Abstract

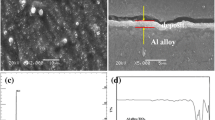

The thermal oxide layer formed of TA15 alloy has poor corrosion resistance. In this paper, the changes of the elements and components on the surface after laser ablation with different energy densities (E) were researched. The formation process and corrosion behavior of laser-generated oxide layer were clarified. As E increases, the oxygen content decreases from 8.52% to 5.43% and then increases to 11.89%. The surface oxide layer changes from TiO2(R) (i.e., rutile) to Ti2O3 + TiO2(R) and finally becomes TiO2(R) + TiO2(A) (i.e., anatase). The TiO2(R) gasification was confirmed by calculating the surface temperature rise. The surface reoxidation process was illustrated by a thermodynamically calculated ∆G-T(i.e., the Gibbs free energy changes with temperature). When E ≥ 17.5 J·cm−2, the oxide layer exhibits an agitated morphology, and oxide falls off at the bottom. As E increases, the corrosion rate decreases first and then increases. With energy density of 8.75 J·cm−2, the surface corrosion rate was 20.43 times slower than that of the untreated sample. The impedance spectrum and equivalent resistance results also prove the best corrosion resistance at 8.75 J·cm−2. The corrosion behavior of the oxide layer is analyzed from the properties of the oxide layer components and the reaction products with the electrolyte.

Graphic abstract

Similar content being viewed by others

References

Xiong Y, Guan C, Zhu S, Wang F. Effect of enamel coating on oxidation and hot corrosion behaviors of Ti–24Al–14Nb–3V alloy. J Mater Eng Perform. 2006;15(5):564.

Wang Y, Zhao W, Wu Y, Liu G, Wu X. Micro/nano-structures transition and electrochemical response of Ti–6Al–4V alloy in simulated seawater. Surf Topogr Metrol Prop. 2018;6(3):034009.

Shankar AR, Mudali UK. Refractory oxide coatings on titanium for nitric acid applications, metallurgical and materials transactions a-physical metallurgy and materials. Science. 2014;45A(8):3560.

Abey S, Mathew MT, Lee DJ, Knoernschild KL, Wimmer MA, Sukotjo C. Electrochemical behavior of titanium in artificial saliva: influence of pH. J Oral Implantol. 2014;40(1):3.

AlShaer AW, Li L, Mistry A. The effects of short pulse laser surface cleaning on porosity formation and reduction in laser welding of aluminium alloy for automotive component manufacture. Opt Laser Technol. 2014;64:162.

Wang Q, Guan Y, Cong B, Qi B. Laser cleaning of commercial Al alloy surface for tungsten inert gas welding. J Laser Appl. 2016;28(2):025007.

Aerni HR, Kobler B, Rutishauser BV, Wettstein FE, Fischer R, Giger W, Hungerbuhler A, Marazuela MD, Peter A, Schonenberger R, Vogeli AC, Suter MJF, Eggen RIL. Combined biological and chemical assessment of estrogenic activities in wastewater treatment plant effluents. Anal Bioanal Chem. 2004;378(3):688.

Sun S, Wu G, Sun L, Shan X, Li M, Ji S. Effects of different surface treatments of aluminum alloy 5083 on interlaminar strength and anticorrosion properties of FMLs. Mater Res Express. 2018;5(11):116506.

Qiang W, Yingchun G, Baoqiang C, Bojin Q. 008-Laser cleaning of commercial Al alloy surface for tungsten inert gas welding. J Laser Appl. 2016;28(2):022507.

See TL, Liu Z, Cheetham S, Dilworth S, Li L. Laser abrading of carbon fibre reinforced composite for improving paint adhesion. Appl Phys A Mater Sci Process. 2014;117(3):1045.

Zhang FD, Liu H, Suebka C, Liu YX, Liu Z, Guo W, Cheng YM, Zhang SL, Li L. Corrosion behaviour of laser-cleaned AA7024 aluminium alloy. Appl Surf Sci. 2018;435:452.

Kumar A, Sapp M, Vincelli J, Gupta MC. A study on laser cleaning and pulsed gas tungsten arc welding of Ti–3Al–2.5V alloy tubes. J Mater Process Technol. 2010;210(1):64.

Ageev EI, Andreeva YM, Karlagina YY, Kolobov YR, Manokhin SS, Odintsova GV, Slobodov AA, Veiko VP. Composition analysis of oxide films formed on titanium surface under pulsed laser action by method of chemical thermodynamics. Laser Phys. 2017;27(4):046001.

Whitehead DJ, Crouse PL, Schmidt MJJ, Li L, Turner MW, Smith AJE. Monitoring laser cleaning of titanium alloys by probe beam reflection and emission spectroscopy. Appl Phys A Mater Sci Process. 2008;93(1):123.

Heakal FE-T, Ghoneim AA, Mogoda AS, Awad K. Electrochemical behaviour of Ti–6Al–4V alloy and Ti in azide and halide solutions. Corros Sci. 2011;53(9):2728.

Shanaghi A, Chu PK. Investigation of corrosion mechanism of NiTi modified by carbon plasma immersion ion implantation (C-PIII) by electrochemical impedance spectroscopy. J Alloys Compd. 2019;790:1067.

Yang X, Du C, Wan H, Liu Z, Li X. Influence of sulfides on the passivation behavior of titanium alloy TA2 in simulated seawater environments. Appl Surf Sci. 2018;458:198.

Hu T, Chu C, Xin Y, Wu S, Yeung KWK, Chu PK. Corrosion products and mechanism on NiTi shape memory alloy in physiological environment. J Mater Res. 2010;25(2):350.

Hashinokuchi M, Tode M, Yoshigoe A, Teraoka Y, Okada M. Oxidation of TiAl surface with hyperthermal oxygen molecular beams. Appl Surf Sci. 2013;276:276.

Wang RM, Chu CL, Hu T, Dong YS, Guo C, Sheng XB, Lin PH, Chung CY, Chu PK. Surface XPS characterization of NiTi shape memory alloy after advanced oxidation processes in UV/H2O2 photocatalytic system. Appl Surf Sci. 2007;253(20):8507.

Kitamura Y, Okinaka N, Shibayama T, Mahaney OOP, Kusano D, Ohtani B, Akiyama T. Combustion synthesis of TiO2 nanoparticles as photocatalyst. Powder Technol. 2007;176(2–3):93.

Mizusawa M, Stoev KN, Sakurai K. Density gradient of a mirror-polished rutile (110) surface: X-ray reflectivity evaluation. Jpn J Appl Phys Part 1 Reg Pap Short Notes Rev Pap. 2003;42(6A):3709.

Arafin S, Singh RN. Thermal and physical properties of titanium oxide at high pressure. J Phys Chem Solids. 2016;99:86.

Pinto MA, Cheung N, Ierardi MCF, Garcia A. Microstructural and hardness investigation of an aluminum–copper alloy processed by laser surface melting. Mater Charact. 2003;50(2–3):249.

Kumar S, Chattopadhyay K, Mahobia GS, Singh V. Hot corrosion behaviour of Ti–6Al–4V modified by ultrasonic shot peening. Mater Des. 2016;110:196.

Koh YH, Kim HW, Kim HE. Improvement in oxidation resistance of TiB2 by formation of protective SiO2 layer on surface. J Mater Res. 2001;16(1):132.

Sekimoto H, Uda T, Nose Y, Sato S, Kakiuchi H, Awakura Y. Reduction of titanium oxide in the presence of nickel by nonequilibrium hydrogen gas. J Mater Res. 2009;24(7):2391.

Tal-Gutelmacher E, Eliezer D. High fugacity hydrogen effects at room temperature in titanium based alloys. J Alloy Compd. 2005;404:613.

Yuan B, Zheng Y, Wang Y, Chen Q, Gong L, Lv M. Effect of temperature on hydrogen absorption characteristic and microstructural evolution of TC21 alloy. J Alloys Compd. 2015;648:794.

Periyat P, Pillai SC, McCormack DE, Colreavy J, Hinder SJ. Improved high-temperature stability and sun-light-driven photocatalytic activity of sulfur-doped anatase TiO2. J Phys Chem C. 2008;112(20):7644.

Yudoyono G., NurIchzan, Zharvan V., Daniyati R., Santoso H., Indarto B., Pramono Y. H., Zainuri M., Darminto, Effect of calcination temperature on the photocatalytic activity of TiO2 powders prepared by co-precipitation of TiCl3, Edited by Sutikno, Khairurrijal, H. Susanto, R. Suryana, K. Triyana and Markusdiantoro, 3rd International Conference on Advanced Materials Science and Technology, Semarang, Indonesia, 2016;020099.

Albetran HM, O’Connor BH, Low IM. Effect of pressure on TiO2 crystallization kinetics using in situ high-temperature synchrotron radiation diffraction. J Am Ceram Soc. 2017;100(7):3199.

Wang J, Mishra AK, Zhao Q, Huang L. Size effect on thermal stability of nanocrystalline anatase TiO2. J Phys D Appl Phys. 2013;46(25):255303.

Kordouli E, Dracopoulos V, Vaimakis T, Bourikas K, Lycourghiotis A, Kordulis C. Comparative study of phase transition and textural changes upon calcination of two commercial titania samples: a pure anatase and a mixed anatase-rutile. J Solid State Chem. 2015;232:42.

Osiceanu P. An XPS study on ion beam induced oxidation of titanium silicide. Appl Surf Sci. 2006;253(1):381.

Adams DP, Murphy RD, Saiz DJ, Hirschfeld DA, Rodriguez MA, Kotula PG, Jared BH. Nanosecond pulsed laser irradiation of titanium: oxide growth and effects on underlying metal. Surf Coat Technol. 2014;248:38.

Suzuki S, Kosaka T, Sato S, Saito M, Matsubara E, Waseda Y. GIXS/AES study of polycrystalline titanium and titanium oxide films sputtered on Si substrate. Phys Status Solidi A Appl Res. 1997;161(1):193.

Kim Y, Mitsugi F, Tomoaki I, Hokamoto K, Itoh S. Shock-consolidated TiO2 bulk with pure anatase phases fabricated by explosive compaction using underwater shockwave. J Eur Ceram Soc. 2011;31(6):1033.

Kavan L, Zukalova M, Ferus M, Kuerti J, Koltai J, Civis S. Oxygen-isotope labeled titania: (TiO2)-O-18. Phys Chem Chem Phys. 2011;13(24):11583.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51861165202 and 51705173) and the Science and Technology Planning Project of Guangdong Province (No. 2017B090913001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, BW., Mi, GY. & Wang, CM. Reoxidation process and corrosion behavior of TA15 alloy by laser ablation. Rare Met. 40, 865–876 (2021). https://doi.org/10.1007/s12598-020-01553-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01553-8