Abstract

In this study, the effect of tensile mean strain on the fatigue behavior of aluminum alloy 2099-T83 was experimentally examined for the first time. In order to elucidate the effect of tensile mean strain on fatigue lives, strain-control fatigue testing was conducted at three strain ratios (R = − 1, 0.1, 0.7). Experimental results show that the application of greater mean strains during cyclic deformation resulted in shorter fatigue lives, particularly at lower strain amplitudes. At these lower strain amplitudes, the mean stress response to deformation did not fully relax as it did when subjected to larger strain amplitudes, where the effect of mean strains on fatigue performance was negligible. The Morrow and Smith–Watson–Topper mean strain correction models were implemented using monotonic and fully reversed fatigue properties in order to account for the damage associated with the relaxed mean stresses. A new model is presented that incorporates a mean stress sensitivity material property to capture, within a scatter band of three, the effects of tensile mean strains on the fatigue behavior of AA2099.

Similar content being viewed by others

References

K.K. Sankaran and N.J. Grant, The Structure and Properties of Splat-Quenched Aluminum Alloy 2024 Containing Lithium Additions, Mater. Sci. Eng., 1980, 44, p 213–227. https://doi.org/10.1016/0025-5416(80)90122-6

D.L. Chen and M.C. Chaturvedi, Near-Threshold Fatigue Crack Growth Behavior of 2195 Aluminum-Lithium-Alloy—Prediction of crack propagation direction and Influence of Stress Ratio, Metall. Mater. Trans. A, 2000, 31, p 1531–1541. https://doi.org/10.1007/s11661-000-0164-5

F.A. Tchitembo Goma, D. Larouche, A. Bois-Brochu, C. Blais, J. Boselli, and M. Brochu, Effect of Extrusion Aspect Ratio and Test Temperatures on Fatigue Crack Growth Behavior of a 2099-T83 Al-Li Alloy, Int. J. Fatigue, 2014, 59, p 244–253. https://doi.org/10.1016/j.ijfatigue.2013.08.013

K.T. Venkateswara Rao, R.J. Bucci, K.V. Jata, and R.O. Ritchie, A Comparison of Fatigue-Crack Propagation Behavior in Sheet and Plate Aluminum-Lithium Alloys, Mater. Sci. Eng. A, 1991, 141, p 39–48. https://doi.org/10.1016/0921-5093(91)90705-R

G. Bray, M. Glazov, R. Rioja, D. Li, and R. Gangloff, Effect of Artificial Aging on the Fatigue Crack Propagation Resistance of 2000 Series Aluminum Alloys, Int. J. Fatigue, 2001, 23, p 265–276. https://doi.org/10.1016/S0142-1123(01)00159-1

R.J. Rioja and J. Liu, The Evolution of Al-Li Base Products for Aerospace and Space Applications, Metall. Mater. Trans. A, 2012, 43, p 3325–3337

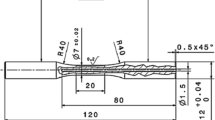

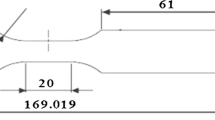

Standard A. E606/E606M-12, Stand Test Method Strain-Controlled Fatigue Testing, ASTM International, West Conshohocken, 2012

A.R. Cisko, J.B. Jordon, D.Z. Avery, Z.B. McClelland, T. Liu, T.W. Rushing et al., Characterization of Fatigue Behavior of Al-Li Alloy 2099, Mater. Charact., 2019, 151, p 496–505. https://doi.org/10.1016/j.matchar.2019.03.026

Y. Ma, X. Zhou, G.E. Thompson, T. Hashimoto, P. Thomson, and M. Fowles, Distribution of Intermetallics in an AA 2099-T8 Aluminium Alloy Extrusion, Mater. Chem. Phys., 2011, 126, p 46–53. https://doi.org/10.1016/j.matchemphys.2010.12.014

C. Cauthen, K.V. Anderson, D.Z. Avery, A. Baker, C.J. Williamson, S.R. Daniewicz et al., Fatigue Crack Nucleation and Microstructurally Small Crack Growth Mechanisms in High Strength Aluminum Alloys, Int. J. Fatigue, 2020, 2020, p 105790. https://doi.org/10.1016/j.ijfatigue.2020.105790

A.T. Brammer, J.B. Jordon, P.G. Allison, and M.E. Barkey, Strain-Controlled Low-Cycle Fatigue Properties of Extruded 6061-T6 Aluminum Alloy, J. Mater. Eng. Perform., 2013, 22, p 1348–1350. https://doi.org/10.1007/s11665-012-0411-0

R.I. Stephens, A. Fatemi, R.R. Stephens, and H.O. Fuchs, Metal Fatigue in Engineering, Wiley, New York, 2000

T. Wehner and A. Fatemi, Effects of Mean Stress on Fatigue Behaviour of a Hardened Carbon Steel, Int. J. Fatigue, 1991, 13, p 241–248. https://doi.org/10.1016/0142-1123(91)90248-W

K.N. Smith, P. Watson, and T.H. Topper, A Stress–Strain Function for the Fatigue of Metals, Journal of Materials, 1970, 5, p 767–778

Acknowledgments

A portion of this work was performed under the auspices of the U.S. Army Engineer Research and Development Center, administered by CEED, Subcontract No. W15QKN-13-9-001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rutherford, B.A., Cisko, A.R., Allison, P.G. et al. Effect of Tensile Mean Strain on Fatigue Behavior of Al-Li Alloy 2099. J. of Materi Eng and Perform 29, 4928–4933 (2020). https://doi.org/10.1007/s11665-020-04983-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04983-8