Abstract

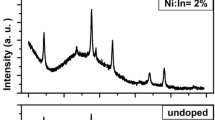

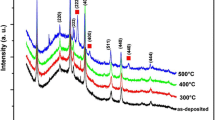

Nickel doped In2S3 films have been prepared by the chemical spray pyrolysis technique at 350 °C on glass substrates. The Ni doping level was changed by varying Ni:In molar ratio from 0 to 4% in solution. The structural studies reveal that the Ni-doped In2S3 films are polycrystalline and exhibit a cubic structure. As the Ni:In molar ratio increases, the crystallite size decreases from 27.5 to 23 nm and RMS roughness values increase from 12 to 18 nm, respectively. The presence of Ni in the deposited films was confirmed by energy dispersive spectroscopy. Raman studies show different peaks related to In2S3 phase and do not reveal any secondary phases of In–Ni and Ni–S. The transmission coefficient is about 70–55% in the visible region and 85–75% in near-infrared region. The band gap energy increases from 2.66 to 2.82 eV for direct transitions with the increase of Ni:In ratio from 0 to 4%. The refractive index values of In2S3:Ni thin films decrease from 2.46 to 2.40 and the extinction coefficient values are in the range 0.01–0.20.

Similar content being viewed by others

References

S S Wang, F J Shiou, C C Tsao, S W Huang and C Y Hsu Mater. Sci. Semicond. Process. 16 1879 (2013)

L Bhira, H Essaidi, S Belgacem, G Couturier, J Salardenne, N Barreau and J C Bernede Phys. Stat. Sol (a) 181 427 (2000)

M Roy, B P Mandal, D P Dutta and A K Tyagi Scr. Mater. 63 93 (2010)

M Kraini, N Bouguila, J El Ghoul, I Halidou, S A Gomez-Lopera, C Vázquez-Vázquez, M A López-Quintela and S Alaya J. Mater. Sci. Mater. Electron. 26 5774 (2015)

N Kamoun, S Belgacem, M Amlouk, R Bennaceur, J Bonnet, F Touhari, M Nouaoura and L Lassabatere J. Appl. Phys. 89 2766 (2001)

S Acharya, M Dutta, S Sarkar, D Basak, S Chakraborty and N Pradhan J. Mater. Chem. 24 1779 (2012)

W T Kim and C D Kim J. Appl. Phys. 60 2631 (1986)

A A El Sbazly, D A Elhady, H S Metwally and M A M Seyam J. Phys. Condens. Matter 10 5943 (1998)

M Kilani, B Yahmadi, N K Turki and M Castagné J. Mater. Sci. 46 6293 (2011)

J Sterner, J Malmström and L Stolt Photovoltaics 13 179 (2005)

E Dalas and L Kobotiatis J. Mater. Sci. 28 6595 (1993)

K Hara, K Sayama and H Arakawa Sol. Energy Mater. Sol. Cells 62 441 (2000)

D K Nagesha, X Liang, A A Mamedov, G Gainer, M A Eastman, M Giersig, J J Song, T Ni and N A Kotov J. Phys. Chem. B 105 7490 (2001)

F E Osterloh Chem. Mater. 20 35 (2008)

S Acharya, M Dutta, S Sarkar, D Basak, S Chakraborty and N Pradhan Chem. Mater. 24 1779 (2012)

X Fu, X Wang, Z Chen, Z Zhang, Z Li, D Y C Leung, L Wu and X Fu Appl. Catal. B 95 393 (2010)

N Barreau Sol. Energy 83 363 (2009)

S Cingarapu, M A Ikenberry, D B Hamal, C M Sorensen, K Hohn and K J Klabunde Langmuir 28 3569 (2012)

L J Liu, W D Xiang, J S Zhong, X Y Yang, X J Liang, H T Liu and W Cai J. Alloys Compd. 493 309 (2010)

Z Li, X Tao, Z Wu, P Zhang and Z Zhang Ultrason. Sonochem. 16 221 (2009)

H Spasevska, C C Kitts, C Ancora and G Ruani Int. J. Photoenergy 2012 1 (2011)

A Akkari, C Guasch, M Castagne and N K Turki J. Mater. Sci. 46 6285 (2011)

A Timoumi, H Bouzouita and B Rezig Thin Solid Films 519 7615 (2011)

D Perednis and L J Gauckler J. Electroceram. 14 103 (2005)

K Otto, A Katerski, O Volobujeva, A Mere and M Krunks Energy Proc. 3 63 (2011)

J J Lee, J D Lee, B Y Ahn and K H Kim J. Korean Phys. Soc. 53 3255 (2008)

S Ghosh, M Saha, V D Ashok, A Chatterjee and S K De Nanotechnology 27 155708 (2016)

R Lucena, J C Conesa, I Aguilera, P Palacios and P Wahnon J. Mater. Chem. A 2 8236 (2014)

B Asenjo, J Herrero and M Teresa Gutiérrez Mater. Res. Soc. Symp. Proc. 1165 M05 (2009)

K M A Hussain J Podder and D K Saha Indian J. Phys. 87 141 (2013)

A Mhamdi, B Ouni, A Amlouk, K Boubaker and M Amlouk J. Alloys Compd. 582 810 (2014)

A Khorsand Zak, W H Abd Majid, M E Abrishami and R Yousefi Solid State Sci. 13 251 (2011)

K Ravichandran and P Philominathan Sol. Energy 82 1062 (2008)

V Bilgin, S Kose, F Atay and I Akyuz Mater. Chem. Phys. 94 103 (2005)

P Roy and S K Srivastava Thin Solid Films 496 293 (2006)

J Alvarez Garcia, A Perez Rodriguez, A Romano-Rodriguez, T Jawhari, J R Morante, R Scheer and W Calvet Thin Solid Films 387 216 (2001)

Y Xiong, Y Xie, G Du, X Tian and Y Qian J. Solid State Chem. 166 336 (2002)

K Kambas, J Spyridelis and M Balkanski Phys. Stat. Sol. (b) 105 291 (1981)

C Guillen and J Herrero Thin Solid Films 510 260 (2006)

H Tao, H Zang, G Dong, J Zeng and X Zhao J. Optoelectron. Adv. Mater. 2 356 (2008)

M Kraini, N Bouguila, I Halidou, A Moadhen, C Vázquez Vázquez, M A López Quintela and S Alaya J. Electron. Mater. 44 2536 (2015)

M Kraini, N Bouguila, J Koaib, C Vázquez Vázquez, M A López Quintela and S Alaya J. Electron. Mater. 45 5936 (2016)

H Tao, S Mao, G Dong, H Xiao and X Zhao Solid State Commun. 137 408 (2006)

Y. Xiong, Y. Xie, G. Du, X. Tian, Y. Qian J. Solid State Chem. 166 336 (2002)

E. Kärber, K. Otto, A. Katerski, A. Mere, M. Krunks Mater. Sci. Semicond. Process. 25 137 (2013)

S J Ikhmayies and R N Ahmad Bitar Appl. Surf. Sci. 255 2627 (2008)

M Öztas and M Bedir Thin Solid Films 516 1703 (2008)

G B Kamath, C M Joseph and C S Menon Mater. Lett. 57 730 (2002)

S Rajeh, A Mhamdi, K Khirouni, M Amlouk and S Guermazi Opt. Laser Technol. 69 113 (2015)

M Kraini, N Bouguila, I Halidou, A Timoumi and S Alaya Mater. Sci. Semicond. Process. 16 1388 (2013)

F Urbach Phys. Rev. 92 1324 (1953)

E Yücel and Y Yücel Optik 142 82 (2017)

H Arizpe-Chavez, R Ramirez-Bon, F J Espinoza-Beltran, O Zelaya-Angel, J L Marin and R Riera J. Phys. Chem. Solids 61 511 (2000)

U Manzoor, M Islam, L Tabassam and S U Rahman Physica E 41 1669 (2009)

J Koaib, N Bouguila, M Kraini, A Mhamdi, I Halidou, M Ben Salem, H Bouzouita and S Alaya J. Mater. Sci. Mater. Electron. 27 9216 (2016)

C Guillén, T Garcia, J Herrero, M T Gutiérrez and F Briones Thin Solid Films 451 112 (2004)

P J L Herve and L K J Vandamme J. Appl. Phys. 77 5476 (1995)

S P Nehra, S Chander, A Sharma and M S Dhaka Mater. Sci. Semicond. Process. 40 26 (2015)

M M El-Nahass, B A Khalifa, H S Soliman and M A M Seyam Thin Solid Films 515 1796 (2006)

A Timoumi, H Bouzouita and B Rezig Aust. J. Basic Appl. Sci. 7 448 (2013)

N Bouguila, M Kraini, A Timoumi, I Halidou, C Vázquez Vázquez, M A López Quintela and S Alaya J. Mater. Sci. Mater. Electron. 26 7639 (2015)

M Bedir, M Özta¸ D Korkmaz and Y Özdemir Arab. J. Sci. Eng. 39 503 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kraini, M., Bouguila, N. & El Ghoul, J. Nickel doping effect on properties of sprayed In2S3 films. Indian J Phys 92, 989–997 (2018). https://doi.org/10.1007/s12648-018-1195-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-018-1195-3