Abstract

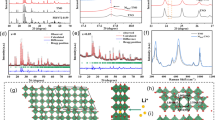

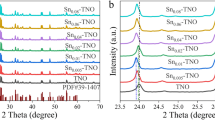

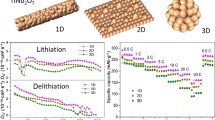

TiNb2O7 is an advanced anode material for high-energy density lithium-ion batteries (LIBs) due to its considerable specific capacity and satisfactory safety. However, its rate capability is limited by its poor ionic conductivity and electronic conductivity. To solve this problem, TiNb2O7 with W6+ doping was synthesized by a convenient solid-state method. The doping of W6+ will lead to arranging cation mixing and charge compensation. The cation rearrangement creates a new Li-conductive environment for lithiation, resulting in a low-energy barrier and the fast Li+ storage/diffusion. The results show that the Li+ diffusion coefficient of W0.06Ti0.91Nb2O7 is increased by 9.96 times greater than that of TiNb2O7. Besides, as the calculation proves, due to the partial reduction of the Nb5+ and Ti4+ caused by charge compensation, W6+ doping results in low charge transfer resistance and excellent electronic conductivity. Moreover, W6+ doping accounts for a high pseudocapacitive contribution. At the scan rate of 1 mV·s−1, the pseudocapacitive contribution for TiNb2O7 is 78%, while that for W0.06Ti0.91Nb2O7 increases to 83%. The reversible specific capacity of W0.06Ti0.91Nb2O7 after 600 cycles is maintained at 148.90 mAh·g−1 with a loss of only 16.37% at 10.0C. Also, it delivers a commendable capacity of 161.99 mAh·g−1 at 20.0C. Even at 30.0C, it still retains a satisfactory capacity of 147.22 mAh·g−1, much higher than TiNb2O7 (97.49 mAh·g−1). Our present study provides ideas for the development of electrode materials for lithium-ion batteries.

Graphical abstract

摘要

TiNb2O7具有可观的比容量和良好的安全性,是一种先进的高能量密度锂离子电池负极材料。然而,其倍率性能受限于较差的离子电导率和电子电导率。为了解决这一问题,采用一种简便的固相法合成了W6+掺杂的TiNb2O7。W6+的掺杂会导致阳离子混排和电荷补偿,阳离子的重新排列创造了一个新的锂导电环境,从而导致低能垒和快速的Li+存储/扩散。结果表明,W0.06Ti0.91Nb2O7的Li+扩散系数与TiNb2O7相比提高了9.96倍。此外,计算证明,W6+的掺杂会导致较低的电荷转移阻抗和优异的电子导电性因为电荷补偿会导致部分Nb5+和Ti4+发生还原。W6+掺杂还会产生高的赝电容贡献。在1 mV·s‒1的扫描速率下,TiNb2O7的赝电容贡献为78%,而W0.06Ti0.91Nb2O7的赝容量贡献提高到83%。在10.0C的电流下循环600次后,W0.06Ti0.91Nb2O7的可逆比容量保持在148.90 mAh·g−1,损耗仅为16.37%。在20.0C时,W0.06Ti0.91Nb2O7的可逆比容量为161.99 mAh·g−1。即使在30.0C时,W0.06Ti0.91Nb2O7的可逆比容量仍能保持在147.22 mAh·g−1,远远高于TiNb2O7(97.49 mAh·g−1)。该研究为锂离子电池电极材料的发展提供了思路。

Similar content being viewed by others

References

Naveed A, Chen J, Raza B, Liu Y, Wang J. Rechargeable hybrid organic Zn battery (ReHOZnB) with non-flammable electrolyte. J Electroanal Chem. 2022;904:115949. https://doi.org/10.1016/j.jelechem.2021.115949.

Spada D, Albini B, Galinetto P, Versaci D, Francia C, Bodoardo S, Bais G, Bini M. FeNb11O29, anode material for high-power lithium-ion batteries: pseudocapacitance and symmetrisation unravelled with advanced electrochemical and in situ/operando techniques. Electrochim Acta. 2021;393:139077. https://doi.org/10.1016/j.electacta.2021.139077.

Zhao W, Pan Z, Zhang Y, Liu Y, Dou H, Shi Y, Zuo Z, Zhang B, Chen J, Zhao X, Yang X. Tailoring coordination in conventional ether-based electrolytes for reversible magnesium-metal anodes. Angew Chem. 2022;134(30):e202205187. https://doi.org/10.1002/anie.202205187.

Zhang SS. The effect of the charging protocol on the cycle life of a Li-ion battery. J Power Sources. 2006;161(2):1385. https://doi.org/10.1016/j.jpowsour.2006.06.040.

Zhou Y, Niu PH, Li ZH, Zhang PP, Su MR, Dou AC, Li XW, Liu YJ. Metallurgy of aluminum-inspired formation of aluminosilicate-coated nanosilicon for lithium-ion battery anode. Rare Met. 2022;41(6):1880. https://doi.org/10.1007/s12598-022-01961-y.

Zhao B, Ran R, Liu M, Shao Z. A comprehensive review of Li4Ti5O12-based electrodes for lithium-ion batteries: the latest advancements and future perspectives. Mater Sci Eng R. 2015;98:1. https://doi.org/10.1016/j.mser.2015.10.001.

Han JT, Huang YH, Goodenough JB. New anode framework for rechargeable lithium batteries. Chem Mater. 2011;23(8):2027. https://doi.org/10.1021/cm200441h.

Goodenough JB, Kim Y. Challenges for rechargeable Li batteries. Chem Mater. 2010;22(3):587. https://doi.org/10.1021/cm901452z.

Sun RX, Yue Y, Cheng XF, Zhang K, Jin SY, Liu GY, Fan YX, Bao Y, Liu XD. Ionic liquid-induced ultrathin and uniform N-doped carbon-wrapped T-Nb2O5 microsphere anode for high-performance lithium-ion battery. Rare Met. 2021;40(11):3205. https://doi.org/10.1007/s12598-020-01681-1.

Zhu S, Cheng C, Wu D, Yan Y, Qin L, Hou L, Yuan C. Nb-based mixed oxides as anodes for metal-ion capacitors: progress, challenge, and perspective. Energy Fuels. 2022;36(19):11760. https://doi.org/10.1021/acs.energyfuels.2c02352.

Dyson P. The unit cell and space group of the compound TiNb2O7. Acta Cryst. 1957;10:140. https://doi.org/10.1107/S0365110X57000420.

Gao Y, Cheng C, An J, Liu H, Zhang D, Chen G, Shi L. High tap density Li4Ti5O12 anode materials synthesized for high rate performance lithium ion batteries. ChemistrySelect. 2018;3(2):348. https://doi.org/10.1002/slct.201702477.

Lin C, Yu S, Wu S, Lin S, Zhu ZZ, Li J, Lu L. Ru0.01Ti0.99Nb2O7 as an intercalation-type anode material with a large capacity and high rate performance for lithium-ion batteries. J Mater Chem A. 2015;3(16):8627. https://doi.org/10.1039/c5ta01073j.

Song H, Kim YT. A Mo-doped TiNb2O7 anode for lithium-ion batteries with high rate capability due to charge redistribution. Chem Commun. 2012;51(48):9849. https://doi.org/10.1039/c5cc02221e.

Shannon RD. Revised effective ionic radii and systematic studies of interatomie distances in halides and chaleogenides. Acta Cryst. 1976;A32:751. https://doi.org/10.1107/S0567739476001551.

Qin L, Zhu S, Cheng C, Wu D, Wang G, Hou L, Yuan C. Single-crystal nano-subunits assembled accordion-shape WNb2O8 framework with high ionic/electronic conductivities towards Li-ion capacitors. Small. 2022;18(13):2107987. https://doi.org/10.1002/smll.202107987.

Ji H, Urban A, Kitchaev DA, Kwon DH, Artrith N, Ophus C, Huang W, Cai Z, Shi T, Kim JC, Kim H, Ceder G. Hidden structural and chemical order controls lithium transport in cation-disordered oxides for rechargeable batteries. Nat Commun. 2019;10:592. https://doi.org/10.1038/s41467-019-08490-w.

Ceder G. Opportunities and challenges for first-principles materials design and applications to Li battery materials. MRS Bull. 2010;35:693. https://doi.org/10.1557/mrs2010.681.

Hauck J. Short-range order and superstructures of ternary oxides AMO2, A2MO3 and A5MO6 of monovalent A and multivalent M metals related to the NaCl structure. Acta Cryst. 1980;A36:228. https://doi.org/10.1107/S0567739480000460.

Lv Z, Zhu H, Meng W, Wei L, Yang Y, Zhang Y, Ye M, Li CC. Cation mixing in Wadsley-Roth phase anode of lithium-ion battery improves cycling stability and fast Li+ storage. Appl Phys Rev. 2021;8(3):031404. https://doi.org/10.1063/5.0054030.

Hsiao YS, Chang-Jian CW, Weng HC, Chiang HH, Lu CZ, Kong Pang W, Peterson VK, Jiang XC, Wu PI, Chen CP, Huang JH. Doping with W6+ ions enhances the performance of TiNb2O7 as an anode material for lithium-ion batteries. Appl Surf Sci. 2022;573:151517. https://doi.org/10.1016/j.apsusc.2021.151517.

Kresse G, Joubert D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys Rev B. 1999;59(3):1758. https://doi.org/10.1103/PhysRevB.59.1758.

Kresse G, Furthmüller J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B. 1996;54(16):11169. https://doi.org/10.1103/PhysRevB.54.11169.

Segall MD, Lindan PJD, Probert MJ, Pickard CJ, Hasnip PJ, Clark SJ, Payne MC. First-principles simulation: ideas, illustrations and the CASTEP code. J Phys Condens Matter. 2002;14(11):2717. https://doi.org/10.1088/0953-8984/14/11/301.

Perdew JP, Burke K, Ernzerhof M. Generalized gradient approximation made simple. Phys Rev Lett. 1996;77(18):3865. https://doi.org/10.1103/PhysRevLett.77.3865.

Perdew JP, Zunger A. Self-interaction correction to density-functional approximations for many-electron systems. Phys Rev B. 1981;23:5048. https://doi.org/10.1103/PhysRevB.23.5048.

Anisimov VV, Korotin MA, Zaanen J, Andersen OK. Spin bags, polarons, and impurity potentials in La2-xSrxCuO4 from first principles. Phys Rev Lett. 1992;68:345. https://doi.org/10.1103/PhysRevLett.68.345.

Henkelman G, Uberuaga BP, Jónsson H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J Chem Phys. 2000;113(22):9901. https://doi.org/10.1063/1.1329672.

Momma K, Izumi F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J Appl Cryst. 2011;44(6):1272. https://doi.org/10.1107/s0021889811038970.

Mitome M, Kohiki S, Murakawa Y, Hori K, Kurashima K, Bando Y. Transmission electron microscopy and electron diffraction study of the short-range ordering structure of alpha-LiFeO2. Acta Cryst. 2004;B60:698. https://doi.org/10.1107/S0108768104023456.

Kocer CP, Griffith KJ, Grey CP, Morris AJ. Cation disorder and lithium insertion mechanism of Wadsley-Roth crystallographic shear phases from first principles. J Am Chem Soc. 2019;141(38):15121. https://doi.org/10.1021/jacs.9b06316.

Liu K, Wang JA, Yang J, Zhao D, Chen P, Man J, Yu X, Wen Z, Sun J. Interstitial and substitutional V5+-doped TiNb2O7 microspheres: a novel doping way to achieve high-performance electrodes. Chem Eng J. 2021;407:127190. https://doi.org/10.1016/j.cej.2020.127190.

Li M, Su A, Qin Q, Qin Y, Dou A, Zhou Y, Su M, Liu Y. High-rate capability of columbite CuNb2O6 anode materials for lithium-ion batteries. Mater Lett. 2021;284:128915. https://doi.org/10.1016/j.matlet.2020.128915.

Lu X, Jian Z, Fang Z, Gu L, Hu Y-S, Chen W, Wang Z, Chen L. Atomic-scale investigation on lithium storage mechanism in TiNb2O7. Energy Environ Sci. 2011;4(8):2638. https://doi.org/10.1039/c0ee00808g.

Paulraj V, Saha T, Vediappan K, Kamala BK. Synthesis and electrochemical properties of TiNb2O7 nanoparticles as an anode material for lithium ion batteries. Mater Lett. 2021;304:130681. https://doi.org/10.1016/j.matlet.2021.130681.

Liu G, Zhao L, Sun R, Chen W, Hu M, Liu M, Duan X, Zhang T. Mesoporous TiNb2O7 microspheres as high performance anode materials for lithium-ion batteries with high-rate capability and long cycle-life. Electrochim Acta. 2018;259:20. https://doi.org/10.1016/j.electacta.2017.10.138.

Wu X, Miao J, Han W, Hu YS, Chen D, Lee JS, Kim J, Chen L. Investigation on Ti2Nb10O29 anode material for lithium-ion batteries. Electrochem Commun. 2012;25:39. https://doi.org/10.1016/j.elecom.2012.09.015.

Lou S, Cheng X, Zhao Y, Lushington A, Gao J, Li Q, Zuo P, Wang B, Gao Y, Ma Y, Du C, Yin G, Sun X. Superior performance of ordered macroporous TiNb2O7 anodes for lithium ion batteries: understanding from the structural and pseudocapacitive insights on achieving high rate capability. Nano Energy. 2017;34:15. https://doi.org/10.1016/j.nanoen.2017.01.058.

Zhang H, Zhang X, Zeng T, Dou A, Zhang P, Su M, Zhou Y, Liu Y. Conversion of residual lithium into fast ionic conductor coating to achieve one-step double modification strategy in LiNi0.8Co0.15Al0.05O2. J Alloys Compd. 2023;931:167638. https://doi.org/10.1016/j.jallcom.2022.167638.

Yan L, Cheng X, Yu H, Zhu H, Liu T, Zheng R, Zhang R, Shui M, Shu J. Ultrathin W9Nb8O47 nanofibers modified with thermal NH3 for superior electrochemical energy storage. Energy Storage Mater. 2018;14:159. https://doi.org/10.1016/j.ensm.2018.03.005.

Tian T, Lu LL, Yin YC, Li F, Zhang TW, Song YH, Tan YH, Yao HB. Multiscale designed niobium titanium oxide anode for fast charging lithium ion batteries. Adv Funct Mater. 2020;31(4):2007419. https://doi.org/10.1002/adfm.202007419.

Wu XL, Jiang LY, Cao FF, Guo YG, Wan LJ. LiFePO4 nanoparticles embedded in a nanoporous carbon matrix: superior cathode material for electrochemical energy-storage devices. Adv Mater. 2009;21(25–26):2710. https://doi.org/10.1002/adma.200802998.

Li H, Shen L, Pang G, Fang S, Luo H, Yang K, Zhang X. TiNb2O7 nanoparticles assembled into hierarchical microspheres as high-rate capability and long-cycle-life anode materials for lithium ion batteries. Nanoscale. 2015;7(2):619. https://doi.org/10.1039/c4nr04847d.

Park H, Song T, Paik U. Porous TiNb2O7 nanofibers decorated with conductive Ti1−xNbxN bumps as a high power anode material for Li-ion batteries. J Mater Chem A. 2015;3(16):8590. https://doi.org/10.1039/c5ta00467e.

Gao J, Cheng X, Lou S, Ma Y, Zuo P, Du C, Gao Y, Yin G. Self-doping Ti1-xNb2+xO7 anode material for lithium-ion battery and its electrochemical performance. J Alloys Compd. 2017;728:534. https://doi.org/10.1016/j.jallcom.2017.09.045.

Kong L, Zhang C, Wang J, Qiao W, Ling L, Long D. Nanoarchitectured Nb2O5 hollow, Nb2O5@carbon and NbO2@carbon core-shell microspheres for ultrahigh-rate intercalation pseudocapacitors. Sci Rep. 2016;6:21177. https://doi.org/10.1038/srep21177.

Qu X, Huang H, Wan T, Hu L, Yu Z, Liu Y, Dou A, Zhou Y, Su M, Peng X, Wu HH, Wu T, Chu D. An integrated surface coating strategy to enhance the electrochemical performance of nickel-rich layered cathodes. Nano Energy. 2022;91:106665. https://doi.org/10.1016/j.nanoen.2021.106665.

Yu Z, Qu X, Wan T, Dou A, Zhou Y, Peng X, Su M, Liu Y, Chu D. Synthesis and mechanism of high structural stability of nickel-rich cathode materials by adjusting Li-excess. ACS Appl Mater Interfaces. 2020;12(36):40393. https://doi.org/10.1021/acsami.0c12541.

Chen X, Liu K, Qin Q, Yu Z, Li M, Qu X, Zhou Y, Dou A, Su M, Liu Y. High-rate capability of carbon-coated micron-sized hexagonal TT-Nb2O5 composites for lithium-ion battery. Ceram Int. 2021;47(11):15400. https://doi.org/10.1016/j.ceramint.2021.02.105.

Yu Z, Huang H, Liu Y, Qu X, Zhou Y, Dou A, Su M, Wu HH, Zhang L, Dai K, Guo Z, Wan T, Li M, Chu D. Design and tailoring of carbon-Al2O3 double coated nickel-based cation-disordered cathodes towards high-performance Li-ion batteries. Nano Energy. 2022;96:107071. https://doi.org/10.1016/j.nanoen.2022.107071.

Gao P, Chen Z, Gong Y, Zhang R, Liu H, Tang P, Chen X, Passerini S, Liu J. The role of cation vacancies in electrode materials for enhanced electrochemical energy storage: synthesis, advanced characterization, and fundamentals. Adv Energy Mater. 2020;10(14):1903780. https://doi.org/10.1002/aenm.201903780.

Yang C, Yu S, Ma Y, Lin C, Xu Z, Zhao H, Wu S, Zheng P, Zhu ZZ, Li J, Wang N. Cr3+ and Nb5+ co-doped Ti2Nb10O29 materials for high-performance lithium-ion storage. J Power Sources. 2017;360:470. https://doi.org/10.1016/j.jpowsour.2017.06.026.

Wang YY, Hou BH, Guo JZ, Ning QL, Pang WL, Wang J, Lü CL, Wu XL. An ultralong lifespan and low-temperature workable sodium-ion full battery for stationary energy storage. Adv Energy Mater. 2018;8(18):1703252. https://doi.org/10.1002/aenm.201703252.

Qin L, Liu Y, Zhu S, Wu D, Wang G, Zhang J, Wang Y, Hou L, Yuan C. Formation and operating mechanisms of single-crystalline perovskite NaNbO3 nanocubes/few-layered Nb2CTx MXene hybrids towards Li-ion capacitors. J Mater Chem A. 2021;9(36):20405. https://doi.org/10.1039/d1ta03684j.

He SR, Zou JP, Chen LB, Chen YJ. A nanostructured Ni/T-Nb2O5@carbon nanofibers as a long-life anode material for lithium-ion batteries. Rare Met. 2021;40(2):374. https://doi.org/10.1007/s12598-020-01444-y.

Wu Z, Guo M, Yan Y, Dou H, Zhao W, Zhang Y, Li S, Wu J, Bin X, Zhao X, Yang X, Ruan D. Reducing crystallinity of micrometer-sized titanium–niobium oxide through cation substitution for high-rate lithium storage. ACS Sustainable Chem Eng. 2021;9(22):7422. https://doi.org/10.1021/acssuschemeng.1c01215.

Zhou Y, Liu K, Zhou Y, Ni JH, Dou AC, Su MR, Liu YJ. Synthesis of a novel hexagonal porous TT-Nb2O5 via solid state reaction for high-performance lithium ion battery anodes. J Cent South Univ. 2021;27:3625. https://doi.org/10.1007/s11771-020-4570-0.

Su M, Li J, He K, Fu K, Nui P, Chen Y, Zhou Y, Dou A, Hou X, Liu Y. NiSb/nitrogen-doped carbon derived from Ni-based framework as advanced anode for lithium-ion batteries. J Colloid Interface Sci. 2023;629:83. https://doi.org/10.1016/j.jcis.2022.08.126.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 52274299, 52004103 and 51974137), the Postdoctoral Science Foundation of China (Nos. 2021M691321 and 2020M671361), and the Postdoctoral Science Foundation of Jiangsu Province (No. 2020Z090). The simulations were performed on resources provided by the Pawsey Supercomputing Centre with funding from the Australian Government and the Government of Western Australia.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cui, P., Li, GT., Zhang, PP. et al. Arranging cation mixing and charge compensation of TiNb2O7 with W6+ doping for high lithium storage performance. Rare Met. 42, 3364–3377 (2023). https://doi.org/10.1007/s12598-023-02315-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02315-y