Abstract

Titrations are a group of techniques that have contributed considerably to developing the chemical industry and chemistry itself. Currently, the Consultative Committee for Amount of Substance has recognized titration as one of the primary methods for determining the amount of substance. In this context, an accurate gravimetric complexometric titration method was implemented to determine the purity of ethylenediaminetetraacetic acid (EDTA) disodium salt dihydrate using a lead nitrate-certified reference material (CRM). The titration reaction was followed potentiometrically using a lead ion-selective electrode. The equivalence point was found by the inflection of a non-parametric regression line that fits the experimental data. The titrations were made in diluted ammonium hydroxide media and sodium tartrate was added to avoid the lead hydroxide precipitation that occurs at high pH. The effect of both concentrations, ammonium hydroxide and sodium tartrate, were evaluated by a Box-Behnken experimental design. A complete uncertainty statement for the measurement method is presented in terms of the International System of Units (SI). The combined relative standard uncertainty of the measurement results is 0.034 % for the purity of the EDTA disodium salt. The atomic weight of the lead that applies to the lead nitrate CRM was determined with mass spectrometry to decrease the uncertainty budget contribution of this parameter which, otherwise, would have been the most important. The main sources of uncertainty were the mass of the EDTA solution for titration blanks, the purity of the lead nitrate CRM, and the precision of the equivalence point determination. The method was evaluated using an EDTA disodium salt dihydrate CRM and no significant bias was found. Finally, the results indicated that the developed method could be used for the value assignment of the mass fraction of EDTA disodium salt dihydrate to produce CRMs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Certified Reference Materials (CRM) are used in the trueness assessment and the calibration of chemical analytical methods [1], and therefore are essential to disseminate metrological traceability of most measurement results in chemistry to The International System of Units (SI) [2, 3]. A CRM is a material sufficiently homogeneous and stable with reference to one or more specified properties, whose property values are provided with associated uncertainties and traceabilities in a document issued by an authoritative body [4]. The characterization of a CRM consists of determining the property values as part of the production process. According to ISO17034, the characterization of reference materials can be carried out using different approaches: (i) use of a primary reference measurement procedure, (ii) use of a single method for value transfer between closely matched materials, (iii) use of one or more methods performed by a network of competent laboratories, or (iv) use of two or more independent methods in one or several laboratories [5]. A primary reference measurement procedure is a method having the highest metrological qualities, whose operation can be completely described and understood, for which a complete uncertainty statement can be written down in terms of SI units [6]. Despite the lack of consensus regarding the meaning of the highest metrological qualities, it is reasonable to assume that the primary methods shall provide measurement results with relatively small uncertainties [7].

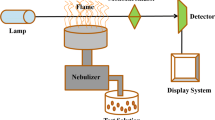

The most common references for elemental analysis in inorganic chemistry metrology are mono-elemental calibration solutions [8]. The characterization of mono-elemental calibration solutions requires the accurate determination of the mass fraction of the element in the solution (typically around 1000 mg kg\(^{-1}\)), with a relative standard uncertainty expected to be better than 0.15 % [9]. These requirements can be met by complexometric titration with ethylenediaminetetraacetic acid (EDTA), a classical analytical method introduced more than 70 years ago [10] that is capable of outperforming instrumental techniques such as atomic absorption spectrometry (AAS) and Inductively Coupled Mass Spectrometry (ICP-MS) for this kind of applications [11, 12].

The working principle of titrimetry is to react an unknown amount of a substance of interest with known quantities of another substance used as a reference. The titration reaction must proceed quantitatively, fast, and with a clearly defined stoichiometry. The standard substance of interest may be added as a solution with a well-known concentration or may be generated in situ by electrolysis. The former approach is the traditional titration and the latter is the coulometric titration. The amount of the standard substance generated in coulometric titrations is proportional to the amount of electrical charge passed to the system for the electrolysis [13], which often is measurable with higher precision than the amount of a given solution that is incorporated to a titration vessel. Coulometric titrations may produce results with lower measurement uncertainties than traditional titrations, but at the expense of the experimental setup being considerably more complicated. On the other hand, the quality of the measurement results of traditional titrations substantially improves by controlling gravimetrically the addition of the standard solution, leading to gravimetric titrations [7]. Both kinds of titrimetry measurement methods are powerful for accurately quantifying substances predominantly at a high amount of substance concentrations in relatively simple matrices. While coulometric titration has the potential to be considered a primary direct method [14], gravimetric titration has the potential to be considered a primary ratio method [15], thus, both approaches are suitable for the purity assessment of CRMs. The metrological traceability chain of a measurement result of elemental analysis using the EDTA route proposed in this work, using gravimetric titration, is shown in Fig. 1.

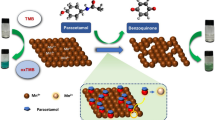

Complexometric titrations with EDTA performed at a high metrological level, to characterize mono-elemental calibration solutions, require at some point establishing the purity of the EDTA reagent to disseminate the metrological traceability of the element mass fraction to the amount of substance unit in the SI [7]. The EDTA, in the neutral form, is a tetraprotic acid capable of forming stable 1:1 complexes with most metallic cations, but it might be unadvantageous because of its low solubility in water. Instead, the EDTA disodium salt dihydrate (Na\(_2\)EDTA . 2H\(_2\)O) is significantly easier to dissolve in water and, therefore, easier to use. The EDTA disodium salt dissociates entirely in water and behaves the same way as EDTA for a given pH.

In titrimetry, it is of uttermost importance to monitor the titration reaction. The crucial step of titrations commonly relies on correctly identifying when the amount added of the reference substance is stoichiometrically equivalent to the amount of the unknown substance initially present in the sample. This moment is known as the titration equivalence point. Another possibility is to fit the complete data of the titration curve to a theoretical titration function that is derived from the systematic treatment of chemical equilibrium [16]. This work uses the equivalence point approach that is simple and yields results that are fit for the present purpose as long as the indication of the equivalence point is clear and unambiguous [7]. The instrumental indication of the equivalence point in complexometric titration is commonly done electrochemically [7, 17, 18] or spectrophotometrically [16].

This work focuses on establishing a measurement method to disseminate the metrological traceability of a lead nitrate CRM to certified Na\(_2\)EDTA . 2H\(_2\)O throughout a complexometric titration at a pH around 10 [19], achieved by adding enough ammonium hydroxide, and also adding sodium tartrate as an auxiliary complex formation substance to avoid the lead hydroxide precipitation [20]. A complete uncertainty statement for the measurement method is presented in terms of SI units and principal contributions to the uncertainty budget are discussed.

2 Materials and Methods

2.1 Chemicals and Reagents

High-purity EDTA disodium salt dihydrate CRM (GSO 2960-84) was provided by the Ural Research Institute for Metrology (UNIIM, Russia). Lead nitrate standard (SRM 928) and lead metal isotopic standard (SRM 981) were provided by the National Institute of Standards and Technology (NIST, USA). Ammonium hydroxide (ca. 25 % solution), sodium tartrate dihydrate and concentrated nitric acid were of analytical grade provided by Merk (Emsure\(^\circledR\), Germany). The nitric acid was purified by double sub-boiling distillation (DST-1000-230, Savillex, Minnesota, USA). All other chemical reagents were used as received. Ultrapure water (18 M\({\Omega }\) cm resistivity) was obtained through a Purelab Flex water purification system (ELGA LabWater, United Kingdom) and used in the preparation of all solutions.

2.2 Instrumentation and Materials

A semi-micro balance (XPE 205, Mettler Toledo, Ohio, USA) was used with a scale division setting of 0.01 mg for the weighing of solids and 0.1 mg for the weighing of liquid solutions. A moisture analyzer (HX 204, Mettler Toledo, Ohio, USA) was used to dry the EDTA salt. Electric potential differences were measured using a lead ion-selective electrode and a reference Ag\(^{0}/\hbox {AgCl}\) electrode with a high impedance potentiometer (848 Titrino Plus, Metrohm, Switzerland). The titration vessels were polypropylene (PP) cylindrical beakers and the gravimetric burettes were PP syringes of 5 mL nominal capacity (Precision Dispenser Tip, Brand, Germany) with a PP 10 \({\upmu }\)L pipette tip attached to the delivering end. The use of the capillary tip allows the addition of small drops down to 3 mg. A quadrupole ICP-MS instrument (NexION 300D, PerkinElmer, Pennsylvania, USA) was used to measure the atomic weight of the lead in the SRM 928 (RF power, 1250 W; plasma gas flow, 13.5 L min\(^{-1}\); auxiliary gas flow, 1.38 L min\(^{-1}\); carrier gas, 0.70 L min\(^{-1}\); scan mode, peak hopping; dwell time, 20 ms; number of sweeps per reading, 500).

2.3 Gravimetric Titration

The EDTA disodium salt was dried at 353.15 K until a constant mass was achieved and was allowed to cool down to room temperature in a desiccator. At this temperature, the salt can be dried without causing it to lose hydration water [21]. An EDTA solution was prepared gravimetrically to an estimated amount of substance concentration of about 10 mmol kg\(^{-1}\). The complete dissolution of the salt was ensured by placing the solution in an ultrasonic bath for 30 min. A lead ion standard solution was prepared gravimetrically in 2 % nitric acid to a known amount of substance concentration of about 4.8 mmol kg\(^{-1}\) using the lead nitrate CRM. The buoyancy effect of weighing in air during the preparation of solutions was considered since the required accuracy of the method must be better than 0.1% [22]. Environmental conditions (ambient temperature, barometric pressure, and relative humidity) were measured at the time of weighing to calculate the local air density using the CIPM-2007 revised formula [23].

A titration experiment starts with an aliquot of the lead standard solution weighed in the titration vessel (ca. 9.5 g), followed by the addition of the sodium tartrate (240 \({\upmu }\)L of a 1 mol L\(^{-1}\) solution) and the ammonium hydroxide (9.5 mL of a 1 mol L\(^{-1}\) solution). The latter amount of ammonium hydroxide is enough to maintain constant pH during the EDTA titration with lead under the conditions of the present study. The concentrations of sodium tartrate and ammonium hydroxide in the media, at the beginning of titration, are about 13 \({\upmu }\)mol kg\(^{-1}\) and 0.5 mol kg\(^{-1}\), respectively. Then, the electrodes are submerged in the solution to measure the electric potential difference (\(\Delta E\)) under constant magnetic stirring. The gravimetric burette filled with the EDTA salt solution is weighed at the beginning and after each addition of the EDTA solution. The titration curve, \(\Delta E\) versus the mass of the EDTA solution added (\(m_{{{\text{add}}}}\)), is plotted in real-time to anticipate the occurrence of the equivalence point. At least 99 % of the estimated equivalent mass of the EDTA solution is added at the beginning of the titration. At this point, the solution is added in small drops until ca. 101 % of the estimated equivalent mass was reached, procuring to incorporate drops of about 3 mg in the vicinity of the equivalence point to improve the accuracy of the titration [24]. The mass fraction of EDTA disodium salt dihydrate (\(w_{_\mathrm{{EDTA}}}\)) is calculated using the measurement model shown in Eq. 1. The meaning of the symbols used in Eq. 1 is compiled in Table 1.

Five determinations were performed each day on three different days during a week. The mass of the titration blanks \(m_{blank}\) was determined by titrating 2 % nitric acid solutions and following the same procedure described for the titration of the lead standard solution.

2.4 Metrological Traceability of the Measurement Result

The metrological traceability of the measurement result for the amount of substance concentration is given through the NIST SRM 928 - lead nitrate, which in turn is traceable to the SI by the NIST SRM 136c - potassium dichromate, characterized by a primary coulometric measurement method. The metrological traceability chain for the measurement results is shown in Fig. 1. The weighing instrument was calibrated by the Mass Laboratory of the Instituto Nacional de Metrología de Colombia (INM, Colombia) using E2 class weight standards. The electronic thermometer-hygrometer-barometer (Lufft Opus 20) used for the air density calculation was calibrated at the Pressure Laboratory and the Temperature and Humidity Laboratory of the INM. The isotope-number ratios are traceable to the NIST SRM 981 - lead natural abundance isotopic standard.

2.5 Determination of Lead Atomic Weight

The lead nitrate standard solution was diluted to ca. 20 \({\upmu }\)g kg\(^{-1}\) and the isotope-number ratios \(R(\mathrm {^{204}Pb,^{206}Pb})\), \(R(\mathrm {^{207}Pb,^{206}Pb})\) and \(R(\mathrm {^{208}Pb,^{206}Pb})\) were measured. Instrumental isotope fractionation effects were corrected using a lead isotopic standard (NIST SRM 981), dissolved in diluted nitric acid to a final mass fraction similar to that of the lead nitrate standard solution. The isotope-number ratios were measured for both solutions using the sample-standard bracketing (SSB) approach. The atomic weight of lead that applies to the material NIST SRM 928, \(A_r(\mathrm {Pb},{SRM928})\), is calculated as shown in Eq. 2 [25]:

where \(A_r(^i\hbox {Pb})\) is the atomic weight (or relative atomic mass) of isotope \(^i\hbox {Pb}\), as reported in [25], and \(x(^i\hbox {Pb})\) is the amount fraction (or isotopic abundance) of isotope \(^i\hbox {Pb}\). The amount fraction of the isotopes is calculated from the isotope-number ratios as shown in Eq. 3. Isotope-number ratios are corrected as described elsewhere [26, 27], using the ratio of measured values to reference values for the isotope-number ratios of the lead isotopic standard.

2.6 Data Analysis

The data treatment was made in the open-source programming language R for statistical computing and graphics [28]. The titration curves were fitted to cubic splines that consist of several piecewise (non-parametric) regression polynomial curves that allow for the prediction of values in the zones between the points of the experimental data. The cubic splines were obtained using the R function predict.smooth.spline() [29] which is also used to obtain their first derivative. The equivalence point of the titration is indicated by the global minimum of the first derivative curve. The minimum coincides with the inflection point of the regression line, which predicts the zone of the steepest change in the titration curve.

The individual titration results were evaluated for possible within-day outliers using Grubb’s outliers test implemented in package outliers [30]. The homogeneity of variances across groups was tested using the Levene test implemented in package car [31]. Uncertainty calculations were made according to the GUM [32] using the packages metRology [33] and propagate [34].

The within-day repeatability of the measurement method was taken as the pooled standard deviation of the three days (\(s_p\)), calculated using Eq. 4, after confirming the homogeneity of variances among the groups.

where \(n_i\) is the number of data in the group i, \(s_i^2\) is the variance of data in the group i, and k is the number of groups.

The between-days repeatability (\(s_{bd}\)) was obtained by an analysis of variance (ANOVA), according to Eq. 5.

where \(MS_{between}\) is the mean sum of squares between groups (days), \(MS_{within}\) is the mean sum of squares within groups, and \(n_0\) is the effective number of individual data in the groups [35].

The robustness of the analytical method was evaluated using a Box-Behnken experimental design with the package rsm [36]. The variables studied were the volume and amount of substance concentration of the ammonium hydroxide solution used to buffer the pH of the media, and the volume of the sodium tartrate solution 1 mol L\(^{-1}\) used as the auxiliary complex formation agent. Box-Behnken experimental designs are an efficient approach to studying the effect of three-level factors over a response variable while requiring few treatment combinations [37]. These experimental designs are response surface methodologies that have proven useful in studying and optimizing measurement processes [38, 39].

The estimation of uncertainty associated with the weighing processes considered the effect of the tare. The density of the air (\(\rho _{air}\)) and the magnitude of the air buoyancy correction factors (\(B_i\)), with their associated uncertainties, were calculated using the package masscor, which also served to manipulate the calibration information of the balance [40]. The magnitude of the air buoyancy correction factors is calculated according to the following equation [41]:

where \(\rho _{weights}\) is the density of the mass standards used in the balance calibration (8000 kg m\(^{-3}\) for stainless steel weights), and \(\rho _{i}\) is the density of the object being weighed.

3 Results and Discussion

The typical moisture content in the EDTA disodium salt dihydrate was around 0.6 %. Constant mass was obtained within the first 30 minutes of drying. The experimental conditions for the gravimetric titrations were studied in preliminary experiments, after which the factors and the intervals studied later in this work were defined. The pH of the solutions, at the beginning of the titration, were close to 9.79. Then, during titration, the reaction liberates two hydronium ions per lead ion being complexed, causing a small decrement in the pH of the experimental solution. However, the ammonium hydroxide concentration in the media is two orders of magnitude higher than that of the lead ion, whereby the pH of the solutions, at the end of the titration, was observed to diminish by less than 0.05.

A typical potentiometric titration curve (\(\Delta E\) vs. \(m_\mathrm{{add}}\)) obtained for the EDTA complexometric titration of a lead standard solution is shown in Fig. 2a. The titration curve includes a (non-parametric) regression line that passes throughout all points along with its first derivative. The data presents a sigmoid-shaped behavior that is typical of potentiometric titration curves. The global minimum of the first derivative curve can be used to accurately indicate the titration equivalence point [42]. The titration curve of a titration blank is shown in Fig. 2b. The mass of equivalence of EDTA solution for the titration blank cannot be distinguished from zero as there is no evident inflection point in the titration curve. This curve depicts only the behavior of a potentiometric titration after the equivalence has been reached. The method’s performance parameters and the uncertainty estimation of the measurement results are discussed in the following sections.

Potentiometric titration curve of the EDTA complexometric gravimetric titration using a lead standard solution a and a titration blank b, black dots. The titration was monitored with a lead selective electrode and a silver/silver chloride reference electrode. The black curves are non-parametric regression lines fitted to the experimental data set using the R function predict.cubic.spline(). The red curves depict the first derivative of the regression lines and indicates the titration equivalence point at their corresponding global minima

3.1 Method Performance Parameters

The individual results obtained each day for the mass fraction of the EDTA salt in the UNIIM GSO 2960-84 CRM are compiled in Table 2. The data was used for the evaluation of the method’s precision, considering within-day and between-days components, and for the evaluation of the method’s trueness by assessing the metrological compatibility of the average measurement result with the certified value of the CRM.

3.1.1 Precision

The within-day relative standard deviations were between 0.013 and 0.034 % (as shown in Table 2). The variance among the day groups can be considered homogeneous (p-value of Levene’s test for equality of variances, 0.206), hence it is appropriate to calculate the pooled standard deviation using Eq. 4. The relative within-days precision is \(s_p = 0.021~\%\). The between-days relative precision, according to the ANOVA results (using \(n_0 = 4.64\) in Eq. 5) is \(s_{bd} = 0.0045~\%\). There is no statistically significant difference among the averages of the results for each day (p-value of ANOVA, 0.344).

Observe that the between-days variation is significantly lower than the within-day typical variation. The latter is because the lead nitrate and EDTA solutions were prepared fresh each day under complete gravimetric control, which minimizes the between-day variations and makes evident that the main contribution to the lack of repeatability comes from variations within each day, such as the determination of the equivalence point. Then, if the analysis is repeated for more days, the repeatability uncertainty source will not significantly improve.

3.1.2 Trueness

The trueness of the method cannot be expressed numerically, but instead, the agreement between the measurement results and a reference value in a CRM can be studied [4]. A measurement result (\(x_{meas}\)) is metrologically compatible with a reference value (\(x_{ref}\)) if their difference (the measurement bias) does not significantly differ from zero in view of its expanded uncertainty. Equation 7 defines a parameter \(\zeta (x_{ref},x_{meas})\) which is closer to zero when the measurement results show good metrological compatibility and is bigger than one when the measurement results are not metrologically compatible [43].

where k is often given a value of 2.

The CRM GSO 2960-84 has a certified mass fraction value (\(x_{ref}\)) of \((0.9986\pm 0.0003)\) g g\(^{-1}\) (expanded uncertainty with \(k=2\)). The reference value was assigned at UNIIM using a coulometric titration method. On the other hand, the measured mass fraction of EDTA disodium salt dihydrate in the CRM using the gravimetric titration method (\(x_{meas}\)) was \((0.9987\pm 0.0007)\) g g\(^{-1}\)(expanded uncertainty with \(k=1.997\), details on the uncertainty estimation are given in Sect. 3.2). The value of \(\zeta (x_{ref},x_{meas})\) evaluated for the GSO 2960-84 is 0.0014, indicating that the measured value agrees well with the reference value given their stated standard uncertainties. Then, the measurement method presented in this work does not present significant bias.

3.1.3 Robustness

A low amount of ammonium hydroxide in the titration media would introduce bias in the measurement result because it would fail to ensure that the alkalinity of the media does not significantly decrease during titration. On the other hand, the amount of sodium tartrate must be high enough to avoid the precipitation of lead hydroxide at high pH, which can be a critical factor that might also lead to bias in the measurement result. Therefore, these two variables were included for the evaluation of the robustness of the method, which was assessed using the Box-Behnken experimental design [36], varying the concentrations of the ammonium hydroxide between 0.17 and 0.92 mol kg\(^{-1}\), and the sodium tartrate between 8.4 and 16.8 \({\upmu }\)mol kg\(^{-1}\), at the beginning of the titration. The measurement results did not show any statistically significant correlation with the studied variables, implying that the method is robust to changes in those variables between the intervals considered.

3.1.4 Selectivity

EDTA complexometric titrations are not selective because EDTA will react with almost any metallic cation potentially present in media [20]. In this way, using high-purity chemical reagents in the measurement method is relevant to ensure that the only metallic cations in the media are lead ions from the lead nitrate CRM and sodium ions from the EDTA disodium salt. Sodium ions are not a problem during titration since the EDTA complexes with alkali cations dissociate almost completely in aqueous media and are easily displaced by the cations of transition metals such as lead. The titration of matrix blanks is useful to determine if any of the matrix components interfere with the measurement results [44]. The selectivity of the titrimetric measurement method can be addressed this way without implying whether the titration reaction is selective itself. The titration of matrix blanks presented equivalent masses of EDTA solution indistinguishable from zero, as shown in Fig. 2b. According to the latter statement, the measurement method is selective.

Table 3 summarizes the performance parameters of the measurement method discussed in the four previous sections.

3.2 Uncertainty Estimation

The uncertainty budget for the mass fraction of EDTA disodium salt dihydrate is summarized in Table 4. The relative contribution of each of the uncertainty components to the uncertainty budget is shown in Fig. 3. The most important uncertainty sources are the apparent mass of the EDTA solution for a titration blank, \(m_{blank}\), the lead mass fraction in the lead nitrate NIST SRM 928, \(w_{_\mathrm{{Pb}}}\), and the precision of the method, \(F_{pre}\).

The apparent mass of the EDTA solution for a titration blank, \(m_{blank}\), accounts for possible impurities in the titration media and is assigned a value of 0 mg as long as the titration curves of the blanks only depicted the behavior of a titration reaction after the equivalence point, as shown in Fig. 2b. This parameter is assigned a rectangular distribution whose width is the mass of the smallest drop of the EDTA salt solution added in those experiments (2.77 mg). The standard uncertainty of a value with such distribution corresponds to its half interval divided by \(\sqrt{3}\) [32]. The uncertainty of the apparent mass of the EDTA solution for a titration blank, \(u(m_{blank})\), is 0.80 mg and has a relative contribution to the uncertainty budget of the final result of 29.5 %.

The mass fraction of lead nitrate in the NIST SRM 928 is 100.00 % ± 0.03 % (expanded uncertainty with a coverage factor \(k=2\)). The given mass fraction of lead nitrate is calculated from the lead mass fraction in the material, divided by a factor of 0.625 595. The same factor can be used reversely to determine the lead mass fraction in the NIST SRM 928, \(w_{_\mathrm{{Pb}}}\), as 0.625 595 g g\(^{-1}\) with a standard uncertainty, \(u(w_{_\mathrm{{Pb}}})\), of 0.000 094 g g\(^{-1}\) (relative standard uncertainty, 0.015 %). The relative contribution of this parameter to the combined uncertainty of the final result is 24.7 %.

The uncertainty from precision of the method, \(u(F_{pre})\), combines the within-day repeatability (\(s_p\), relative value 0.021 %) and the between-day repeatability (\(s_{bd}\), relative value 0.0049 %). The relative standard deviations can be combined by the square root of the sum of squares. The result is divided by the square root of the number of independent data (n), as shown in Eq. 8 (Type A evaluation of standard uncertainty [32]).

Individual within-day measurement results are not considered independent since the same lead standard solution and EDTA solution were used. Any mistake in the preparation of the solutions would affect all the determinations performed that day. Fresh solutions were prepared each day; thus, the day-average measurement results were considered independent among them (\(n=3\)). Consequently, the relative uncertainty from the lack of repeatability of the method is 0.013 %. The relative contribution of this parameter to the uncertainty budget of the final result is 17.3 %.

The parameters that follow in order of their relative contribution to the combined uncertainty of the final result are the apparent masses of the EDTA and the standard lead nitrate solids, with relative contributions of 16.0 % and 11.0 %, respectively. The other parameters (atomic weight of lead for the NIST SRM 928 material, apparent final masses of the prepared solutions, and the air buoyancy correction factors) do not significantly impact the combined uncertainty of the final result and account for 1.5 % of the total uncertainty budget.

Observe that the equivalence mass of EDTA solution for the titration (\(m_{eq,\mathrm {EDTA}}\)), shown in Table 4, only reflects the uncertainty arising from the use of the balance. The uncertainty contribution from the determination of the equivalence point itself is considered in the repeatability component of uncertainty [7, 45], as discussed in Sect. 3.1.1. Also, the uncertainty in the potential measurements of the ion selective electrode is part of the repeatability component of uncertainty.

The combined uncertainty of the measurement result is 0.00034 g g\(^{-1}\). The only uncertainty source evaluated as Type A is the uncertainty from the lack of repeatability of the method, which has a number of degrees of freedom (\(\nu _{R_{rep}}\)) of \(3-1=2\). All other sources of uncertainty were evaluated as Type B and are assigned an infinite number of degrees of freedom [32]. The effective number of degrees of freedom of the combined uncertainty (\(\nu _{eff}\)) is calculated with the Welch–Satterthwaite equation [32] and the result is 106. The corresponding coverage factor (k) for a 95 % level of confidence with 106 degrees of freedom is 1.983. Accordingly, the expanded uncertainty of the measurement result is 0.00068 g g\(^{-1}\).

Notice that the metrological traceability chain of the gravimetric complexometric titration method, proposed in this work, is longer than it would be for a coulometric method which offers direct traceability of the measurement result to the SI. However, the uncertainty of the measurement results of the gravimetric titration is only twice that of coulometric titration. Then, the established method can disseminate the metrological traceability to the amount of substance unit of the SI, from the NIST SRM 928-lead nitrate to the EDTA disodium salt dihydrate, with uncertainties that fit the requirements of most applications. It is noteworthy that both the identified sources and the uncertainty budget obtained are consistent with other literature reports ( [7, 45]).

3.2.1 Effect of the Lead Atomic Weight Estimate in the Combined Uncertainty Budget

The measured atomic weight of lead that applies to the NIST SRM 928 lead nitrate, \(A_r(\hbox {Pb},{SRM928})\), was found in this work as 207.2094 ± 0.0039 g mol\(^{-1}\). This value is similar to the informative value in the certificate of the CRM provided by the NIST (207.209 g mol\(^{-1}\)). The standard relative uncertainty for this parameter is \(0.0019~\%\), whereby has an insignificant impact on the uncertainty budget of the measurement result as shown in Fig. 3.

At this point, it is important to mention that the standard atomic weight of lead, \(A^o_r(\hbox {Pb})\), reported by the International Union of Pure and Applied Chemistry (IUPAC), has recently been changed to an interval due to the large range of lead isotopic composition in normal terrestrial materials: [207.94 - 206.14] g mol\(^{-1}\) [46]. Now, in case \(A_r(\mathrm {Pb},{SRM928})\) could not have been measured by mass spectrometry, as was made in this work, the value of \(A^o_r(\mathrm {Pb})\) could be used in the measurement model shown in Eq. 1. The uncertainty of \(A^o_r(\mathrm {Pb})\), assuming a rectangular distribution, is the half-width of its interval divided by \(\sqrt{3}\) [32], resulting in \(u(A^o_r(\mathrm {Pb})) = {0.52}\,\hbox {g mol}^{-1}\)(relative standard uncertainty of 0.25%). A hypothetical uncertainty budget of the measurement result under these conditions, keeping all other input quantities constant in the measurement model, would have yielded a standard relative combined uncertainty with an 8-fold increase, from 0.034 % to 0.26 % (relative uncertainty values).

Figure 4 shows the relative contribution to the uncertainty budget of the measurement result in the hypothetical scenario described above. Under such circumstances, \(A^o_r(\mathrm {Pb})\) would be the unique significant uncertainty source with a relative contribution of 98 %. As previously noted by other authors, measuring a more precise value for the atomic weight of lead that applies to the material in use is key to decreasing the impact of this parameter on the uncertainty budget of the final result [12, 16].

The relative contribution of the uncertainty components to the hypothetical uncertainty budget of the EDTA mass fraction in the solid reagent if the uncertainty in the standard atomic weight of lead, \(u(A^o_r(\mathrm {Pb}))\) estimated from the recent report of the standard atomic weight of Pb by the IUPAC [207.94 - 206.14] g mol\(^{-1}\) [46], is used in the calculations

4 Conclusion

The gravimetric complexometric titration of EDTA with lead ion using potentiometric detection of the equivalence point (lead ion selective electrode with silver/silver chloride reference electrode) yields measurement results with a combined relative standard uncertainty of 0.034 % for the mass fraction of the EDTA disodium salt dihydrate when high purity solid materials are used. The CRM GSO 2960-84 - EDTA disodium salt dihydrate was found to have a mass fraction (14 data average), \(w_{_\mathrm{{EDTA}}}\), of \(0.9987\pm 0.0007~\hbox {g g}^{-1}\) (expanded uncertainty with a coverage factor \(k = 1.983\)). Major sources of uncertainty were the mass of the EDTA solution for a titration blank (29.5 % of the uncertainty budget), the mass fraction of lead in the NIST SRM 928 - lead nitrate (24.7 % of the uncertainty budget), and the precision of the determination of the equivalence point (17.3 % of the uncertainty budget). The standard relative uncertainty of the measurement result is small, indicating that the complexometric gravimetric titration is good enough to certify EDTA salts as reference materials. Then, the EDTA material characterized by the latter methodology can disseminate metrological traceability from the lead standard CRM salt to other measurands in calibrating mono-elemental solutions.

References

B. Magnusson and U. Ornemark, eds, Eurachem guide: the fitness for purpose of analytical methods - a laboratory guide to method validation and related topics. Eurachem, Denmark, (2014).

S. L. R. Ellison and A. Williams, eds, Eurachem/CITAC guide: metrologicaltraceability in analytical measurement. Eurachem/CITAC, Denmark, (2019).

P. De Bièvre, R. Dybkær, A. Fajgelj, and D. B. Hibbert, Metrological traceability of measurement results in chemistry: concepts and implementation (IUPAC Technical Report). Pure Appl. Chem., 83(10) (2011) 1873–1935.

BIPM, IEC, IFCC, ILAC, IUPAC, IUPAP, ISO, and OIML. The international vocabulary of metrology-basic and general concepts and associated terms (VIM). JCGM, (2012).

ISO 17034, General requirements for the competence of reference material producers. Standard, International Organization for Standardization Geneva, Switzerland, (2016).

Bureau International des Poids et Mesures, BIPM, Consultative committee for amount of substance (CCQM) 4th meeting report. Technical report february. Bureau International des Poids et Mesures, BIPM, (1998).

H. Felber, S. Rezzonico, and M. Máriássy, Titrimetry at a metrological level. Metrologia, 40(5) (2003) 249–254.

H. Kipphardt, R. Matschat, O. Rienitz, D. Schiel, W. Gernand, and D. Oeter, Traceability system for elemental analysis. Accredit. Qual. Assur., 10(11) (2006) 633–639.

J.L. Molloy, M.R. Winchester, T.A. Butler, A.M. Possolo, O. Rienitz, A. Roethke, V. Goerlitz, R. Caciano de Sena, M. Dominguez-Almeida, L. Yang, B. Methven, K. Nadeau, P. Romero Arancibia, W. Bing, Z. Tao, J. Snell, J. Vogl, M. Koenig, R. K. Kotnala, S. Swarupa Tripathy, C. Elishian, R. Ketrin, T. Suzuki, T. Oduor-Okumu, Y.H. Yim, S. Woo Heo, H. Sik-Min, M. Sub-Han, Y. Lim, J.V. Lara Manzano, F. Segoviano-Regalado, M.R. Arvizu-Torres, E. Valle-Moya, M. Buzoianu, A. Sobina, V. Zyskin, E. Sobina, P. Migal, M. Linsky, S. Z. Can, B. Ari, and H. Goenaga-Infante, CCQM-K143 comparison of copper calibration solutions prepared by NMIs/DIs. Metrologia, 58(A1) (2020) 08006.

G. Schwarzenbach and H. Ackermann, Komplexone v die athylendiamin-tetraessigsaure. Helv. Chim. Acta, 30(6) (1947) 1798–1804.

H. Felber, M. Weber, and C. Rivier, Final report on key comparison CCQM-K8 of monoelemental calibration solutions. Metrologia, 39(1A) ( 2002) 08002.

O. Rienitz, D. Schiel, V. Gorlitz, R. Jahrling, J. Vogl, J. V. Lara-Manzano, A. Zon, W.H. Fung, M. Buzoianu, R. Caciano de Sena, L.A. dos Reis, L. Valiente, Y.H. Yim, S. Hill, R. Champion, P. Fisicaro, W. Bing, G.C. Turk, M.R. Winchester, D. Saxby, J. Merrick, A. Hioki, T. Miura, T. Suzuki, M. Linsky, A. Barzev, M. Mariassy, O. Cankur, B. Ari, M. Tunc, L.A. Konopelko, Y.A. Kustikov, and M. Bezruchko, Final report on CCQM-K87: mono-elemental calibration solutions. Metrologia, 49(1A) (2012) 08010.

P. De Bièvre, R. Dybkær, A. Fajgelj, and B. Hibbert, Metrological traceability of measurement results in chemistry: concepts and implementation (IUPAC technical report). Pure Appl. Chem., 83(10) (2011) 1873–1935.

M. J. T. Milton and T. J. Quinn, Primary methods for the measurement of amount of substance. Metrologia, 38(4) (2001) 289–296.

B. King, Review of the potential of titrimetry as a primary method. Metrologia, 34(1) (1997) 77–82.

T. Suzuki, D. Tiwari, and A. Hioki, Precise chelatometric titrations of Zinc, Cadmium, and Lead with molecular spectroscopy. Anal. Sci. 23(10) (2007) 1215–1220.

J. W. Ross and M. S. Frant, Chelometric indicator titrations with the solid-state cupric ion-selective electrode. Anal. Chem., 41(13) (1969) 1900–1902.

M. A. Zayed, M. S. Rizk, H. Khalifa, and W. F. Omer, Use of EDTA for potentiometric back-titration of rare earths and analysis of their mixtures. J. Indian Chem. Soc., 64(1) (1987) 49–51.

M. Niinae, K. Nishigaki, and K. Aoki, Removal of lead from contaminated soils with chelating agents. Mater. Trans., 49(10) (2008) 2377–2382.

H.A. Flaschka, Examples of direct titrations. In H.A. Flaschka, ed, EDTA titrations an introduction to theory and practice, Pergamon, New York, (1964).

W. W. Wendlandt, Thermogravimetric and differential thermal analysis of (ethylenedinitrilo) tetraacetic acid and its derivatives. Anal. Chem., 32(7) (1960) 848–849.

R. Battino and A. G. Williamson, Single-pan balances, buoyancy, and gravity or ”a mass of confusion”. J. Chem. Educ., 61(1) (1984) 51.

A. Picard, R. S. Davis, M. Gläser, and K. Fujii Revised formula for the density of moist air (CIPM-2007). Metrologia, 45(2) (2008) 149–155.

L.V. Morales, I.A. Gonzalez, J.P. Abella, and D.A. Ahumada, Tecnicas de titulacion acido-base: consideraciones metrologicas. Rev. Colomb. de Quim., 48 (2019) 26–34.

J. Meija, T. B. Coplen, M. Berglund, W. A. Brand, P. De Bièvre, M. Gröning, N. E. Holden, J. Irrgeher, R. D. Loss, T. Walczyk, and T. Prohaska, Atomic weights of the elements 2013 (IUPAC Technical Report). Pure Appl. Chem., 88(3) ( 2016) 265–291.

P. K. Yadav, C. Kochar, L. Taneja, and S. S. Tripathy, Measurement and traceability issues in isotope amount ratio determination of stable isotopes. MAPAN, 37(1) (2022) 227–235.

J. Vogl and W. Pritzkow, Isotope dilution mass spectrometry - a primary method of measurement and its role for rm certification. MAPAN, 25(3) (2010) 135–164.

R. Core-Team, R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, (2020).

R. Core-Team, Predict.smooth.spline: predict from smoothing spline fit, (2020). https://www.rdocumentation.org/packages/stats/versions/3.6.2/topics/predict.smooth. spline

L. Komsta, Outliers: tests for outliers. R package version 0.14 (2011).

F. John, and W. Sanford, An R companion to applied regression. Sage, Thousand Oaks CA, (2019).

Joint Committee for Guides in Metrology JCGM, JCGM 100: evaluation of measurement data - guide to the expression of uncertainty in measurement. Technical report, JCGM, (2008).

S.L.R. Ellison, metRology: support for metrological applications. R package version 0.9-28-1, (2018).

A.N. Spiess, Propagate: propagation of uncertainty. R package version 1.0-6, (2018).

O. Rienitz, R. Jahrling, J. Noordmann, C. Pape, K. Rohker, J. Vogl, J.V. Lara-Manzano, W. Kozlowski, R. Caciano de Sena, M. Rodrigues, A.H. Galli, Y.H. Yim, K.S. Lee, J.H. Lee, H.S. Min, C. Jingbo, S. Naijie, W. Qian, T. Ren, W. Jun, N. Tangpaisarnkul, T. Suzuki, N. Nonose, Z. Mester, L. Yang, E. Pagliano, P. Grinberg, M. Mariassy, T. Naykki, O. Cankur, F.G. Coskun, B. Ari, and S.Z. Can, CCQM-K122 ”anionic impurities and lead in salt solutions”. Metrologia, 57(1A) (2020) 08012.

R. V. Lenth, Response-surface methods in R, using rsm. J. Stat. Softw. Artic., 32(7) (2009) 1–17.

G. E. P. Box and D. W. Behnken, Some new three level designs for the study of quantitative variables. Technometrics, 2(4) (1960) 455–475.

A. Czyrski and J. Sznura, The application of Box-Behnken-Design in the optimization of HPLC separation of fluoroquinolones. Sci. Rep., 9(1) (2019) 19458.

D. Xiong, X. Chen, and J. Yang, Optimization of a low-voltage load switch for a smart meter based on a double response surface model. MAPAN, 33(3) (2018) 261–270.

C. Paredes, masscor: Mass measurement corrections. R package version 0.0.7.1, (2021).

G. Harris, Selected laboratory and measurement practices and procedures to support basic mass calibrations. NIST interagency/internal report (NISTIR), (2019).

O. Glatter and H. Greschonig, Approximation of titration curves and other sigmoidal functions by proportionally spaced cubic b-splines. Microchimica Acta, 89(1) (1986) 389–399.

R. Kacker, R. Kessel, K. D. Sommer, and X. Bian, Metrological compatibility and statistical consistency. In Proceedings of the tenth international symposium on measurement and quality control, Osaka. https://tsapps.nist. gov/publication/get_pdf.cfm? pub_id=902441 (2010).

H. Cantwell, Blanks in method validation, a supplement to the eurachem guide ”the fitness for purpose of analytical methods”. Eurachem, Denmark, (2019).

M. Máriássy, K. W. Pratt, and P. Spitzer, Major applications of electrochemical techniques at national metrology institutes. Metrologia, 46(3) (2009) 199–213.

T. Prohaska, J. Irrgeher, J. Benefield, J.K. Bohlke, L.A. Chesson, T.B. Coplen, T. Ding, P.J.H. Dunn, M. Groning, N.E. Holden, H.A.J. Meijer, H. Moossen, A. Possolo, Y. Takahashi, J. Vogl, T. Walczyk, J. Wang, M.E. Wieser, S. Yoneda, X.K. Zhu, and J. Meija, Standard atomic weights of the elements 2021 (IUPAC technical report). Pure Appl. Chem. (2022). 10.1515/pac-2019-0603

Acknowledgements

This work was financially supported by the Ministerio de Ciencia, Tecnología e Innovación de Colombia (MinCiencias), under project number 9932100271370. The authors thank the support of Universidad Nacional de Colombia sede Bogotá and Instituto Nacional de Metrología de Colombia. Cristhian Paredes acknowledges the BIPM-TÜBÏTAK UME Project Placements Program and, particularly Dr. Betül Ari, for the knowledge transfer on the determination of lead atomic weight using mass spectrometry.

Funding

Open Access funding provided by Colombia Consortium.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Paredes, C., Ahumada, D. & Ágreda, J. Gravimetric Complexometric Titration Method to Determine Mass Fraction of Ethylenediaminetetraacetic Acid Disodium Salt Dihydrate in Candidate-Certified Reference Materials. MAPAN 38, 179–191 (2023). https://doi.org/10.1007/s12647-022-00602-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12647-022-00602-0