Abstract

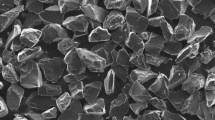

Aluminium metal matrix composites are widely used in the automobile industry due to their superior properties like high strength to weight ratio, high ductility and better corrosion resistance. In this study, the effect of naturally available and low-cost kaoline particles on the microstructural and mechanical behaviour of Al- SiC- Kaoline Hybrid metal matrix composite was investigated. Al-10 % SiC- X% Kaoline (X = 0, 2, 4, 6, 8) composite samples were fabricated through powder metallurgy technique by applying a compaction pressure of 350 MPa. The fabricated composite samples were subjected to Density, Hardness, Tensile and impact tests to study the mechanical behaviour of fabricated hybrid composite. The presence of SiC and Kaoline reinforcements was confirmed by using SEM and X-Ray Diffraction analysis. It was observed that the maximum ultimate tensile strength ( U.T.S ) and maximum Yield Strength ( Y.S) of the hybrid composite were found to be 263 MPa and 202 MPa for Al-10 %SiC-4 %kaoline reinforcement. The formation of the intermetallic compound such as Al2Cu was observed in XRD and SEM analysis for Al-10 % SiC-6 % kaoline and Al-10 % SiC-8 % of kaoline reinforcement which leads to decrease in the U.T.S and Y.S of fabricated specimens. The impact strength of Al-10 %SiC-8 % kaoline found to be decreased by 44.4 % compared to unreinforced Aluminium due to the presence of harder SiC and Kaoline reinforcements particles. To study the fracture mechanism, Scanning Electron Microscopy study was carried on the fractured tensile specimens which reveal that ductile fracture in unreinforced Al, Al-10 % SiC, Al-10 % SiC-2 % Kaoline due to the formation of dimples and brittle fracture was observed in Al-10 % SiC-4 % Kaoline, Al-10 % SiC-6 % Kaoline and Al-10 % SiC-8 % Kaoline due to the existence of cleavages and microcracks. The best suitable combination of mechanical properties was obtained at Al-10 % SiC-4 % Kaoline hybrid composite.

Similar content being viewed by others

Data Availability

Authors confirm that the entire data obtained during the experiment was included in this available manuscript.

References

Liu S, Wang Y, Muthuramalingam T, Anbuchezhiyan G (2019) Effect of B4C and MOS2 reinforcement on micro structure and wear properties of aluminum hybrid composite for automotive applications. Compos Part B Eng 176

Manikandan R, Arjunan TV, Akhil AR (2020) Studies on micro structural characteristics, mechanical and tribological behaviours of boron carbide and cow dung ash reinforced aluminium (Al 7075) hybrid metal matrix composite. Compos Part B Eng 183:107668. https://doi.org/10.1016/j.compositesb.2019.107668

Bhowmik A, Dey D, Biswas A (2019) Tribological behaviour of aluminium-titanium diboride (Al7075-TiB2) metal matrix composites prepared by stir casting process. In: Materials Today: Proceedings. Elsevier Ltd, Amsterdam, pp 2000–2004

Bains PS, Singh S, Sidhu SS et al (2018) Investigation of surface properties of Al–SiC Composites in hybrid electrical discharge machining. Springer, Singapore, pp 181–196

Irfan Ul Haq M, Raina A, Anand A et al (2020) Elucidating the effect of MoS2 on the mechanical and tribological behavior of AA7075/Si3N4 composite. J Mater Eng Perform 29:7445–7455. https://doi.org/10.1007/s11665-020-05197-8

Ghosh S, Sahoo P, Sutradhar G (2012) Wear behaviour of Al-SiCp metal matrix composites and optimization using taguchi method and grey relational analysis. J Miner Mater Charact Eng 11:1085–1094. https://doi.org/10.4236/jmmce.2012.1111115

Manoj M, Jinu GR, Muthuramalingam T (2018) Multi response optimization of AWJM process parameters on machining TiB2 particles reinforced Al7075 composite using Taguchi-DEAR methodology. Silicon 10:2287–2293. https://doi.org/10.1007/s12633-018-9763-x

Kumar PN, Rajadurai A, Muthuramalingam T (2018) Multi-response optimization on mechanical properties of silica fly ash filled polyester composites using Taguchi-grey relational analysis. Silicon 10:1723–1729. https://doi.org/10.1007/s12633-017-9660-8

Dey D, Bhowmik A, Biswas A (2020) Effect of SiC content on mechanical and tribological properties of Al2024-SiC composites. Silicon. https://doi.org/10.1007/s12633-020-00757-y

Bhowmik A, Chakraborty D, Dey D, Biswas A (2019) Investigation on wear behaviour of Al7075-SiC metal matrix composites prepared by stir casting. In: Materials Today: Proceedings. Elsevier Ltd, Amsterdam, pp 2992–2995

Ravi Kumar K, Kiran K, Sreebalaji VS (2017) Microstructural characteristics and mechanical behaviour of aluminium matrix composites reinforced with titanium carbide. J Alloys Compd 723:795–801. https://doi.org/10.1016/j.jallcom.2017.06.309

Ravikumar K, Kiran K, Sreebalaji VS (2017) Characterization of mechanical properties of aluminium/tungsten carbide composites. Measurement 102:142–149. https://doi.org/10.1016/j.measurement.2017.01.045

Bhui AS, Bains PS, Sidhu SS, Singh G (2019) Parametric optimization of ED machining of Ti-6Al-4V in CNTs mixed dielectric medium. In: Materials Today: Proceedings. Elsevier Ltd, Amsterdam, pp 1532–1539

Venkatesh VSS, Deoghare AB (2020) Fabrication and mechanical behaviour of Al-Kaoline metal matrix composite fabricated through powder metallurgy technique. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.10.021

Surya MS, Prasanthi G, Gugulothu SK (2021) Investigation of mechanical and wear behaviour of Al7075/SiC composites using response surface methodology. Silicon. https://doi.org/10.1007/s12633-020-00854-y

Sattari S, Jahani M, Atrian A. Effect of volume fraction of reinforcement and milling time on physical and mechanical properties of Al7075-SiC composites fabricated by powder metallurgy method. Powder Metall Met Ceram 56. https://doi.org/10.1007/s11106-017-9896-2

Nassar AE, Nassar EE (2017) Properties of aluminum matrix Nano composites prepared by powder metallurgy processing. J King Saud Univ - Eng Sci 29:295–299. https://doi.org/10.1016/j.jksues.2015.11.001

Uyyuru RK, Surappa MK, Brusethaug S (2007) Tribological behavior of Al-Si-SiCp composites/automobile brake pad system under dry sliding conditions. Tribol Int 40:365–373. https://doi.org/10.1016/j.triboint.2005.10.012

Rao VR, Ramanaiah N, Sarcar MMM (2016) Tribological properties of aluminium metal matrix composites (AA7075 Reinforced with Titanium Carbide (TiC) particles). Int J Adv Sci Technol 88:13–26. https://doi.org/10.14257/ijast.2016.88.02

Baradeswaran A, Elayaperumal A, Franklin Issac R (2013) A statistical analysis of optimization of wear behaviour of Al- Al 2O3 composites using taguchi technique. Procedia Eng 64:973–982

Radhika N, Raghu R (2017) Investigation on mechanical properties and analysis of dry sliding wear behavior of Al LM13/AlN metal matrix composite based on Taguchi’s technique. J Tribol 139. https://doi.org/10.1115/1.4035155

Singh Bains P, Bahraminasab M, Sidhu SS, Singh G. On the machinability and properties of Ti-6Al-4V biomaterial with n-HAp powder-mixed ED machining. J Eng Med 2020:232–242. https://doi.org/10.1177/0954411919891887

Bhandakkar A, Prasad RC, Sastry SML (2014) Fracture toughness of AA2024 aluminum fly ash metal matrix composites. Int J 4:108–124. https://doi.org/10.5923/j.cmaterials.20140402.10

Sulaiman S, Marjom Z, Ismail MIS et al (2017) Effect of modifier on mechanical properties of Aluminium Silicon Carbide (Al-SiC) composites. Procedia Eng 184:773–777. https://doi.org/10.1016/j.proeng.2017.04.156

Sarkar S, Bhirangi A, Mathew J et al (2018) Fabrication characteristics and mechanical behavior of Rice Husk Ash-Silicon Carbide reinforced Al-6061 alloy matrix hybrid composite. Mater Today Proc 5:12706–12718. https://doi.org/10.1016/j.matpr.2018.02.254

Alaneme KK, Adewale TM, Olubambi PA (2014) Corrosion and wear behaviour of Al-Mg-Si alloy matrix hybrid composites reinforced with rice husk ash and silicon carbide. J Mater Res Technol 3:9–16. https://doi.org/10.1016/j.jmrt.2013.10.008

Manohar G, Pandey KM, Maity SR (2020) Effect of china clay on mechanical properties of AA7075/B4C hybrid composite fabricated by powder metallurgy techniques. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.10.740

Zhu J, Jiang W, Li G et al (2020) Microstructure and mechanical properties of SiCnp/Al6082 aluminum matrix composites prepared by squeeze casting combined with stir casting. J Mater Process Technol 283. https://doi.org/10.1016/j.jmatprotec.2020.116699

Balasivanandha Prabu S, Karunamoorthy L (2008) Microstructure-based finite element analysis of failure prediction in particle-reinforced metal-matrix composite. J Mater Process Technol 207:53–62. https://doi.org/10.1016/j.jmatprotec.2007.12.077

Mu DKQ, Zhang Z, Xie YH et al (2021) The microstructures and mechanical properties of a 5vol%SiC/AA2024 nanocomposite fabricated by powder metallurgy. Mater Charact 175:111090. https://doi.org/10.1016/j.matchar.2021.111090

Singh N, Mir IUH, Raina A et al (2018) Synthesis and tribological investigation of Al-SiC based nano hybrid composite. Alexandria Eng J 57:1323–1330. https://doi.org/10.1016/j.aej.2017.05.008

Ul Haq MI, Anand A (2018) Dry sliding friction and wear behavior of AA7075-Si3N4 composite. Silicon 10:1819–1829. https://doi.org/10.1007/s12633-017-9675-1

Rajmohan T, Palanikumar K, Ranganathan S (2013) Evaluation of mechanical and wear properties of hybrid aluminium matrix composites. Trans Nonferrous Met Soc China (Eng Ed) 23:2509–2517. https://doi.org/10.1016/S1003-6326(13)62762-4

Fatile OB, AkinruliI J, fedayo, Amori AA (2014) Microstructure and mechanical behaviour of Stir-Cast Al-Mg-Sl alloy matrix hybrid composite reinforced with corn cob ash and silicon carbide. Int J Eng Technol Innov 4:251–259

Manohar G, Pandey KM, Maity SR (2021) Effect of sintering mechanisms on mechanical properties of AA7075/B4C composite fabricated by powder metallurgy techniques. Ceram Int. https://doi.org/10.1016/j.ceramint.2021.02.073

Toptan F, Kilicarslan A, Karaaslan A et al (2010) Processing and microstructural characterisation of AA 1070 and AA 6063 matrix B4Cp reinforced composites. Mater Des 31:S87–S91. https://doi.org/10.1016/j.matdes.2009.11.064

Ramadoss N, Pazhanivel K, Anbuchezhiyan G (2020) Synthesis of B4C and BN reinforced Al7075 hybrid composites using stir casting method. J Mater Res Technol 9:6297–6304. https://doi.org/10.1016/j.jmrt.2020.03.043

Gatea S, Ou H, McCartney G (2018) Deformation and fracture characteristics of Al6092/SiC/17.5p metal matrix composite sheets due to heat treatments. Mater Charact 142:365–376. https://doi.org/10.1016/j.matchar.2018.05.050

Liu R, Wu C, Zhang J et al (2018) Microstructure and mechanical behaviors of the ultrafine grained AA7075/B4C composites synthesized via one-step consolidation. J Alloys Compd 748:737–744. https://doi.org/10.1016/j.jallcom.2018.03.152

Viala JC, Bouix J, Gonzalez G, Esnouf C (1997) Chemical reactivity of aluminium with boron carbide. J Mater Sci 32:4559–4573. https://doi.org/10.1023/A:1018625402103

Zhang L, Shi G, Xu K et al (2020) Phase transformation and mechanical properties of B4C/Al composites. J Mater Res Technol 9:2116–2126. https://doi.org/10.1016/j.jmrt.2019.12.042

Erdemir F, Canakci A, Varol T (2015) Microstructural characterization and mechanical properties of functionally graded Al2024/SiC composites prepared by powder metallurgy techniques. Trans Nonferrous Met Soc China (Eng Ed) 25:3569–3577. https://doi.org/10.1016/S1003-6326(15)63996-6

Rouhi M, Moazami-Goudarzi M, Ardestani M (2019) Comparison of effect of SiC and MoS2 on wear behavior of Al matrix composites. Trans Nonferrous Met Soc China (Eng Ed) 29:1169–1183

Bhowmik A, Dey D, Biswas A (2020) Comparative study of microstructure, physical and mechanical characterization of SiC/TiB2 reinforced aluminium matrix composite. Silicon. https://doi.org/10.1007/s12633-020-00591-2

Kumar CAV, Rajadurai JS (2016) Influence of rutile (TiO2) content on wear and microhardness characteristics of aluminium-based hybrid composites synthesized by powder metallurgy. Trans Nonferrous Met Soc China (Eng Ed) 26:63–73. https://doi.org/10.1016/S1003-6326(16)64089-X

Zhang X, Zhang Z, Liu Y et al (2019) High-performance B 4 C–TiB 2 –SiC composites with tuneable properties fabricated by reactive hot pressing. J Eur Ceram Soc 39:2995–3002. https://doi.org/10.1016/j.jeurceramsoc.2019.04.001

Selvam JDR, Smart DSR, Dinaharan I (2013) Microstructure and some mechanical properties of fly ash particulate reinforced AA6061 aluminum alloy composites prepared by compocasting. Mater Des 49:28–34. https://doi.org/10.1016/j.matdes.2013.01.053

Michael Rajan HB, Ramabalan S, Dinaharan I, Vijay SJ (2013) Synthesis and characterization of in situ formed titanium diboride particulate reinforced AA7075 aluminum alloy cast composites. Mater Des 44:438–445. https://doi.org/10.1016/j.matdes.2012.08.008

Sudarshan SMK (2008) Synthesis of fly ash particle reinforced A356 Al composites and their characterization. Mater Sci Eng A 480:117–124. https://doi.org/10.1016/j.msea.2007.06.068

Arunkumar S, Kumar AS (2021) Studies on egg shell and SiC reinforced hybrid metal matrix composite for tribological applications. Silicon. https://doi.org/10.1007/s12633-021-00965-0

Dey D, Biswas A (2020) Comparative study of physical, mechanical and tribological properties of Al2024 alloy and SiC-TiB2 composites. Silicon. https://doi.org/10.1007/s12633-020-00560-9

Bhowmik A, Dey D, Biswas A (2021) Characteristics study of physical, mechanical and tribological behaviour of SiC/TiB2 dispersed aluminium matrix composite. Silicon 1–14. https://doi.org/10.1007/s12633-020-00923-2

Sharma P, Sharma S, Khanduja D (2016) Effect of graphite reinforcement on physical and mechanical properties of aluminum metal matrix composites. Part Sci Technol 34:17–22. https://doi.org/10.1080/02726351.2015.1031924

Das D, Chakraborty V, Kumar Nanda B, Chandra Routara B (2018) Turning performance of Al 7075/SiCp MMC and multi-response optimization using WPCA and Taguchi approach. Mater Today Proc 5:6030–6037. https://doi.org/10.1016/j.matpr.2017.12.207

Fadavi Boostani A, Tahamtan S, Jiang ZY et al (2015) Enhanced tensile properties of aluminium matrix composites reinforced with graphene encapsulated SiC nanoparticles. Compos Part A Appl Sci Manuf 68:155–163. https://doi.org/10.1016/j.compositesa.2014.10.010

Sachinkumar NS, Chakradhar D (2019) Microstructure, hardness and tensile properties of friction stir welded aluminum matrix composite reinforced with SiC and fly ash. Silicon 11:2557–2565. https://doi.org/10.1007/s12633-018-0044-5

Pazhouhanfar Y, Eghbali B (2018) Microstructural characterization and mechanical properties of TiB2 reinforced Al6061 matrix composites produced using stir casting process. Mater Sci Eng A 710:172–180. https://doi.org/10.1016/j.msea.2017.10.087

Balasubramanian I, Maheswaran R (2015) Effect of inclusion of SiC particulates on the mechanical resistance behaviour of stir-cast AA6063/SiC composites. Mater Des 65:511–520. https://doi.org/10.1016/j.matdes.2014.09.067

Ozden S, Ekici R, Nair F (2007) Investigation of impact behaviour of aluminium based SiC particle reinforced metal-matrix composites. Compos Part A Appl Sci Manuf 38:484–494. https://doi.org/10.1016/j.compositesa.2006.02.026

Acknowledgements

Authors like to thank Central Instrumentation Facility at National Institute of Technology Silchar for XRD analysis. The authors also would like to appreciate the Advance centre for Material Science at Indian Institute of Technology Kanpur for SEM and EDS analysis.

Author information

Authors and Affiliations

Contributions

V.S.S Venkatesh carried out the fabrication, Mechanical characterization of composite samples and Drafted the initial version of the manuscript. Ashish B Deoghare Reviewed and Edited the prepared manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

The Authors declare that they don’t have known personal relationships or competing financial interest that could have appeared to influence the work reported in this manuscript.

Conflict of Interest

Authors declared that they have no conflict of interest.

Consent to Participate

All the Authors are happily agree to contribute in this research work.

Consent of Publication

Consent was obtained from all authors to publish this manuscript. All the authors read and approved this manuscript to publish this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Venkatesh, V.S.S., Deoghare, A.B. Microstructural Characterization and Mechanical Behaviour of SiC and Kaoline Reinforced Aluminium Metal Matrix Composites Fabricated Through Powder Metallurgy Technique. Silicon 14, 3723–3737 (2022). https://doi.org/10.1007/s12633-021-01154-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01154-9