Abstract

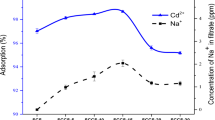

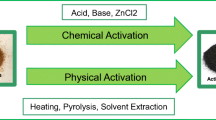

Hydrophobic flocculation pretreatment was performed to assess its effect on the recovery of fine cuprite in sulfidation−flotation. The results of the micro-flotation experiment showed that cuprite recovery is related to the particle size, and that an excessive content of fine particles (<18 μm) impacted the recovery of coarse particles. When hydrophobic flocculation pretreatment was used, the recovery of fine cuprite in sulfidation−flotation increased from 60.3% to 86.3% under optimum conditions (pH 9.5; sodium oleate concentration, 2 × 10−4 mol·L−1; stirring time, 6 min; stirring speed, 1600 r·min−1). The laser particle size analysis and optical microscopy results indicate that hydrophobic flocculation pretreatment effectively reduces the content of fine cuprite, and augments the apparent particle size in the pulp. We performed the Derjaguin–Landau–Verwey–Overbeek (DLVO) theory and extended DLVO theory calculations to further support the interpretation of the results.

Similar content being viewed by others

References

B. Lanz, T. F. Rutherford, and J. E. Tilton, Subglobal climate agreements and energy-intensive activities: An evaluation of carbon leakage in the copper industry, World Economy, (36(2013), No. (3), p. 254.

M. C. Roberts, Metal use and the world economy, Resources Policy, (22(1996), No. (3), p. 183.

J. W. Han, J. Xiao, W. Q. Qing, D. X. Chen, and W. Liu, Copper recovery from Yulong complex copper oxide ore by flotation and magnetic separation, JOM, (69(2017), No. (9), p. 1563.

D. D Wu, W. H. Ma, Y. B. Mao, J. S. Deng, and S. M. Wen, Enhanced sulfidation xanthate flotation of malachite using ammonium ions as activator, Sci. Rep., (7(2017), art. No. 2086.

Q. C. Feng, W. J. Zhao, S. M. Wen, and Q. B. Cao, Copper sulfide species formed on malachite surfaces in relation to flotation, J. Ind. Eng. Chem., (48(2017), p. 125.

Q. C. Feng, S. M. Wen, W. J. Zhao, J. S. Deng, and Y. J. Xian, Adsorption of sulfide ions on cerussite surfaces and implications for flotation, Appl. Surf. Sci., (360(2016), Part A, p. 365.

Q. C. Feng, S. M. Wen, W. J. Zhao, W. J. Zhao, J. Liu, and D. Liu, Effect of pH on surface characteristics and flotation of sulfidized cerussite, Physicochem. Prob. Miner. Process., (52(2016), No. (2), p. 676.

Q. C. Feng, W. J. Zhao, and S. M. Wen, Ammonia modification for enhancing adsorption of sulfide species onto malachite surfaces and implications for flotation, J. Alloys Compd., (744(2018), p. 301.

Q. C. Feng, W. J. Zhao, and S. M. Wen, Surface modification of malachite with ethanediamine and its effect on sulfidization flotation, Appl. Surf. Sci., (436(2018), p. 823.

Q. C. Feng, S. M. Wen, W. J. Zhao, Q. B. Cao, and C. Lü, A novel method for improving cerussite sulfidization, Int. J. Miner. Metall. Mater., 23(2016), No. (6), p. 609.

Q. C. Feng, S. M. Wen, J. S. Deng, and W. J. Zhao, Combined DFT and XPS investigation of enhanced adsorption of sulfide species onto cerussite by surface modification with chloride, Appl. Surf. Sci., (425(2017), p. 8.

Q. C. Feng, S. M. Wen, W. J. Zhao, Y. J. Wang, and C. F. Cui, Contribution of chloride ions to the sulfidization flotation of cerussite, Miner. Eng., (83(2015), p. 128.

L. J. Warren, Shear-flocculation of ultrafine scheelite in sodium oleate solutions, J. Colloid Interface Sci., (50(1975), No. (2), p. 307.

Q. Wang and K. Heiskanen, Selective hydrophobic flocculation in apatite-hematite system by sodium oleate, Miner. Eng., (5(1992), No. 3–5, p. 493.

W. Z. Yin, X. S. Yang, D. P. Zhou, Y. J. Li, and Z. F. Lu, Shear hydrophobic flocculation and flotation of ultrafine Anshan hematite using sodium oleate, Trans. Nonferrous Met. Soc. China, (21(2011), No. (3), p. 652.

W. Chen, Q. M. Feng, G. F. Zhang, L. F. Li, and S. Z. Jin, Effect of energy input on flocculation process and flotation performance of fine scheelite using sodium oleate, Miner. Eng., (112(2017), p. 27.

S. X. Song, A. Lopez-Valdivieso, and Y. Q. Ding, Effects of nonpolar oil on hydrophobic flocculation of hematite and rhodochrosite fines, Powder Technol., (101(1999), No. (1), p. 73.

S. C. Lu, Y. Q. Ding, and J. Y. Guo, Kinetics of fine particle aggregation in turbulence, Adv. Colloid Interface Sci., (78(1998), No. (3), p. 197.

A. Ozkan, H. Ucbeyiay, and S. Aydogan, Shear flocculation of celestite with anionic surfactans and effects of some inorganic dispersants, Colloids Surf. A, (281(2006), No. 1–3, p. 92.

W. Z. Yin, Y. F. Fu, J. Yao, B. Yang, S. H Cao, and Q. Y. Sun, Study on the dispersion mechanism of citric acid on chlorite in hematite reverse flotation system, Minerals, (7(2017), No. (11), p. 221.

W. Z. Yin, J. W. Xue, D. Li, Q. Y. Sun, J. Yao, and S. Hang, Flotation of heavily oxidized pyrite in the presence of fine digenite particles, Miner Eng., (115(2018), p. 142.

W. Z. Yin and J. Z. Wang, Effects of particle size and particle interactions on scheelite flotation, Trans. Nonferrous Met. Soc. China, (24(2014), No. (11), p. 3682.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51374079 and 51504053), the Hundred, Thousand and Ten Thousand Talent Project of Liaoning Province (No. 2014921014), and the Postdoctoral Science Foundation of China (No. 2015M571324).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Qy., Yin, Wz., Li, D. et al. Improving the sulfidation−flotation of fine cuprite by hydrophobic flocculation pretreatment. Int J Miner Metall Mater 25, 1256–1262 (2018). https://doi.org/10.1007/s12613-018-1678-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-018-1678-4