Abstract

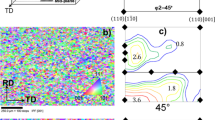

In this study, the effect of decarburization annealing temperature and time on the carbon content, microstructure, and texture of grain-oriented pure iron was investigated by optical microscopy and scanning electron microscopy with electron-backscatter diffraction. The results showed that the efficiency of decarburization dramatically increased with increasing decarburization temperature. However, when the annealing temperature was increased to 825°C and 850°C, the steel’s carbon content remained essentially unchanged at 0.002%. With increasing decarburization time, the steel’s carbon content generally decreased. When both the decarburization temperature and time were increased further, the average grain size dramatically increased and the number of fine grains decreased; meanwhile, some relatively larger grains developed. The main texture types of the decarburized sheets were approximately the same: {001}<110> and {112~115}<110>, with a γ-fiber texture. Furthermore, little change was observed in the texture. Compared with the experimental sheets, the texture of the cold-rolled sheet was very scattered. The best average magnetic induction (B 800) among the final products was 1.946 T.

Similar content being viewed by others

References

Z.Z. He, Y. Zhao, and H.W. Luo, Electrical Steel, Metallurgical Industry Press, Beijing, 2012, p. 646.

R.D. Blaugher and R.H. Hopkins, Development of Grain-oriented Iron Sheet for Electrical Apparatus, US Patent, Appl. 4265683, 1981.

D.R. Thornburg, Method of Producing Primary Recrystallized Textured Iron Alloy Member Having an Open Gamma Loop, US Patent, Appl. 3892605, 1975.

T. Wada, K. Takashima, and M. Kawashima, (110)[001] Textured 0.80% Si−Fe for the proton synchrotron, AIP Conf. Proc., 18(1974), No. 1, p. 1363.

Y. Hiroyoshi and T. Masashi, Manufacture of Grain Oriented Electrical Steel Sheet, Japan Patent, Appl. 61-091329, 1986.

Y. Hiroyoshi and O. Atsuki, Production of Grain Oriented Electrical Steel Sheet, Japan Patent, Appl. 62-83421, 1987.

Y. Hiroyoshi and K. Teruo, Production of Grain-oriented Magnetic Steel Sheet, Japan Patent, Appl. 1-309923, 1989.

Y. Hiroyoshi and K. Teruo, Grain-oriented Magnetic Steel Sheet and Its Production, Japan Patent, Appl. 1-309924, 1989.

N. Yoshio and O. Yasuo, Production of Unidirectionally Oriented Electrical Steel Sheet Having High Magnetic Flux Density, Japan Patent, Appl. 3-47920, 1991.

N. Ujihiro, K. Tsutomu, N. Kiyohiko, and S. Kazuhiro, Soft Magnetic Iron Sheet Excellent in Magnetic Property and Its Manufacture, Japan Patent, Appl. 5-24764, 1992.

N. Yoshio and O. Yasuo, Production of Grain-oriented Electrical Steel Sheet Having High Magnetic Flux Density, Japan Patent, Appl. 4-13811, 1992.

N. Yoshio and O. Yasuo, Grain-Oriented Pure Iron Excellent in Magnetic Permeability and Coercive Force in Coil-width Direction and Its Production, Japan Patent, Appl. 4-301052, 1992.

N. Yoshio, O. Yasuo, N. Tadao, M. Takashi, N. Takeo, Y. Shuichi, F. Hiroyasu, and K. Takao, Grain-oriented Silicon Steel Sheet Having Excellent Magnetostrictive Characteristic, Japan Patent, Appl. 7-062501, 1995.

K. Ryutaro and W. Takeaki, Production of Grain-oriented Silicon Steel Sheet Extremely High in Magnetic Flux Density, Japan Patent, Appl. 10-298651, 1998.

K. Ryutaro and W. Takeaki, Manufacture of Grain Oriented Silicon Steel Sheet Having Stable and Extremely High Magnetic Flux Density in Longitudinal Direction of Coil, Japan Patent, Appl. 10-306318, 1998.

K. Ryutaro and W. Takeaki, Manufacture of Grain Oriented Silicon Steel Sheet Having Extremely High Magnetic Flux Density, Japan Patent, Appl. 10-306319, 1998.

K. Ryutaro and W. Takeaki, Production of Grain Oriented Silicon Steel Sheet with Extremely High Magnetic Flux Density, Japan Patent, Appl. 11-50151, 1999.

W. Takeaki and K. Ryutaro, Grain Oriented Silicon Steel Sheet with Extremely High Magnetic Flux Density, and Its Manufacture, Japan Patent, Appl. 11-189851, 1999.

B. Fu, H.J. Wang, J.X. Yan, L. Xiang, S.T. Qiu, and G.G. Cheng, Effects of temperature and alloying elements on γ phase fraction of grain-oriented silicon steel, J. Iron Steel Res. Int., 23(2016), No. 6, p. 573.

N. Takahashi, Y. Suga, and H. Kobayashi, Recent developments in grain-oriented silicon-steel, J. Magn. Magn. Mater., 160(1996), No. 7, p. 98.

H.A. Wriedt, Solubility product of aluminum nitride in 3 percent silicon iron, Metall. Trans. A, 11(1980), No. 10, p. 1731.

H.W. Luo, R. Xiang, L.F. Chen, and L.M. Pan, Modeling decarburization kinetics of grain-oriented silicon steel, Chin. Sci. Bull., 59(2014), No. 15, p. 1778.

L.Z. Dai, The recrystallization and magnetic properties of Armco iron, Acta Metall. Sin., 3(1958), No. 3, p. 227.

L.Z. Dai and X.Y. Zhang, The rolling and recrystallization textures of Armco iron, Acta Phys. Sin., 14(1958), No. 1, p. 17.

C.Y. Li, Z.M. Fang, L.Z. Liang, and S.J. Quan, Theoretical and experimental study on surface decarburization of 60Si2Mn spring steel, Trans. Mater. Heat Treat., 36(2015), No. 1, p. 192.

M.K. Marques, A.E.D. Azevedo, and B.V.T. Lopes, Decarburization kinetics during annealing of a semi-processed electrical steel, ISIJ Int., 44(2004), No. 3, p. 618.

J.Y. Park, K.S. Han, J.S. Woo, S.K. Chang, N. Rajmohan, and J.A. Szpunar, Influence of primary annealing condition on texture development in grain oriented electrical steels, Acta Mater., 50(2002), No. 7, p. 1825.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Hj., Rong, Z., Xiang, L. et al. Effect of decarburization annealing temperature and time on the carbon content, microstructure, and texture of grain-oriented pure iron. Int J Miner Metall Mater 24, 393–400 (2017). https://doi.org/10.1007/s12613-017-1419-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1419-0