Abstract

In Kenya, agriculture is an important economic activity, which implies that a significant amount of bio-waste is generated. This is on one hand a waste management problem, but on the other hand, it is an opportunity for creating a sustainable bioeconomy. Therefore, this study investigates the potential recovery of bioresources from Kenyan bio-waste. The study first quantifies occurrence, current usage and disposal of three selected biomass types, being banana, Irish potato and coconut waste. Next, material flow analysis is used to systematically track the mass flow of these wastes. Finally, the potential of biomolecules, biomaterials and bioenergy from the waste streams is evaluated. The study revealed that about 6007, 426 and 50 kt of banana, Irish potato and coconut biomass is wasted. All these wastes can be biorefined, offering potential towards recovery of; flavonoids (74 kt), starch (377 kt), cellulose (2001 kt) and biogas (1757 GWh), being the total potential of the main bioresources from the three waste streams. The study therefore, concluded that, with proper waste collection, sorting and valorisation, there is a huge potential for bioeconomy in Kenya, at the same time reducing waste management problems.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

Resource recovery potential analysis is performed on Kenyan fruits, vegetable and nut wastes. With proper waste collection, sorting and valorisation, there is a huge potential for improved bioeconomy in Kenya and similarly to many other (developing) countries, at the same time reducing waste management problems. In Kenya, and in broader sense, many developing countries, where agriculture is a key economic activity, implying that a significant amount of bio-waste is generated, there is no waste mapping or systematic study due to lack of data collected on the agricultural and food waste generation and destination. Limited literature that exist, however, show that the wastes are generally not valorized, despite the potential of recovering a high value bioresource from the waste streams. The paper also evaluates the logistics of the bioresource recovery.

Introduction

In the year 2019, around 8 million tons of solid waste was generated in Kenya and the rate of generation is likely to double by the year 2030, driven by socio-economic development and rapid population growth [1]. Between 2009 and 2019, Kenya’s population increased by an average of 1 million people annually, while at the same time, the country achieved a middle-level income status, which resulted into an increasing demand for food and other resources [2]. Further, this implies that a significant amount of bio-waste is generated. To alleviate these challenges, efforts should focus on resource efficiency and circular economy. This would imply that resources are used efficiently throughout all stages of their lifecycle and throughout the supply chain, by emphasizing minimizing waste or transforming them into high quality secondary raw materials [3].

In Kenya, and similarly too to many other (developing) countries, these bio-wastes are often burned or disposed of in open landfills, directly leading to environmental pollution and to climate change through particulate and greenhouse gas (GHG) emissions. Furthermore, due to prevalent tropical climate, the pile of bio-waste often becomes a habitat to pests and rodents and hence becomes a nuisance with corresponding health implications [4].

Since agriculture is the main economic activity in Kenya, contributing directly and indirectly to over 50% of the country’s gross domestic product (GDP) and providing livelihoods to over 80% of the entire population, the sector is expected to generate high quantity of bio-wastes [5]. Indeed, according to research conducted in Kenya, organic wastes from urban markets alone (excluding waste or inedible parts that remains at the farm gate and collection centers), forms over 4000 kt representing over 50% of all wastes produced in the urban centers per year [6]. However, despite the high quantity of these types of waste and their related environmental and health hazards, the rate of valorization is just about 40 kt accounting for about 1% of the total urban organic waste alone per year, thus, bio-wastes is a key contributor to waste management problem in Kenya [6]. This can be ascribed to the dispersity of waste generation, but also, there seems to be little knowledge about the potential benefits of waste valorization. In cases where these wastes are utilized, they are turned into relatively low added value products such as mulch, compost, energy (by burning) or in best case scenario, as animals feed [7].

At a policy level, Kenya adopted the “Transforming our world: the 2030 Agenda for Sustainable Development”, which aims to make the human environment safe, resilient and sustainable, ensuring sustainable production and consumption patterns and also reducing GHG emission by 30% by 2030 under the United Nation (UN) Framework Convention on Climate Change [1]. Strategic decisions now have to be made on how to achieve these targets. Science could support interventions towards an effective conversion of wastes from the food chain to usable, preferably high-valued products.

As a starting point for policy implementation in this context, mapping of the situation of these wastes should be performed, including current quantities, origin and destinations. One of the tools that can be used for this purpose is material flow analysis (MFA). Indeed, MFA has been used for the analysis of organic waste flow in amongst others, Europe [8], UK [9], US [10], Asia [11] and proven to be useful in the support of organic waste management and recycling policies by allowing visualization and quantification of flows that are to be managed. Nevertheless, agricultural and food waste generation and destination in Kenya, and in broader sense, many developing countries still lacks mapping as there is no systematically collected data. There is, however, a bit of unpublished literature, sometimes in local languages, and some other local information which is generally not accessible to a broad audience [12].

Within this specific Kenyan context, the main objective of this research is to study the potential of bioresource material recovery from selected Kenyan agricultural-based waste. This paper identifies quantity, occurrence, current usage and disposal trends of the most important fruit, vegetable, and nut waste streams in Kenya. The information is summarized in a comprehensive MFA, to track the mass flow of selected waste streams from production through processing, consumption and disposal. Finally, the potential bioresource materials recoverable from the waste streams and the logistics of recovery are evaluated.

Preface: Selection of Case Study

Within this study, a broad inventory of fruit, vegetable and nut wastes quantities in Kenya was made that informed the selection of different case studies for the valorization potential of the waste streams. In each category, the individual waste stream that has the single highest production and potential waste biomass quantities (as illustrated in Table 1) were selected. Apart from the production and potential waste quantities, the case studies were also selected based on their inherent differences, including, dry versus wet (in terms of moisture content) waste, soil grown vis-a-vis above ground (tree) based wastes. Table 1 gives an overview of top ten fruit, vegetable and nut wastes in Kenya. Based on this inventory, we selected banana, Irish potato (hereafter, referred to as “potato”) and coconut waste as case studies, for each of these groups. In Table 1, the potential quantity of waste (column 7) is derived from the production quantity (column 5) and the potential waste proportion (column 6) found in literature.

Description of the Case Studies

Banana is a herbaceous plant in the family Musaceae and genus Musa and is cultivated mainly for its fruits [21]. Banana plant consist of a rhizome (corm), a succulent stem called pseudostem, leaves, and a stock (rachis or peduncle) which supports an oval inflorescence consisting of deep purple waxy bracts (male bud) enclosing the female and male flowers in the lower and upper rows respectively. The female flowers eventually develop into banana fruits (hand). The fruits are harvested after 10 to 12 months of planting [22] and are normally covered by a thick skin (peel) which is peeled off to expose the edible part (pulp). Except for the pulps and sometimes the rhizomes (which sprout to a new banana tree), all parts of the banana plant are potential waste [21].

In Kenya, there are typically two cultivars of bananas namely, the desert (Musa sapientum)—the ripe edible cultivar and the plantain (Musa paradisiaca)—the cooking cultivars [23]. The two cultivars generally have similar morphology and are generalized as bananas [23] and will be considered so in this study.

Irish potato (Solanum tuberosum L.), is a root vegetable in the family of Solanaceae and genus Solanum. The plants consist of stems, branches, leaflets, roots, auxiliary buds, flowers and an enlarged portion of the stolon called tubers. Maturity of the tubers is characterized by dehaulming, senescence or vine desiccation involving stem, branches and leaves yellowing or turning brownish and eventually drying and dropping off or being mechanically removed to allow tuber skin to harden and reduce damage to the tubers during harvesting [24]. Therefore the main part that remains after desiccation is the tuber, of which during harvesting and subsequent processing, generates rotten, rejected (due to sprouting, bruises and under/over size) tubers and peels as the main potential wastes [25].

Apart from farm gate production wastes for both bananas and potatoes, further wastes are generated during transportation, packaging, storage, sales and consumption due to, among other factors, adverse weather effects such as high temperatures, poor road networks, etc. [26]. Furthermore, rejects are created due to attacks by pests and diseases, damage or inefficiencies during harvesting and processing, or as a result of over-supply and competition [27]. Furthermore, both banana and potato peels are generated mainly due to use of poor peeling methods such as manual peeling.

Cocos nucifera L. is a palm tree that belongs to the family Arecaceae and genus Cocos. The coconut palm tree produces a nut referred to as 'coconut'. The tree consists of roots, trunk, fonds or leaves, flowers and the nuts which are all comprehensively commercially exploited [28, 29]. However, coconut generates shell and husk as the main by-products during nut processing [18]. Also, coconut cake meal is produced as a by-product of copra processing but due to its nutritional value, it is being used in confectionery [30].

For these three case studies of banana, Irish potatoes and coconut, a Material Flow Analysis (MFA) in Kenya context was performed.

Methodology

Material Flow Analysis

MFA is a methodology that allows systematic analysis and quantification of flows and stocks of material or substances in a well-defined system in space and time. It analyses material sources, pathways and final destinations according to the mass balance principle i.e. the sum of all inputs equals the sum of all outputs, corrected with stock change if any. In this study, MFA is used to point out the potential for the valorization of the three selected types of biomass. Based on data availability, the MFA evaluate production quantities from the year 2018. Flow calculations were performed in Microsoft Excel, while the Sankey 5 pro software (version e! Sankey pro 5.1.0) was used to develop the MFA flow diagrams. The subsequent section present essential information on system description, data used, and assumptions made.

System Boundary Description

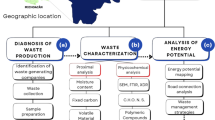

The spatial border of Kenya defines the system boundary, implying that only waste generated within this spatial boundary will be considered in this study i.e., wastes related to import or export are excluded from this study. The temporal boundary was the year 2018. Furthermore, throughout the study, the term “waste” refers to a secondary product derived from agricultural production, supply, agro-industrial processing and consumption of the selected agro-products. This normally includes biomass that is inedible to humans, including food or by-products that are edible but are degraded beyond consumption or processing [31]. We follow waste generated over the production chain of the fruits, vegetables and nuts, including harvesting, processing, trading, consumption and final waste residual treatment. However, some potential wastes are not included in the study, for example, potato flowers, stem, branches and leaves dry out and drops before harvesting. Also, the banana rhizome is excluded from the study, since the new bud and suckers normally sprout from it [32]. Coconut roots, trunk and leaves are already extensively used thus are not considered as wastes in this study. To facilitate the usage of MFA, a generic scheme is developed (Fig. 1) that was used to assess the occurrence of the wastes. The functional unit is the total quantity of produce in 2018, being 1447 kt for bananas, 1870 kt for potatoes and 105 kt for coconut.

Figure 1 considers all parts of the banana plant except the rhizome. It also considers potato tubers and husked coconut and their associated processing wastes. All of the three case studies generate wastes at the farm gate (lines 2 and 3). However, those from coconut such as husks are separated by retting or decortication process (line 9 and 10) before they are finally processed and/or disposed of. Also, there are potato and banana rejects at the post-harvest (preparation, storage and distribution) (line 6), retailing (line 12) and consumption (line 13) stage. However, the quantity of banana rejected at post-harvest and retail stages is insignificant thus have not been considered, likewise the quantity of coconut used as seeds. “Reused waste” refers to waste materials generated after initial use hence a by-product or waste from a process.

Data Source and Assumptions

In this study, mainly literature data was used. Production data for 2018 was sourced from FAOSTAT 2019 since it was the most recent and authoritative source for which all required data on production were available for Kenya. Other available local data were used whenever possible. For the case of banana waste proportion and use, credible local data was not available, hence data was obtained from research conducted within the East and Central African region and transposed to the Kenyan context. Waste was quantified in both dry and wet biomass. The data on some potential key material resources in each by-product considered are given in Table 2.

In this work, quantity determinations were subjected to certain assumptions. The most important assumptions are:

-

i.

All produce from each of the selected case studies strictly follow the supply chain as shown in Fig. 1.

-

ii.

There is no significant difference in yield, morphology and phytochemical constituents among different varieties in each of the case studies, hence, an average value is adopted, and

-

iii.

Due to lack of authoritative data and for simplicity, imports and exports were not included.

Further, the quality of data (in Table 2) used in the analysis was assessed by the Data Quality Assessment analysis approach, which is similar to the pedigree-matrix [40] and was recently also proposed by Godoy et al. 2020 [41] as a way to assess uncertainty in MFA. This state-of-the-art method employs the use of quality indicators to give a semi-quantitative indication of reliability; and representativeness in terms of temporal, geographical and technological correlations, through Data Quality Indicators (DQIs). Definition of DQI and the decision criteria used is given in Supplementary Table 1 while the Data Quality Rating (DQR) scores are given in Supplementary Table 2. A score of 1 is given when the data point is of the best quality, while a score of 4 is given when the data point has the lowest quality. The DQR scores are averaged and categorized as; 1.0–1.6, 1.7–2.4, 2.5–3.2, 3.3–4, indicating very high quality, high quality, low quality, and very low quality data respectively [41]. For example, the DQR for data used in banana waste valorization (line 15) and banana waste reuse (line 16) [37] given in Fig. 1 and summarized in Table 2 was determined as described below:

From the methodology used, the data values generation method (Gm) has a score of 2, since the data values are generated by calculations based on physical counting and also through stakeholders response. Also, the integrity of the data source (Ds), that assesses how data was communicated, was evaluated. Here, Ds has a score of 1, since the data used is from a peer reviewed scientific journal. After, the validity (V) of the data values was analyzed as well. This indicator assesses the authenticity of data origin by evaluating stakeholders involved in its generation and confirmation. In this case, the data values used were obtained from (correspondents) or confirmed (authors) by 4 or more types of stakeholders in the field of study, hence V has a score of 1. Also evaluated was time correlation (T) which evaluates datum values with respect to time (i.e. how old the data is, from year of this study). The data value used here was generated in the year 2015 which is within 5 years from our temporal boundary (2018) of this study. Thus T score is 1. Additionally, Geographical (G) source of the data that compares how close the geographical reference area is to the region of data origin was examined. Here, the data was generated in the Democratic Republic of Congo, which has near similar socio-demographical factors as the study region and thus categorized as East and central Africa (hence G has a score of 2). Last to be evaluated was the Technological (Tch) correlation data value. In this case, both cases studied similar product i.e. banana, produced in similar ways, thus Tch score is 1). The DQR if finally given by expression;

Hence, DQR is thus 1.3. The final DQR scores for all data points are given in Table 2.

From Table 2, the data points used are of high to very high quality, except the data points for farm waste generation (line number 2 and 3) for banana waste stream which had low quality data. Overall, this study was thus able to collect reliable data.

Recoverable Bioresource Classification

The potential recovery of essential material from these wastes is discussed in the context of Kenyan need. A literature search was done on the concentrations of recoverable components and bioenergy potential. We classified recovery routes into four groups: high value compounds (e.g. phenolic materials), extractable (macro)compounds for use in feed and food (such as protein, starch and sugar), macrocompounds to be used as technical materials for industrial applications (such as fibers, cellulose and lignin), and bioenergy potential (such as biogas and bioethanol potential). The groups are as shown in Fig. 2 below.

Results and Discussion

Quantity and Occurrence

Table 3 shows bananas, potatoes and coconut production and waste quantities, their current use and final disposal trends while Fig. 3, show their respective material flows. From Table 3 it can be deduced that, on fresh weight basis, 6007 kt or 89.2% of total banana plant by-products is potential waste. Out of the total waste, pseudostem waste stream accounts for 72.2%, followed by leaves (11.6%), peels (10.6%), stock (3.9%), pulp (1.3%) and male bud (0.4%). As shown in Fig 3a, a significant quantity of banana wastes (4359 kt) representing about 72.6% of the total wastes is discarded to nature (i.e. either disposed of in open landfills or water bodies, left to rot or burned without energy recovery). The rest of the wastes (1648 kt or about 27.4%) are used as animal feed (649 kt) and as soil improver (999 kt). However, soil improvement activities such as mulching are discouraged due to possibility of the propagation of diseases such as banana bacterial wilt [27].

In the case of potato, for the total tuber produced, 1257 kt (67.2%) is edible human food, 187 kt (10%) is retained as planting seeds, while about 426 kt (22.8%) are by-products in the form of peel (239 kt) and rejected tuber (187 kt). Further, the MFA analysis shown in Fig. 3b, depicts that just like in the case of banana, potato by-products are currently used as animal feed (136 kt) and for soil improvement (60 kt), representing 31.9% and 14.1% of the total by-products respectively, while 230 kt representing about 54% of all potato wastes are discarded to nature.

For coconut, the Sankey diagram for coconut is shown in Fig. 3c. It shows that 49.5 kt or 47.0% of the entire coconut produced is potential waste, consisting of 12.6 kt shell (25.5%), 25.8 kt dust or pith (52.1%), and 11.1 kt fiber (22.4%). Also, from the diagram, only 459 t (3.6%) of the shell is usable either for making charcoal (456 t) or artifacts (3 t), while about 12.2kt (96.4%) is discarded to nature. A combined 0.2% of fiber is used for making brooms (4 t), ropes (9 t) and mats/mattresses (4 t), while (11.0 kt) 99.8% of the fibers, especially short fibers, is discarded. So far, pith or dust or cocopeat is only used as soil improver or as plant growing medium at about 2.1 kt (8.0%), while a significant proportion 2.4 kt (92.0%) is discarded in open land fill, thus, lost. In total, about 2.5 kt (5.2%) of coconut wastes are consumed while 47.0 kt (94.8%) is either discarded to nature whereas about 20 t, is generated as a secondary waste source.

Comparably, on the basis of their respective total wastes, the highest percentage of materials discarded to open land fill occur in banana at 4359 kt (94%) followed by potato at 230 kt (5.0%) and coconut at about 47 kt (1.0%). However, it is remarkable that where the wastes are used, so far, it is limited to animal feed and soil improvement, besides some very specific applications such as ropes and toys.

Potential Resource Recovery Analysis

This section discusses the potential recoveries of the four classes of biomaterials (see supplementary data), and are summarized in Table 4.

High Value Compounds

From Table 4, it is shown that, flavonoid can mainly be obtained from banana wastes, with banana peels having the highest potential at 34.9 kt, followed by pseudostem (33.9 kt), leaves (3.8 kt), stock (1.5), and bud (0.1 kt), all totaling to 74.2 kt flavonoids. Potato peels and mixed wastes have a potential to produce 0.4 kt flavonoids while there is limited potential for these components in coconut waste. For tannin extract, the highest quantity can be extracted from banana peel (8.3 kt), coconut husk (1.8 kt), banana stock (0.9 kt), coconut shell (0.4 kt) and banana pulp (0.2 kt). In total, banana waste has a total potential to produce (9.4 kt) tannin, coconut waste (2.2 kt), while potato wastes have limited potential.

If these resources are tapped e.g. as a natural dye, flavonoids from banana wastes (74.2 kt) can be used to dye about 608 million m2 of wool fabric (using dye to fabric ratio of 1:5 (w/w) [43] assuming wool fabric weight 610 g/m2), tannin from coconut (2.2 kt) would be used to tan about 220 kt skin (at 1% (w/w) tanning process [44]).

Extractable (Macro)compounds for Use in Feed and Food

Banana waste has a high potential for refining extractable macro(compounds) that are usable as starting material for food and animal feed production processes (Table 4). In this category, starch is the main potential extractable material from banana waste streams (340.8 kt) with the highest quantities recoverable being from pseudostem (241.0 kt), followed by peel (71.2 kt), pulp (26.6 kt), leaves (1.2 kt) and stock (0.8 kt). From potato waste streams, mixed waste and peels can generate 25.2 kt and 11.0 kt relatively while the coconut waste has limited potential. For banana, the respective potential for extractable sugar from pseudostem is 113.3 kt, leaves (6.5 kt), peel (2.1 kt), and pulp and bud (1.4 kt) each. Each of the potato waste streams can produce 0.2 kt each of the extractable sugar, while for coconut, only coconut husk has a potential to produce 13.7 kt of sugar. Banana pseudostem (31.0 kt), peel (13.4 kt), stock (5.9 kt), pulp (1.5 kt), leaves (1.5 kt) and bud (0.7 kt) have potential of producing protein.

Also, potato peels and mixed wastes streams each have a potential to produce 5.1 kt of protein. In total, the most promising extractable feed materials from banana wastes in terms of masses are starch (340.8 kt), followed by sugar (124.7 kt) then protein (54.0 kt). From potato waste, starch (36.2 kt) and protein (10.2 kt) are the most significant recoverable (macro)compounds for use in feed and food, while from coconut waste, sugar (13.7 kt) from the husk seems most promising.

The starch from banana (340.8 kt) and potato (36.2 kt) wastes can support sizing of about 2272.0 kt and 241.3 kt of cotton yarn (taking 15% of starch size per yarn (weight/weight) [45]) respectively. Sugar from banana (124.7 kt) can produce 105 million liters ethanol, coconut (13.7 kt) can produce 11.5 million liters of ethanol (with the assumption that 1.6 g of sugar can produce 1.06 g ethanol [46]), while protein from banana 54.0 kt can be used as a food supplement to produce 540 kt spaghetti meal (at 10% protein supplement in spaghetti flour [47]).

Macrocompounds Used as Technical Materials for Industrial Applications

Technical fiber can be recovered from banana pseudostem (476.1 kt), stock (9.8 kt), leaves (2.8 kt) and coconut husk (11.1 kt) as shown in Table 4. For cellulose, the potential recoveries are banana pseudostem (1670.4 kt), leaves (247.3 kt), peel (23.3 kt), stock (15.3 kt) and bud (2.4 kt), potato mix (13.6 kt), potato peel (0.7 kt), coconut husk (19.2 kt), coconut shell (8.5 kt).

For lignin, the highest potential sources lie in pseudostem (250.5 kt), banana leaves (73.5 kt), banana peel (24.9 kt), coconut husk (15.5 kt), potato peel (9.6 kt), banana stock (9.2), coconut shell (3.9 kt), potato mix (2.8 kt) and bud (0.6 kt). Thus, the total potential recovery for macrocompounds used as technical materials for industrial applications include: fiber from banana (488.7 kt) and from coconut (11.1 kt); cellulose from banana (1958.7 kt), potato (14.3 kt) and coconut (27.7 kt); while from lignin from banana (358.7 kt), potato (12.4 kt) and coconut (19.4 kt).

The fiber from banana (488.7 kt) is capable of producing 570.2 kt plain-woven banana fiber/polyester blend fabric or 1.1 million m3 of fabric (assuming a 70% raw fiber to woven fabric conversion efficiency [54] and also assuming 40% banana fiber in hybrid polyester blend [55], banana fiber density 1200 kg/m3 and polyester fiber density of 60 kg/m3, thus the fiber-blend density is 516 kg/m3). From coconut (11.1 kt), 13 kt fabric or about 25,000 m3 fiber can be produced (taking the density of coir fiber to be the same as that of banana fiber 12,000 kg/m3 [56] and also assuming same values as for banana/polyester blend). The cellulose from banana (1670.4 kt) is capable of producing 2002.9 kt of paper hand sheet (assuming 84.3% of cellulose in paper pulp (45° Schopper-Riegler pulp consistency) [57]), while from potato (14.3 kt), 16.9 kt can be produced, and coconut (27.7 kt) can produce 32.9 kt. Lignin from banana (358.7 kt) is capable of producing 377.6 kt composite polymer blend material (taking cases of 95% lignin, 5% poly(ethylene) oxide [58]), 13.1 kt from potato (12.4 kt), while coconut (20.4 kt) has a potential to produce 21.5 kt.

Bioenergy Potential

In relation to biogas production, as shown in Table 4, banana waste streams have potential to give 173.6 (981.7 GWh), 54.0 (305.4 GWh), 16.2 (91.6 GWh), 12.5 (70.7 GWh), 12.2 (69.0 GWh), 1.2 (6.8 GWh) million m3 biogas (energy equivalent) from pseudostem, peel, leaves, stock, pulp and buds respectively, totaling to 269.7 million m3 or 1525.2 GWh biogas energy potential (energy conversion is 6.5 kWh per m3 biogas and considering transportation and biodigester self-consumption of about 13% [48, 53]). Bioethanol energy can potentially be produced from pseudostem 27.6 (189.7 GWh), peels 5.0 (34.4 GWh), leaves 4.2 (28.8 GWh), stock 3.9 (26.8 GWh), pulp 2.8 (19.2 GWh) and bud 0.1 (0.7 GWh), with a potential total of 43.6 kt or 299.6 GWh (calculated from the lower heating value (LHV) of 1 kg of EtOH generating 7.47 kWh energy and transportation energy consumption of 8% [49, 53]). Potato peel and mix waste have a potential to produce 13.7 (77.4 GWh) and 14.0 (79.2 GWh) million m3 biogas, and about 5 kt (34.4 GWh) and 1.7 kt (11.6 GWh) potential bioethanol respectively, totaling to about 6.7 million m3 (156.6 GWh) biogas and 6.7 kt (46.0 GWh) bioethanol. While for coconut wastes, the husk and shell are capable of giving about 9.9 (56 GWh) and 3.4 (19.2 GWh) million m3 biogas respectively totaling to 13.3 million m3 (75.2 GWh) biogas, with only the coconut husk being able to give 1.5 kt (10.3 GWh) bioethanol.

The biogas energy realizable from banana waste (1525.2 GWh) (which can be converted as 40% to electricity and 50% to heat [59]) is capable of producing 610.1 GWh electricity/year and 762.6 GWh heat/year to support (at an average consumption of 620 kWh electricity and 600 kWh heat per year per house hold) about 984,032 and 1.3 million households per year respectively. Bioethanol energy from banana waste has a potential to generate 299.6 GWh/year of heat energy/year capable of supporting about 499,333 households. Biogas from potato (156.6 GWh) has a potential to generate 62.6 GWh electricity and 78.3 GWh heat per year capable of supporting about 100,967 and 130,500 households per year respectively while 46 GWh potential heat energy from bioethanol can support 76,666 households. Potential biogas energy from coconut waste (75.2 GWh) having the potential to generate 30.1 and 37.6 GWh of electricity and heat/year capable of supporting 48,548 and 62,666 households per year while bioethanol energy (1.5 kt or 10.3 GWh) can support 17,166 households. Overall, production biogas as a source of energy has more potential than bioethanol production.

The Overall Potential of Waste Valorization

Figure 1, given in Sect. “Material Flow Analysis”, illustrate the supply chains for banana, potato and coconut produce and the corresponding wastes generated at each stage. From Fig. 1, it is evident that wastes generated at the farm gate, supply line 2 and 3 such as pseudostem, leaves, buds, damaged tubers and coconut husks are centrally generated in the farms. Similarly, wastes given by supply line 6 and 11 such as stock, and rejects and those from factory processing such as peels, rejects and shells are also centrally generated thus, are easier to collect. Conversely, the by-products that are generated at the last two stages of the supply chain (line 12 and line 13) such as wastes from retailers, household and restaurant processing are more widely dispersed. For example, hawking or street vending, a common method of retailing in Kenya, typically involves vendors constantly moving from one street to the other with their merchandise in search of buyers [60]. This method of selling covers a wide random area, without a strategy of waste collection, consequently spreads the generated wastes over a winder area. Nevertheless, for centralized customers and restaurants, with the introduction of waste segregation and collection arrangements, a significant quantity (at least 50%) of peels and rejects can be recovered. Thus, in general, all waste streams from bananas, potatoes and coconut have the potential for valorization except those generated at retailing, household and restaurant processing stage, which might better be mixed with other organic wastes towards composting or digestion (Table 5).

Considering the waste biomass availability, occurrences and current destination as summarized in Table 5, it is evident that all waste streams have high to medium potential for biorefining of various indicated biomaterials. However, an effort to recover the biomaterial should take into account the moisture content. For example, nut waste has a lower moisture content, thus, it is durable and can be stored for a longer period before use, while most of the other wastes have high moisture content hence are susceptible to decay, therefore, they might need drying before a delayed use or should be used within a few days after harvesting, which might be challenging from practical perspective. Thus, coconut wastes (shell and husk) can be used directly without any treatment, while biomass such as banana and potato wastes might require some form of pretreatment such as drying and densification for preservation and to reduce volume.

Another important factor for the sustainability and practicability of biorefining this type of waste is a cost effective collection. Indeed, since agricultural crop residues are generally dispersed throughout the country, are owned by many individuals and companies, and have a variable physico-chemical composition, it is difficult to build business models for collection and storage. Residue collection and stabilisation increases total production costs, and thus revenues from biorefining will determine the profitability of this bioeconomic activity. For this purpose, a collection and supply scheme based on a circular economy hub system (Fig. 4) can be proposed. The system is based on distributed network of biomass collection centers (hubs) that collect different waste biomass and conveys them to hubs that can aggregate, process, store and supply wastes from a region. A gradual increase in size of hubs might be beneficial, starting from mini-hubs that are dispersed in villages or at local industrial terrains, to larger hubs, to one or more centralized hubs that then actually feed the biorefinery. Depending on the time of collection between mini-hubs to central hubs, some operations might already be required at the mini hubs or at the larger hubs. This could involve drying or other stabilization methods such as ensilaging, fermenting or acidification. Furthermore, these hubs might actively densify the waste to allow cheaper transportation. Regional hubs could also perform other preprocessing procedures to homogenize the feedstock from several sources or in some cases already perform a certain biorefining step such as an extraction and then transporting the extract to the biorefinery.

Depending on the place and way how the waste comes free, it can be transported to a mini-hub or directly to one of the larger hubs. It also determines how the transport can be arranged. Wastes such as banana pseudostem, bud, leaves, stock and coconut husks for example, can be collected by foot into a cart or car (for small farms) and/or by a baler or boom grabber into a tractor pulled trailer or truck (for a plantation) to the collection hubs. Then, the collected waste is transported by bigger trucks to the central hubs, and eventually to the refinery. Trucks are preferred since they are fast, simple and low cost solutions that can be easily organized centrally and decentrally. However, for wastes biomass (such as culled or rotten banana pulps and potato tuber, and coconut shell) that occur at central points in dispersed areas (such as produce collection centers, storing, processing and selling points), mini collection hubs can be established at the points of activity for each waste stream. Also, farmers should be encouraged to deliver their culled or rotten tubers and bananas to the collection hubs at negotiated prices. Further, those wastes from households and market places (such as potato peel and waste tubers, banana peels and pulps, and coconut shells) can be collected through a proper sorting and collection schemes such as well-placed shared collection points, since for case of Kenyan households, most houses do not have sufficient space for conventional drop-off containers. Crucial in the developments of these hubs is of course, citizen sanitization allowing safe storage without risk of diseases, leaching, or environmental risks.

Additionally, from this analysis, flavonoids, starch, cellulose and biogas seem to be the most promising bioresources generated from banana, potato and coconut wastes. However, these bioresource (and others) are not only limited to these waste streams. Other wastes sources given in Table 1 can also be used to produce/or supplement production of the studied bioresources. For example, flavonoid is a common compound that can be found in array of waste streams, such as mangoes [61], guavas [62], tomato [63], pineapple [64], beans and brassicas [63] wastes etc., starch can also be obtained from cassava [65], avocado, mango, pineapple [66] wastes streams, cellulose can be generated as well, from Macadamia shell [67], groundnut shell [68], cashew nut shell [69], cassava, and pineapple [70] etc., while pineapple, mango, avocado seed, orange peel, papaya, water melon wastes among others can supplement production of biomethane [63]. Thus, besides the studied case studies, other waste streams can be exploited to supplement the biorefinery routes proposed in this paper.

E-supplementary data of this work can be found in online version of the paper.

Conclusion

Bio-waste generation and analysis in Kenya was mapped for banana, potatoes and coconut. It is evident that these waste streams generate wastes in large quantities over the value chain (such as banana (6007 kt), potato (426 kt) and about coconut (50 kt), with the bulk being generated centrally and thus relatively feasible for collection and biorefinery. Currently, 73%, 54% and 94.8% of wastes from banana, potato and coconut respectively, is discarded. The rest of the wastes are used mainly for animal feed, soil improvement and some specific local options such as ropes and toys. However, many of these waste streams can be valorized via different valorization routes to produce different bioresources. Only banana peel, banana pulp, potato peel and their mixed wastes are dispersed and mixed with other wastes thus, a potential suitable route for their use is anaerobic co-digestion, e.g. combined with other locally generated organic wastes. However, with efficient waste collection and sorting, and assuming 100% waste use, banana waste valorization could as well focus on bio-refining the waste to about high end products such as; flavonoids (74 kt), starch (341 kt), cellulose (1959 kt) or generating biogas (1525 Gwh of energy); potato waste has high potential to produce; starch (36 kt), cellulose (14 kt), biogas (157 Gwh energy); while for coconut wastes, the main targeted products could be; tannin (2 kt), sugar (14 kt), cellulose (28 kt) and biogas (75 Gwh energy). Thus, in general, the three selected biomass types have a combined potential to valorize about flavonoids (74 kt), starch (377 kt), cellulose (2001 kt) and biogas (1757 GWh) being the most promising bioresources.

Material Flow Analysis typically requires many simplifications and assumptions, especially when performed with a broad scope such as at country level. Furthermore, Data Quality was assessed by the DQR approach and in general, high quality data was found. In this sense, this study is one of the first holistic MFA studies on different types of organic waste in Kenya, and it shows that a significant amount of waste can be collected and valorized, which could be a great input in the Kenyan bioeconomy. Further, the results of the study can inform policy making on waste management systems.

Data Availability

All data generated or analysed during this study are included in this published article [and its supplimentary information files]

References

Government of Kenya.: National sustainable waste management policy. In: Ministry of Environment and Forestry, (ed.), Sessional paper no. x, Revised draft, Republic of Kenya, (2019)

Government of Kenya.: Distribution of population administrative units. In: 2019 Kenya population and housing census. Kenya National Bureau of Statistics, vol. II., (2019)

Corrado, S., Sala, S.: Bio-economy contribution to circular economy. In: Benetto, E., Gericke, K., Guiton, M. (eds.) Designing sustainable technologies, products and policies: from science to innovation, pp. 49–59. Springer, Cham (2018)

Alexandra Soezer.: Nationally appropriate mitigation action on a circular economy: Solid waste management approach for urban areas in kenya. United Nations Development Programme, New York, USA, (2016)

United Nations Development Programme: Green economy sector study on agriculture in Kenya, United Nations Development Programme, New York, USA, (2015)

Blottnitz, H.V., Allison K.: Solid waste management in Nairobi: A situation analysis, Environmental & Process Systems Engineering Group, University of Cape Town, South Africa, (2010)

Gituma, K., Waswa, F.: Enhancing benefits from biomass wastes within small-medium scale coffee processing factories in Kiambu County, Kenya. Afr. J. Environ. Sci. Technol. 11, 198–206 (2017). https://doi.org/10.5897/AJEST2016.2243

Caldeira, C., De Laurentiis, V., Corrado, S., van Holsteijn, F., Sala, S.: Quantification of food waste per product group along the food supply chain in the European Union: a mass flow analysis. Resour. Consserv. Recycl. 149, 479–488 (2019). https://doi.org/10.1016/j.resconrec.2019.06.011

Turner, D.A., Williams, I.D., Kemp, S.: Combined material flow analysis and life cycle assessment as a support tool for solid waste management decision making. J. Clean. Prod. 129, 234–248 (2016). https://doi.org/10.1016/j.jclepro.2016.04.077

Eckelman, M.J., Chertow, M.R.: Using material flow analysis to illuminate long-term waste management solutions in Oahu, Hawaii. J. Ind. Ecol. 13(5), 758–774 (2009). https://doi.org/10.1111/j.1530-9290.2009.00159.x

Pirani, S.I., Arafat, H.A.: Reduction of food waste generation in the hospitality industry. J. Clean. Prod. 132, 129–145 (2016). https://doi.org/10.1016/j.jclepro.2015.07.146

Waweru, S.: Covid-19 yaharibu faida ya wakulima wa machungwa. In: Kilimo biashara, Taifa leo, Nairobi, Kenya, (2020)

Food and Agricultural Organization of United Nations: Food and Agricultural Organization Statistics, Rome, (2019)

Elanthikkal, S., Gopalakrishnapanicker, U., Varghese, S., Guthrie, J.T.: Cellulose microfibres produced from banana plant wastes: isolation and characterization. Carb. Polym. 80(3), 852–859 (2010). https://doi.org/10.1016/j.carbpol.2009.12.043

De Laurentiis, V., Corrado, S., Sala, S.: Quantifying household waste of fresh fruit and vegetables in the EU. Waste Manage. 77, 238–251 (2018). https://doi.org/10.1016/j.wasman.2018.04.001

Joshi, V., Kumar, A., Kumar, V.: Antimicrobial, antioxidant and phyto-chemicals from fruit and vegetable wastes: a review. Int. J. Food Ferment. Technol. 2, 123–136 (2012)

Ubalua, A.: Cassava wastes: treatment options and value addition alternatives. Afr. J. Biotechnol. (2007). https://doi.org/10.5897/AJB2007.000-2319

Verma, D., Gope, P.C.: The use of coir/coconut fibers as reinforcements in composites. In: Faruk, O., Sain, M. (eds.) Biofiber reinforcements in composite materials, pp. 285–319. Woodhead Publishing, Sawston (2015)

Braga, N., Rodrigues, F., Oliveira, M.B.P.P.: Castanea sativa by-products: a review on added value and sustainable application. Nat. Prod. Res. 29(1), 1–18 (2015). https://doi.org/10.1080/14786419.2014.955488

Rivas, S., Moure, A., Parajó, J.C.: Pretreatment of hazelnut shells as a key strategy for the solubilization and valorization of hemicelluloses into bioactive compounds. Agronomy 10(6), 760 (2020)

Padam, B.S., Tin, H.S., Chye, F.Y., Abdullah, M.I.: Banana by-products: an under-utilized renewable food biomass with great potential. J. Food Sci. Technol. 51(12), 3527–3545 (2014). https://doi.org/10.1007/s13197-012-0861-2

Tock, J.Y., Lai, C.L., Lee, K.T., Tan, K.T., Bhatia, S.: Banana biomass as potential renewable energy resource: a Malaysian case study. Renew. Sustain. Energy Rev. 14(2), 798–805 (2010). https://doi.org/10.1016/j.rser.2009.10.010

Food and Agricultural Organization of United Nations: Food loss assessments: Causes and solutions. In: Global Initiative on Food Loss and Waste Reduction, Rome, (2014)

Pavlista, A.D.: EC95-1249 potato production stages: Scheduling key practices. In: Historical Materials from University of Nebraska-Lincoln Extension, USA, pg. 1584. (1995)

Musita, C., Okoth, M., Abong, G.: Postharvest handling practices and perception of potato safety among potato traders in Nairobi, Kenya. Int. J. Food Sci. 2019, 1–8 (2019). https://doi.org/10.1155/2019/2342619

Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ): Challenge: Food not waste – Developing innovative business solutions for the food waste problem in Kenya. In: Food not waste-Kenya, Federal ministry of economic cooperative and development, Berlin, Germany, (2016)

Gumisiriza, R., Hawumba, J., Simon, A., Balyeidhusa, P., Okure, M., Hensel, O.: Processing of East African highland green bananas: waste generation and characterization as a potential feedstock for biogas production in Uganda. Am. Sci. Res. J. Eng. Technol. Sci. 53, 215–236 (2019)

Agriculture and Food Authority: Annual market research. In: Nuts and oil crops directorate, Government of Kenya, Mombasa, Kenya, (2016)

Abuya, W.: What is in a coconut? An ethnoecological analysis of mining, social displacement, vulnerability, and development in rural Kenya. Afr. Stud. Q. 14, 1–21 (2013)

Kaur, K., Chhikara, N., Sharma, P., Garg, M.K., Panghal, A.: Coconut meal: nutraceutical importance and food industry application. Foods Raw Mater. 7, 419–427 (2019). https://doi.org/10.21603/2308-4057-2019-2-419-427

Alexander, P., Brown, C., Arneth, A., Finnigan, J., Moran, D., Rounsevell, M.: Losses, inefficiencies and waste in the global food system. Agric. Syst. 153, 190–200 (2017). https://doi.org/10.1016/j.agsy.2017.01.014

Kadere, T., Oniango, R., Kutima, P., Njoroge, S.: Production, marketing and economic importance of mnazi and other coconut-based products in Kenya. Res. J. of Agric. and Biol. Sci. 5(5): 815–822 (2009)

Fernandes, E., Marangoni, C., Souza, O., Sellin, N.: Thermochemical characterization of banana leaves as a potential energy source. Energy Convers. Manage. 75, 603–608 (2013). https://doi.org/10.1016/j.enconman.2013.08.008

Kaguongo, W., Maingi, G., Giencke, S.: Post-harvest losses in potato value chains in Kenya: Analysis and recommendations for reduction strategies, Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ), Bonn, Germany, (2014)

Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ): Modernization options for the potato value chain in Kenya and Nigeria, Bonn, Germany, (2016)

Alpex: National coconut survey 2013 final report. In: Kenya Coconut Development Authority, (2014)

Kamira, M., Sivirihauma, C., Ntamwira, J., Ocimati, W., Katungu, M.G., Bigabwa, J.B., Vutseme, L., Blomme, G.: Household uses of the banana plant in eastern Democratic Republic of Congo. J. Appl. Biosci. (2015). https://doi.org/10.4314/jab.v95i1.1

Mugo, S.W.: Assessment of solid waste management at Wakulima Market in Nairobi city, Kenya. University of Nairobi thesis, (2019)

Mwachofi, H.P.: Value chain analysis of the coconut sub-sector in Kenya. University of Nairobi thesis, (2016)

Weidema, B.P., Wesnæs, M.S.: Data quality management for life cycle inventories—an example of using data quality indicators. J. Clean. Prod. 4(3), 167–174 (1996). https://doi.org/10.1016/S0959-6526(96)00043-1

Godoy León, M.F., Dewulf, J.: Data quality assessment framework for critical raw materials. The case of cobalt. Resour. Conserv. Recycl. 157, 104564 (2020). https://doi.org/10.1016/j.resconrec.2019.104564

Laititi, M.S.: Potato market survey in Kenya: an agricultural product value chain approach. Int. J. Bus. Manage. Rev. 2(6), 59–87 (2014)

Guinot, P., Gargadennec, A., Valette, G., Fruchier, A., Andary, C.: Primary flavonoids in marigold dye: Extraction, structure and involvement in the dyeing process. Phytochem. Anal. 19(1), 46–51 (2008). https://doi.org/10.1002/pca.1014

Pinto, P.C.R., Sousa, G., Crispim, F., Silvestre, A.J.D., Neto, C.P.: Eucalyptus globulus bark as source of tannin extracts for application in leather industry. ACS Sustain. Chem. Eng. 1(8), 950–955 (2013). https://doi.org/10.1021/sc400037h

Djordjevic, S., Kovacevic, S., Djordjevic, D., Konstantinovic, S.: Sizing process of cotton yarn by size from a copolymer of methacrylic acid and hydrolyzed potato starch. Text. Res. J. 89(17), 3457–3465 (2018). https://doi.org/10.1177/0040517518813628

Ergun, M., Ferda Mutlu, S.: Application of a statistical technique to the production of ethanol from sugar beet molasses by Saccharomyces cerevisiae. Bioresour. Technol. 73(3), 251–255 (2000). https://doi.org/10.1016/S0960-8524(99)00140-6

Alzuwaid, N.T., Pleming, D., Fellows, C.M., Sissons, M.: Fortification of durum wheat spaghetti and common wheat bread with wheat bran protein concentrate-impacts on nutrition and technological properties. Food Chem. 334, 127497 (2021). https://doi.org/10.1016/j.foodchem.2020.127497

Pongrácz, E., Tomperi, J.: Energy potential of biodegradable wastes in Kolari. Pollack Period. 9, 5–15 (2014). https://doi.org/10.1556/Pollack.9.2014.S.1

Wobiwo, F., Chaturvedi, T., Boda, M., Fokou, E., Emaga, T., Cybulska, I., Deleu, M., Gerin, P., Thomsen, M.: Bioethanol potential of raw and hydrothermally pretreated banana bulbs biomass in simultaneous saccharification and fermentation process with Saccharomyces cerevisiae. Biomass Convers. Biorefin. (2019). https://doi.org/10.1007/s13399-018-00367-0

Salyeem, E.E., Mshandete, A., Kivaisi, A.K.: Biovalorization of banana waste: auditing and improvement of bio-methane production by fungal pre-treatment. J. Chem. Biol. Phys. Sci. 4, 818–833 (2014)

Chintagunta, A.D., Jacob, S., Banerjee, R.: Integrated bioethanol and biomanure production from potato waste. Waste Manage. 49, 320–325 (2016). https://doi.org/10.1016/j.wasman.2015.08.010

Yaw Obeng, G., Yeboah, D., Opoku, R., Sekyere, C., Adjei, E.A., Mensah, E.: Coconut wastes as bioresource for sustainable energy: quantifying wastes, calorific values and emissions in Ghana. Energies 13, 2178 (2020). https://doi.org/10.3390/en13092178

Wobiwo, F., Emaga, T., Fokou, E., Boda, M., Gillet, S., Deleu, M., Richel, A., Gerin, P.: Comparative biochemical methane potential of some varieties of residual banana biomass and renewable energy potential. Biomass Convers. Biorefin. (2016). https://doi.org/10.1007/s13399-016-0222-x

Patil, P.: Measuring Cotton Consumption: Better Cotton Initiative conversion factors and multipliers, Better cotton initiative, version 1, (2020)

Alavudeen, A., Rajini, N., Karthikeyan, S., Thiruchitrambalam, M., Venkateshwaren, N.: Mechanical properties of banana/kenaf fiber-reinforced hybrid polyester composites: effect of woven fabric and random orientation. Mater. Des. (1980–2015) 66, 246–257 (2015). https://doi.org/10.1016/j.matdes.2014.10.067

Adeniyi, A.G., Onifade, D.V., Ighalo, J.O., Adeoye, A.S.: A review of coir fiber reinforced polymer composites. Composites B 176, 107305 (2019). https://doi.org/10.1016/j.compositesb.2019.107305

Saikia, C., Goswami, T., Ali, F.: Evaluation of pulp and paper making characteristics of certain fast growing plants. Wood Sci. Technol. 31, 467–475 (2004)

Kadla, J.F., Kubo, S.: Miscibility and hydrogen bonding in blends of poly(ethylene oxide) and kraft lignin. Macromolecules 36(20), 7803–7811 (2003). https://doi.org/10.1021/ma0348371

Pöschl, M., Ward, S., Owende, P.: Evaluation of energy efficiency of various biogas production and utilization pathways. Appl. Energy 87(11), 3305–3321 (2010). https://doi.org/10.1016/j.apenergy.2010.05.011

Mitullah, W.: Street vending in African cities: a synthesis of empirical finding from Kenya, Cote D'Ivoire, Ghana, Zimbabwe, Uganda and South Africa. (2003)

Garcia-Mendoza, M.P., Paula, J.T., Paviani, L.C., Cabral, F.A., Martinez-Correa, H.A.: Extracts from mango peel by-product obtained by supercritical CO2 and pressurized solvent processes. LWT - Food Sci. Technol. 62(1), 131–137 (2015). https://doi.org/10.1016/j.lwt.2015.01.026

De Silva Lima, R., Ferreira, S.R.S., Vitali, L., Block, J.M.: May the superfruit red guava and its processing waste be a potential ingredient in functional foods? Food Res. Int. 115, 451–459 (2019). https://doi.org/10.1016/j.foodres.2018.10.053

Aires, A., Carvalho, R., Saavedra, M.J.: Reuse potential of vegetable wastes (broccoli, green bean and tomato) for the recovery of antioxidant phenolic acids and flavonoids. Int. J. Food Sci. Technol. 52(1), 98–107 (2017). https://doi.org/10.1111/ijfs.13256

Madhumeena, S., Preetha, R., Prasad, S.: Effective utilization of pineapple waste. J. Phys. Conf. Ser. 1979(1), 012001 (2021). https://doi.org/10.1088/1742-6596/1979/1/012001

Moorthy, S.N., Ramanujam, T.: Variation in properties of starch in cassava varieties in relation to age of the crop. Starch - Stärke 38(2), 58–61 (1986). https://doi.org/10.1002/star.19860380206

Calderón-Oliver, M., López-Hernández, L.H.: Food vegetable and fruit waste used in meat products. Food Rev. Int. (2020). https://doi.org/10.1080/87559129.2020.1740732

Wechsler, A., Zaharia, M., Crosky, A., Jones, H., Ramírez, M., Ballerini, A., Nuñez, M., Sahajwalla, V.: Macadamia (Macadamia integrifolia) shell and castor (Rícinos communis) oil based sustainable particleboard: a comparison of its properties with conventional wood based particleboard. Mater. Des. 50, 117–123 (2013). https://doi.org/10.1016/j.matdes.2013.03.008

Bano, S., Negi, Y.S.: Studies on cellulose nanocrystals isolated from groundnut shells. Carbohydr. Polym. 157, 1041–1049 (2017). https://doi.org/10.1016/j.carbpol.2016.10.069

Bamgbola, A.A., Adeyemi, O.O., Olubomehin, O.O., Akinlabi, A.K., Sojinu, O.S., Iwuchukwu, P.O.: Isolation and characterization of cellulose from cashew (Anacardium occidentale L.) nut shells. Curr. Res. Green Sustain. Chem. 3, 100032 (2020). https://doi.org/10.1016/j.crgsc.2020.100032

Ahmad Khorairi, A.N.S., Sofian-Seng, N.-S., Othaman, R., Abdul Rahman, H., Mohd Razali, N.S., Lim, S.J., Wan Mustapha, W.A.: A review on agro-industrial waste as cellulose and nanocellulose source and their potentials in food applications. Food Rev. Int. (2021). https://doi.org/10.1080/87559129.2021.1926478

Acknowledgements

The authors hereby acknowledge that this research work has been conducted within the framework of the TEAM project ‘Towards a more integrated management of organic waste in Kenya; the production of natural dyes from fruit and vegetable waste’, Project No. KE2018TEA464A103 with financial support from the VLIR-UOS, Belgium.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dulo, B., Githaiga, J., Raes, K. et al. Material Flow Analysis and Resource Recovery Potential Analysis of Selected Fruit, Vegetable and Nut Waste in Kenya. Waste Biomass Valor 13, 3671–3687 (2022). https://doi.org/10.1007/s12649-022-01751-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01751-8