Abstract

Purpose

This work studies the immobilization of two enzymes, the alcohol dehydrogenase (ADH) and the aldehyde dehydrogenase (AldDH) both from Saccharomyces cerevisiae, which could be used to produce high value-added molecules from carboxylic acids embedded in anaerobic digestate.

Methods

In particular, three mesoporous siliceous materials, with different specific surface areas and pore sizes, (MSU-H, MSU-F and MCF0.75) were used as supports for covalent immobilization. The support materials were characterized by complementary techniques. Then, after a functionalization, creating a covalent bond between the enzyme and the support was performed. The specific activity and immobilization yield of the biocatalysts were then evaluated.

Results

The best results were obtained with MSU-H and MSU-F, resulting in an immobilization yield greater than 50% in all cases, a specific activity of 0.13 IU/gsupp with the AldDH/MSU-H, 0.10 IU/gsupp with AldDH/MSU-F, 48.6 IU/gsupp with ADH/MSU-H and 12.6 IU/gsupp with ADH/MSU-H. These biocatalysts were then characterized by optimal pH and temperature and the stability factor was evaluated. With ADH/MSU-F no decrease in activity was observed after 120 h incubated at 50 °C. Finally, the biocatalysts AldDH/MSU-H and ADH/MSU-H were used to perform the reduction reaction and it was seen that after five reaction cycles the residual activity was greater than 20% in both cases.

Conclusion

The ADH and AldDH enzymes have been successfully immobilized on mesoporous siliceous supports, considerably increasing their thermal stability and being able to reuse them for several reaction cycles. The use of this immobilization and these supports is adaptable to a wide variety of enzymes.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

The valorization of digestate from anaerobic fermentation processes can make a great contribution to the development of increasingly sustainable processes. In particular, by enhancing the carboxylic acids it is possible to obtain alcohols, which can be used in a great variety of chemical processes. For the first time, the AldDH enzyme was covalently immobilized on mesoporous siliceous supports and used in series with the ADH enzyme to carry out the carboxylic acid reduction reaction. In this way, it is possible to obtain alcohols starting from an organic waste fraction. The two enzymes were successfully immobilized on different mesoporous siliceous supports. Their thermal stability was considerably increased, and it was possible to use them for more reaction cycles.

Introduction

Converting carbon dioxide, the organic fraction of municipal solid waste and other types of waste, agricultural or industrial, into high value-added molecules in a sustainable manner is the main challenge to be overcome worldwide to facilitate a transition to a circular economy model. In particular, by fully exploiting the organic fraction of municipal solid waste and the numerous agricultural by-products, carboxylic acids, biohydrogen, and biomethane can be produced through an anaerobic fermentation process [1].

Carboxylic acids, after a first phase of concentration and purification, can be further enhanced to produce molecules with higher added value, for example, alcohols, which have countless applications in the chemical industry and can be used as fuels, fragrances, emollients, and plasticizers [2].

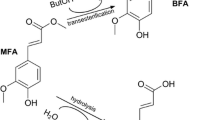

There are several techniques to enhance carboxylic acids, for example using inorganic catalysts [3] or different fungal species [4]. In this work, an enzymatic strategy using two enzymes in series was proposed. In the first step of the reaction, carboxylic acids are reduced to aldehydes, using the enzyme aldehyde dehydrogenase (AldDH), and then the aldehydes to alcohols, using the enzyme alcohol dehydrogenase (ADH). Both the enzymes were obtained from Saccharomyces cerevisiae. To the best of our knowledge, the use of two enzymes in a series has never been used to carry out the carboxylic acid reduction reaction.

The enzyme carboxylic acid reductase (CAR) is widely used to perform the first reaction [2]. However, this enzyme uses at the same time two cofactors to perform the reduction, ATP and NADH [5]. It was therefore decided to use the AldDH enzyme. This enzyme is widely studied to catalyze the oxidation of aldehydes to alcohols [6, 7]; however, the use in series with the enzyme ADH could shift the reaction to the right, as shown in Fig. 1, as the aldehydes produced would be immediately converted to alcohols. Similar behavior is found in the case of the production of methanol from formic acid, although in this case the enzyme formaldehyde dehydrogenase is used [8]. The second enzyme of the series, on the other hand, catalyzes very well the reaction of interest, that is, the reduction of aldehydes to alcohols [8]. Both enzymes, therefore, use only NADH as a cofactor and a high concentration is necessary to obtain high quantities of desirable products. NADH is a very expensive molecule and it is, therefore, necessary to carry out a process of regeneration of the cofactor to make the process more sustainable and feasible in its scalability [9].

Due to the high production and purification cost of enzymes, it is essential to immobilize them in order to increase thermal stability and at the same time be able to recover and reuse them for more than one reaction. In literature, among the various immobilization techniques, excellent results on a wide variety of enzymes regarding thermal stability were obtained using covalent immobilization. In addition, the use of a covalent bond prevents leaching and allows to use the biocatalyst (enzyme immobilized on the support) for more batch reactions. In particular, covalent immobilization with glyoxyl or amino groups appears to be very promising [10,11,12]. In the first case, glyoxyl groups react directly with the amino groups of the lysine residues, whereas by using an amino-functionalized support, the covalent immobilization is carried out using glutaraldehyde, after a first ionic immobilization between the enzymes and the support. Glutaraldehyde is a bifunctional molecule, that reacts with the amino groups of the lysine residues and the amino groups of the support [13]. The choice of support is also of great importance and it is crucial to optimize the immobilization of each enzyme [14].

A wide variety of materials can be used as supports in covalent immobilization, with different characteristics and properties such as natural zeolite [10], agarose [15, 16] or chitosan [17]. Another very interesting option is the use of mesoporous silica, highly suitable for enzymatic immobilization [18,19,20]. These materials have very high surface areas and there is the possibility of synthesizing them with different pore structures (e.g. foam-like, cubic, hexagonal) and diameters (in the range of 2–50 nm) [19, 21]. These characteristics can be optimized according to the enzyme used.

In this work, three types of silica have been characterized, with field emission scanning electron microscopy (FESEM) and N2 physisorption at − 196 °C, and tested as immobilization supports for AldDH and ADH enzymes. In particular, a mesoporous silica with a hexagonal structure (MSU-H), with an average pore diameter of 7 nm, and two mesoporous silicas with a mesocellular foam-type structure (MSU-F and MCF0.75), having an average pore diameter of 15 and 25 nm respectively, were used [18, 22]. After a functionalization of the supports, with amino or glyoxyl groups, the enzymes were covalently bound to the supports. To the best of the authors' knowledge, these biocatalysts were never used to enhance carboxylic acids embedded in anaerobic digestate, and thus obtain alcohols. Furthermore, the AldDH enzyme has never been covalently immobilized on mesoporous silica.

The best support for each enzyme used was chosen, evaluating the enzymatic activity and the immobilization yield. For the most promising biocatalyst, the activity of the biocatalyst (enzyme immobilized on the support) was then evaluated with varying pH and temperature for each enzyme immobilized on the different supports, comparing it with that of free enzymes. It has been observed that the immobilized enzyme is relatively more active when the optimal conditions vary compared to the free enzyme, both in terms of temperature and pH. The thermal stability was also evaluated by incubating the free and immobilized enzyme at 50 °C and evaluating the residual activity at different times. This shows that these types of supports are very suitable for these enzymes and immobilization allows obtaining a high stability factor. Subsequently, the two reduction reactions were carried out. The first reaction was carried out using propionic acid and NADH and the second using propionaldehyde and NADH. To evaluate the conversion, the decrease in absorbance of NADH over time was measured using a UV–VIS spectrophotometer. The actual production of propionaldehyde using the first enzyme and propanol using the second enzyme has been evaluated using a GC–MS headspace. Finally, a reuse test was carried out, evaluating the residual activity after several reaction cycles.

Good results were obtained in terms of thermal stability and reuse of immobilized enzymes. Furthermore, the use of these supports and these types of immobilization can therefore be used on a large variety of enzymes, being able to optimize the average pore diameter of the support according to the chosen enzyme.

Materials and Methods

Materials

MSU-H, MSU-F, pluronic P-123 [poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol)], mesitylene (1,3,5-trimethylbenzene, 98wt%), HCl (37% wt%.), TEOS (tetraethylorthosilicate, 99 wt%), toluene (≥ 99.5), GPTMS [(3-Glycidyloxypropyl)trimethoxysilane, ≥ 98%], sulfuric acid (≥ 98%), sodium metaperiodate, APTES [(3-Aminopropyl)triethoxysilane, 99%], propionaldehyde (≥ 98%), ethanol (≥ 98%), glycerol (86%), sodium borohydride (≥ 98%), glutaraldehyde (50%) and aldehyde dehydrogenase from S. cerevisiae were purchased from Sigma Aldrich. Alcohol dehydrogenase from S. cerevisiae was acquired from Thermo Scientific. Nicotinamide adenine dinucleotide derivatives (NAD+, 99.6% and NADH, 97.1%) were supplied respectively from PanReach AppliChem and Acros Organics.

Silica Supports

For this study, two commercial silica supports, namely MSU-H and MSU-F, were investigated along with a synthesized mesocellular foam-type silica, namely MCF.

The synthesized MCF was prepared by a literature procedure slightly modified [23, 24]. The Pluronic P-123 is the templating agent and mesitylene is the organic swelling agent. The mesitylene-to-P-123 ratio was fixed to 0.75 wt%.

In 150 mL HCl solution (1.6 M), 4 g of P-123 were dissolved and stirred at 40 °C for 1 h. After that, 3 mL of mesitylene were added by drop-wising into the P-123 and HCl solution [21, 25, 26]. Subsequently, 8.5 g of TEOS were drop-wised into the previous solution and stirred continuously for 24 h at 40 °C. Then, the suspension was prepared for the hydrothermal treatment at 100 °C for 24 h in order to increase both the window size and the cell of the foam: the solution was put inside a Teflon autoclave in order to keep the temperature constant during the thermal treatment. Finally, the suspension was filtered by a vacuum pump, washed with deionized water, dried overnight at 100 °C and calcined at 500 °C for 6 h (heating rate of 10 °C/min) [25,26,27]. The MCF was labeled as “MCF0.75”.

Textural Characterization of the Supports

The Specific Surface Area (SBET), the total pore volume (Vp), and the average pore diameter (Dp) were investigated using the N2 physisorption at − 196 °C (Micrometrics Tristar II, USA instrument). The SBET was evaluated by the Brunauer–Emmett–Teller method (BET). The Vp was calculated at P/P0 = 0.97. The Dp was calculated by either applying the Barrett–Joyner–Halenda (BJH) algorithm according to a modified Broekhoff de Boer (BdB) method using Hill’s approximation for the adsorbed layer thickness (MCF materials) [28]. Before the N2 physisorption analysis, the samples were previously outgassed at 200 °C for 2 h in order to remove the molecular water and other atmospheric contaminants.

The sample morphology was analyzed using Field Emission Scanning Electron Microscopy (FESEM, Zeiss MERLIN, Gemini-II column).

Functionalization of the Supports with Glyoxyl Groups

The supports were functionalized to create glyoxyl groups after three reactions in series. In particular, 1.0 g of support was put in contact with 30 mL of GPTMS (1.0% v/v in toluene) at 105 °C for 5 h under strong agitation to generate epoxy groups. After washing with acetone and water, an hydrolysis with sulfuric acid was carried out using 30 mL of H2SO4 0.1 M at 85 °C for 2 h. Finally, after washing with water, an oxidation reaction with sodium metaperiodate was performed using 30 mL NaIO4 0.1 M at room temperature (r.t.) for 2 h. In this way, glyoxyl groups were created on the support. The support was then washed with water and phosphate buffer 0.1 M pH 7 and subsequently dried at r.t.. The protocol was modified from the literature [12]. The quantification of glyoxyl groups was performed by a back titration method as described by Guisan [29]. With the different supports, an amount of glyoxyl groups of about 500 μmol/gsupp was found.

Functionalization of the Supports with Amino Groups

To create amino groups, a functionalization was carried out with APTES. In particular, 1.0 g of support was put in contact with 30 mL of APTES (1.0% v/v in toluene) at 105 °C for 5 h. Subsequently, the support was washed with water and phosphate buffer 0.1 M pH 7 and dried at r.t. The protocol was modified from the literature [30].

Activity Assay of AldDH and ADH Enzymes

For the AldDH enzyme a solution consisting of 1.8 mL of phosphate buffer 100 mM pH 7, 0.125 mL of propionaldehyde 7.5 mM, 0.125 mL of NAD+ 50 mM was used. Then 0.025 mg of AldDH (for the activity of the free enzyme) or 5 mg of support (for the activity of the immobilized enzyme) was added. The change in absorbance at 340 nm dependent on the formation of NADH, which is generated during the oxidation of propionaldehyde, is measured using a Jasco V-730 UV–Vis spectrophotometer. The activity (A) is expressed in IU (international units) and corresponds to the amount of enzyme necessary to produce one μmol/min of NADH at pH 7 and 30 °C. The protocol was modified from the literature [7]. The activity of the ADH enzyme was obtained according to Ottone et al. [15]. In particular, the change in absorbance of NADH at 340 nm generated by the oxidation of ethanol was measured. A solution containing 2 mL of 250 mM ethanol and 0.1 mL of NAD+ 100 mM was used both in 100 mM phosphate buffer pH 7. Then 0.005 mg of ADH (for the activity of the free enzyme) or 5 mg of support (for the activity of the immobilized enzyme) was added.

Enzymatic Immobilization

Briefly, 4 mg of the enzyme (AldDH or ADH) were put in contact with 1.0 g of the functionalized support (with glyoxyl or amino groups) in 30 mL of buffer, as described in the following sections. During the test, the activity of the enzyme in the immobilization solution and the blank (enzyme not in contact with the support) was evaluated. The protein concentration was then evaluated by Bradford assay [31]. The immobilization was evaluated through the specific activity per gram of support (IU/gsupp), the specific activity per milligram of protein immobilized (IU/mgprot) and the immobilization yield (IY) expressed as in our previous work [18]. Through IY it is also possible to obtain the effective mg of protein immobilized on the support, defined by the product of the immobilization yield and the enzymatic load offered.

Immobilization on Glyoxyl Support

Immobilization on supports functionalized with glyoxyl groups was carried out at 4 °C, in 100 mM pH 10.05 carbonate buffer and under gentle stirring. A reaction time of 3 h was used, then glycerol and sodium borohydride to have respectively 15% v/v and 0.5 mg/mL in solution, were added. Finally, a washing was carried out with distilled water/phosphate buffer 100 mM pH 7, then the support was dried at 4 °C. This method was adapted from literature [10, 12].

Immobilization on Amino Support

The immobilization was carried out in accordance with our previous work [10]. It was carried out in phosphate buffer 5 mM pH 7 at a temperature of 4 °C under gently stirring. A reaction time of 3 h was used, then the support was separated from the immobilization solution and was put in contact with a 0.1% v/v glutaraldehyde in 25 mM buffer solution pH 7, for 30 min at 4 °C. Subsequently, a washing was carried out with water and phosphate buffer 5 mM pH 7 and finally the support was dried at 4 °C.

Temperature and pH Profiles for Free and Immobilized Enzymes

To evaluate the temperature profile, the enzymatic activity was calculated, as described previously in section “Activity Assay of AldDH and ADH Enzymes”, by varying only the temperature and keeping the pH fixed at 7. The pH profile was obtained by calculating the activity as described in section “Activity Assay of AldDH and ADH Enzymes”, varying the pH, and keeping the temperature fixed at 30 °C. A phosphate buffer was used for the activity at pH 6, 7 and 8. A carbonate buffer was used for the activity at pH 9 and 10.

Thermal Stability

The free and immobilized enzyme was incubated at 50 °C. Then, residual activity was measured as time increased to evaluate deactivation. First-order deactivation models, with or without residual activity, were used to describe the experimental points [14, 32]. Finally, the stability factor expressed as the ratio of the half-life of the immobilized and free enzyme was evaluated. The deactivations with or without residual activity are expressed by Eqs. (1) and (2) respectively where A0 is the initial activity (IU), kD is the deactivation constant (h−1), t is the time (h) and α is the ratio between the final and initial states of the enzyme [32]. Finally, from the ratio of the half-life between immobilized and free enzymes it is possible to derive the stability factor, expressed by Eq. (3).

Reduction Reactions

The conversion of propionic acid to propionaldehyde was evaluated using the immobilized AldDH enzyme, using the NADH cofactor as a reducing agent. The reaction was carried out using 0.1 g of the immobilized enzyme with propionic acid (99%, Sigma-Aldrich) 50 mM and NADH 50 mM in 10 mL of 0.1 M phosphate buffer pH 7 at 30 °C. The reduction of propionaldehyde to propanol was evaluated using the immobilized ADH enzyme, also in this case using the NADH cofactor as a reducing agent. The reaction was carried out using 0.1 g of immobilized enzyme with propionaldehyde 50 mM and NADH 50 mM in 10 mL of 0.1 M phosphate buffer pH 7 at 30 °C.

During the reduction reactions, the decrease over time of NADH was evaluated, by measuring its absorbance at 340 nm through a Jasco V-730 UV–Vis spectrophotometer. The concentration of propionaldehyde or propanol is then measured via a headspace GC–MS, with a Stabilwax column (60 m, 0.53 mm ID, 1.00 µm).

Reusability of Immobilized Enzyme

To evaluate the reusability of the immobilized enzyme several batch reactions were carried out, as described in the previous section. After each reaction the immobilized enzyme was washed with water and phosphate buffer 0.1 M pH 7, then activity was measured, as described in section “Activity Assay of AldDH and ADH Enzymes”. Each batch had a duration of 1 h.

Results and Discussions

Characterization of Supports

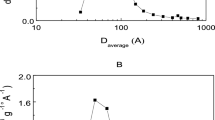

N2 Physisorption at − 196 °C

Table 1 reports the results derived from the N2 physisorption analysis. All the supports exhibit surface areas greater than 500 m2/g. The material with the highest specific surface area is MSU-H, which has a DP and Vp smaller than the other two materials. MSU-F has an SBET slightly lower than the other two materials and an average pore diameter of 15 nm. On the other hand, the MCF0.75 presents the largest Dp.

FESEM Analysis

In Fig. 2 are reported the FESEM micrograph of the studied supports, at two different magnifications for each. All the samples form aggregates of a few microns order. The MSU-H (Fig. 2A and B) has a structure with an elongated cylindrical shape, with the pores overlapping each other. MSU-F and MCF0.75 exhibit a spongy, ball-shaped structure, with larger pores for the MCF0.75 (Fig. 2E and F) than for the MSU-F (Fig. 2C and D). These results confirm the data in Table 2 and agree with the literature [23, 24, 33].

Characterization of Free and Immobilized Enzymes

The molecular weight of the ADH and AldDH enzymes is approximately 144 and 200 kDa, respectively [7]. Approximating them to a sphere [34], an average diameter equal to 6.85 nm and 7.72 nm can be obtained, respectively, for ADH and AldDH. The activity for free enzymes, calculated as described in section “Activity Assay of AldDH and ADH Enzymes”, is equal to 45.4 ± 1.2 IU/mgenz for ADH and 0.29 ± 0.04 IU/mgenz for the AldDH.

Comparison Between Different Support Materials

The different biocatalysts were evaluated using specific activity and immobilization yield. The results are shown in Table 2. In the immobilization solution, all the supports were put in contact with an offered enzymatic load q = 4 mgprot/gsupp. The duration of the immobilization process was 3 h, equal for all tests. After this time, in all cases the supernatant of the immobilization solution did not show any more activity.

For the ADH enzyme, the specific activity (both referred to g of support and mg of protein) is greater as the pore diameter of the support decreases. The pore diameter of the MSU-H is very similar to the enzyme diameter and therefore the enzyme is immobilized outside the pores, so the mass transfer phenomena are lower. With MSU-F, having a pore diameter slightly larger than that of the enzyme, part of the enzyme will be immobilized inside the pores and part outside.

With MCF0.75, having a pore diameter of about three times that of the enzyme, probably the immobilization takes place all within the pores, therefore the activity is affected by the mass transfer. This would explain why the specific activity is greater with MSU-F than with MCF0.75. Probably, MSU-F is more suitable for immobilizing ADH than MCF0.75. The immobilization yields and the expressed activities are in line with what is observed in the literature. For example, with agarose functionalized with various groups, were obtained immobilization yields of 100% and expressed activities ranging from 0 to 90% [16]. With MSU-F and MCF0.75, it is obtained an IY of 100%, so all the effective enzymatic load is equal to the offered at the starting time of immobilization. Instead, with MSU-H, an IY of 82% is obtained, corresponding to an effective enzymatic load of 3.28 mgprot/gsupp.

Also with the AldDH enzyme, very similar in size to ADH, the activity is greater with decreasing the pore diameter. Also in this case the trend for the specific activity referred to the grams of support and for mg of protein is the same. With MSU-H, an immobilization yield of 50% is obtained corresponding to an effective enzymatic load of 2 mgprot/gsupp. Instead, with the other two materials, almost all the offered protein is immobilized on the support. Furthermore, it seems that the immobilization does not affect the activity. Since this reaction is very slow, probably the limiting stage is reaction kinetics and not the mass transfer. The specific activity in fact does not vary much with the different support. The specific activity is in line with that observed with AldDH immobilized on nanostructured carbon platforms [7].

Since for ADH the best values of activity were obtained with MSU-H and MSU-F, subsequent tests of pH and temperature optimum and thermal stability were made only with these two materials, also using these for the enzyme AldDH.

Thermal Stability

Figure 3 shows the results of the stability test for ADH and AldDH derivates. To describe the experimental points of free ADH and free and immobilized AldDH a first-order deactivation model with no residual activity was used. For ADH/MSU-H, a first-order deactivation model with residual activity was used. The parameters of the models are summarized in Table 3. It is possible to obtain α, the ratio between the final and initial states of the enzyme [32], only for the model with residual activity. The free ADH (in concentration 0.001 mg/mL) shows no activity after 24 h, obtaining a deactivation constant equal to 0.28 h−1 which corresponds to a half-life equal to 2.47 h. With ADH/MSU-F there is a clear improvement in stability, in fact, there is no observed decrease in activity in 120 h. This is a further confirmation that in this case, the immobilization takes place within the pores and that there are mass transfer limitations. In fact, when the enzyme present in the outer part of the pores is deactivated, the substrate can still react with the enzyme in the inner part and which it previously could not reach. For this reason, it was not possible to obtain the deactivation constant and the half-life, so it will be necessary to extend the test times. With the ADH/MSU-H biocatalyst, on the other hand, a residual activity of about 40% is observed after 120 h at 50 °C. A deactivation time of 83.5 h is therefore obtained and therefore a stability factor equal to 33.8.

With the free AldDH (in concentration 1 mg/mL) a half-life of 13.86 h is obtained. A half-life of 46.21 h is obtained with the AldDH/MSU-H biocatalyst, corresponding thus to a stabilization factor equal to 3.3. Contrary to what was expected, in this case with MSU-F a lower stabilization factor is obtained, equal to 2, compared to that obtained with MSU-H. However, the two stability factors obtained are very similar. To the knowledge of the authors, no work has been found in the literature on stability factors after the immobilization of this enzyme.

In the literature, the best values of stabilization factors for different types of enzymes were obtained with immobilization carried out with glyoxyl groups, as reported for example by Guisan with chymotrypsin, immobilized on glyoxyl agarose. In this case, a stability factor as high as 60,000 was obtained [35]. Stabilization factors up to 500-fold have been reported, for example with ADH immobilized on agarose modified with glyoxyl groups and subsequently coated with PEI [16].

Therefore, also AldDH has been immobilized by this method. In this case, with ADH, the immobilization carried out at pH 10 and without post-immobilization techniques led to complete deactivation of the enzyme during immobilization (data not shown), therefore the immobilization with amino groups at pH 7 has been tested. Future work could focus on this type of immobilization also for AldDH, to see if a neutral pH of immobilization is better for enzymatic stability.

As also observed in other works [18], these siliceous mesoporous supports are confirmed as very suitable materials for enzyme immobilization. In fact, at least with ADH/MSU-F, no decrease in activity has been observed after 5 days of incubation at 50 °C. Probably, optimizing the immobilization of AldDH a good stabilization factor can be obtained also for this enzyme. In addition, having the ability to synthesize different types of mesoporous silica it is also possible to optimize the average pore diameter to optimize the specific activity [18].

Effect of pH and Temperature on Biocatalyst Activity

Figure 4 show the activity of the different biocatalysts with varying pH and T. Regarding ADH (Fig. 4), the only difference between free and immobilized enzymes is in the optimal pH of ADH/MSU-H. In order to obtain the optimal pH of ADH/MSU-H, a further test at pH 11 was carried out to observe a decrease in activity. A similar behavior, in a microenvironment with amino groups, occurred with ADH immobilized on agarose [15] and FDH on natural zeolite [10]. It is interesting to note that immobilized enzymes are less affected by changes in pH and temperature.

With AldDH derivatives (Fig. 5), an increase in the optimal temperature is noted, reaching 50 °C with MSU-F. This confirms a good immobilization and the creation of a microenvironment that protects the enzyme. With MSU-H there is no optimal T increment. Although the activity remains higher in a broader range with respect to the free enzyme, at 60 °C there is a collapse of activity of the immobilized enzyme showing no activity.

On the other hand, an optimal pH variation is not observed. As for ADH, also in this case the immobilized enzyme is less affected by changes in pH and T. This is especially observed with MSU-F. As the pores are larger, they allow the creation of a microenvironment and the immobilized enzyme is less affected by external conditions. The pores of MSU-H are smaller than the enzyme diameter, thus, probably most of the enzyme is immobilized on the external surface of the particles and not inside of the pores.

Reduction Reaction and Reusability of Immobilized Enzyme

The reduction reaction was carried out at 30 °C and a neutral pH, in order to avoid deactivation at a more acidic pH and a more high temperature [36]. From an anaerobic digestion process, VFA concentrations ranging from 10 to 100 mM in solution can be obtained [37]. It was therefore chosen to work with a synthetic wastewater solution with a concentration of propionic acid (for the first reaction) or propionaldehyde (for the second reaction) equal to 50 mM, using NADH 50 mM as reducing agent. The reduction reaction was studied with the two biocatalysts first separately and subsequently in series, starting only from propionic acid. From the first reaction, using the AldDH/MSU-H biocatalyst, with a headspace GC–MS, traces of propionaldehyde are observed, obtaining a concentration of 0.21 ± 0.02 μM with a reaction time equal to 5 h, although a decrease in NADH of 30% was observed. Probably the NADH is adsorbed on the support but does not contribute to the reaction. Most likely, the energy needed to carry out this reaction is relatively high and the mere presence of NADH is not enough to make the reaction of interest occur. The CAR enzyme in fact also uses the ATP cofactor for this type of reaction [2, 4, 5]. With AldDH/MSU-F a concentration of 0.08 ± 0.02 μM is obtained. In this case, a process should be developed in which to regenerate ATP in addition to the cofactor NADH. However, this would make the process even more complex and costly, having to implement two very complex systems for the regeneration of the two cofactors. In addition, it has been reported in the literature the use of this enzyme from Mycobacterium marinum co-expressed in E. coli, which combined with the enzyme ADH allows to reach C6-C12 alcohol concentrations equal to 330 mg/L [2].

The enzyme ADH should be very active in catalyzing the aldehyde reduction reaction [8, 9], but contrary to what was expected also in the second reaction, with the ADH/MSU-F biocatalyst, a very low conversion is obtained. After 5 h of reaction, a concentration of 1.2 ± 0.2 μM of 1-propanol is obtained, although a decrease in NADH greater than 40% was observed. With ADH/MSU-H a considerable high concentration, three orders of magnitude higher than with ADH/MSU-F, of 7.05 ± 0.01 mM is obtained, corresponding to a conversion yield of 14%.

After, the two enzymes have been utilized in series to perform the sequential reactions to produce propanol, starting from propionic acid. Sequential immobilization can have some advantages over co-immobilization: (1) it is easier to change each enzyme when it is inactivated independently of the other; (2) it is easier to change the ratio of the specific activities of the two enzymes (by adding more biocatalyst of the less active enzyme).

The two enzymes in series have been used both immobilized separately on the same support. With the two enzymes immobilized on MSU-H or MSU-F, a slight increase in propionaldehyde production is observed, reaching respectively 0.11 ± 0.01 and 0.09 ± 0.02 μM. Furthermore, propanol is formed in both cases in a concentration lower than 0.1 μM. With the two enzymes immobilized separately on MSU-H it is therefore observed that the concentration of propionaldehyde is lower than that produced with AldDH alone; probably since MSU-H is very active a part of the propionaldehyde produced is immediately converted to propanol. No difference in propionaldehyde production is observed with MSU-F. In any case, the rate-determining step is the reduction of propionic acid to propionaldehyde, and it will be necessary to optimize this step to make this process sustainable and scalable. To increase the production of propanol, the two enzymes could also be co-immobilized on the same particle, so that propionaldehyde could be immediately converted to propanol, in order to avoid mass transfer phenomena between particles. After the immobilization on the same particle, it could be also optimized the weight ratio between the two enzymes, in order to have a more similar specific activity of the two enzymes on the same particle. In this way, by increasing the amount of AldDH, it could be possible to optimize the first step of the reaction in order to carry out a more efficient reduction of propionic acid to propionaldehyde.

With a more conventional process, it is possible to obtain much higher concentrations of propanol. For example, with engineered E. coli, it is been reported in literature a concentration of propanol of 2.7, operating with a fed-batch in a mineral medium with 10 g/L of yeast extract and with repeated addition of glucose [38]. With a classic synthesis process, starting from syngas and ethylene, an alcohol yield of 99% is obtained after two reactions in series. The first reaction, hydroformylation of ethylene, is carried with a ruthenium-based catalyst at a temperature of 90–130 °C and a pressure of 28 bar. The second reaction, hydrogenation of propanal, is carried out at 110–150 °C at 1.5–10 bar with a catalyst based on copper, zinc, nickel, and chromium [39].

LCA analysis should be carried out to assess the best process in economic, energy and emission terms. However, this process still has a very low Technology Readiness Level (TRL), and further experiments, optimizations, and scale-ups are needed to perform a reliable analysis.

Figure 6 shows the reusability test with AldDH/MSU-H and ADH/MSU-H. After each batch, the residual activity is calculated, as described in section “Activity Assay of AldDH and ADH Enzymes”, and compared to the initial one.

After 5 cycles of reaction, with both biocatalysts there is a residual activity greater than 20%. A similar result was obtained by Ottone et al. [15], with 30% of residual activity after three reaction cycles of ADH immobilized on glyoxyl agarose, or by Li et al. [17] who obtained 30% of residual activity after 5 cycles with ADH covalently immobilized on chitosan-coated magnetic nanoparticles. No work regarding the reuse of AldDH immobilized enzyme was found in the literature.

Conclusions

ADH and AldDH have been successfully immobilized on three different types of mesoporous siliceous materials (MSU-H, MSU-F and MCF0.75). In particular, ADH was immobilized on supports functionalized with amino groups while AldDH on supports functionalized with glyoxyl groups. With both enzymes, it was possible to obtain 100% immobilization yields. Regarding specific activity, the best values have been obtained with MSU-H, reaching 0.13 IU with AldDH and 48.6 IU with ADH immobilized on MSU-H. Furthermore, the optimum pH and temperature have been evaluated on MSU-H and MSU-F derivates. Thus, thermal stability and the possibility of reusing biocatalysts were studied. The two biocatalysts were used to perform a reduction reaction of propionic acid (with immobilized AldDH) and propionaldehyde (with immobilized ADH). Using ADH/MSU-H a good concentration of propanol (7 mM) was obtained corresponding to a conversion yield of 14%. To obtain higher conversion values the two enzymes could be co-immobilized on the same particle in order to decrease mass transfer limitations and optimize the weight ratio between the two enzymes.

These supports and these types of immobilizations can also be used to immobilize other types of enzymes, even of different sizes compared to those used having the possibility to use supports with different average pore diameters.

Data Availability

All data generated and analyzed during this study are included in this published article.

Change history

27 August 2022

Missing Open Access funding information has been added in the Funding Note.

References

Ruggeri, B., Tommasi, T., Sanfilippo, S.: BioH2 & BioCH4 Through Anaerobic Digestion. Springer London, London (2015). https://doi.org/10.1007/978-1-4471-6431-9

Kalim Akhtar, M., Turner, N.J., Jones, P.R.: Carboxylic acid reductase is a versatile enzyme for the conversion of fatty acids into fuels and chemical commodities. Proc. Natl. Acad. Sci. USA 110, 87–92 (2013). https://doi.org/10.1073/pnas.1216516110

Pritchard, J., Filonenko, G.A., Van Putten, R., Hensen Ab, E.J.M., Pidko, E.A.: Heterogeneous and homogeneous catalysis for the hydrogenation of carboxylic acid derivatives: history, advances and future directions. Chem. Soc. Rev. 44, 3808 (2015). https://doi.org/10.1039/c5cs00038f

Napora-Wijata, K., Strohmeier, G.A., Winkler, M.: Biocatalytic reduction of carboxylic acids. Biotechnol. J. 9, 822–843 (2014). https://doi.org/10.1002/biot.201400012

Winkler, M.: Carboxylic acid reductase enzymes (CARs). Curr. Opin. Chem. Biol. 43, 23–29 (2018). https://doi.org/10.1016/j.cbpa.2017.10.006

Wang, M.F., Han, C.L., Yin, S.J.: Substrate specificity of human and yeast aldehyde dehydrogenases. Chem. Biol. Interact. 178, 36–39 (2009). https://doi.org/10.1016/j.cbi.2008.10.002

Aquino Neto, S., Forti, J.C., Zucolotto, V., Ciancaglini, P., De Andrade, A.R.: The kinetic behavior of dehydrogenase enzymes in solution and immobilized onto nanostructured carbon platforms. Process Biochem. 46, 2347–2352 (2011). https://doi.org/10.1016/j.procbio.2011.09.019

Luo, J., Meyer, A.S., Mateiu, R.V., Pinelo, M.: Cascade catalysis in membranes with enzyme immobilization for multi-enzymatic conversion of CO2 to methanol. New Biotechnol. 32, 319–327 (2015). https://doi.org/10.1016/j.nbt.2015.02.006

Marpani, F., Pinelo, M., Meyer, A.S.: Enzymatic conversion of CO2 to CH3OH via reverse dehydrogenase cascade biocatalysis: quantitative comparison of efficiencies of immobilized enzyme systems. Biochem. Eng. J. 127, 217–228 (2017). https://doi.org/10.1016/j.bej.2017.08.011

Pietricola, G., Ottone, C., Fino, D., Tommasi, T.: Enzymatic reduction of CO2 to formic acid using FDH immobilized on natural zeolite. J. CO2 Util. 42, 101343 (2020). https://doi.org/10.1016/j.jcou.2020.101343

Bolivar, J.M., Wilson, L., Ferrarotti, S.A., Guisán, J.M., Fernández-Lafuente, R., Mateo, C.: Improvement of the stability of alcohol dehydrogenase by covalent immobilization on glyoxyl-agarose. J. Biotechnol. 125, 85–94 (2006). https://doi.org/10.1016/j.jbiotec.2006.01.028

Bernal, C., Sierra, L., Mesa, M.: Improvement of thermal stability of β-galactosidase from Bacillus circulans by multipoint covalent immobilization in hierarchical macro-mesoporous silica. J. Mol. Catal. B 84, 166–172 (2012). https://doi.org/10.1016/j.molcatb.2012.05.023

Guisan, J.M., Bolivar, J.M., Lopez-Gallego, F., Rocha-Martín, J.: Immobilization of Enzymes and Cells. Springer, New York (2020). https://doi.org/10.1007/978-1-0716-0215-7

Illanes, A.: Enzyme Biocatalysis: Principles and Applications. Springer, Cham (2008). https://doi.org/10.1007/978-1-4020-8361-7

Ottone, C., Bernal, C., Serna, N., Illanes, A., Wilson, L.: Enhanced long-chain fatty alcohol oxidation by immobilization of alcohol dehydrogenase from S. cerevisiae. Appl. Microbiol. Biotechnol. 102, 237–247 (2018). https://doi.org/10.1007/s00253-017-8598-5

Bolivar, J.M., Rocha-Martín, J., Mateo, C., Guisan, J.M.: Stabilization of a highly active but unstable alcohol dehydrogenase from yeast using immobilization and post-immobilization techniques. Process Biochem. 47, 679–686 (2012). https://doi.org/10.1016/j.procbio.2012.01.012

Li, G.Y., De Zhou, Z., Li, Y.J., Huang, K.L., Zhong, M.: Surface functionalization of chitosan-coated magnetic nanoparticles for covalent immobilization of yeast alcohol dehydrogenase from Saccharomyces cerevisiae. J. Magn. Magn. Mater. 322, 3862–3868 (2010). https://doi.org/10.1016/j.jmmm.2010.08.008

Pietricola, G., Tommasi, T., Dosa, M., Camelin, E., Berruto, E., Ottone, C., Fino, D., Cauda, V., Piumetti, M.: Synthesis and characterization of ordered mesoporous silicas for the immobilization of formate dehydrogenase (FDH). Int. J. Biol. Macromol. 177, 261–270 (2021). https://doi.org/10.1016/j.ijbiomac.2021.02.114

Zezzi do Valle Gomes, M., Palmqvist, A.E.C.: Immobilization of formaldehyde dehydrogenase in tailored siliceous mesostructured cellular foams and evaluation of its activity for conversion of formate to formaldehyde. Colloids Surf. B 163, 41–46 (2018). https://doi.org/10.1016/j.colsurfb.2017.11.069

Dreifke, M., Brieler, F.J., Fröba, M.: Immobilization of alcohol dehydrogenase from E. coli onto mesoporous silica for application as a cofactor recycling system. ChemCatChem 9, 1197–1210 (2017). https://doi.org/10.1002/cctc.201601288

Lettow, J.S., Han, Y.J., Schmidt-Winkel, P., Yang, P., Zhao, D., Stucky, G.D., Ying, J.Y.: Hexagonal to mesocellular foam phase transition in polymer-templated mesoporous silicas. Langmuir 16, 8291–8295 (2000). https://doi.org/10.1021/la000660h

Alessi, A., Buscarino, G., Agnello, S., Messina, F., Sciortino, L., Cannas, M., Gelardi, F.M.: Effects of pressure, thermal treatment, and O2 loading in MCM-41, MSU-H, and MSU-F mesoporous silica systems probed by raman spectroscopy. J. Phys. Chem. C 119, 27434–27441 (2015). https://doi.org/10.1021/acs.jpcc.5b10206

Piumetti, M., Hussain, M., Fino, D., Russo, N.: Mesoporous silica supported Rh catalysts for high concentration N2O decomposition. Appl. Catal. B 165, 158–168 (2015). https://doi.org/10.1016/j.apcatb.2014.10.008

Piumetti, M., Bonelli, B., Massiani, P., Dzwigaj, S., Rossetti, I., Casale, S., Gaberova, L., Armandi, M., Garrone, E.: Effect of vanadium dispersion and support properties on the catalytic activity of V-SBA-15 and V-MCF mesoporous materials prepared by direct synthesis. Catal. Today 176, 458–464 (2011). https://doi.org/10.1016/j.cattod.2010.10.066

Kim, H., Jung, J.C., Yeom, S.H., Lee, K.Y., Yi, J., Song, I.K.: Immobilization of a heteropolyacid catalyst on the aminopropyl-functionalized mesostructured cellular foam (MCF) silica. Mater. Res. Bull. 42, 2132–2142 (2007). https://doi.org/10.1016/j.materresbull.2007.01.010

Karkamkar, A., Kim, S.S., Pinnavaia, T.J.: Hydrothermal restructuring of the cell and window sizes of silica foams. Chem. Mater. 15, 11–13 (2003). https://doi.org/10.1021/cm020867r

Su, Y., Liu, Y.M., Wang, L.C., Chen, M., Cao, Y., Dai, W.L., He, H.Y., Fan, K.N.: Tungsten-containing MCF silica as active and recyclable catalysts for liquid-phase oxidation of 1,3-butanediol to 4-hydroxy-2-butanone. Appl. Catal. A 315, 91–100 (2006). https://doi.org/10.1016/j.apcata.2006.09.002

Lukens, W.W., Schmidt-Winkel, P., Zhao, D., Feng, J., Stucky, G.D.: Evaluating pore sizes in mesoporous materials: a simplified standard adsorption method and a simplified Broekhoff-de Boer method. Langmuir 15, 5403–5409 (1999). https://doi.org/10.1021/la990209u

Guisán, J.M.: Aldehyde-agarose gels as activated supports for immobilization-stabilization of enzymes. Enzyme Microb. Technol. 10, 375–382 (1988). https://doi.org/10.1016/0141-0229(88)90018-X

Vejayakumaran, P., Rahman, I.A., Sipaut, C.S., Ismail, J., Chee, C.K.: Structural and thermal characterizations of silica nanoparticles grafted with pendant maleimide and epoxide groups. J. Colloid Interface Sci. 328, 81–91 (2008). https://doi.org/10.1016/j.jcis.2008.08.054

Bradford, M.M.: A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72, 248–254 (1976). https://doi.org/10.1016/0003-2697(76)90527-3

Tavernini, L., Ottone, C., Illanes, A., Wilson, L.: Entrapment of enzyme aggregates in chitosan beads for aroma release in white wines. Int. J. Biol. Macromol. 154, 1082–1090 (2020). https://doi.org/10.1016/j.ijbiomac.2020.03.031

Piumetti, M., Bonelli, B., Armandi, M., Gaberova, L., Casale, S., Massiani, P., Garrone, E.: Vanadium-containing SBA-15 systems prepared by direct synthesis: physico-chemical and catalytic properties in the decomposition of dichloromethane. Microporous Mesoporous Mater. 133, 36–44 (2010). https://doi.org/10.1016/j.micromeso.2010.04.011

Erickson, H.P.: Size and shape of protein molecules at the nanometer level determined by sedimentation, gel filtration, and electron microscopy. Biol. Proced. Online 11, 32–51 (2009). https://doi.org/10.1007/s12575-009-9008-x

Guisán, J.M., Bastida, A., Cuesta, C., Fernandez-Lafuente, R., Rosell, C.M.: Immobilization-stabilization of α-chymotrypsin by covalent attachment to aldehyde-agarose gels. Biotechnol. Bioeng. 38, 1144–1152 (1991). https://doi.org/10.1002/bit.260381005

Lowry, O.H., Passonneau, J.V., Rock, M.K.: The stability of pyridine nucleotides. J. Biol. Chem. 236, 2756–2759 (1961)

La Licata, B., Sagnelli, F., Boulanger, A., Lanzini, A., Leone, P., Zitella, P., Santarelli, M.: Bio-hydrogen production from organic wastes in a pilot plant reactor and its use in a SOFC. Int. J. Hydrogen Energy 36, 7861–7865 (2011). https://doi.org/10.1016/j.ijhydene.2011.01.096

Inokuma, K., Liao, J.C., Okamoto, M., Hanai, T.: Improvement of isopropanol production by metabolically engineered Escherichia coli using gas stripping. J. Biosci. Bioeng. 110, 696–701 (2010). https://doi.org/10.1016/J.JBIOSC.2010.07.010

Papa, A.J.: Propanols. Ullmann’s Encycl. Ind. Chem. (2011). https://doi.org/10.1002/14356007.A22_173.PUB2

Acknowledgements

The authors thank the regional project SATURNO for the financial support.

Funding

Open access funding provided by Politecnico di Torino within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: the funding statement is added, Open access funding provided by Politecnico di Torino within the CRUI-CARE Agreement.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pietricola, G., Dosa, M., Ottone, C. et al. Covalent Immobilization of Aldehyde and Alcohol Dehydrogenases on Ordered Mesoporous Silicas. Waste Biomass Valor 13, 4043–4055 (2022). https://doi.org/10.1007/s12649-022-01812-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01812-y