Abstract

Purpose

Animal bedding, a mixture of straw and manure, could be used as a feedstock for bioenergy production, but its heterogeneity poses new challenges in its use in biorefineries. We have investigated the origin of this heterogeneity and quantified it, and discuss its impact on bioenergy production.

Methods

Samples were collected from the bedding at different points and depths and analysed by first separating the manure from the straw by means of washing with water, and then determining the chemical composition of the liquid and solid fractions.

Results

The results supported our hypothesis that animal bedding behaves as a combination of several layers at different stages of degradation. Analysis revealed that the layers with higher organic content in the manure exhibited a poorer performance during the washing, since the residence time in the barn alters the washing profile of the organic fraction in the manure. It was also found that the variability in the composition of animal bedding was much greater than in other agricultural feedstocks: the manure content in animal bedding varied from 26 to 41%, and the content of fermentable carbohydrates varied by 20%. Total carbon and total nitrogen analyses showed that these changes in composition also affected the C/N ratio of the material, and thus its suitability as a feedstock for anaerobic digestion.

Conclusions

This implies that the residence time in the barn affects not only the heterogeneity of the properties of animal bedding, but also the best way to process it in a biorefinery.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

Our work presents a new methodology for the analysis of animal bedding and studies its heterogeneity for the first time, which affects the design of biorefineries and the managing of the farm.

Introduction

Since the industrial revolution, Western economies have been based on the linear consumption of natural resources [1], which has had both economic and environmental effects. Resource depletion, especially since 2000, has resulted in a marked increase in the price of natural resources [1], while unsustainable practices are degrading our environment [2, 3]. To remedy this situation, many governments and companies are taking steps to establish a circular economy, to replace current practices [4]. Such a shift towards a circular economy calls for renewable energy sources, where biomass will play an important role in changing the current energy production paradigm, in which 75% of the energy generated worldwide currently originates from non-renewable sources [4]. The workhorse of this new bioeconomy will be biorefineries [5], i.e., facilities where biomass is converted into a range of products, including biofuels, to maximize raw material usage [6].

An interesting agricultural residue in this context is animal bedding, which is a mixture of straw and manure. This residue has advantages as a potential feedstock for biofuel production over other agricultural residues more widely investigated, such as wheat straw, corn stover and sugarcane bagasse. In particular, the cost of animal bedding is lower than that of other residues, and it would also reduce the environmental impact of the agricultural sector in terms of greenhouse gas emissions from the manure itself, nutrient leaching from its use as a fertilizer, and waste generation [7].

Despite its considerable potential, no attempt has yet been made to use animal bedding for biofuel production, on demonstration scale or commercial scale, although some research has been carried out on laboratory scale [8,9,10]. One possible reason for this is the heterogeneity of animal bedding, which complicates its use as a feedstock in biorefineries [11, 12]. The problems associated with this heterogeneity are feedstock variability and the Maillard reaction.

The chemical and physical properties of manure vary considerably between different animals and farms [13]. Furthermore, changes take place in its composition with time after excretion due to combination with urine, bacterial decomposition, ambient temperature and moisture, and admixture with soil [14]. This would be especially the case in animal bedding in some areas of Denmark, where the technique of spreading fresh straw in the barn every day increases the heterogeneity. Feedstock variability leads to problems in a biorefinery, as a homogeneous feedstock is desirable. Studies on bioenergy production from manure are usually based on the average composition obtained from several samples [9, 10, 14], thus information is lacking on the variability in composition, and how this may affect energy production.

Regarding the Maillard reaction, manure contains a higher amount of nitrogen than other agricultural waste, such as wheat straw [15], which leads to the risk of the loss of reducing sugars due to their reaction at elevated temperatures with nitrogen compounds (e.g. ammonia, primary and secondary amines) once they are released from the carbohydrates contained in animal bedding [16, 17]. The best way to design a biorefinery so as to minimize the loss of substrate through the Maillard reaction is currently the subject of debate in the scientific community. Some authors have proposed the use of animal bedding in an anaerobic digester to produce biogas, and subsequent processing of the digestate for ethanol or fertilizer production [10, 18]. Others have proposed washing with water to separate the manure from the straw, so that the fibre can be hydrolysed separately without the risk of reducing sugars reacting with nitrous compounds [9, 11, 15]. However, no consensus has been reached on the best way to use animal bedding in a biorefinery.

The aim of this study was to explain the variability of animal bedding by proposing the following hypothesis: animal bedding can be described as the linear combination of several layers at different stages of degradation. Each of these layers was analysed separately, as opposed to previous studies where only values for the bulk were presented, to quantify the differences in terms of the washing profile and composition. In addition, we contribute to the discussion on the processing of manure-containing feedstocks by proposing a novel approach based on comparing the C/N ratios in animal bedding with optimal values for biogas production. Based on the implications of this study, it could be said that our new analysis methodology has the potential to be extrapolated to analyse similar materials and investigate other farms.

Materials and Methods

Animal Bedding Collection and Sampling

Animal bedding from a dairy farm at Lille Skensved, a small town close to Køge (Denmark), was studied. The barn has a rectangular shape, approximately 600 m2, hosts 150 dairy cows in loose housing regime and approximately 500 ton of straw per year are used as bedding. Samples were collected on three different occasions in September 2016, January 2017 and September 2017. The material was stored frozen before being analysed, according to previous recommendations [19].

On the first two occasions, samples were taken from an outdoor pile where animal bedding was stored after cleaning the barn. Material from these two samples was used to create artificial mixtures of bedding at different stages of degradation in order to test the hypothesis of an ideal mixture. The material collected in September 2016 (S16) had remained in the barn considerably longer than that collected in January 2017 (J17), and can therefore be expected to show a higher degree of degradation.

The samples collected in September 2017 (S17) were taken from several places in the barn after the accumulation of bedding for 5 weeks. Non-agitated systems can exhibit considerable variability in manure composition [20], and it has therefore been recommended that at least around 40 samples be collected to obtain representative mean values [21]. Following these recommendations, 13 sampling positions were established: 8 around the perimeter of the barn, 1 in the centre and 4 along the diagonals (Fig. 1), where the greatest variability was expected [22]. Three different samples were collected at each sampling position: bedding from the top layer, bedding from the middle layer and bedding from the bottom layer. This gives 39 samples in total, which should ensure representability.

After the sample collection, a subsample was taken from each of the 13 positions after thorough mixing of the material in a concrete mixer. The 13 subsamples were then mixed to create an average sample that is representative of the whole barn. This procedure was repeated for each of the three samples from different layers of the bedding, rendering three average samples: top layer, middle layer, and bottom layer.

Characterization of the Washing: Washing Profile and Washing Efficiency

Four hundred g of wet animal bedding was mixed with 1 L distilled water and then pressed in a filter press at 6 bar to remove the liquid. The procedure was repeated until a total of ten washing cycles had been performed. The weight of the expressed liquid was recorded, and liquid samples were taken for further analysis after each washing cycle.

The results of the washing were characterized by two parameters: the mass removed and the washing efficiency. The first is the accumulated mass removed during the ten washing cycles, while the second is the ratio of the mass removed in the nth cycle to the total mass removed in all ten washing cycles (see Eqs. 1 & 2).

where Mliquid,i is the weight of the expressed liquid after washing cycle i; TSi the total solids content of the liquid after washing cycle i; bedding mass is the initial animal bedding weight in the first washing cycle; TSbedding the total solids content of the bedding; Mliquid,n is the weight of the expressed liquid after washing cycle n; and TSn the total solids content of the liquid after washing cycle n.

Compositional Analysis

Animal bedding was considered to be a mixture of two components: manure and straw. The manure content in the animal bedding was assumed to be equal to the proportion of mass removed during washing, while the rest was assumed to be straw. Soluble organic carbon from the straw is a source of error in this methodology, but to a minor extent since only a small portion of the soluble organic carbon would be transferred to the liquid when using room temperature water. In fact, the National Renewable Energy Laboratory (NREL) analysis methods recommend the use of much higher temperature (around 100 °C) to successfully extract all these components from the straw [23]. Thus, we consider that our assumption is true as the mentioned effect is negligible.

Each of these fractions was further analysed to determine its chemical composition, and each analysis was performed in triplicate. The composition of the animal bedding was then obtained by multiplying the composition of manure and straw by their respective content in the mixture.

Analysis of the Washed Straw

The solid material remaining after the ten washing cycles was dried at 45 °C and milled to a particle size of 1 mm prior to analysis using the methodology described by NREL. The ash content was determined by incineration at 575 °C for 3 h [24]. The extractives content corresponded to the mass removed by 24 h of water extraction followed by 24 h of ethanol extraction [23]. Double-step acid hydrolysis was performed on the extracted fibre to determine the content of structural carbohydrates and lignin [25].

The sugar content in the structural carbohydrates and lignin analysis was determined using high-performance anion-exchange chromatography coupled with pulsed amperometric detection. A Dionex system with a Carbo Pac PA1 column, a GP50 gradient pump and an AS50 autosampler were used. The flow rate was 1 mL/min and the solutions used as eluents were: deionized water, 200 mmol/L sodium hydroxide, and 200 mmol/L sodium hydroxide mixed with 170 mmol/L sodium acetate.

Samples of the washed fibre were sent to an external laboratory, where total carbon and total nitrogen were analysed with a Vario Max CN elemental analyser (Elementar, Langenselbold, Germany). The operating principle of this equipment consists of combusting the sample at 850–1150 °C and analysing the exhaust gas.

Analysis of the Washing Liquid

The total solids (TS) in the washing liquid after each cycle was analysed by drying an aliquot at 105 °C overnight. The resulting solids were incinerated at 575 °C for 3 h to determine the organic matter content. The inorganic matter content was calculated as the difference between the TS and the organic matter content.

Lange cuvette tests (LCK 338 and LCK 138) were used to determine the total nitrogen in the washing liquids. This analysis consists of converting the nitrogen compounds to one species through chemical treatments and subsequently measure the absorbance of this species to determine the nitrogen content. The spectrophotometer used was a Hach Lange DR2800. Total carbon was analysed with a TOC-5050A Shimadzu total organic carbon analyser, equipped with an ASI-5000A autosampler. This analysis is based on combusting the sample at 680 °C and then determining the CO2 content in the exhaust gas.

Results and Discussion

Validation of the Ideal Mixture Hypothesis

Animal bedding was collected on two occasions from an outdoor pile after the barn had been cleaned. The material collected in September 2016 showed a higher degree of degradation than the material collected in January 2017. This is indicated by the higher manure content, as can be seen in Fig. 2a: S16 contained 52% manure while J17 contained 38%. S16 not only contained more manure, the fibre in this material also showed a higher degree of degradation. For example, S16 contained 18.4% hexoses, while the content in J17 was 27.2% (Table 1). The chemical composition of the samples thus corroborates the visual assessment of the degree of degradation of the materials.

The degree of degradation had a clear effect on the washing of the materials. Manure was removed from S16 at a slower rate than from J17 (Fig. 2). J17 showed a high initial washing efficiency, which decreased rapidly after a few washing cycles. 80% of the manure was removed during the first two washing cycles, and only residual amounts were removed in the subsequent cycles. The slower decrease in washing efficiency for S16 indicates that manure was not removed as quickly as from J17 (60% removal in the first two cycles), but that removal was distributed over more washing cycles. This can be seen in Fig. 2b.

Since S16 was more degraded than J17, mixing the two materials may provide a mixture that resembles animal bedding in the barn. Figure 3 shows the results obtained for a 50:50 mixture of S16 and J17 during washing, and the predicted values based on the ideal mixture hypothesis (i.e. linear combination). It can be seen that there is good agreement between the experimental and predicted values, which means that the profiles for the 50:50 mixture are the same as the average of the profiles for S16 and J17, thus proving that our hypothesis was correct. A similarly good fit was obtained when performing the same experiment with a 25:75 mixture of S16 and J17 (data not shown), which further confirms our hypothesis.

The results of the chemical analysis provided some evidence that the ideal mixture hypothesis may also apply to the chemical composition (Table 1). However, accurate values were only obtained for the main components in animal bedding: manure, glucan, xylan and lignin, while the determination of minor carbohydrates (galactan, arabinan and mannan), ash and extractives was not sufficiently accurate to confirm this.

The verification of the ideal mixture hypothesis describes the heterogeneity of animal bedding: the properties of animal bedding result from the mixing of several fractions with different properties due to different stages of degradation. The proportion of each of these fractions in the material would be key in assessing the quality of the material, and therefore in establishing its value and possible price. In principle, our findings suggest that it is possible to measure the properties of each fraction and those of the mixture, and then calculate the amount of each fraction in animal bedding using the washing profile and the content of glucan, xylan and lignin. However, due to practical problems during the sampling procedure, it is difficult to validate this principle empirically. In order to validate the principle, it would be needed to develop a sampling method that does not modify the amount of each fraction during the collection, i.e. the amount of each fraction in the sample is the same as in the native material.

Effect of Degree of Degradation on Washing

After our hypothesis had been verified, material S17 was collected to identify the different fractions in animal bedding and to quantify the differences in their properties. It was observed that each of the layers had a slightly different washing efficiency profile (Fig. 4), which confirms that the degree of degradation influences the behaviour of the material during washing. The reproducibility of the analysis was investigated by washing the bottom layer of material S17 twice, where greater variability was expected due to its higher degree of degradation. Due to the lack of replicates in the analysis of other samples, errors could not be calculated, but the small difference between the two replicates from the bottom layer of S17 indicates that these should be small. Thus, the differences are significant compared to the standard deviation, i.e. the different curves do not overlap when considering the standard deviation and therefore it can be said that pure experimental error is not enough to explain such differences, even if they are small.

It can then be said that manure was removed more efficiently from the top layer than from the middle and bottom layers, which indicates that manure becomes more attached to the straw during degradation of animal bedding, making the washing more difficult. Interestingly, the middle layer showed a lower removal rate than the bottom layer. For example, after two washing cycles, 63% and 73% of the manure had been removed from the middle and bottom layers, respectively. Thus, loss of performance during washing was not proportional to the residence time in the barn. In other words, it is not necessarily true that the longer animal bedding stays in the barn, the more difficult it is to separate the manure from the straw.

Figure 5 shows the washing efficiency for the inorganic and organic fractions of manure for each of the layers. The removal of inorganic mass was similar in all the layers, but differences were seen in the profiles for organic mass. Furthermore, the patterns for the organic fraction were very similar to those obtained for the washing efficiency based on total mass (Fig. 4). These results imply that the heterogeneous behaviour of the layers during washing is due to different degrees of change in the organic fraction of manure. A longer residence time in the barn, and thus a higher degree of degradation, leads to changes in the organic fraction of manure that modify its behaviour during washing, however, differences in the overall removal rate are counterbalanced by the similar behaviour of the inorganic fraction in all three layers.

Effect of Degree of Degradation on Bedding Composition

Residence time in the barn affects animal bedding composition, as shown by analysis of the fibre and washing liquid after ten washing cycles. The manure content in the bedding was 26%, 36% and 41% in the top, middle and bottom layers (average samples), respectively (Fig. 6). This increase in manure content is probably due to the sinking of manure towards the bottom due to gravity. These values are in agreement with compositions reported previously [11, 12], and show that the longer the bedding remains in the barn, the higher its manure content or, the lower its fibre content.

Apart from affecting the content of manure in the mixture, residence time also had an effect on the composition of the manure. The manure composition in each layer was different as residence time did not affect inorganic and organic compounds in the same way. Inorganic compounds increased with increasing residence time, but the highest organic fraction was found in the middle layer, which means that the organic compounds in manure started to decrease after a certain residence time (Fig. 6). This could explain the observed pattern in the washing of the layers, i.e. the middle layer was the most difficult to wash because the manure in this layer contained the highest fraction of organic compounds, the washing of which was modified by residence time. The total manure content in the middle layer was approximately 10% more than in the top layer, the main reason being an increase in organic compounds, 9% more than in the top layer (Fig. 6). However, the origin of the 5% higher amount of manure in the bottom layer than in the middle layer was that the inorganic fraction increased by 7% while the organic fraction decreased by 2%. A possible explanation of this may be that the methanogenic bacteria present in the manure degrade organic matter to methane and carbon dioxide [26], while inorganic matter (e.g., sand, gravel, stones, etc.) increases due to mixing with soil from the barn [14].

The composition of the other component in animal bedding, straw, also underwent changes with increased residence time. The top, middle and bottom layers had hexose contents of 35%, 25% and 22%, and pentose contents of 18%, 14% and 13%, respectively (Fig. 6), which are similar to values reported previously [11, 12]. This accounts for a variation of almost 20% in the content of fermentable carbohydrates: 13% difference in hexose content and 5% in pentose content. This decrease in fermentable carbohydrates resulted from the combination of two factors: a lower amount of straw in the mixture and a lower amount of fermentable carbohydrates in the straw. The decrease in hexose and pentose contents in the straw could be due to the high cellulolytic activity of microorganisms in rumen fluid, which makes these bacteria very efficient in degrading lignocellulosic material [27, 28].

An interesting observation is that the variability in the composition of the animal bedding found in this study was much greater than that in other agricultural waste investigated for bioenergy production. Wheat straw from the same source showed only an 8% variation in fermentable carbohydrate content between different occasions [29, 30], which is the same variation as in wheat straw from another source [31, 32]. The variations between wheat straw from several sources are also smaller than the variation in animal bedding from the same occasion. Thus, the variability in the composition of feedstock for bioenergy production when using animal bedding can be expected to be more than twice that when using wheat straw. This will have important implications on the planning of biomass supply to the biorefinery as the amount of substrate available for bioenergy production per ton of biomass could vary considerably.

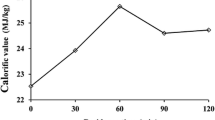

These compositional changes strongly affect the bioenergy potential of animal bedding. During the time spent in the barn, fresh bedding, consisting of straw with some manure (top layer), is transformed into degraded straw with a high manure content (bottom layer). Initially, the loss of bioenergy potential of the straw due to a decrease in its fermentable carbohydrate content would be counteracted by the higher potential of the manure, due to the increase in its organic fraction. However, the organic fraction in manure starts to decrease after a few weeks residence time, which means that the potential of both the straw and manure would decrease, seriously compromising the usability of this feedstock in a biorefinery. This suggests that farmers could increase the value of their waste by cleaning the barn more often, since this would reduce the residence time in the barn, thus avoiding the formation of low-quality fractions, leading to a decrease in bioenergy production, and thus revenue. However, this would lead to higher costs for the farmer, both in terms of raw material and labour.

C/N Ratio as an Indication of the Best Processing Technology

The analysis of the chemical composition of each layer was complemented with the determination of the total carbon and total nitrogen content in order to estimate the C/N ratio. It can be seen from Table 2 that residence time in the barn had little effect on the total carbon and total nitrogen contents of the straw in animal bedding. However, it affected the nitrogen content of the manure; the total nitrogen content almost doubling between the top and bottom layers. This means that the nitrogen content in animal bedding increases with increasing residence time in the barn, due, not only, to an increased manure content, but also to a higher nitrogen content in the manure.

This variation in nitrogen content results in a modification of the C/N ratio in animal bedding, being 56, 38 and 30 for the top, middle and bottom layers, respectively. This difference in C/N ratio affects the suitability of the material for anaerobic digestion, since this process is best operated at a C/N ratio of 25–30 [33, 34]. Thus, the bottom layer of animal bedding, with the highest degree of degradation, is suitable for anaerobic digestion, in terms of the C/N ratio, while the top and middle layers contain too much carbon.

We therefore suggest that high-quality animal bedding (short time in the barn) be processed using a biorefinery concept in which carbon and nitrogen are separated, for example, by removing the manure through washing with water. If correctly designed, this would render a stream containing mainly carbon with little nitrogen, and the carbohydrates could be hydrolysed without the risk of the Maillard reaction, even if the process is performed at elevated temperatures [15], and another stream with an optimal C/N ratio for anaerobic digestion, which could be used for biogas production. However, above a certain degree of degradation, it seems more suitable to feed the material directly to an anaerobic digester. Further research should be directed towards establishing more appropriate indicators for the quality of animal bedding, and using them together with techno-economic calculations to determine this threshold.

Conclusions

In this study, we have investigated and quantified the heterogeneity of animal bedding, and discussed its impact on bioenergy production. The results show that the heterogeneous nature of animal bedding originates from the fact that the material is a combination of several layers at different stages of degradation. These layers exhibit differences in both their washing and composition. It appears that washing is modified as a result of changes in the removal rate of the organic fraction of the manure. Regarding compositional differences, increasing the residence time in the barn not only increases the manure/straw ratio in animal bedding, but also modifies the composition of both the straw and manure: altering the organic fraction in manure and decreasing the content of fermentable carbohydrates in the straw. These changes result in a reduction in the quality of the material that influences its potential for bioenergy production, and suggest that farmers could increase the value of their residue by cleaning the barn more often. Furthermore, changes in the composition of animal bedding will also affect the best way to process the material, which means that operations at the farm would affect the design of the biorefinery. In terms of the C/N ratio, the results of this study suggest that high-quality bedding could be processed in a biorefinery where the carbon and nitrogen are separated, however, above a certain degree of degradation it would be more suitable to use the material directly for biogas production.

References

Ellen MacArthur Foundation (EMAF): Towards the circular economy. https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf (2013)

Millennium Ecosystem Assessment: Ecosystems and Human Well-Being: Synthesis. Island Press, Washington, DC (2005)

Millennium Ecosystem Assessment: Ecosystems and Human Well-being: Current State and Trends. Island Press, Washington, DC (2005)

Korhonen, J., Honkasalo, A., Seppälä, J.: Circular economy: the concept and its limitations. Ecol. Econ. 143, 37–46 (2018). https://doi.org/10.1016/j.ecolecon.2017.06.041

Demirbas, A.: Biorefineries: For Biomass Upgrading Facilities, vol. 26. Green Energy and Technology. Springer, London (2010)

Rabaçal, M., Ferreira, A.F., Silva, C.A., Costa, M.: Biorefineries: Targeting Energy, High Value Products and Waste Valorisation, vol. 57. Springer, Cham (2017)

Liebig, M.A., Franzluebbers, A.J., Follett, R.F.: Agriculture and climate change: mitigation opportunities and adaptation imperatives. In: Managing Agricultural Greenhouse Gases, pp. 3–11. Academic Press, San Diego (2012)

Vancov, T., Schneider, R.C., Palmer, J., McIntosh, S., Stuetz, R.: Potential use of feedlot cattle manure for bioethanol production. Bioresour. Technol. 183, 120–128 (2015). https://doi.org/10.1016/j.biortech.2015.02.027

Woldesenbet, G.A., Shiferaw, G., Chandravanshi, B.S.: Bio-ethanol production from poultry manure at Bonga Poultry Farm in Ethiopia. Afr. J. Environ. Sci. Technol. 7(6), 435–440 (2013). https://doi.org/10.5897/ajest2013.1443

Elumalai, S., Roa-Espinosa, A., Markley, J.L., Runge, T.M.: Combined sodium hydroxyde and ammonium hydroxide pretreatment of post-biogas digestion dairy manure fiber for cost effective cellulosic bioethanol production. Sustain. Chem. Process. 2(12), 1–13 (2014). https://doi.org/10.1186/2043-7129-2-12

Chen, S., Wen, Z., Liao, W., Liu, C., Kincaid, R.L., Harrison, J.H., Elliott, D.C., Brown, M.D., Stevens, D.J.: Studies into using manure in a biorefinery concept. Appl. Biochem. Biotechnol. 124(1), 999–1015 (2005). https://doi.org/10.1385/ABAB:124:1-3:0999

Bona, D., Vecchiet, A., Pin, M., Fornasier, F., Mondini, C., Guzzon, R., Silvestri, S.: The Biorefinery Concept Applied to Bioethanol and Biomethane Production from Manure. Waste Biomass Valoriz. 9(11), 2133–2143 (2017). https://doi.org/10.1007/s12649-017-9981-2

Wallace, T.: Sampling Liquid Manure for Analysis. Alberta Agriculture and Food, Alberta (2008)

Ward, G.M., Muscato, T.V., Hill, D.A., Hansen, R.W.: Chemical composition of feedlot manure. J. Environ. Qual. 7(2), 159–164 (1978)

Liao, W., Liu, Y., Liu, C., Chen, S.: Optimizing dilute acid hydrolysis of hemicellulose in a nitrogen-rich cellulosic material–dairy manure. Bioresour. Technol. 94(1), 33–41 (2004). https://doi.org/10.1016/j.biortech.2003.11.011

Collins, P.M., Ferrier, R.J.: Monosaccharides: Their Chemistry and Their Roles in Natural Products. Wiley, Chichester (1995)

Hodge, J.E.: Dehydrated foods, chemistry of browning reactions in model systems. J. Agric. Food Chem. 1(15), 928–943 (1953). https://doi.org/10.1021/jf60015a004

Yue, Z., Teater, C., Liu, Y., Maclellan, J., Liao, W.: A sustainable pathway of cellulosic ethanol production integrating anaerobic digestion with biorefining. Biotechnol. Bioeng. 105(6), 1031–1039 (2010). https://doi.org/10.1002/bit.22627

Peters, J., Combs, S.M., Hoskins, B., Kovar, J.L., Watson, M.E., Wolf, A.M., Wolf, N.: Recommended Methods of Manure Analysis. University of Wisconsin System, Cooperative Extension Publishing Operations, Madison (2003)

Tasistro, A.S., Kissel, D.E., Bush, P.B.: Sampling broiler litter: how many samples are needed? J. Appl. Poult. Res. 13(2), 163–170 (2004)

Dou, Z., Galligan, D.T., Allshouse, R.D., Toth, J.D., Ramberg, C.F., Ferguson, J.D.: Manure sampling for nutrient analysis: variability and sampling efficacy. J. Environ. Qual. 30(4), 1432–1437 (2001)

Roberts, S., Xin, H., Swestka, R., Yum, M., Bregendahl, K.: Spatial variation of manure nutrients and manure sampling strategy in high-rise laying-hen houses. J. Appl. Poult. Res. 25(3), 428–436 (2016). https://doi.org/10.3382/japr/pfw013

Sluiter, A., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D.: Determination of Extractives in Biomass. Laboratory Analytical Procedure (LAP). National Renewable Energy Laboratory, Golden (2008)

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D.: Determination of Ash in Biomass. Laboratory Analytical Procedure (LAP). National Renewable Energy Laboratory, Golden (2008)

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., Crocker, D.: Determination of Structural Carbohydrates and Lignin in Biomass. Laboratory Analytical Procedure (LAP). National Renewable Energy Laboratory, Golden (2008)

Ozbayram, E.G., Ince, O., Ince, B., Harms, H., Kleinsteuber, S.: Comparison of rumen and manure microbiomes and implications for the inoculation of anaerobic digesters. Microorganisms 6(1), 15 (2018)

Hu, Z.-H., Yu, H.-Q.: Application of rumen microorganisms for enhanced anaerobic fermentation of corn stover. Process. Biochem. 40(7), 2371–2377 (2005). https://doi.org/10.1016/j.procbio.2004.09.021

Yue, Z.-B., Li, W.-W., Yu, H.-Q.: Application of rumen microorganisms for anaerobic bioconversion of lignocellulosic biomass. Bioresour. Technol. 128, 738–744 (2013). https://doi.org/10.1016/j.biortech.2012.11.073

Erdei, B., Barta, Z., Sipos, B., Réczey, K., Galbe, M., Zacchi, G.: Ethanol production from mixtures of wheat straw and wheat meal. Biotechnol. Biofuels 3(1), 16 (2010)

Linde, M., Jakobsson, E.-L., Galbe, M., Zacchi, G.: Steam pretreatment of dilute H2SO4-impregnated wheat straw and SSF with low yeast and enzyme loadings for bioethanol production. Biomass Bioenerg. 32(4), 326–332 (2008). https://doi.org/10.1016/j.biombioe.2007.09.013

Erdei, B., Frankó, B., Galbe, M., Zacchi, G.: Separate hydrolysis and co-fermentation for improved xylose utilization in integrated ethanol production from wheat meal and wheat straw. Biotechnol. Biofuels 5(1), 12 (2012)

Erdei, B., Hancz, D., Galbe, M., Zacchi, G.: SSF of steam-pretreated wheat straw with the addition of saccharified or fermented wheat meal in integrated bioethanol production. Biotechnol. Biofuels 6(1), 169 (2013)

Kayhanian, M.: Ammonia inhibition in high-solids biogasification: an overview and practical solutions. Environ. Technol. 20(4), 355–365 (1999). https://doi.org/10.1080/09593332008616828

Wang, X., Yang, G., Feng, Y., Ren, G., Han, X.: Optimizing feeding composition and carbon–nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresour. Technol. 120, 78–83 (2012). https://doi.org/10.1016/j.biortech.2012.06.058

Acknowledgements

This work was financially supported by the Swedish Energy Agency and BESTF3 (Grant No. P42674-1). The authors are also grateful to TK Energy A/S and Niels Lundager for their help in the collection of the animal bedding and to Margaréta Rozbach for her participation in the experimental work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sanchis-Sebastiá, M., Erdei, B., Kovacs, K. et al. Analysis of Animal Bedding Heterogeneity for Potential Use in Biorefineries Based on Farmyard Manure. Waste Biomass Valor 11, 2387–2395 (2020). https://doi.org/10.1007/s12649-018-00578-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-00578-6