Abstract

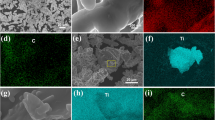

The configuration and quality of reinforcements, as well as the robustness of interfacial bonding, holding a critical significance in determining the concurrence between electrical conductivity and mechanical strength in metal matrix composites. In this study, citric acid was employed as the precursor for synthesizing multi-scale carbon nanomaterials (graphene quantum dots and graphene, abbreviated as GQDs and GN). The GQDs@GN/Cu composites were fabricated through a segmented ball milling process in conjunction with subsequent spark plasma sintering (SPS). The intragranular GQDs and intergranular GQDs@GN had synergistically reinforced Cu composites through Orowan strengthening, load transfer strengthening and refinement strengthening. Furthermore, the robust interface bonding between GQDs@GN and Cu effectively mitigated interfacial impedance stemming from electron-boundary scattering. The yield strength and ultimate tensile strength of the GQDs@GN/Cu composites were recorded as 270 and 314 MPa, respectively, representing an improvement of 92 and 28% over pure Cu, while maintaining electrical conductivity at a level comparable to that of pure Cu. This study advances the understanding of the possibility of realizing a synergistic compatibility between electrical conductivity and mechanical strength in Cu composites.

Graphical abstract

摘要

增强体的结构和质量以及界面结合的强度对于金属基复合材料的导电性和强度的兼容性具有至关重要的意义。本研究以柠檬酸为前驱体合成了多尺度碳纳米材料(石墨烯量子点和石墨烯, 简称GQDs和GN)。GQDs@GN/Cu复合材料是通过分段球磨工艺 (SBM) 和随后的SPS烧结制备。晶粒内GQDs和晶间GQDs@GN通过Orowan强化、载荷传递强化和细化强化协同增强Cu复合材料。此外, GQDs@GN和Cu之间强的界面结合有效地减轻了电子界面散射引起的界面阻抗。GQDs@GN/Cu复合材料的屈服强度和极限抗拉强度分别为270 MPa和314 MPa, 比纯Cu提高了92%和28%, 并且其电导率与纯Cu的差异不大。这项研究对制备高强高导的Cu基复合材料具有指导意义。

Similar content being viewed by others

References

Sayyad R, Ghambari M, Ebadzadeh T, Pakseresht AH, Ghasali E. Preparation of Ag/reduced graphene oxide reinforced copper matrix composites through spark plasma sintering: an investigation of microstructure and mechanical properties. Ceram Int. 2020;46(9):13569. https://doi.org/10.1016/j.ceramint.2020.02.142.

Bolotin KI, Sikes KJ, Jiang Z, Klima M, Fudenberg G, Hone J, Kim P, Stormer HL. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008;146(9):351. https://doi.org/10.1016/j.ssc.2008.02.024.

Chen ZH, Hui HY, Li CL, Chen F, Mei XM, Ma Y, Li JY, Choi SW, Mei QS. GNPs/Al nanocomposites with high strength and ductility and electrical conductivity fabricated by accumulative roll-compositing. Rare Met. 2021;40(9):2593. https://doi.org/10.1007/s12598-020-01695-9.

Avcu E, Cao H, Zhang X, Guo Y, Withers PJ, Li X, Wang N, Yan S, Xiao P. The effect of reduced graphene oxide content on the microstructural and mechanical properties of copper metal matrix composites. Materials Science and Engineering: A. 2022;856:143921. https://doi.org/10.1016/j.msea.2022.143921.

Jiang Y, Xu R, Tan Z, Ji G, Fan G, Li Z, Xiong D, Guo Q, Li Z, Zhang D. Interface-induced strain hardening of graphene nanosheet/aluminum composites. Carbon. 2019;146:17. https://doi.org/10.1016/j.carbon.2019.01.094.

Pu B, Sha J, Liu E, Hea C, Zhao N. Synergistic effect of Cu on laminated graphene nanosheets/AlCu composites with enhanced mechanical properties. Mater Sci En, A. 2019;742:201. https://doi.org/10.1016/j.msea.2018.11.016.

Wei SH, Nie JH, Liu YQ, Hao XX, Ma ZL, Fan JZ. Effect of particle size on fracture toughness of 15%SiCp/2009Al composites. Chin J Rare Met. 2020;44(2):147. https://doi.org/10.13373/j.cnki.cjrm.xy19040042

Yang Y, Liang Y, He G, Luo P. Graphene core–shell structure guided functionalized interface to prepare high-strength, high-plasticity, and high-conductivity copper matrix composites. Mater Sci Eng A. 2022;847:143349. https://doi.org/10.1016/j.msea.2022.143349.

Zhang R, Gao L, Guo J. Effect of Cu2O on the fabrication of SiCp/Cu nanocomposites using coated particles and conventional sintering. Compos A Appl Sci Manuf. 2004;35(11):1301. https://doi.org/10.1016/j.compositesa.2004.03.021.

Yan M, Liu L, Chen L, Li N, Jiang Y, Xu Z, Jing M, Hu Y, Liu L, Zhang X. Radiation resistance of carbon fiber-reinforced epoxy composites optimized synergistically by carbon nanotubes in interface area/matrix. Compos B Eng. 2019;172:447. https://doi.org/10.1016/j.compositesb.2019.04.041.

Zhao Z, Teng K, Li N, Li X, Xu Z, Chen L, Niu J, Fu H, Zhao L, Liu Y. Mechanical, thermal and interfacial performances of carbon fiber reinforced composites flavored by carbon nanotube in matrix/interface. Compos Struct. 2017;159:761. https://doi.org/10.1016/j.compstruct.2016.10.022.

Wang H, Li N, Niu J, Teng K, Xu Z, Jing M, Li F, Wang W, Zhang X. Fiber-welded ciliated-like nonwoven fabric nano-composite multiscale architectures for superior mechanical and electromagnetic shielding behaviors. Compos A Appl Sci Manuf. 2019;121:321. https://doi.org/10.1016/j.compositesa.2019.03.043.

Wang H, Li N, Wang W, Shi J, Xu Z, Liu L, Hu Y, Jing M, Liu L, Zhang X. Bead nano-necklace spheres on 3D carbon nanotube scaffolds for high-performance electromagnetic-interference shielding. Chem Eng J. 2019;360:1241. https://doi.org/10.1016/j.cej.2018.10.221.

Han T, Wang F, Li J, Zhao N, He C. Simultaneously enhanced strength and ductility of Al matrix composites through the introduction of intragranular nano-sized graphene nanoplates. Composites Part B: Engineering. 2021;212:108700. https://doi.org/10.1016/j.compositesb.2021.108700.

Liu Q, Fan G, Tan Z, Guo Q, Xiong D, Su Y, Li Z, Zhang D. Reinforcement with intragranular dispersion of carbon nanotubes in aluminum matrix composites. Compos Part B: Eng. 2021;217:108915. https://doi.org/10.1016/j.compositesb.2021.108915.

Zhou KC, Pei HL, Xiao JK, Zhang L. Micro-scratch behavior of WC particle-reinforced copper matrix composites. Rare Met. 2022;41(7):2337. https://doi.org/10.1007/s12598-015-0586-2.

Dong Y, Lin X, Wang D, Yuan R, Zhang S, Chen X, Bulusheva LG, Okotrub AV, Song H. Modulating the defects of graphene blocks by ball-milling for ultrahigh gravimetric and volumetric performance and fast sodium storage. Energy Storage Mater. 2020;30:287. https://doi.org/10.1016/j.ensm.2020.05.016.

Guo R, Li L, Wang B, Xiang Y, Zou G, ZhuY, Hou H, Ji X. Functionalized carbon dots for advanced batteries. Energy Storage Mater. 2021;37:8. https://doi.org/10.1016/j.ensm.2021.01.020.

Dong Y, Shao J, Chen C, Li H, Wang R, Chi Y, Lin X, Chen G. Blue luminescent graphene quantum dots and graphene oxide prepared by tuning the carbonization degree of citric acid. Carbon. 2012;50(12):4738. https://doi.org/10.1016/j.carbon.2012.06.002.

Ali M, Anjum AS, Bibi A, Wageh S, Sun KC, Jeong SH. Gradient heating-induced bi-phase synthesis of carbon quantum dots (CQDs) on graphene-coated carbon cloth for efficient photo-electrocatalysis. Carbon. 2022;196:649. https://doi.org/10.1016/j.carbon.2022.05.040.

Zhao W, Bao R, Yi J, Zhang Y, Pu Y, Zhang J. Influence of carbonized polymer dot (CPD) structure on mechanical and electrical properties of copper matrix composite. Mater Characterization. 2021;181:111463. https://doi.org/10.1016/j.m atchar.2021.111463.

Meng Q, Song X, Han S, Abbassi F, Zhou Z, Wu B, Wang X, Araby S. Mechanical and functional properties of polyamide/graphene nanocomposite prepared by chemicals free-approach and selective laser sintering. Compos Commun. 2022;36:101396. https://doi.org/10.1016/j.coco.2022.101396.

Shi H, Liu Q, Dai X, Zhang T, Shi Y, Wang T. Magnetic graphene oxide-anchored Ni/Cu nanoparticles with a Cu-rich surface for transfer hydrogenation of nitroaromatics. Chin J Chem Eng. 2022;50:235. https://doi.org/10.1016/j.cjche.2022.06.019.

Wang C, Ke F, Fan W, Chen Y, Guan F, Chen S, Wang H. Efficient large-scale preparation of defect-free few-layer graphene using a conjugated ionic liquid as green media and its polyetherimide composite. Compos Sci Technol. 2018;157:144. https://doi.org/10.1016/j.compscitech.2018.01.035.

Huang G, Jiang P, Zhang X, Zhou C, Zhou J, Huang Y, Yang P, Yang L, Tian X, Hao Y. Efficient preparation and characterization of graphene based on ball milling. Diamond Related Mater. 2022;130:109438. https://doi.org/10.1016/j.diamond.2022.109438.

Xu R, Tan Z, Xiong D, Fan G, Guo Q, Zhang J, Su Y, Li Z, Zhang D. Balanced strength and ductility in CNT/Al composites achieved by flake powder metallurgy via shift-speed ball milling. Compos A Appl Sci Manuf. 2017;96:57. https://doi.org/10.1016/j.compositesa.2017.02.017.

Okoro AM, Machaka R, Lephuthing SS, Awotunde MA, Oke SR, Falodun OE, Olubambi PA. Dispersion characteristics, interfacial bonding and nanostructural evolution of MWCNT in Ti6Al4V powders prepared by shift speed ball milling technique. J Alloy Compd. 2019;785:356. https://doi.org/10.1016/j.jallcom.2019.01.174.

Zhou KC, Pei HL, Xiao JK, Zhang L. Micro-scratch behavior of WC particle-reinforced copper matrix composites. Rare Met. 2022;41(7):2337. https://doi.org/10.1007/s12598-015-0586-2.

Ma L, Zhang X, Zhao D, He C, Zhao N. Achieving the strength-ductility balance of boron nitride nanosheets/Al composite by designing the synergistic transition interface and intragranular reinforcement distribution. Compos Part B: Eng. 2022;246:110243. https://doi.org/10.1016/j.compositesb.2022.110243.

Huang L, Jiang L, Topping TD, Dai C, Wang X, Carpenter R, Haines C, Schoenung JM. In situ oxide dispersion strengthened tungsten alloys with high compressive strength and high strain-to-failure. Acta Mater. 2017;122:1931. https://doi.org/10.1016/j.actamat.2016.09.034.

Khodabakhshi F, Nosko M, Gerlich AP. Effects of graphene nano-platelets (GNPs) on the microstructural characteristics and textural development of an Al-Mg alloy during friction-stir processing. Surf Coat Technol. 2018;335:288. https://doi.org/10.1016/j.surfcoat.2017.12.045.

Wang P, Xiong Z Y, Fei P, Cai Jie, Walayat N, Xiong H. An approach for compatibilization of the starch with poly (lactic acid) and ethylene-vinyl acetate-glycidyl-methacrylate. Int J Biol Macromolecules. 2020;161:44. https://doi.org/10.1016/j.ijbiomac.2020.06.011.

Song K, Xing J, Dong Q, Liu P, Tian B, Cao X. Internal oxidation of dilute Cu–Al alloy powers with oxidant of Cu2O. Mater Sci Eng A. 2004;380(1–2):117. https://doi.org/10.1016/j.msea.2004.03.042.

Long F, Guo X, Song K, Liu J, Wang X, Yang Y, Li S. An internal-oxidation-based strategy induced high-density alumina in-situ nanoprecipitation and carbon nanotube interface optimization for co-reinforcing copper matrix composites. Compos Part B: Eng. 2022;229:109455. https://doi.org/10.1016/j.compositesb.2021.109455.

Zhang L, Bao R, Yi J, Tao J, Guo S, Tan S. Improving the interfacial bonding of CNT/Cu composites using CPD bridges. Mater Sci Eng A. 2022;845:143222. https://doi.org/10.1016/j.msea.2022.143222.

Zuo T, Li J, Gao Z, Wu Y, Zhang L, Da B, Zhao X, Xiao L. Simultaneous improvement of electrical conductivity and mechanical property of Cr doped Cu/CNTs composites. Mater Today Commun. 2020;23:100907. https://doi.org/10.1016/j.mt comm.2020.100907.

Yang Z, Wang L, Shi Z, Wang M, Cui Y, Wei B, Xu S, Zhu Y, Fei W. Preparation mechanism of hierarchical layered structure of graphene/copper composite with ultrahigh tensile strength. Carbon. 2018;127:329. https://doi.org/10.1016/j.carbon.2017.10.095.

Jiang D, Dong Z, Du Z, Zhao Q, Wang H, Ma Z. Effect mechanism of oxide doping on the microstructure and mechanical properties of Mo-Y2O3 alloys. Mater Sci Eng A. 2022;831:142344. https://doi.org/10.1016/j.msea.2021.142344.

Zhu J, Liu X, Wang Z, Yang Q. Wrinkles-assisted nanocrystalline formation and mechanical properties of wrinkled graphene/aluminum matrix composites. Modell Simulation Mater Sci Eng. 2021;29(5):055017. https://doi.org/10.1088/1361-651X /ac03a5.

Dong LL, Fu YQ, Liu Y, Lu JW, Zhang W, Huo WT, Jin LH, Zhang YS. Interface engineering of graphene/copper matrix composites decorated with tungsten carbide for enhanced physico-mechanical properties. Carbon. 2021;173:41. https://doi.org/10.1016/j.carbon.2020.10.091.

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (Nos. 52174345 and 52064032) and the Science and Technology Major Project of Yunnan Province (No. 202202AG050004).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, SY., Liu, L., Bao, R. et al. Attaining synergetic equilibrium of electrical conductivity and tensile strength in GQDs@GN/Cu composites through multi-scale intragranular and intergranular reinforcements. Rare Met. 43, 366–379 (2024). https://doi.org/10.1007/s12598-023-02391-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02391-0