Abstract

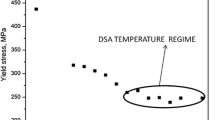

With the increasing use of Al-Si-Mg alloys in the automotive industry, the fatigue performance of Al-Si-Mg alloy has become a major concern with regard to their reliability. The fatigue characteristics and microcosmic mechanism of an Al-Si-Mg alloy under multiaxial proportional loadings were investigated in this research. As low cycle fatigue life and material strengthening behavior are closely related, the effect of equivalent strain amplitude on the multiaxial fatigue properties was analyzed. Fatigue tests were conducted to determine the influence of equivalent strain amplitude on the multiaxial proportional fatigue properties. The fatigue life exhibits a stable behavior under multiaxial proportional loadings. The dislocation structures of the Al-Si-Mg alloy were observed by transmission electron microscopy (TEM). The dislocation structure evolution of the Al-Si-Mg alloy under multiaxial proportional loadings during low cycle fatigue develops step by step by increasing fatigue cycles. Simultaneously, the dislocation structure changes with the change in equivalent strain amplitude under multiaxial proportional loadings. The experimental evidence indicates that the multiaxial fatigue behavior and life are strongly dependent on the microstructure of the material, which is caused by multiaxial proportional loadings.

Similar content being viewed by others

References

D. StJohn, C.H. Cáceres, and C.H. Zhang, Aluminum alloys for cast automotive components, Mater. Aust., 28(1996), p.14.

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, et al., Recent development in aluminum alloys for the automotive industry, Mater. Sci. Eng. A, 280(2000), p.37.

J.Z. Yi, P.D. Lee, T.C. Lindley, et al., Statistical modeling of microstructure and defect population effects on the fatigue performance of cast A356-T6 automotive components, Mater. Sci. Eng. A, 432(2006), p.59.

K.S. Chan, P. Jones, and Q.G. Wang, Fatigue crack growth and fracture paths in sand cast B319 and A356 aluminum alloys, Mater. Sci. Eng., A, 341(2003), p.18.

J.Z Yi., Y.X. Gao, P.D Lee, et al., Microstructure-based fatigue life prediction for cast A356-T6 aluminum-silicon alloys, Metall. Mater. Trans. B, 37(2006), p.301.

P. Li, D.M. Maijer, T.C. Lindley, and P.D. Lee, Simulating the residual stress in an A356 automotive wheel and its impact on fatigue life, Metall. Mater. Trans. B, 38(2007), p.505.

Y.B. Bai, W.M. Mao, S.F. Gao, et al., Filling ability of semi-solid A356 aluminum slurry in rheo-diecasting, J. Univ. Sci. Technol. Beijing, 15(2008), p.48.

H.R Ammar, A.M. Samuel, F.H. Samuel, Effect of casting imperfections on the fatigue life of 319-F and A356-T6 Al-Si casting alloys, Mater. Sci. Eng. A, 473(2008), p.65.

Y. Zhao, L. Wang, H.Y. Li, et al., Effects of recrystallization on the low cycle fatigue behavior of directionally solidified superalloy DZ40M, Rare Met., 27(2008), p.425.

B.R. You and S.B. Lee, A critical review on multiaxial fatigue assessments of metals, Int. J. Fatigue, 18(1996), p.235.

Y.Y. Wang and W.X. Yao, Evaluation and comparison of several multiaxial fatigue criteria, Int. J. Fatigue, 26(2004), p.7.

L.Q. Wang, J.G. Wang, H.Y. Wang, et al., Interaction of fatigue and creep of GH33 under multi-axial stress at high temperature, J. Univ. Sci. Technol. Beijing, 10(2003), p.79.

D.F Mo, G.Q. He, Z.F. Hu, et al., Crack initiation and propagation of cast A356 aluminum alloy under multi-axial cyclic loadings, Int. J. Fatigue, 30(2008), p.1843.

D.L. McDowell, K. Gall, M.F. Horstemeyer, and J. Fan, Microstructure-based fatigue modeling of cast A356-T6 alloy, Eng. Fract. Mech., 70(2003), p.49.

C.Y Jeong, C.S. Kang, J.I. Cho, et al., Effect of microstructure on mechanical properties for A356 casting alloy, Int. J. Cast Met. Res., 21(2008), p.193.

C. Laird, Fatigue, Mater. Sci. Eng., 25(1976), p.187.

S. Nishino, N. Hamada, and M. Sakane, Microstructural study of cyclic strain hardening behaviors in biaxial stress states at elevated temperature, Fatigue Fract. Eng. Mater. Struct., 9(1986), p.65.

R.L. Fleischer, Rapid solution hardening, dislocation mobility, and the flow stress of crystals, J. Appl. Phys., 33(1962), p.3504.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the Major State Basic Research and Development Program of China (No.2007CB714704), the National Natural Science Foundation of China (No.50771073), and the Program for New Century Excellent Talents in Chinese Universities (No.NCET-05-0388).

Rights and permissions

About this article

Cite this article

Jiang, Xs., He, Gq., Liu, B. et al. Fatigue characteristics and microcosmic mechanism of Al-Si-Mg alloys under multiaxial proportional loadings. Int J Miner Metall Mater 18, 437–443 (2011). https://doi.org/10.1007/s12613-011-0459-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-011-0459-0