Abstract

Currently, thermophilic membrane biological reactors (TMBRs) are used to treat industrial wastewaters and biological sewage sludge with the aim of nutrients recovery. The performance of the biological process is strongly influenced by rheological behaviour of the thermophilic biological sludge (TBS) inside the reactor. Considering the high concentration of heavy metals in matrices fed to the reactors, this work aims to evaluate the influence of heavy metal types and concentration on rheological properties of TBS. Sludge has been extracted from a full-scale TMBR and conditioned with Fe3+, Cu2+, and Al3+. Rheological measures have been conducted and constants k and n of Herschel–Bulkley model were used to define the rheological properties of TBS. Rheological properties of high consistency TBS (0.06 ≤ k0 < 0.2 and 0.6 ≤ n0 < 0.8) were not significantly affected by the conditioning with Fe3+, Cu2+, and Al3+. In case of TBS with initial low consistency (0.02 ≤ k0 < 0.06) and behaviour more similar to Newtonian fluids (0.8 ≤ n0 < 1), Fe3+ and Al3+ determined a significant increase in consistency. On the contrary, the addition of Cu2+ reduced k of conditioned TBS with a lower impact on the distance for Newtonian behaviour (n). This work demonstrates the strong influence of Fe3+, Cu2+, and Al3+ on the rheological properties of TBS depending on the initial consistency of the sludge, and the types and dosage of heavy metals.

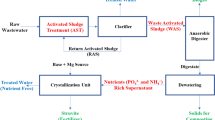

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

The rheological behaviour of sludge represents a key factor for optimal hydrodynamic behaviour in biological process. Several studies deal with rheological properties of biological sludge, but they are mainly focused on the influence of parameters such as temperature, pH and total solids on mesophilic sewage sludge. The novelty of this study is that the influence of heavy metals concentration on the rheological properties of a thermophilic biological sludge has been studied. This work can serve as a reference for (i) further studies on parameters influencing the rheological behaviour of thermophilic sludge, and (ii) for an optimal management of full-scale thermophilic membrane biological reactors predicting the effects of feeding waste with a high heavy metal content.

Introduction

Biological reactors nowadays represent a valid solution for the treatment of wastewater (WW) and aqueous waste (AW), as amply demonstrated by the literature and evidenced by their diffusion in industrial plants [1]. Thanks to their tolerance to high concentration of pollutants, thermophilic membrane bioreactors (TMBRs) have been recently promoted and used to treat high-strength industrial WWs and biological sewage sludge (BSS) to recover nutrients, both in organic and inorganic form [2,3,4]. However, as for conventional biological processes, the characterization of the system with suitable quantitative methods remains a crucial point to optimize the process, improving performances and minimizing costs.

For instance, performance of biological processes is strongly influenced by the hydrodynamic behaviour of sludge in reactor. To date, computational fluid dynamics (CFD) models are solid and well-founded approaches that represent a fundamental tool for the design of biological reactors [5]. They can also be effectively used in monitoring the hydraulic behaviour of already built systems to detect dead volumes and flow bypasses [6,7,8]. However, fluid dynamic models are based on many parameters such as, for instance, shear stress, shear rate and apparent viscosity. Therefore, the knowledge of rheological properties represents a necessary requirement to compute representative CFD models [8, 9].

Moreover, the rheological properties of activated sludge have been investigated since they severely impact many aspects of biological systems management [10]. Typical examples are sludge pumping, bioreactor hydrodynamics, mass transfer efficiency of aeration systems, sludge-water separation by decantation and filtration [11,12,13,14]. Therefore, knowing the relationships between the rheological parameters of the biological reactor and the input of the plant allows also to program the feeding process to optimize performance and reduce costs [15].

TMBRs are generally fed with industrial AW and BSS very variable in terms of composition [2,3,4]. In urban BSS fed to TMBRs, heavy metals generally do not represent an issue with concentration in the order of 100–1000 mg kg−1 of dry matter [3]. On the contrary, in AW, the content of heavy metals can be very high depending mainly by the industrial process in which they originate. For instance, aqueous residue from the treatment of metal surface can contain heavy metals over 50,000 mg L−1 [16] and must be therefore subjected to a coagulation/flocculation pre-treatment to reduce content. In general, the biota in thermophilic conditions showed good activity even in the presence of high concentrations of heavy metals but the maximum acceptable concentration is highly dependent on the type of cation. For instance, Cu2+ presents toxicity on thermophilic biota at concentration of one order of magnitude lower than Al3+ (almost 0.3 vs. 1 mg g−1) [17, 18].

Several previous studies were focused on the influence of physico-chemical parameters on rheological behaviour of TBS highlighting a strong dependence from total solids content, pH, and temperature while a not clear impact of aeration conditions was pointed out [19,20,21]. Other studies also showed a significant impact of pre-treatment. For instance, Riley and Forster [22] demonstrated that thermophilic aerobically digested sludge showed yield stresses one order of magnitude lower than not-digested sludge with similar TS concentration. Also Dai et al. [19] found that higher sludge retention time in anaerobic digester stimulates lower levels viscosity and consistency index with higher value of flow behaviour index.

However, literature lacks information about the influence of specific pollutants as heavy metals on rheological behaviour of biological sludge, representing a huge gap especially for a proper management of TMBRs.

In this work, the influence of heavy metals on the rheological properties of the TBS are presented and discussed. The shear stress and the apparent viscosity of TBS, extracted from a full-scale TMBR, have been evaluated as a function of the increasing concentration of iron (Fe3+), copper (Cu2+), and aluminium (Al3+) and of the initial consistency of the sludge. This work can serve as a reference for (i) other researchers, answering questions as how do heavy metals affect the rheology of a TBS? Does the effect depend on the type of metal tested? and for (ii) water utilities, providing helpful information to predict the effects of feeding AW with high heavy metals content on the rheological properties of TBS in a full-scale plant.

Materials and Methods

Rheological Model

In literature, several models that interpolate shear stress—shear rate evaluated by experimental measurements in order to obtain the relative flow curve are available [23]. Most of these models adopt a power-low curve including an offset to account for stress yield y. When considering TBS from a membrane system, Herschel–Bulkley model (Eq. 1) can provide an adequate adaptation of experimental data of these sludge samples because characterized by a high concentration of solids [20, 24].

τ (Pa) is the shear stress and γ ̇ represents the share rate (s−1). τ0 (Pa) represents the yield shear stress and quantifies the amount of stress that the fluid may experience before it yields and begins to flow. k and n are characteristic constants of the fluid. k indicates the consistency of the fluid and the higher the more viscous the fluid is. The exponent n, less than 1, expresses the non-Newtonian behaviour; the more n differs from the unit, the more the characteristics of the fluid differ from the Newtonian ones.

Sludge Characteristics

TBS was collected from a full-scale TMBR located in Mortara (Lombardy, Italy). The plant treats AW containing also high concentration of heavy metals. The system (1700 m3) is composed by a biological reactor and an ultrafiltration line (membrane cut-off: 300 kDa) operating with 3–5 bar of pressure. In the biological reactor, aerobic conditions (1.5–3 mg L−1O2) are maintained injecting pure oxygen. Thanks to spontaneous exothermic reactions due to organic matter degradation by thermophilic biota [25], the temperature is maintained constant at almost 49 °C. Full details of the characteristics of this biological plant are available in our previous study [26].

To evaluate the effect of initial consistency of the fluid and level of non-Newtonian behaviour, full-scale plant was monitored until the initial rheological conditions of thermophilic sludge changed. Two extractions were made: (i) one in low consistency sludge conditions and (ii) the other one with high-consistent sludge. Extracted TBS were diverse in term of rheological properties but not in terms of physico-chemical characteristics and heavy metals concentration (which was almost zero) (Table 1). In fact, to easy the conditioning procedure, samples were taken after a period of almost no feeding of heavy metals-rich AW in the reactor.

Preparation of Heavy Metals Solutions

CuSO4, FeCl3 and AlCl3, purchased from Sigma-Aldrich (Merck Group, MO, USA), were used to prepare doping solutions with copper, iron, and aluminium, respectively, in ultrapure water (Purite Select; SUEZ Water Purification Systems Ltd, France). To avoid change in total solids content of the sludge samples after conditioning, highly concentrated heavy metals solutions (80–300 mg g−1) were prepared.

Practical Procedure

The TBS was withdrawn from the full-scale plant and delivered to the laboratory in a plastic tank within 1 h after sampling. To evaluate the effect of the increase in the concentration of heavy metals on the rheological features, the TBS was conditioned with the alternative addition of Fe3+, Cu2+, and Al3+ by testing up to a concentration of 1.35 mg g−1, 0.65 mg g−1, and 0.52 mg g−1, respectively. This choice was made: (i) considering typical concentration of Fe3+, Cu2+, and Al3+ in TBS when heavy metals-rich AW are fed (data not shown), and (ii) to study the phenomenon in a wider spectrum testing heavy metals also in extreme conditions of concentration. After heavy metals dosage, the conditioned TBS was mixed for 4 h before carrying out the rheological measurement to completely homogenize the sample.

The rheological tests were carried out using rheometer RC20 (RheoTec) with a configuration CC25DIN of coaxial cylinders. Spindle radius measured 12.5 mm while the internal radius of the measuring cylinder was 13.56 mm. The working principle of the instrument is based on the sliding of the TBS in the cavity between the coaxial cylinders, thanks to the spindle rotation with a fixed share rate, while the external cylinder is held, needs a torque that is measured by the instrument [20]. Each rheological test was performed with fixed shear rates maintained for 150 s and increased step by step. Shear stress and apparent viscosity were recorded every 15 s (ten data sets for each share rate). The following shear rates were tested: 25 s−1–50 s−1–100 s−1–200 s−1–400 s−1–600 s−1–800 s−1–1000 s−1. The mean and confidence interval of the shear stress measurements for each applied shear rate were calculated.

To better simulate real conditions at full-scale, the temperature during test was maintained at 48–50 °C using a thermostatic bath. The scheme of the apparatus is reported in Fig. 1.

Data Analysis

In the present study, for the calculation of the initial/breaking shear stress, yield was considered as a deterministic parameter in the interval 0–3.99 Pa with steps of 0.05 Pa. For each of these values, the regression coefficient R2 was estimated and used for the choice of τ0 that produce a best fitting. The accuracy of the interpolation was estimated through an additional statistical descriptor which is the standard estimation error.

The Herschel-Buckley model was used to estimate ki and ni of conditioned samples and results were referred to k and n of not-conditioned sludge (k0 and n0) in which heavy metals were almost absent (Table 1). ki k0−1 were fitted with 2-nd degree polynomial function (in case of Fe3+ and Al3+) and linear function (in case of Cu2+) as a function of heavy metals dosage. To evaluate the influence of initial rheological characteristics of sludge, data has been also analysed grouping results in two diverse cases depending on initial k0 and n0. Moreover, to better highlight the influence of the metal in the change of rheological properties, ki mod and ni mod were calculated for diverse predetermined iron, copper, and aluminium concentrations based on fitting functions previously found.

Results and Discussion

Influence of Initial Rheological Properties

Iron (Fe3+)

In Fig. 2, values of ki k0−1 and ni n0−1 as a function of Fe3+ concentration are showed considering also diverse initial rheological condition of TBS.

a ki k0−1 and b ni n0−1as a function of Fe.3+ concentration. Orange lines represent the 2-nd degree fitting while black lines represent the unchanged situation (ki = k0 or ni = n0). The bars represent the 95% confidence interval (n = 3). (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article)

The effect of the Fe3+ dosage on the rheological properties of the TBS was diverse depending on the initial characteristics of the sludge. In case of a TBS with a higher initial consistency value of the fluid (0.06 ≤ k0 < 0.2) and a behaviour more distant from the Newtonian one (0.6 ≤ n0 < 0.8), it was not possible to highlight significant variations in the rheological parameters when varying of the tested metal concentration (Fig. 2).

On the contrary, the Fe3+ concentration seemed to have a greater influence on the rheology of the TBS with initial characteristics typical of a Newtonian fluid (0.8 ≤ n0 < 1) and characterized by a low consistency index (0.02 ≤ k0 < 0.06). As the metal concentration increased beyond 0.4 mg g−1, the consistency index increased considerably (ki k0−1 up to 5.29 with 1.13 mg g−1 of Fe3+), and the behaviour of the fluid deviated more than that typical of Newtonian fluids (ni n0−1 dropped down to 0.75).

This increase can be attributed to the strong coagulating effect caused by the reaction of the iron in contact with the TBS. The dosage of Fe3+ determined the formation of bridge bonds that reduce the negative zeta-potential typical of biological sludge [27], leading to the formation of aggregates more resistant to shear stress. The consequent limitation of Brownian movements of particles increased the consistency index and reduced the value of n [28,29,30]. However, this result was apparently in contrast with Shrestha et al. [31] who highlighted a reduction in the viscosity of the biological sludge in case of FeCl3 dosage. However, difference of results can be mainly attributed to three aspects: (i) the diverse dosage method (continuous in the previous one, impulse in our study), (ii) the diverse type of sludge tested (mesophilic in the previous study), and (iii) the Fe3+ dosage of at least one order of magnitude lower in the previous study compared to this one.

The different behaviour of TBS with a higher initial consistency and more distant from the Newtonian fluids (0.06 ≤ k0 < 0.2; 0.6 ≤ n0 < 0.8) and that with a lower initial consistency and behaviour closer to the Newtonian ones (0.02 ≤ k0 < 0.06; 0.8 ≤ n0 < 1) can be attributed to the diverse initial zeta-potential. In the first case, the zeta-potential can be considered very low, given the high initial consistency due to a limited phenomenon of Brownian motion of the particles [28, 29]. Therefore, the addition of cations did not cause an appreciable variation of the rheological properties. In the second case, the low initial consistency, determined by the strongly negative zeta-potential, produced a more appreciable coagulating phenomenon upon the addition of Fe3+.

Copper (Cu2+)

In Fig. 3, values of ki k0−1 and ni n0−1 as a function of Cu2+ concentration are presented considering also diverse initial rheological condition of TBS.

a ki k0−1 and b ni n0−1as a function of Cu.2+ concentration. Orange lines represent the 1-st degree fitting while black lines represent the unchanged situation (ki = k0 or ni = n0). The bars represent the 95% confidence interval (n = 3). (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article)

Unlike Fe3+, Cu2+ showed a different effect on the rheological properties of the TBS. The dosage of copper caused a behaviour that was qualitatively and quantitatively dependent on the initial consistency and distance from the Newtonian behaviour.

In the case of TBS with higher initial consistency value and a fluid behaviour more distant from the Newtonian (0.06 ≤ k0 < 0.2; 0.6 ≤ n0 < 0.8), it was not possible to highlight significant variations in the rheological parameters as the metal concentration (Fig. 3).

On the contrary, the concentration of Cu2+ seemed to have a greater influence on the rheology of the TBS with initial characteristics typical of a Newtonian fluid (0.8 ≤ n0 < 1) characterized by a low consistency index (0.02 ≤ k0 < 0.06). As the metal concentration increased, the consistency index decreased considerably (ki k0−1 up to 0.542 with about 0.65 mg g−1 of Cu2+, maximum tested concentration), and the behaviour of the fluid tended to slightly deviate from that typical of Newtonian fluids (ni n0−1 grown up to 1.09).

This decrease in viscosity can be attributed to the lack of coagulating capacity of copper and its toxic-inhibiting effect also in lower concentrations [32]. The stress condition imposed by the presence of Cu2+ could have determined the release of soluble microbial products (SMP) by the biomass [33, 34]. These, together with the extracellular polymeric substances (EPS) could cause the reduction of the consistency of the fluid (k). These results are confirmed by Chen et al. [35] which found in their study that the release of EPS determined a reduction in sludge viscosity increasing sludge settleability.

The absence of perceived decrease in consistency as the Cu2+ dosage increased in the presence of a TBS with a higher initial consistency value and a fluid behaviour more distant from the Newtonian one (0.06 ≤ k0 < 0.2; 0.6 ≤ n0 < 0.8) is to be attributed to the more marked initial presence of bridge bonds which are only minimally reduced by the formation of substances with surfactant power.

Aluminium (Al3+)

In Fig. 4, values of ki k0−1 and ni n0−1 as a function of Al3+ concentration are showed considering also diverse initial rheological condition of TBS.

a ki k0−1 and b ni n0−1as a function of Al.3+ concentration. Orange lines represent the 2-nd degree fitting while black lines represent the unchanged situation (ki = k0 or ni = n0). The bars represent the 95% confidence interval (n = 3). (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article)

In terms of behaviour, the effect of the Al3+ dosage was similar to that obtained with the addition of Fe3+. Also in this case, in the case of TBS with higher initial values of the fluid consistency (0.06 ≤ k0 < 0.2) and greater distance from the Newtonian behaviour (0.6 ≤ n0 < 0.8), no significant rheological changes have been highlighted (Fig. 4).

On the contrary, as for Fe3+, the concentration of Al3+ has a greater influence on the rheology of the TBS with initial characteristics typical of a Newtonian fluid (0.8 ≤ n0 < 1) and with a low consistency index (0.02 ≤ k0 < 0.06). As the metal concentration increases beyond 0.2 mg g−1, the consistency index increases considerably (ki k0−1 up to 4.82 with 0.52 mg g−1 of Al3+, maximum tested concentration), and the behaviour of the fluid deviates more than that typical of Newtonian fluids (ni n0−1 decreased to 0.74).

This result can be compared to what has already been stated for Fe3+ (Sect. 3.1.1.): the addition of the metal leads to the formation of aggregates which increase the consistency index by binding to the negatively charged sites on the TBS surface and stepped away the behaviour of the sludge from that typical of Newtonian fluids [36].

Similarly to what was observed for Fe3+ (Sect. 3.1.1.), the diverse behaviour between the TBS with higher initial consistency and non-Newtonian properties (0.06 ≤ k0 < 0.2; 0.6 ≤ n0 < 0.8) and that with a more limited initial consistency and more close to the Newtonian one (0.02 ≤ k0 < 0.06; 0.8 ≤ n0 < 1) can be attributed to the different initial zeta-potential (very close to zero in the first case, markedly negative in the second) [28, 29]. The addition of Al3+ in the first case did not cause an appreciable variation of the rheological properties while in the second case produced a more appreciable formation of bridge bonds producing aggregated particles more resistant to shear stress [28,29,30].

Comparison of the Influence of Metals Dosed

Considering the interpolating models (2-nd degree for Fe3+ and Al3+, 1-st degree for Cu2+) identified for each single metal, the ki mod k0−1 and ni mod n0−1 at diverse predetermined metal concentrations were calculated, by way of comparison (Fig. 5).

Only 0.02 ≤ k0 < 0.06 and 0.8 ≤ n0 < 1 cases were evaluated considering that rheological properties of initial high consistency TBS were not significantly affected by the conditioning with heavy metals. The diverse behaviour of Fe3+ and Al3+ compared to Cu2+ was highlighted.

In the first two cases, the coagulating effect of the metal substantially increased the consistency of the fluid away from the typically Newtonian behaviour. TBS conditioned with Al3+ showed a more pronounced effect than Fe3+ (C: 0.05 mg g−1), with ki mod k0−1 reaching 1.33 and 1.16, respectively. In case of higher concentration (C: 0.75 mg g−1), the effect of Al3+ was almost third times the effect of Fe3+ (ki mod k0−1 equals to 9.44 and 3.04, respectively).

Instead, TBS conditioned with Cu2+ showed an opposite effect due to the absence of the coagulating phenomenon associated with an inhibitory phenomenon of biomass [32]. In presence of 0.05 mg g−1 of copper, the model estimated that ki mod k0−1 dropped to 0.84 with an almost constant value of n (ni mod n0−1 equals to 1.02). Increasing Cu2+ concentration up to 0.75 mg g−1, ki mod k0−1 decreased to 0.39 and not significant differences in n have been evaluated (ni mod n0−1: 1.1).

Conclusions

This study demonstrates the strong influence of Fe3+, Cu2+, and Al3+ on the rheological properties of TBS depending on the initial consistency of the sludge and the types and dosage of heavy metals. In case of TBS with initial low consistency (0.02 ≤ k0 < 0.06) and behaviour similar to Newtonian fluids (0.8 ≤ n0 < 1), Fe3+ and Al3+ determined a significant increase in consistency, especially in high concentration. In case of TBS conditioned with 0.05 mg g−1 of Fe3+ or Al3+, with ki mod k0−1 reached 1.16 and 1.33, respectively. On the contrary, the addition of Cu2+ on initial low consistency TBS, markedly reduced k with a lower impact on the distance for Newtonian behaviour (n). In presence of 0.05 mg g−1 of copper, the model estimates that ki mod k0−1 dropped to 0.84 with an almost constant value of n (ni mod n0−1 equals to 1.02). Rheological properties of initial high consistency TBS (0.06 ≤ k0 < 0.2 and 0.6 ≤ n0 < 0.8) were not significantly affected by the conditioning with Fe3+, Cu2+, and Al3+. Therefore, this study provides helpful information for the proper management of thermophilic biological systems giving details about expected changes in rheological characteristics of sludge based on types and amount of heavy metals fed. This knowledge represents a crucial point considering that sludge consistency affects hydrodynamic behaviour in reactors and therefore performances of the process.

Data Availability

All data generated or analysed during this study are included in this published article.

References

Henze, M., Comeau, Y.: Wastewater characterization. In: Biological Wastewater Treatment: Principles Modelling and Design, pp. 33–52 (2008)

Collivignarelli, M.C., Abbà, A., Caccamo, F.M., Carnevale Miino, M., Durante, A., Bellazzi, S., Baldi, M., Bertanza, G.: How to produce an alternative carbon source for denitrification by treating and drastically reducing biological sewage sludge. Membranes (Basel) 11, 977 (2021). https://doi.org/10.3390/membranes11120977

Collivignarelli, M.C., Abbà, A., Carnevale Miino, M., Caccamo, F.M., Argiolas, S., Bellazzi, S., Baldi, M., Bertanza, G.: Strong minimization of biological sludge production and enhancement of phosphorus bioavailability with a thermophilic biological fluidized bed reactor. Process Saf. Environ. Prot. 155, 262–276 (2021). https://doi.org/10.1016/j.psep.2021.09.026

Collivignarelli, M.C., Abbà, A., Bertanza, G., Baldi, M., Setti, M., Frattarola, A., Carnevale Miino, M.: Treatment of high strength wastewater by thermophilic aerobic membrane reactor and possible valorisation of nutrients and organic carbon in its residues. J. Clean. Prod. (2021). https://doi.org/10.1016/j.jclepro.2020.124404

Leonzio, G.: Fluid dynamic study of anaerobic digester: optimization of mixing and geometric configuration by using response surface methodology and factorial design. Renew. Energy. 136, 769–780 (2019). https://doi.org/10.1016/j.renene.2018.12.115

Hreiz, R., Latifi, M.A., Roche, N.: Optimal design and operation of activated sludge processes: state-of-the-art. Chem. Eng. J. 281, 900–920 (2015). https://doi.org/10.1016/j.cej.2015.06.125

Collivignarelli, M.C., Carnevale Miino, M., Manenti, S., Todeschini, S., Sperone, E., Cavallo, G., Abbà, A.: Identification and localization of hydrodynamic anomalies in a real wastewater treatment plant by an integrated approach: RTD-CFD analysis. Environ. Process. 7, 563–578 (2020). https://doi.org/10.1007/s40710-020-00437-4

Manenti, S., Todeschini, S., Collivignarelli, M.C., Abbà, A.: Integrated RTD − CFD hydrodynamic analysis for performance assessment of activated sludge reactors. Environ. Process. 5, 23–42 (2018). https://doi.org/10.1007/s40710-018-0288-5

Terashima, M., Goel, R., Komatsu, K., Yasui, H., Takahashi, H., Li, Y.Y., Noike, T.: CFD simulation of mixing in anaerobic digesters. Biores. Technol. 100(7), 2228–2233 (2009). https://doi.org/10.1016/j.biortech.2008.07.069

Campbell, H.W., Crescuolo, P.J.: The use of rheology for sludge characterization. Water Sci. Technol. 14, 475–489 (1982). https://doi.org/10.2166/wst.1982.0120

Todeschini, S., Ciaponi, C., Papiri, S.: Laboratory experiments and numerical modelling of the scouring effects of flushing waves on sediment beds. Eng. Appl. Comput. Fluid Mech. 4, 365–373 (2010). https://doi.org/10.1080/19942060.2010.11015324

Craig, K.J., Nieuwoudt, M.N., Niemand, L.J.: CFD simulation of anaerobic digester with variable sewage sludge rheology. Water Res. 47, 4485–4497 (2013). https://doi.org/10.1016/j.watres.2013.05.011

Seyssiecq, I., Ferrasse, J.-H., Roche, N.: State-of-the-art: rheological characterisation of wastewater treatment sludge. Biochem. Eng. J. 16, 41–56 (2003). https://doi.org/10.1016/S1369-703X(03)00021-4

Collivignarelli, M.C., Carnevale Miino, M., Bellazzi, S., Caccamo, F.M., Durante, A., Abbà, A.: Review of rheological behaviour of sewage sludge and its importance in the management of wastewater treatment plants. Water Pract. Technol. (2021). https://doi.org/10.2166/wpt.2021.098

Eshtiaghi, N., Markis, F., Yap, S.D., Baudez, J.-C., Slatter, P.: Rheological characterisation of municipal sludge: a review. Water Res. 47, 5493–5510 (2013). https://doi.org/10.1016/j.watres.2013.07.001

Collivignarelli, M.C., Abbà, A., Bestetti, M., Crotti, B.M., Carnevale Miino, M.: Electrolytic recovery of nickel and copper from acid pickling solutions used to treat metal surfaces. Water Air Soil Pollut. 230, 101 (2019). https://doi.org/10.1007/s11270-019-4158-1

Ahring, B.K., Westermann, P.: Toxicity of heavy metals to thermophilic anaerobic digestion. Europ. J. Applied Microb. Biotech. 17(6), 365–370 (1983)

Cabirol, N., Barragán, E.J., Durán, A., Noyola, A.: Effect of aluminium and sulphate on anaerobic digestion of sludge from wastewater enhanced primary treatment. Water Sci. Technol. 48(6), 235–240 (2003). https://doi.org/10.2166/wst.2003.0407

Dai, X., Gai, X., Dong, B.: Rheology evolution of sludge through high-solid anaerobic digestion. Biores. Technol. 174, 6–10 (2014). https://doi.org/10.1016/j.biortech.2014.09.122

Abbá, A., Collivignarelli, M.C., Manenti, S., Pedrazzani, R., Todeschini, S., Bertanza, G.: Rheology and microbiology of sludge from a thermophilic aerobic membrane reactor. J. Chem. (2017). https://doi.org/10.1155/2017/8764510

Collivignarelli, M.C., Abbà, A., Frattarola, A., Manenti, S., Todeschini, S., Bertanza, G., Pedrazzani, R.: Treatment of aqueous wastes by means of thermophilic aerobic membrane reactor (TAMR) and nanofiltration (NF): process auditing of a full-scale plant. Environ. Monit. Assess. 191(12), 1–17 (2019). https://doi.org/10.1007/s10661-019-7827-z

Riley, D.W., Forster, C.F.: The physico-chemical characteristics of thermophilic aerobic sludges. J. Chem. Technol. Biotechnol. 76(8), 862–866 (2001). https://doi.org/10.1002/jctb.456

Ratkovich, N., Horn, W., Helmus, F.P., Rosenberger, S., Naessens, W., Nopens, I., Bentzen, T.R.: Activated sludge rheology: a critical review on data collection and modelling. Water Res. 47, 463–482 (2013). https://doi.org/10.1016/j.watres.2012.11.021

Yang, F., Bick, A., Shandalov, S., Brenner, A., Oron, G.: Yield stress and rheological characteristics of activated sludge in an airlift membrane bioreactor. J. Memb. Sci. 334, 83–90 (2009). https://doi.org/10.1016/j.memsci.2009.02.022

Collivignarelli, M.C., Carnevle Miino, M., Cillari, G., Bellazzi, S., Caccamo, F.M., Abbà, A., Bertanza, G.: Estimation of thermal energy released by thermophilic biota during sludge minimization in a fluidized bed reactor: influence of anoxic conditions. Process Saf. Environ. Prot. 166, 249–256 (2022). https://doi.org/10.1016/j.psep.2022.08.034

Collivignarelli, M.C., Carnevale Miino, M., Caccamo, F.M., Baldi, M., Abbà, A.: Performance of full-scale thermophilic membrane bioreactor and assessment of the effect of the aqueous residue on mesophilic biological activity. Water 13, 1754 (2021). https://doi.org/10.3390/w13131754

Mikkelsen, L.H.: The shear sensitivity of activated sludge. Colloids Surfaces A Physicochem. Eng. Asp. 182, 1–14 (2001). https://doi.org/10.1016/S0927-7757(00)00772-X

Chang, S.H., Ryan, M.H., Gupta, R.K.: The effect of pH, ionic strength, and temperature on the rheology and stability of aqueous clay suspensions. Rheol. Acta. 32, 263–269 (1993). https://doi.org/10.1007/BF00434190

Morariu, S., Bercea, M.: Effect of temperature and aging time on the rheological behavior of aqueous poly(ethylene glycol)/laponite RD dispersions. J. Phys. Chem. B. 116, 48–54 (2012). https://doi.org/10.1021/jp208136g

Zhao, Y.X., Gao, B.Y., Zhang, G.Z., Qi, Q.B., Wang, Y., Phuntsho, S., Kim, J.-H., Shon, H.K., Yue, Q.Y., Li, Q.: Coagulation and sludge recovery using titanium tetrachloride as coagulant for real water treatment: a comparison against traditional aluminum and iron salts. Sep. Purif. Technol. 130, 19–27 (2014). https://doi.org/10.1016/j.seppur.2014.04.015

Shrestha, S., Sharma, K., Chen, Z., Yuan, Z.: Unravelling the influences of sewer-dosed iron salts on activated sludge properties with implications on settleability, dewaterability and sludge rheology. Water Res. 167, 115089 (2019). https://doi.org/10.1016/j.watres.2019.115089

Esquivel-Rios, I., González, I., Thalasso, F.: Microrespirometric characterization of activated sludge inhibition by copper and zinc. Biodegradation 25, 867–879 (2014). https://doi.org/10.1007/s10532-014-9706-1

Liu, T., Wang, Z., Wu, L., Guo, M., Yang, C., Cao, X., Qiu, X., Kong, Z., Zhong, M., Pan, B., Ke, Y., Zheng, X.: Acute impact of Hg2+, Cu2+, and Ag+ on the formation of biopolymers and nitrogenous soluble microbiological products in activated sludge for wastewater treatment. Environ. Pollut. 267, 115388 (2020). https://doi.org/10.1016/j.envpol.2020.115388

Li, J., Liu, X., Liu, Y., Ramsay, J., Yao, C., Dai, R.: The effect of continuous exposure of copper on the properties and extracellular polymeric substances (EPS) of bulking activated sludge. Environ. Sci. Pollut. Res. 18, 1567–1573 (2011). https://doi.org/10.1007/s11356-011-0492-6

Chen, Y., Chen, Y., Gu, G.: Influence of pretreating activated sludge with acid and surfactant prior to conventional conditioning on filtration dewatering. Chem. Eng. J. 99, 137–143 (2004). https://doi.org/10.1016/j.cej.2003.08.027

Forster, C.F.: The rheological and physico-chemical characteristics of sewage sludges. Enzyme Microb. Technol. 30, 340–345 (2002). https://doi.org/10.1016/S0141-0229(01)00487-2

Acknowledgements

The authors wish to thank ASMia S.r.l. (ASMortara Group) and Idroclean S.r.l. (Itelyum Group) for the support during the research. The authors wish also to thanks Prof. Sara Todeschini and Prof. Sauro Manenti (Department of Civil Engineering and Architecture, University of Pavia) for their very helpful suggestions in elaboration of rheological measures.

Funding

Open access funding provided by Università degli Studi di Pavia within the CRUI-CARE Agreement. The authors declare that no funds, grants, or other financial support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

MCC: conceptualization, methodology, funding acquisition, resources, supervision. SB: formal analysis and investigation, writing-original draft preparation, visualization. MCM: writing-original draft preparation, writing-review and editing, visualization. FMC: writing-original draft preparation. SC: writing-original draft preparation. AD: formal analysis and investigation. MB: conceptualization, methodology, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Collivignarelli, M.C., Bellazzi, S., Carnevale Miino, M. et al. Influence of Heavy Metals on the Rheology of a Thermophilic Biological Sludge for nutrients Recovery: Effect of Iron, Copper, and Aluminium on Fluid Consistency. Waste Biomass Valor 14, 2495–2504 (2023). https://doi.org/10.1007/s12649-022-01928-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01928-1