG (1998) Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr Mater 39:1221–1227

Saito Y, Utsunomiya H, Tsuji N, Sakai T (1999) Novel ultra-high straining process for bulk materials development of the accumulative roll-bonding (ARB) process. Acta Mater 47:579–583

Sieber H, Perepezko JH (2000) Intermetallic phase formation in bulk multilayered structures. In: Morris DG, Naka S, Caron P (eds) Intermetallics and superalloys. WILEY-VCH Verlag GmbH, New York, pp 324–329

Smallman RE, Bishop RJ (1999) Mechanical behaviour of materials, Modern physical metallurgy and materials engineering, 6th edn. Butterworth-Heinemann, Oxford, pp 197–258

Tsuji N, Ito Y, Saito Y, Minamino Y (2002) Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scr Mater 47:893–899

Yang DK, Hodgson P, Cui EW (2009) The kinetics of two-stage formation of TiAl3 in multilayered Ti/Al foils prepared by accumulative roll bonding. Intermetallics 17:727–732

Yazdani Z, Toroghinejad MR, Edris H, Ngan AHW (2018a) A novel method for the fabrication of Al-matrix nanocomposites reinforced by mono-dispersed TiAl3 intermetallic via a three-step process of cold-roll bonding, heat-treatment and accumulative roll bonding. J Alloys Compd 747:217–226

Yazdani Z, Toroghinejad MR, Edris H, Ngan AHW (2018b) Effect of cold rolling parameters on bond strength of Ti particle embedded Al strips. Trans Indian Inst Metals 71:2497–2504

Zhang L, Wang Y, Yang X, Li K, Ni S, Du Y, Song M (2017) Texture, microstructure and mechanical properties of 6111 aluminum alloy subject to rolling deformation. Mater Res 20:1360–1368

Zhao Q, Liu Z, Huang T (2016) Enhanced fracture toughness in an annealed Al–Cu–Mg alloy by increasing Goss/Brass texture ratio. Mater Charact 119:47–54

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yazdani, Z., Toroghinejad, M.R. & Edris, H. Investigation of Microstructural Textures in Al–TiAl3 Nanocomposites Fabricated Through Cold Roll Bonding–Annealing–ARB and Cold Roll Bonding–ARB–Annealing Processes. Trans Indian Natl. Acad. Eng. 8, 289–304 (2023). https://doi.org/10.1007/s41403-023-00397-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41403-023-00397-9