Abstract

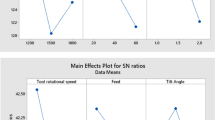

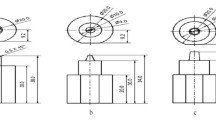

Friction stir welding (FSW) is introduced as a solid-state welding process. Despite the many benefits of the FSW, the effects of the thermal cycles in this process are causing softening of the joint. This phenomenon generally occurs in heat-treatable aluminum alloys and results in reduced mechanical properties of the joint. To solve this limitation, submerged friction stir welding (SFSW) has been developed which is suitable for welding of heat-sensitive alloys. In this study, 31 butt joints were first produced from Al7075-T6 using the FSW. For this purpose, the response surface methodology was selected as the design of experiments method, and the variables: tool rotational speed, tool feed rate, tool shoulder diameter, and tool tilt angle were determined as the input variables. Then, the statistical analysis of the parameters affecting the yield strength and tensile strength of the joints was investigated. Then, 10 joints were produced using the SFSW based on the optimal values of the tool feed rate and tool tilt angle. Results of the ANOVA and regression analysis of the experimental data confirmed the accuracy and precision of regression equations and showed that the linear, interactional and quadratic terms of tool shoulder diameter and tool rotational speed effect on the yield strength and ultimate tensile strength of submerged joints. Also, the optimal conditions of input variables were determined by the desirability method and confirmed by the verification test.

Similar content being viewed by others

References

Qin B, Yin F C, Zeng C Z, Xie J C, and Shen J, Trans Nonferrous Met Soc China 29 (2019) 1864.

Tamasgavabari R, Ebrahimi A R, Abbasi S M, and Yazdipour A R, J Manuf Process 49 (2020) 413.

Thomas W M, Nicholas E D, Needham J C, Murch M G, Smith P T, and Dawes C J, Friction Stir Butt Welding. Int. Patent No. PCT/GB92/02203 (1991).

Guerra M, Schmidt C, Mcclure L C, Murr L E, and Nunes A C, Mater Charact 49 (2003) 95.

Rhodes C G, Mahoney M W, Bingel W H, Spurling R A, and Bampton C C, Scr Mater 36 (1997) 69.

Zhao J, Jiang F, Jian H G, Wen K, Jiang L, and Chen X B, Mater Des 31 (2010) 306.

Steel R J, Packer S M, Fleck R D, Sanderson S, and Tucker C, in Proceedings of the 1st International Joint Symposium on Joining and Welding, (eds) Fujii H, Woodhead Publishing (2013), p 125.

Thomas W M, and Nicholas E D, Mater Des 18 (1997) 269.

Siddiquee A N, and Pandey S, Int J Adv Manuf Technol 73 (2014) 479.

Gite R A, Loharkar P K, and Shimpi R, Mater Today Proc 19 (2019) 361.

Cho J H, Han S H, and Lee C, Mater Lett 180 (2016) 157.

Woo W, Balogh L, Ungár T, Choo H, and Feng Z, Mater Sci Eng A 498 (2008) 308.

Jata K V, and Semiatin S L, Scr Mater 43 (2000) 743.

Liu H J, Fujii H, Maeda M, and Nogi K, Mater Sci Lett 22 (2003) 1061.

Guo Y, Ma Y, and Wang F, Theor Appl Fract Mech 104 (2019) 102372.

Cabibbo M, Mcqueen H J, Evangelista E, Spigarelli S, Paola M D, and Falchero A, Mater Sci Eng A 460–461 (2007) 86.

Fratini L, Buffa G, and Shivpuri R, Int J Adv Manuf Technol 43 (2009) 664.

Sakurada D, Katoh K, and Tokisue H, J Jpn Inst Light Met 52 (2002) 2.

Derazkola H A, and Khodabakhshi F, Int J Adv Manuf Technol 102 (2019) 4383.

Rouzbehani R, Kokabi A H, Sabet H, Paidar M, and Ojo O O, J Mater Process Technol 262 (2018) 239.

Mofid M A, Abdollah-Zadeh A, Ghaini F M, and Gur C H, Metall Mater Trans A 43 (2012) 5106.

Sabari S S, Malarvizhi S, Balasubramanian V, and Reddy G M, Def Technol 12 (2016) 324.

Zhang H J, Liu H J, and Yu L, Mater Des 32 (2011) 4402.

Nelson T W, Steel R J, and Arbegast W J, Sci Technol Weld Join 8 (2003) 283.

Xua W F, Liu J H, Chen D L, Luan G H, and Yao J S, Mater Sci Eng A 548 (2012) 89.

Liu H J, Zhang H J, Huang Y X, and Lei Y, Trans Nonferrous Met Soc China 20 (2010) 1387.

Wang Q, Zhao Z, Zhao Y, Yan K, and Zhang H, Mater Des 88 (2015) 1366.

Liu H J, Zhang H J, and Yu L, Mater Des 32 (2011) 1548.

Zhang H, and Liu H, Mater Des 45 (2013) 206.

Zhang H J, Liu H J, and Yu L, J Mater Eng Perform 21 (2012) 1182.

Wang Q, Zhao Y, Yan K, and Lu S, Mater Des 68 (2015) 97.

Kishta E E, and Darras B, Proc Inst Mech Eng Part B J Eng Manuf 230 (2014) 458.

Sabari S S, Malarvizhi S, and Balasubramanian V, J Mater Process Technol 237 (2016) 286.

Pei X, and Dong P, Int J Adv Manuf Technol 95 (2018) 3549.

Chen C M, and Kovacevic R, Int J Mach Tools Manuf 43 (2003) 1319.

Myers R H, Montgomery D C, and Anderson-Cook C M, Response Surface Methodology: Process and Product Optimization Using Designed Experiments, Wiley, Hoboken (2016), ISBN 978-1-118-91601-8.

Vahdati M, and Moradi M, Iran J Mater Form 7 (2020) 32.

Moradi M, Arabi H, and Shamsborhan M, Optik 202 (2020) 163619.

Design Expert Software, http://www.statease.com, available in 1 April 2020.

Online Materials Information Resource, http://www.matweb.com, available in 1 April 2020.

Heat Treatment of Aluminum Alloys, Aerospace Material Specification, AMSH6088 (1997).

Montgomery D C, Design and Analysis of Experiments, Wiley, Hoboken (2017), ISBN 978-1-119-11347-8.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vahdati, M., Moradi, M. & Shamsborhan, M. Modeling and Optimization of the Yield Strength and Tensile Strength of Al7075 Butt Joint Produced by FSW and SFSW Using RSM and Desirability Function Method. Trans Indian Inst Met 73, 2587–2600 (2020). https://doi.org/10.1007/s12666-020-02075-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02075-8