Abstract

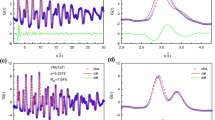

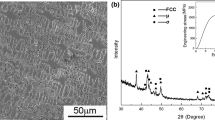

Multi-principal element alloys (MPEAs) have shown extraordinary properties in different fields. However, the composition design of MPEAs is still challenging due to the complicated interactions among principal elements (PEs), and even more challenging with precipitates formation. Precipitation can be either beneficial or detrimental in alloys, thus it is important to control precipitates formation on purpose during alloy design. In this work, cluster-plus-glue-atom model (CGM) composition design method which is usually used to describe short-range order in traditional alloys has been successfully extended to MPEAs for precipitation design. The key challenge of extending CGM to MPEAs is the determination of center atom since there are no solvent or solute in MPEAs. Research has found that the element type of center atom was related not only with chemical affinity, but also with atomic volume difference in MPEAs, which has inevitable effect on atomic arrangement. Based on experimental data of MPEAs with precipitates, it was found that elements with either stronger chemical affinity or larger volume difference with other PEs would occupy the center site of clusters. Therefore, a cluster index (PC), which considers both chemical affinity and atomic volume factors, was proposed to assist the determination of center atom in MPEAs. Based on the approach, a solid-solution Zr-Ti-V-Nb-Al BCC alloy was obtained by inhibiting the precipitation, while precipitation-strengthened Al-Cr-Fe-Ni-V FCC alloy and Al-Co-Cr-Fe-Ni BCC alloy were designed by promoting the precipitation. Corresponding experimental results demonstrated that the approach could provide a relatively simple and accurate predication of precipitation and the compositions of precipitations were in line with PEs in cluster in MPEAs. The research may open an effective way for composition design of MPEAs with desired phase structure.

Graphical abstract

摘要

多主元合金 (MPEA) 在不同领域表现出了非凡的性能。然而, 由于主元间的相互作用十分复杂, 给成分设计与析出相的控制带来极大挑战。析出相对合金性能的影响有利有弊, 因此, 有目的地控制析出相的形成对提升合金性能十分重要。基于此, 本文以实现多主元合金的析出相的成分和结构控制为目的, 基于传统合金的团簇-连接原子结构式理论, 发展了针对多主元合金的理论模型。由于多主元合金中无溶质与溶剂之分, 因此, 这一方法的关键在于主要元素在结构式中位置的准确判断。研究发现, 中心原子的元素类型不仅与化学亲和力有关, 还与其和其他主元间的原子体积差异有关。通过对包含短程序的多主元合金进行总结与归纳, 发现化学亲和力更强或与其他主元体积差异较大的元素会占据团簇的中心位置。基于此, 提出了团簇占位指数PC, 用以判断主元位置。基于该方法, 通过抑制有序相析出, 获得了Zr-Ti-V-Nb-Al体系的体心立方结构单相轻质合金;通过促进有序强化相的析出, 分别设计并制备出了Al-Cr-Fe-Ni-V体系面心立方结构的和Al-Co-Cr-Fe-Ni体系体心立方结构的析出强化型合金。实验结果表明, 该方法可以提供一个相对简单、准确的相组成预测, 预测所得析出相与所确定的团簇结构式吻合较好。因此, 本研究为具有目标相结构的多主元合金成分设计开辟了一条有效途径。

Similar content being viewed by others

References

Zhang W, Liaw PK, Zhang Y. Science and technology in high-entropy alloys. Sci China Mater. 2018;61(1):2. https://doi.org/10.1007/s40843-017-9195-8.

Cantor B, Chang ITH, Knight P, Vincent AJB. Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng. 2004;375:213. https://doi.org/10.1016/j.msea.2003.10.25.

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater. 2004;6(5):299. https://doi.org/10.1002/adem.200300567.

Lu ZP, Wang H, Chen MW, Baker I, Yeh JW, Liu CT, Nieh TG. An assessment on the future development of high-entropy alloys: summary from a recent workshop. Intermetallics. 2015;66:67. https://doi.org/10.1016/j.intermet.2015.06.021.

Pickering EJ, Jones NG. High-entropy alloys: a critical assessment of their founding principles and future prospects. Int Mater Rev. 2016;61(3):183. https://doi.org/10.1080/09506608.2016.1180020.

Chuang MH, Tsai MH, Wang WR, Lin SJ, Yeh JW. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011;59(16):6308. https://doi.org/10.1016/j.actamat.2011.06.041.

Zou Y, Ma H, Spolenak R. Ultrastrong ductile and stable high-entropy alloys at small scales. Nat Commun. 2015;6:7748. https://doi.org/10.1038/ncomms8748.

Wu YD, Cai YH, Wang T, Si JJ, Zhu J, Wang YD, Hui XD. A refractory Hf25Nb25Ti25Zr25 high-entropy alloy with excellent structural stability and tensile properties. Mater Lett. 2014;130:277. https://doi.org/10.1016/j.matlet.2014.05.134.

Deng Y, Tasan CC, Pradeep KG, Springer H, Kostka A, Raabe D. Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 2015;94:124. https://doi.org/10.1016/j.actamat.2015.04.014.

Li D, Li C, Feng T, Zhang Y, Sha G, Lewandowski JJ, Liaw PK, Zhang Y. High-entropy Al0.3CoCrFeNi alloy fibers with high tensile strength and ductility at ambient and cryogenic temperatures. Acta Mater. 2017;123:285. https://doi.org/10.1016/j.actamat.2016.10.038.

Gludovatz B, Hohenwarter A, Catoor D, Chang EH, George EP, Ritchie RO. A fracture-resistant high-entropy alloy for cryogenic applications. Sci China Mater. 2014;345(6201):1153. https://doi.org/10.1016/j.actamat.2016.10.038.

Tang Z, Yuan Y, Tsai CW, Yeh JW, Lundin CD, Liaw PK. Fatigue behavior of a wrought Al0.5CoCrCuFeNi two-phase high-entropy alloy. Acta Mater. 2015;99:247. https://doi.org/10.1016/j.actamat.2015.07.004.

Hemphill MA, Yuan T, Wang GY, Yeh JW, Tsai CW, Chuang A, Liaw PK. Fatigue behavior of Al0.5CoCrCuFeNi high entropy alloys. Acta Mater. 2012;60(16):5723. https://doi.org/10.1016/j.actamat.2012.06.046.

Zhang Y, Zhou YJ, Lin JP, Chen GL, Liaw PK. Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater. 2008;10(6):534. https://doi.org/10.1002/adem.200700240.

Wang Z, Huang Y, Yang YY, Wang Y, Liu CT. Atomic-size effect and solid solubility of multicomponent alloys. Scripta Mater. 2015;94:28. https://doi.org/10.1016/j.scriptamat.2014.09.010.

Poletti MG, Battezzati L. Electronic and thermodynamic criteria for the occurrence of high entropy alloys in metallic systems. Acta Mater. 2014;75:297. https://doi.org/10.1016/j.actamat.2014.04.033.

Guo S, Ng C, Lu J, Liu CT. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J Appl Phys. 2011;109(10): 103505. https://doi.org/10.1063/1.3587228.

King DJM, Middleburgh SC, McGregor AG, Cortie MB. Predicting the formation and stability of single phase high-entropy alloys. Acta Mater. 2016;104:172. https://doi.org/10.1016/j.actamat.2015.11.040.

Zhang C, Zhang F, Chen S, Cao W. Computational thermodynamics aided high-entropy alloy design. JOM. 2012;64(7):839. https://doi.org/10.1007/s11837-012-0365-6.

Zhang F, Zhang C, Chen SL, Zhu J, Cao WS, Kattner UR. An understanding of high entropy alloys from phase diagram calculations. Calphad. 2014;45:1. https://doi.org/10.1016/j.calphad.2013.10.006.

Morral JE, Chen S. A regular solution model for a single-phase high entropy and enthalpy alloy. J Phase Equilib Diffus. 2017;38(4):382. https://doi.org/10.1007/s11669-017-0578-z.

He F, Wang Z, Wu Q, Niu S, Li J, Wang J, Liu CT. Solid solution island of the Co-Cr-Fe-Ni high entropy alloy system. Scripta Mater. 2017;131:42. https://doi.org/10.1016/j.scriptamat.2016.12.033.

Dong C, Wang Q, Qiang JB, Wang Y, Jiang N, Han G, Li Y, Wu J. Topical review: from clusters to phase diagrams: composition rules of quasicrystals and bulk metallic glasses. J Phys D Appl Phys. 2007;40(15):273. https://doi.org/10.1088/0022-3727/40/15/R01.

Hong HL, Wang Q, Dong C, Liaw PK. Understanding the Cu-Zn brass alloys using a short-range-order cluster model: significance of specific compositions of industrial alloys. Sci Rep. 2014;4(2):7065. https://doi.org/10.1038/srep07065.

Pang C, Jiang B, Shi Y, Wang Q, Dong C. Cluster-plus-glue-atom model and universal composition formulas [cluster](glue atom) x, for BCC solid solution alloys. J Alloy Compd. 2015;652:63. https://doi.org/10.1016/j.jallcom.2015.08.209.

Takeuchi A, Inoue A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans. 2005;46(12):2817. https://doi.org/10.2320/matertrans.46.2817.

Takeuchi A, Inoue A. Calculations of mixing enthalpy and mismatch entropy for ternary amorphous alloys. Mater Trans, JIM. 2007;41(11):1372. https://doi.org/10.2320/matertrans1989.41.1372.

Yeh JW. Recent progress in high-entropy alloys. Annales de Chimie Science des Matériaux. 2006;31(6):633. https://doi.org/10.3166/acsm.31.633-648.

Ranganathan S. Alloyed pleasures: multimetallic cocktails. Curr Sci. 2003;85(5):3. https://doi.org/10.1038/nature02146.

Lu YP, Dong Y, Guo S, Jiang J, Kang HJ, Wang YM, Wen B, Wang ZJ, Jie JC, Cao ZQ, Ruan HH, Li TJ. A promising new class of high-temperature alloys: eutectic high-entropy alloys. Sci Rep. 2014;4:6200. https://doi.org/10.1038/srep06200.

Wani IS, Bhattacharjee T, Sheikh S, Lu YP, Chatterjee S, Bhattacharjee PP, Guo S, Tsuji N. Ultrafine-grained AlCoCrFeNi21 eutectic high-entropy alloy. Mater Res Lett. 2016;4(3):174. https://doi.org/10.1080/21663831.2016.1160451.

Kao YF, Chen TJ, Chen SK, Yeh JW. Microstructure and mechanical property of as-cast, homogenized, and deformed AlxCoCrFeNi (0≤x≤2) high-entropy alloys. J Alloy Comp. 2009;488(1):57. https://doi.org/10.1016/j.jallcom.2009.08.090.

Li C, Li JC, Zhao M, Jiang Q. Effect of aluminum contents on microstructure and properties of AlxCoCrFeNi alloys. J Alloy Comp. 2010;504:515. https://doi.org/10.1016/j.jallcom.2010.03.111.

Wang WR, Wang WL, Wang SC, Tsai YC, Lai CH, Yeh JW. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics. 2012;26:44. https://doi.org/10.1016/j.intermet.2012.03.005.

Wang WR, Wang WL, Yeh JW. Phases, Microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures. J Alloy Comp. 2014;589:143. https://doi.org/10.1016/j.jallcom.2013.11.084.

Yang YTF, Xia SQ, Liu S, Wang CX, Liu SS, Zhang Y, Xue JM, Yan S, Wang YG. Effects of Al addition on microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloy. Mater Sci Eng A. 2015;648:15. https://doi.org/10.1016/j.msea.2015.09.034.

Niu C, Zaddach AJ, Oni AA, Sang X, Hurt JW III, LeBeau JM, Koch CC, Irving DL. Spin-driven ordering of Cr in the equiatomic high entropy alloy NiFeCrCo. Appl Phys Lett. 2015;106(16):299. https://doi.org/10.1063/1.4918996.

Ding Q, Zhang Y, Chen X, Fu X, Chen D, Chen S, Gu L, Wei F, Bei H, Gao Y. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature. 2019;574(7777):223. https://doi.org/10.1038/s41586-019-1617-1.

Tong Y, Zhao S, Bei H, Egami Y, Zhang YF. Severe local lattice distortion in Zr- and/or Hf-containing refractory multi-principal element alloys. Acta Mater. 2020;183:172. https://doi.org/10.1016/j.actamat.2019.11.026.

Chen XX, Wang Q, Cheng Z, Zhu M, Zhou H, Jiang P, Zhou L, Xue Q, Yuan F, Zhu J, Wu X. Direct observation of chemical short-range order in a medium-entropy alloy. Nature. 2021;592(7856):712. https://doi.org/10.1038/s41586-021-03428-z.

Xu XD, Liu P, Guo S, Hirata A, Fujita T, Nieh T, Liu CT, Chen MW. Nanoscale phase separation in a fcc-based CoCrCuFeNiAl0.5 high-entropy alloy. Acta Mater. 2015;84:145. https://doi.org/10.1016/j.actamat.2014.10.033.

Afa B, Gol C, Ammb D, Kasatikov S, Scherb S, Huthwelker T, Acapito F, Schumacher G. Short-range chemical order and local lattice distortion in a compositionally complex alloy - ScienceDirect. Acta Mater. 2020;193:329. https://doi.org/10.1016/j.actamat.2020.04.034.

Fernández-Caballero A, Wróbel JS, Mummery PM, Nguyen-Manh D. Short-range order in high entropy alloys: theoretical formulation and application to Mo-Nb-Ta-V-W system. J Phase Equilib Diffus. 2017;38(4):391. https://doi.org/10.1007/s11669-017-0582-3.

Körmann F, Ruban AV, Sluiter MHF. Long-ranged interactions in bcc NbMoTaW high-entropy alloys. Mater Res Lett. 2017;5(1):35. https://doi.org/10.1080/21663831.2016.1198837.

Pan Y, Pu DL, Yu ED. Structural, electronic, mechanical and thermodynamic properties of Cr–Si binary silicides from first-principles investigations. Vacuum. 2020;185: 110024. https://doi.org/10.1016/j.vacuum.2020.110024.

Yurchenko N, Stepanov N, Salishchev G. Laves-phase formation criterion for high-entropy alloys. Mater Sci Technol MST Publ Inst Metals. 2017;704:82. https://doi.org/10.1080/02670836.2016.1153277.

Stepanov ND, Shaysultanov DG, Ozerov MS, Zherebtsov SV, Salishchev GA. Second phase formation in the CoCrFeNiMn high entropy alloy after recrystallization annealing. Mater Lett. 2016;185:1. https://doi.org/10.1016/j.matlet.2016.08.088.

Stepanov ND, Yurchenko NY, Sokolovsky VS, Tikhonovsky MA, Salishchev GA. An AlNbTiVZr0.5 high-entropy alloy combining high specific strength and good ductility. Mater Lett. 2015;161:136. https://doi.org/10.1016/j.matlet.2015.08.099.

Pan Y, Guan WM. The hydrogenation mechanism of PtAl and IrAl thermal barrier coatings from first-principles investigations. Int J Hydrogen Energy. 2020;45(38):20032. https://doi.org/10.1016/j.ijhydene.2020.04.290.

Wang L, Chen SS, Li BL, Cao TQ, Wang BP, Wang L, Ren Y, Liang J, Xue YF. Lightweight Zr1.2V0.8NbTiAl high-entropy alloys with high tensile strength and ductility. Mater Sci Eng, A. 2021;814: 141234. https://doi.org/10.1016/j.msea.2021.141234.

Zhang Y, Zuo TT, Tang Z, Gao MC, Dahmen KA, Liaw PK, Lu ZP. Microstructures and properties of high-entropy alloys. Prog Mater Sci. 2014;61:1. https://doi.org/10.1016/j.pmatsci.2013.10.001.

Liu WH, Lu ZP, He JY, Luan JH, Wang ZJ, Liu B, Li Y, Chen MW, Liu CT. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 2016;116:332. https://doi.org/10.1016/j.actamat.2016.06.063.

Ming K, Bi X, Wang J. Precipitation strengthening of ductile Cr15Fe20Co35Ni20Mo10 alloys. Scripta Mater. 2017;137:88. https://doi.org/10.1016/j.scriptamat.2017.05.019.

He JY, Wang H, Huang HL, Xu XD, Chen MW, Wu Y, Liu XJ, Nieh TG, An K, Lu ZP. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016;102:187. https://doi.org/10.1016/j.actamat.2015.08.076.

Gwalani B, Soni V, Lee M, Mantri SA, Ren Y, Banerjee R. Optimizing the coupled effects of Hall-Petch and precipitation strengthening in a Al0.3CoCrFeNi high entropy alloy. Mater Des. 2017;121:254. https://doi.org/10.1016/j.matdes.2017.02.072.

Wang ZG, Zhou W, Fu LM, Wang JF, Luo RC, Han XC, Chen B, Wang XD. Effect of coherent L12 nanoprecipitates on the tensile behavior of a fcc-based high-entropy alloy. Mater Sci Eng. 2017;696:503. https://doi.org/10.1016/j.msea.2017.04.111.

Zhao YL, Yang TY, Tong Y, Wang T, Luan JH, Jiao ZB, Chen D, Yang YY, Hu A, Liu CT, Kai JJ. Heterogeneous precipitation behavior and stacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy. Acta Mater. 2017;138:72. https://doi.org/10.1016/j.actamat.2017.07.029.

Wani IS, Bhattacharjee T, Sheikh S, Bhattacharjee PP, Guo S, Tsuji N. Tailoring nanostructures and mechanical properties of AlCoCrFeNi2.1 eutectic high entropy alloy using thermo-mechanical processing. Mater Sci Eng. 2016;675:99. https://doi.org/10.1016/j.msea.2016.08.048.

Li Z, Pradeep KG, Deng Y, Raabe D, Tasan CC. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature. 2016;534(7606):227. https://doi.org/10.1038/nature17981.

Lu Y, Gao X, Jiang L, Chen Z, Wang T, Jie J, Kang H, Zhang Y, Guo S, Ruan H, Zhao Y, Cao Z, Li T. Directly cast bulk eutectic and near-eutectic high entropy alloys with balanced strength and ductility in a wide temperature range. Acta Mater. 2017;124:143. https://doi.org/10.1016/j.actamat.2016.11.016.

Choi WM, Hee Y, Dong J, Kim G, Su S. A thermodynamic modelling of the stability of sigma phase in the Cr-Fe-Ni-V high-entropy alloy system. J Phase Equilib Diffus. 2018;39(5):694. https://doi.org/10.1007/s11669-018-0672-x.

Liang YJ, Wang LJ, Wen YR, Chen BY, Wu QL, Cao TQ, Xiao Q, Xue YF, Sha G, Wang Y, Ren Y, Li X, Wang L, Wang FC, Cai HN. High-content ductile coherent nanoprecipitates achieve ultrastrong high-entropy alloys. Nat Commun. 2018;8:1. https://doi.org/10.1038/s41467-018-06600-8.

Gwalani B, Soni V, Choudhuri D, Lee M, Hwang JY, Nam SJ, Banerjee R. Stability of ordered L1(2) and B-2 precipitates in face centered cubic based high entropy alloys-Al0.3CoFeCrNi and Al0.3CuFeCrNi2. Scripta Mater. 2016;123:130. https://doi.org/10.1016/j.scriptamat.2016.06.019.

Acknowledgements

This study was financially supported by the China Postdoctoral Science Foundation (No. 2019M660482). Use of the Advanced Photon Source is supported by the U. S. Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CH11357. We thank Dr. S.B. Jin and Dr. G. Sha at the Materials Characterization Facility of Nanjing University of Science for APT characterization.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Liu, X., Ke, HB., Wang, L. et al. A cluster-plus-glue-atom composition design approach designated for multi-principal element alloys. Rare Met. 41, 3839–3849 (2022). https://doi.org/10.1007/s12598-022-02094-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-022-02094-y