Abstract

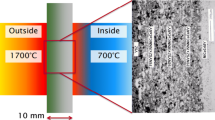

In this study, the Al-Mg2Si FG-composites were developed by in-situ centrifugal casting route with varied Mg contents (2.5, 5.0, 7.5, and 10.0 wt.% Mg). Cast FG-composites subjected to T6 heat treatment processes to achieve the high specific wear resistance and mechanical properties. High temperature linear reciprocating wear and friction properties of in-situ centrifugally cast A356-Mg2Si FG-composites has been studied. The wear resistance properties of Al-Mg2Si FG-composites were characterized by difference of initial and final weight measurement after sliding wear test. As a result, the mass loss decreases steadily as the %Mg increases from 2.5% to 7.5% and slightly increases with 10% Mg. The FG-composites containing 7.5%Mg exhibits the remarkable combination of wear resistance characteristics and coefficient of friction. Microstructural features and phases distributions were analyzed with the help of Optical and SEM microscopy. The surface topography of wear test samples were carried out using the Scanning Electron Microscopy (SEM) followed by Energy-dispersive X-ray spectroscopy (EDX) analysis.

Graphical Abstract

Similar content being viewed by others

Data Availability

Not applicable. However, all relevant data are included in the article and/or its supplementary information files.

References

Javidani M, Larouche D (2014) Application of cast Al–Si alloys in internal combustion engine components. Int Mater Rev 59:132–158. https://doi.org/10.1179/1743280413Y.0000000027

Ram SC, Chattopadhyay K, Chakrabarty I (2019) Microstructures and high temperature mechanical properties of A356-Mg2Si functionally graded composites in as-cast and artificially aged (T6) conditions. J Alloys Compd 805:454–470. https://doi.org/10.1016/j.jallcom.2019.07.075

Dev S, Aherwar A, Patnaik A (2020) Material selection for automotive piston component using entropy-VIKOR method. Silicon 12:155–169. https://doi.org/10.1007/s12633-019-00110-y

Kumar A, Pal K, Mula S (2017) Simultaneous improvement of mechanical strength, ductility and corrosion resistance of stir cast Al7075-2% SiC micro-and nanocomposites by friction stir processing. J Manuf Process 30:1–3. https://doi.org/10.1016/j.jmapro.2017.09.005

Vencl A, Bobić I, Jovanović MT, Babić M, Mitrović S (2008) Microstructural and tribological properties of A356 Al–Si alloy reinforced with Al2O3 particles. Tribol Lett 32:159–170. https://doi.org/10.1007/s11249-008-9374-6

Contatori C, Domingues Jr NI, Barreto RL et al (2020) Effect of Mg and Cu on microstructure, hardness and wear on functionally graded Al–19Si alloy prepared by centrifugal casting. J Mater Res Technol 9:15862–15873. https://doi.org/10.1016/j.jmrt.2020.11.050

Edrisy A, Perry T, Alpas AT (2005) Investigation of scuffing damage in aluminum engines with thermal spray coatings. Wear 259(7-12):1056–1062. https://doi.org/10.1016/j.wear.2005.02.048

Ebhota WS, Jen TC (2018) Casting and applications of functionally graded metal matrix composites. Advanced Casting Technologies 59. https://doi.org/10.5772/intechopen.71225

Yan F (2014) Development of high strength Al- -mg based alloy for high pressure diecasting process (Doctoral dissertation, Brunel University London)

Li C, Wu Y, Li H, Liu X (2009) Microstructural formation in hypereutectic Al–Mg2Si with extra Si. J Alloys Compd 477:212–216. https://doi.org/10.1016/j.jallcom.2008.10.061

Kumar PSSR, Mashinini PM (2021) Dry sliding Wear behavior of AA7075 - Al2SiO5 layered nanoparticle material at different temperature condition. Silicon 13:4259–4274. https://doi.org/10.1007/s12633-020-00728-3

Samal P, Vundavilli PR, Meher A, Mahapatra MM (2020) Recent progress in aluminum metal matrix composites: a review on processing, mechanical and wear properties. J Manuf Process 59:131–152. https://doi.org/10.1016/j.jmapro.2020.09.010

Zhang J, Fan Z, Wang Y, Zhou B (2000) Hypereutectic aluminium alloy tubes with graded distribution of Mg2Si particles prepared by centrifugal casting. Mater Des 21:149–153. https://doi.org/10.1016/S0261-3069(99)00100-4

Zhai YB, Liu CM, Kai WA, Zou MH, Yong XI (2010) Characteristics of two Al based functionally gradient composites reinforced by primary Si particles and Si/in situ Mg2Si particles in centrifugal casting. Trans Nonferrous Met Soc China 20:361–370. https://doi.org/10.1016/S1003-6326(09)60147-3

Lin X, Liu C, Zhai Y, Wang K (2011) Influences of Si and Mg contents on microstructures of Al–xSi–yMg functionally gradient composites reinforced with in situ primary Si and Mg2Si particles by centrifugal casting. J Mater Sci 46:1058–1075. https://doi.org/10.1007/s10853-010-4874-9

Lin X, Liu C, Xiao H (2013) Fabrication of Al–Si–Mg functionally graded materials tube reinforced with in situ Si/Mg2Si particles by centrifugal casting. Compos B: Eng 45:8–21. https://doi.org/10.1016/j.compositesb.2012.09.001

Rahvard MM, Tamizifar M, Boutorabi SM, Shiri SG (2014) Characterization of the graded distribution of primary particles and wear behavior in the A390 alloy ring with various Mg contents fabricated by centrifugal casting. Mater Des 56:105–114. https://doi.org/10.1016/j.matdes.2013.10.070

Ram SC, Chattopadhyay K, Chakrabarty I (2017) High temperature tensile properties of centrifugally cast in-situ Al-Mg2Si functionally graded composites for automotive cylinder block liners. J Alloys Compd 724:84–97. https://doi.org/10.1016/j.jallcom.2017.06.306

Qin QD, Zhao YG, Zhou W (2008) Dry sliding wear behavior of Mg2Si/Al composites against automobile friction material. Wear 264:654–661. https://doi.org/10.1016/j.wear.2007.05.008

Wu XF, Zhang GA, Wu FF (2013) Influence of Bi addition on microstructure and dry sliding wear behaviors of cast Al-Mg2Si metal matrix composite. Trans Nonferrous Met Soc China 23:1532–1542. https://doi.org/10.1016/S1003-6326(13)62627-8

An J, Sun W, Niu XD (2017) Dry sliding wear behavior and a proposed criterion for mild to severe wear transition of Mg–3Al–0.4Si–0.1Zn alloy. Tribol Lett 65:1–15. https://doi.org/10.1007/s11249-017-0882-0

Soltani N, Nodooshan HJ, Bahrami A, Pech-Canul MI, Liu W, Wu G (2014) Effect of hot extrusion on wear properties of Al–15 wt.% Mg2Si in situ metal matrix composites. Mater Des 53:774–781. https://doi.org/10.1016/j.matdes.2013.07.084

Han Y, Samuel AM, Doty HW et al (2014) Optimizing the tensile properties of Al–Si–Cu–Mg 319-type alloys: role of solution heat treatment. Mater Des 58:426–438. https://doi.org/10.1016/j.matdes.2014.01.060

Ibrahim MF, Samuel E, Samuel AM et al (2011) Metallurgical parameters controlling the microstructure and hardness of Al–Si–Cu–Mg base alloys. Mater Des 32:2130–2142. https://doi.org/10.1016/j.matdes.2010.11.040

Gauthier J, Louchez PR, Samuel FH (1995) Heat treatment of 319.2 aluminum automotive alloy: part 1, solution heat-treatment. Cast Met 8:91–106. https://doi.org/10.1080/09534962.1995.11819197

Gauthier J, Louchez PR, Samuel FH (1995) Heat treatment of 319.2 aluminum automotive alloy: part 2, aging behavior. Cast Met 8:107–114. https://doi.org/10.1080/09534962.1995.11819198

Azevedo HM, Botelho TM, Barbosa CR et al (2020) Study of dry wear behavior and resistance in samples of a horizontally solidified and T6/heat-treated automotive AlSiMg alloy. Tribol Lett 68:60. https://doi.org/10.1007/s11249-020-01302-z

Ram SC, Chattopadhyay K, Chakrabarty I (2016) Dry sliding wear behavior of A356 alloy/Mg 2 sip functionally graded in-situ composites: effect of processing conditions. Tribol Ind 38(3):371–384

Anand VK, Aherwar A, Mia M et al (2020) Influence of silicon carbide and porcelain on tribological performance of Al6061 based hybrid composites. Tribol Int 151:106514. https://doi.org/10.1016/j.triboint.2020.106514

Rajeev VR, Dwivedi DK, Jain SC (2010) Effect of load and reciprocating velocity on the transition from mild to severe wear behavior of Al–Si–SiCp composites in reciprocating conditions. Mater Des 31:4951–4959. https://doi.org/10.1016/j.matdes.2010.05.010

Polat S, Sun Y, Çevik E et al (2019) Investigation of wear and corrosion behavior of graphene nanoplatelet-coated B4C reinforced Al–Si matrix semi-ceramic hybrid composites. J Compos Mater 53:3549–3565. https://doi.org/10.1177/0021998319842297

Jiang W, Xu X, Zhao Y et al (2018) Effect of the addition of Sr modifier in different conditions on microstructure and mechanical properties of T6 treated Al-Mg2Si in-situ composite. Mater Sci Eng A 721:263–273. https://doi.org/10.1016/j.msea.2018.02.100

Emamy M, Emami AR, Tavighi K (2013) The effect of Cu addition and solution heat treatment on the microstructure, hardness and tensile properties of Al–15% Mg2Si–0.15% Li composite. Mater Sci Eng A 576:36–44. https://doi.org/10.1016/j.msea.2013.03.066

Zainon F, Ahmad KR, Daud R (2016) Review on the tribology and hardness of aluminum AA332: matrix composites reinforced with Mg2Si. Adv Mater Res 5:55–66

Wang F, Ma Y, Zhang Z et al (2004) A comparison of the sliding wear behavior of a hypereutectic Al–Si alloy prepared by spray-deposition and conventional casting methods. Wear 256:342–345. https://doi.org/10.1016/S0043-1648(03)00412-5

Hekmat-Ardakan A, Liu X, Ajersch F et al (2010) Wear behavior of hypereutectic Al–Si–Cu–Mg casting alloys with variable Mg contents. Wear 269:684–692. https://doi.org/10.1016/j.wear.2010.07.007

Singh J, Chauhan A (2016) Overview of wear performance of aluminium matrix composites reinforced with ceramic materials under the influence of controllable variables. Cer Int 42:56–81. https://doi.org/10.1016/j.ceramint.2015.08.150

Yagi K, Ebisu Y, Sugimura J et al (2011) In situ observation of wear process before and during scuffing in sliding contact. Tribol Lett 43:361–368. https://doi.org/10.1007/s11249-011-9817-3

Rajaram G, Kumaran S, Rao TS (2010) High temperature tensile and wear behaviour of aluminum silicon alloy. Mater Sci Eng A 528:247–253. https://doi.org/10.1016/j.msea.2010.09.020

Pauschitz A, Roy M, Franek F (2008) Mechanisms of sliding wear of metals and alloys at elevated temperatures. Tribol Int 41:584–602. https://doi.org/10.1016/j.triboint.2007.10.003

Viat A, Guillonneau G, Fouvry S et al (2017) Brittle to ductile transition of tribomaterial in relation to wear response at high temperatures. Wear 392:60–68. https://doi.org/10.1016/j.wear.2017.09.015

Jeng YR, Chen JT, Cheng CY (2003) Theoretical and experimental study of a thermal contact conductance model for elastic, elastoplastic and plastic deformation of rough surfaces. Tribol Lett 14:251–259. https://doi.org/10.1023/A:1022632801251

Barati M, Abbasi M, Abedini M (2019) The effects of friction stir processing and friction stir vibration processing on mechanical, wear and corrosion characteristics of Al6061/SiO2 surface composite. J Manuf Process 45:491–497. https://doi.org/10.1016/j.jmapro.2019.07.034

Moustafa SF, Soliman FA (1997) Wear resistance of δ-type alumina fibre reinforced Al-4% Cu matrix composite. Tribol Lett 3:311–315. https://doi.org/10.1023/A:1019166129670

Acknowledgements

The authors are extremely thankful to Indian Institute of Technology (BHU), Varanasi India for providing the well equipped laboratories and central Instruments facility (CIF) to conduct the experimental work presented in this manuscript.

Author information

Authors and Affiliations

Contributions

“All authors contributed their full effort during preparation of present manuscript and study the work. Material preparation, data collection and analysis were performed by (Dr.S.C.Ram), (Dr.K.Chattopadhyay) and (Dr.Awani Bhushan). The first draft of the manuscript was written by Dr.S.C.Ram (Corresponding author) and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.”

Corresponding author

Ethics declarations

Competing Interests

The authors have no relevant financial or non-financial interests to disclose.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ram, S.C., Chattopadhyay, K. & Bhushan, A. High Temperature Dry Sliding Reciprocating Wear Behavior of Centrifugally Cast A356-Mg2Si In-Situ Functionally Graded Composites. Silicon 15, 1063–1083 (2023). https://doi.org/10.1007/s12633-022-02060-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02060-4