Abstract

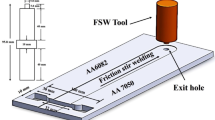

In this research, an attempt has been made to develop mathematical models for predicting mechanical properties including ultimate tensile strength, impact toughness, and hardness of the friction stir-welded AA6061-T6 joints at 95 % confidence level. Response surface methodology with central composite design having four parameters and five levels has been used. The four parameters considered were tool pin profile, rotational speed, welding speed, and tool tilt angle. Three confirmation tests were performed to validate the empirical relations. In addition, the influence of the process parameters on ultimate tensile strength, impact toughness, and hardness were investigated. The results indicated that tool pin profile is the most significant parameter in terms of mechanical properties; tool with simple cylindrical pin profile produced weld with high ultimate tensile strength, impact toughness, and hardness. In addition to tool pin profile, rotational speed was more significant compared to welding speed for ultimate tensile strength and impact toughness, whereas welding speed showed dominancy over rotational speed in case of hardness. Optimum conditions of process parameters have been found at which tensile strength of 92 %, impact toughness of 87 %, and hardness of 95 % was achieved in comparison to the base metal. This research will contribute to expand the scientific foundation of friction stir welding of aluminum alloys with emphasis on AA6061-T6. The results will aid the practitioners to develop a clear understanding of the influence of process parameters on mechanical properties and will allow the selection of best combinations of parameters to achieve desired mechanical properties.

Similar content being viewed by others

References

Ericsson M, Sandström R (2003) Influence of welding speed on the fatigue of friction stir welds, and comparison with MIG and TIG. Int J Fatigue 25(12):1379–1387

Taban E, Kaluc E (2007) Comparison between microstructure characteristics and joint performance of 5086-H32 aluminium alloy welded by MIG, TIG and friction stir welding processes. Kovove Mater 45(5):241–248

Çam G, Koçak M (1998) Progress in joining of advanced materials. Int Mater Rev 43(1):1–44

Çam G, Koçak M (1998) Progress in joining of advanced materials: part 1: solid state joining, fusion joining, and joining of intermetallics. Sci Technol Weld Join 3(3):105–126

Cam G, Koçak M (1998) Progress in joining of advanced materials. Part 2: joining of metal matrix composites and joining of other advanced materials. Sci Technol Weld Join 3(4):159–175

Pakdil M, Cam G, Kocak M, Erim S (2011) Microstructural and mechanical characterization of laser beam welded AA6056 Al-alloy. Mater Sci Eng A 528(24):7350–7356

Çam G, Güçlüer S, Çakan A, Serindag HT (2009) Mechanical properties of friction stir butt‐welded Al‐5086 H32 plate. Mater Werkst 40(8):638–642

Cam G (2011) Friction stir welded structural materials: beyond Al-alloys. Int Mater Rev 56(1):1–48

Çam G, Mistikoglu S (2014) Recent developments in friction stir welding of Al-alloys. J Mater Eng Perform 23(6):1936–1953

Mironov S, Inagaki K, Sato YS, Kokawa H (2015) Effect of welding temperature on microstructure of friction-stir welded aluminum alloy 1050. Metall Mater Trans A 46(2):783–790

Wu CS, Zhang WB, Lei SHI, Chen MA (2012) Visualization and simulation of plastic material flow in friction stir welding of 2024 aluminium alloy plates. Trans Nonferrous Metals Soc China 22(6):1445–1451

Kumar R, Singh K, Pandey S (2012) Process forces and heat input as function of process parameters in AA5083 friction stir welds. Trans Nonferrous Metals Soc China 22(2):288–298

Saeidi M, Manafi B, Givi MB, Faraji G (2015) Mathematical modeling and optimization of friction stir welding process parameters in AA5083 and AA7075 aluminum alloy joints. Proc Inst Mech Eng B J Eng Manuf. doi:10.1177/0954405415573697

Bozkurt Y, Salman S, Çam G (2013) Effect of welding parameters on lap shear tensile properties of dissimilar friction stir spot welded AA 5754-H22/2024-T3 joints. Sci Technol Weld Join 18(4):337–345

İpekoğlu G, Çam G (2014) Effects of initial temper condition and postweld heat treatment on the properties of dissimilar friction-stir-welded joints between AA7075 and AA6061 aluminum alloys. Metall Mater Trans A 45(7):3074–3087

Gibson BT, Lammlein DH, Prater TJ, Longhurst WR, Cox CD, Ballun MC, Dharmaraj KJ, Cook GE, Strauss AM (2014) Friction stir welding: process, automation, and control. J Manuf Process 16(1):56–73

Moreira PMGP, De Figueiredo MAV, De Castro PMST (2007) Fatigue behaviour of FSW and MIG weldments for two aluminium alloys. Theor Appl Fract Mech 48(2):169–177

İpekoğlu G, Erim S, Çam G (2014) Effects of temper condition and post weld heat treatment on the microstructure and mechanical properties of friction stir butt-welded AA7075 Al alloy plates. Int J Adv Manuf Technol 70(1–4):201–213

Zhao J, Jiang F, Jian H, Wen K, Jiang L, Chen X (2010) Comparative investigation of tungsten inert gas and friction stir welding characteristics of Al–Mg–Sc alloy plates. Mater Des 31(1):306–311

Lakshminarayanan AK, Balasubramanian V, Elangovan K (2009) Effect of welding processes on tensile properties of AA6061 aluminium alloy joints. Int J Adv Manuf Technol 40(3–4):286–296

İpekoğlu G, Erim S, Kıral BG, Çam G (2013) Investigation into the effect of temper condition on friction stir weldability of AA6061 Al-alloy plates. Kovove Mater 51(3):155–163

Çam G, İpekoğlu G, Tarık Serindağ H (2014) Effects of use of higher strength interlayer and external cooling on properties of friction stir welded AA6061-T6 joints. Sci Technol Weld Join 19(8):715–720

İpekoğlu G, Erim S, Çam G (2014) Investigation into the influence of post-weld heat treatment on the friction stir welded AA6061 Al-alloy plates with different temper conditions. Metall Mater Trans A 45(2):864–877

İpekoğlu G, Gören Kıral B, Erim S, Çam G (2012) Investigation of the effect of temper condition on friction stir weldability of AA7075 Al-alloy plates. Mater Technol 46(6):627–632

Xu W, Liu J, Zhu H, Fu L (2013) Influence of welding parameters and tool pin profile on microstructure and mechanical properties along the thickness in a friction stir welded aluminum alloy. Mater Des 47:599–606

Elangovan K, Balasubramanian V (2008) Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy. Mater Des 29(2):362–373

Palanivel R, Mathews PK, Murugan N, Dinaharan I (2012) Effect of tool rotational speed and pin profile on microstructure and tensile strength of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys. Mater Des 40:7–16

Salari E, Jahazi M, Khodabandeh A, Ghasemi-Nanesa H (2014) Influence of tool geometry and rotational speed on mechanical properties and defect formation in friction stir lap welded 5456 aluminum alloy sheets. Mater Des 58:381–389

Ilangovan M, Boopathy SR, Balasubramanian V (2015) Effect of tool pin profile on microstructure and tensile properties of friction stir welded dissimilar AA6061-AA5086 aluminium alloy joints. Def Technol 11:174–184

Mohanty HK, Mahapatra MM, Kumar P, Biswas P, Mandal NR (2012) Modeling the effects of tool shoulder and probe profile geometries on friction stirred aluminum welds using response surface methodology. J Mar Sci Appl 11(4):493–503

Bilgin MB, Meran C (2012) The effect of tool rotational and traverse speed on friction stir weldability of AISI 430 ferritic stainless steels. Mater Des 33:376–383

Movahedi M, Kokabi AH, Reihani SS, Najafi H (2012) Effect of tool travel and rotation speeds on weld zone defects and joint strength of aluminium steel lap joints made by friction stir welding. Sci Technol Weld Join 17(2):162–167

Kasman Ş (2013) Multi-response optimization using the Taguchi-based grey relational analysis: a case study for dissimilar friction stir butt welding of AA6082-T6/AA5754-H111. Int J Adv Manuf Technol 68(1–4):795–804

Aydin H, Bayram A, Esme U, Kazancoglu Y, Guven O (2010) Application of grey relation analysis (GRA) and Taguchi method for the parametric optimization of friction stir welding (FSW) process. Mater Tehnol 44(4):205–211

Jayaraman M, Sivasubramanian R, Balasubramanian V, Lakshminarayanan AK (2009) Optimization of process parameters for friction stir welding of cast aluminium alloy A319 by Taguchi method. J Sci Ind Res 68(1):36

Kasman Ş, Kahraman F (2014) Investigations for the effect of parameters on the weld performance of AA 5083-H111 joined by friction stir welding. Proc Inst Mech Eng B J Eng Manuf 228(8):937–946

Gadakh VS, Kumar A (2013) Friction stir welding window for AA6061-T6 aluminium alloy. Proc Inst Mech Eng B J Eng Manuf. doi:10.1177/0954405413510289

Ahmadi H, Arab NM, Ghasemi FA (2014) Optimization of process parameters for friction stir lap welding of carbon fibre reinforced thermoplastic composites by Taguchi method. J Mech Sci Technol 28(1):279–284

Liu HJ, Hou JC, Guo H (2013) Effect of welding speed on microstructure and mechanical properties of self-reacting friction stir welded 6061-T6 aluminum alloy. Mater Des 50:872–878

Li D, Yang X, Cui L, He F, Shen H (2014) Effect of welding parameters on microstructure and mechanical properties of AA6061-T6 butt welded joints by stationary shoulder friction stir welding. Mater Des 64:251–260

Rajakumar S, Muralidharan C, Balasubramanian V (2011) Predicting tensile strength, hardness and corrosion rate of friction stir welded AA6061-T6 aluminium alloy joints. Mater Des 32(5):2878–2890

Fujii H, Cui L, Maeda M, Nogi K (2006) Effect of tool shape on mechanical properties and microstructure of friction stir welded aluminum alloys. Mater Sci Eng A 419(1):25–31

Heidarzadeh A, Saeid T, Khodaverdizadeh H, Mahmoudi A, Nazari E (2013) Establishing a mathematical model to predict the tensile strength of friction stir welded pure copper joints. Metall Mater Trans B 44(1):175–183

Shojaeefard MH, Behnagh RA, Akbari M, Givi MKB, Farhani F (2013) Modelling and Pareto optimization of mechanical properties of friction stir welded AA7075/AA5083 butt joints using neural network and particle swarm algorithm. Mater Des 44:190–198

Okuyucu H, Kurt A, Arcaklioglu E (2007) Artificial neural network application to the friction stir welding of aluminum plates. Mater Des 28(1):78–84

Hwang YM, Kang ZW, Chiou YC, Hsu HH (2008) Experimental study on temperature distributions within the workpiece during friction stir welding of aluminum alloys. Int J Mach Tools Manuf 48(7):778–787

Roshan SB, Jooibari MB, Teimouri R, Asgharzadeh-Ahmadi G, Falahati-Naghibi M, Sohrabpoor H (2013) Optimization of friction stir welding process of AA7075 aluminum alloy to achieve desirable mechanical properties using ANFIS models and simulated annealing algorithm. Int J Adv Manuf Technol 69(5–8):1803–1818

Azam M, Jahanzaib M, Wasim A, Hussain S (2015) Surface roughness modeling using RSM for HSLA steel by coated carbide tools. Int J Adv Manuf Technol 78(5–8):1031–1041

Elangovan K, Balasubramanian V, Babu S (2009) Predicting tensile strength of friction stir welded AA6061 aluminium alloy joints by a mathematical model. Mater Des 30(1):188–193

Heidarzadeh A, Khodaverdizadeh H, Mahmoudi A, Nazari E (2012) Tensile behavior of friction stir welded AA6061-T4 aluminum alloy joints. Mater Des 37:166–173

Lotfi AH, Nourouzi S (2014) Predictions of the optimized friction stir welding process parameters for joining AA7075-T6 aluminum alloy using preheating system. Int J Adv Manuf Technol 73(9–12):1717–1737

Ilkhichi AR, Soufi R, Hussain G, Barenji RV, Heidarzadeh A (2015) Establishing mathematical models to predict grain size and hardness of the friction stir-welded AA 7020 aluminum alloy joints. Metall Mater Trans B 46(1):357–365

Montgomery DC (2001) Design and analysis of experiments, 5th edn. John Wiley and Sons, New York

Box GE, Hunter WG, Hunter JS (2005) Statistics for experimenters II. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Safeen, W., Hussain, S., Wasim, A. et al. Predicting the tensile strength, impact toughness, and hardness of friction stir-welded AA6061-T6 using response surface methodology. Int J Adv Manuf Technol 87, 1765–1781 (2016). https://doi.org/10.1007/s00170-016-8565-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8565-9