Abstract

ZrB2 powders were synthesized using B4C of different particle sizes through boro/carbo thermal reduction (BCTR) of ZrO2 with B4C and carbon as reducing agents. The XRD patterns of all the five different powders produced were similar and showed ZrB2 as a major phase. An increase in B4C particle size showed a significant increase in oxygen and carbon content and the size of agglomerates of the synthesized powders. Even though, the average size of the ZrB2 particles associated with all the agglomerates were same. It was concluded that B4C of fine particle size is necessary for the synthesis of ZrB2 powder with low oxygen and carbon content and lower agglomerates sizes. The synthesis route also provided a novel route to synthesize ZrB2 powder with the required size of agglomerates.

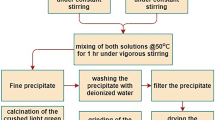

Graphical Abstract

Similar content being viewed by others

References

Cutler R A, Engineering Properties of Borides, ASM International, Materials Park (1991).

Shaffer P T B, Ceramics and Glasses, Engineered Materials Handbook, Jr. ASM International, Materials Park (1991).

Guo S Q, J Eur Ceram Soc 29 (2009) 995.

Upadhya K, Yang J M, and Hoffmann W P, Am Ceram Soc Bull 76 (1997) 51.

Monteverde F, Guicciardi S, and Bellosi A, Mater Sci Eng A 346 (2003) 310.

Chamberlain A L, Fahrenholtz W G, Hilmas G E, and Ellerby D T, J Am Ceram Soc 87 (2004) 1170.

Zhang S C, Hilmas G E, and Fahrenholtz W G, J Am Ceram Soc 91 (2008) 26.

Eakins E, Jayaseelan D D, and Lee W E, Metall Mater Trans A Phys Metall Mater Sci 42 (2011) 878.

FahrenholtzW G, Hilmas G E, Talmy I G, and Zaykoski J A, J Am Ceram Soc 90 (2007) 1347.

Rangaraj L, Divakar C, and Jayaram V, J Eur Ceram Soc 30 (2010) 129.

Jung E Y, Kim J H, Jung S H, and Choi S C, J Alloys Compd 538 (2012) 164.

Patel M, Singh V, Reddy J J, Bhanu Prasad V V, and Jayaram V, Scr Mater 69 (2013) 370.

Yan Y, Huang Z, Dong S, and Jiang D, J Am Ceram Soc 89 (2006) 3585.

Zou J, Zhang G J, Vleugels J, and Van der Biest O, J Eur Ceram Soc 33 (2013) 1609.

Ran S, Van Der Biest O, and Vleugels J, J Am Ceram Soc 93 (2010) 1586.

Guo W M, and Zhang G J, J Am Ceram Soc 92 (2009) 264.

Zhao H, He Y, and Jin Z, J. Am Ceram Soc, 78 (1995) 2534.

Su K, and Sneddon L G, Chem Mater 5 (1993), 1659.

Yan C, Liu R, Zhang C, Cao Y, and Long X, RSC Adv, 5 (2015), 78606.

Qiu H Y, Guo W M, Zou J, Zhang G J, Powder Technol 217 (2012) 462.

Yang B, Li J, Zhao B, Hu Y, Wang T, Sun D, Li R, Yin S, Feng Z, Tang Q, and Sato T, Powder Technol, 256, (2014) 522.

Zhang L, Min G H, Yu H S, Chen H M, Feng G, Key Eng Mater 326–328 (2006) 369.

Matkovich V I (ed), Boron and Refractory Borides (1997), p 319.

Rahaman M N, Ceramic Processing and sintering, New York, Marcel Dekkar, Inc., (1995).

Acknowledgements

The authors thankfully acknowledge the financial support received from DRDO, Govt. of India in order to carry out the present research study. We are also thankful to N. D. VaraPrasad, J. Vimala S. Venkat, and K. R. Iyanger, for their valuable support in the characterisation of the ZrB2 powder samples. We are grateful to the Director, Defence Metallurgical Research Laboratory (DMRL), Hyderabad for giving permission to publish this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Murthy, S.S.N., Patel, M., Reddy, J.J. et al. Influence of B4C Particle Size on the Synthesis of ZrB2 by Boro/Carbothermal Reduction Method. Trans Indian Inst Met 71, 57–65 (2018). https://doi.org/10.1007/s12666-017-1155-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1155-1