Abstract

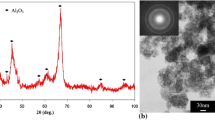

Anticorrosion deposits were prepared on Al alloy substrate surface by a hydrolysis process. In this paper, a hydrolysis reaction technique was applied to prepare TiO2 deposit on Al alloy surface by formation of Al2O3 particles at home temperature. The prepared deposits were investigated using scanning electron microscopy (SEM), X-ray diffraction (XRD), energy dispersive spectrometer (EDS), X-ray photoelectron spectroscopy (XPS), and Fourier-transform infrared spectroscopy (FTIR). The amorphous TiO2 was characterized by potentiodynamic polarization and electrochemical impedance spectroscopy (EIS) methods and the anticorrosion performance in 0.1 M NaCl solution was evaluated by electrochemical measurements. The value of the E corr can positive shift from − 685 to − 539 mV in 0.1 M NaCl. The results indicated that the TiO2 layer provided good barrier on Al alloy surface with Al2O3 particles, and the amorphous TiO2 deposit decreased Al alloy corrosion rate by self-sacrifice. This amorphous deposit can be applied as a protection layer at the Al alloy surface by simple hydrolysis reaction.

Similar content being viewed by others

References

Tamborim SM, Dias SLP, Silva SN, Dick LFP, Azambuja DS (2011) Preparation and electrochemical characterization of amoxicillin-doped cellulose acetate films for AA2024-T3 aluminum alloy coatings. Corros Sci 53(4):1571–1580. https://doi.org/10.1016/j.corsci.2011.01.034

Ho WK, Yu JC, Lee SC (2007) Photocatalytic activity and photo-induced hydrophilicity of mesoporous TiO2 thin films coated on aluminum substrate. Appl Catal B: Enviro 73(1-2):135–143. https://doi.org/10.1016/j.apcatb.2006.06.019

Borisova D, Mohwald H, Shchukin DG (2013) Influence of embedded nanocontainers on the efficiency of active anticorrosive coatings for aluminum alloys part ii: influence of nanocontainer position. ACS Appl Mater Interfaces 5(1):80–87. https://doi.org/10.1021/am302141y

Skorb E, Shchukin D, Möhwald H, Andreeva D (2010) Sonochemical design of cerium-rich anticorrosion nanonetwork on metal surface. Langmuir 26(22):16973–16979. https://doi.org/10.1021/la100677d

Carreira AF, Pereira AM, Vaz EP, Cabral AM, Ghidini T, Pigliaru L, Rohr T (2017) Alternative corrosion protection pretreatments for aluminum alloys. J Coat Technol Res 14(4):879–892. https://doi.org/10.1007/s11998-017-9922-9

Calabrese LG, Bonaccorsi LC, Capr AL, Proverbio E (2016) Assessment of hydrophobic and anticorrosion properties of composite silane–zeolite coatings on aluminum substrate. J Coat Technol Res 13(2):287–297. https://doi.org/10.1007/s11998-015-9760-6

Zuo M, Wu TT, Xu KG, Liu SQ, Zhao DG, Geng HR (2015) Sol–gel route to ceria coatings on AA2024-T3 aluminum alloy. J Coat Technol Res 12(1):75–83. https://doi.org/10.1007/s11998-014-9621-8

Popoola API, Daniyan AA, Umoru LE, Fayomi OSI (2017) Effect of WO3 nanoparticle loading on the microstructural, mechanical and corrosion resistance of Zn matrix/TiO2-WO3 nanocomposite coatings for marine application. J Marine Sci 16:102–109. https://doi.org/10.1007/s11804-017-1389-7

Andreeva DV, Skorb EV, Shchukin DG (2010) Layer-by-layer polyelectrolyte/inhibitor nanostructures for metal corrosion protection. ACS Appl Mater Interfaces 2(7):1954–1962. https://doi.org/10.1021/am1002712

Sonnenschein MF, Michael CC (2002) Effect of interfacial energetics on the protection of steel and aluminum surfaces by alkyl acid coatings. Langmuir 18(9):3578–3584. https://doi.org/10.1021/la011572f

Pan XM, Wu JS, Ge YZ, Xiao K, Luo H, Gao SJ, Li XG (2014) Preparation and characterization of anticorrosion Ormosil sol–gel coatings for aluminum alloy. J Sol-Gel Sci Technol 72(1):8–20. https://doi.org/10.1007/s10971-014-3414-5

Liang J, Hu YC, Fan YH, Chen H (2013) Formation of superhydrophobic cerium oxide surfaces on aluminum substrate and its corrosion resistance properties. Surf Interface Anal 45(8):1211–1216. https://doi.org/10.1002/sia.5255

Borisova D, Möhwald H, Shchukin DG (2011) Mesoporous silica nanoparticles for active corrosion protection. ACS Nano 5(3):1939–1946. https://doi.org/10.1021/nn102871v

Neoh KG, Kang ET (2011) Combating bacterial colonization on metals via polymer coatings: relevance to marine and medical applications. ACS Appl Mater Interfaces 3(8):2808–2819. https://doi.org/10.1021/am200646t

Yuan SJ, Pehkonen SO, Ting YP, Neoh KG, Kang ET (2009) Inorganic-organic hybrid coatings on stainless steel by layer-by-layer deposition and surface-initiated atom-transfer-radical polymerization for combating biocorrosion. ACS Appl Mater Interfaces 3:640–652. https://doi.org/10.1021/am800182d

Schem M, Schmidt T, Gerwann J, Wittmar M, Veith M, Thompson GE, Molchan IS, Hashimoto T, Skeldon P, Phani AR, Santucci S, Zheludkevich ML (2009) CeO2-filled sol–gel coatings for corrosion protection of AA2024-T3 aluminium alloy. Corro Sci 51(10):2304–2315. https://doi.org/10.1016/j.corsci.2009.06.007

Sonawane SH, Teo BM, Brotchie A, Grieser F, Ashokkumar M (2010) Sonochemical synthesis of ZnO encapsulated functional nanolatex and its anticorrosive performance. Ind Eng Chem Res 49(5):2200–2205. https://doi.org/10.1021/ie9015039

Zhao F, Gao YF, Luo HJ (2009) Reactive formation of zircon inclusion pigments by deposition and subsequent annealing of a zirconia and silica double shell. Langmuir 25(23):13295–13297. https://doi.org/10.1021/la903197t

Ertaş FS, Kaş R, Mikó A, Birer Ö (2013) Anticorrosion efficiency of ultrasonically deposited silica coatings on titanium. Appl Surf Sci 276:810–816. https://doi.org/10.1016/j.apsusc.2013.03.176

Lei CX, Zhou H, Wang C, Feng ZD (2013) Self-assembly of ordered mesoporous TiO2 thin films as photoanodes for cathodic protection of stainless steel. Electrochim Acta 87:245–249. https://doi.org/10.1016/j.electacta.2012.09.089

Bamoulid L, Maurette MT, De Caro D, Guenbour A, Ben Bachir A, Aries L, El Hajjaji S, Benoît-Marquié F, Ansart F (2008) An efficient protection of stainless steel against corrosion: combination of a conversion layer and titanium dioxide deposit. Surf & Coat Technol 202(20):5020–5026. https://doi.org/10.1016/j.surfcoat.2008.05.011

Lin WC, Chen CH, Tang HY, Hsiaoc YC, Pan JR, Hu CC, Huang C (2013) Electrochemical photocatalytic degradation of dye solution with a TiO2-coated stainless steel electrode prepared by electrophoretic deposition. Appl Catal B-Environ 140-141:32–41. https://doi.org/10.1016/j.apcatb.2013.03.032

Lenz DM, Delamar M, Ferreira CA (2003) Application of polypyrrole/TiO2 composite films as corrosion protection of mild steel. J Electroanal Chem 540:35–44. https://doi.org/10.1016/S0022-0728(02)01272-X

Shen GX, Chen YC, Lin CJ (2005) Corrosion protection of 316 L stainless steel by a TiO2 nanoparticle coating prepared by sol–gel method. Thin Solid Films 489(1-2):130–136. https://doi.org/10.1016/j.tsf.2005.05.016

Barati N, Faghihi Sani MA (2009) Coating of titania nanoparticles on stainless steel using an alkoxide precursor. Prog Color Colorants Coat 2:71–78

Mansour P, Sanaz N (2017) Potency of commercial TiO2-P25 nanoparticles to form stainless steel protective coating. Int J Appl Ceram Technol 3:433–442. https://doi.org/10.1111/ijac.12661

Liu W, Wang YG, Su G, Cao LX, Sun ML, Guo XQ, Xu HM, Duan RJ (2012) The effect of incorporating carbon nanotubes in titania films used for the photocathode protection of 304 stainless steel. Carbon 50(10):3641–3648. https://doi.org/10.1016/j.carbon.2012.03.036

Dang TD, Bui TTH (2017) The electrowetting and corrosion characterizations of anodized as-prepared titanium dioxide nanotube. J Electron Mater 46(6):3279–3284. https://doi.org/10.1007/s11664-017-5412-1

Karabudak F, Yeşildal R, Süküroğlu EE, Şüküroğlu S, Zamanlou H, Dikbaş N, Bayındır F, Şen S, Totik Y (2017) An investigation of corrosion resistance and antibacterial sensitivity properties of nano-Ag-doped $$\text {TiO}_{2}$$ TiO 2 coating and $$\text {TiO}_{2}$$ TiO 2 coating grown on NiTi alloy with the micro-arc oxidation process. Arab J Sci Eng 42(6):2329–2339. https://doi.org/10.1007/s13369-017-2463-9

Wang MQ, Yan J, Cui HP, Du SG (2013) Low temperature preparation and characterization of TiO2 nanoparticles coated glass beads by heterogeneous nucleation method. Mater Charact 76:39–47. https://doi.org/10.1016/j.matchar.2012.12.002

Lei CX, Zhou H, Feng ZD, Zhu YF, Du RG (2011) Low-temperature liquid phase deposited TiO2 films on stainless steel for photogenerated cathodic protection applications. Appl Surf Sci 257(16):7330–7334. https://doi.org/10.1016/j.apsusc.2011.03.122

Lamaka SV, Zheludkevich ML, Yasakau KA, Serra R, Poznyak SK, Ferreira MGS (2007) Nanoporous titania interlayer as reservoir of corrosion inhibitors for coatings with self-healing ability. Prog Org Coat 58(2-3):127–135. https://doi.org/10.1016/j.porgcoat.2006.08.029

Zhang L, Chen L, Wan HQ, Chen JM, Zhou HD (2011) Synthesis and tribological properties of stearic acid-modified anatase (TiO2) nanoparticles. Tribol Lett 41(2):409–416. https://doi.org/10.1007/s11249-010-9724-z

Zhang Y, Liu JH, Li YD, Yu M, Li SM, Xue B (2015) Fabrication of inhibitor anion-intercalated layered double hydroxide host films on aluminum alloy 2024 and their anticorrosion properties. J Coat Technol Res 12(2):293–302. https://doi.org/10.1007/s11998-014-9644-1

Zhu YF, Zhang L, Wang L, Tan RQ, Cao LL (2001) Interface diffusion and reaction between TiO2 film photocatalyst and aluminium alloy substrate. Surf Interface Anal 32(1):218–223. https://doi.org/10.1002/sia.1041

Maikki C, Muhammad M, Mary OS, Emma MH, Brendan D, Mohamed O (2017) Correlation between the structure and the anticorrosion barrier properties of hybrid sol–gel coatings: application to the protection of AA2024-T3 alloys. J Sol-Gel Sci Technol 82:801–816. https://doi.org/10.1007/s10971-017-4349-4

Ghasemi E, Ramezanzadeh B, Saket S, Ashhari S (2016) Electrochemical investigation of the epoxy nanocomposites containing MnAl2O4 and CoAl2O4 nanopigments applied on the aluminum alloy 1050. J Coat Technol Res 13(1):97–114. https://doi.org/10.1007/s11998-015-9728-6

Cotolan N, Pop A, Marconi D, Ponta O, Muresan LM (2015) Corrosion behavior of TiO2-coated Ti-6Al-7Nb surfaces obtained by anodic oxidation in sulfuric or acetic acid. Mater Corros 66(7):635–642. https://doi.org/10.1002/maco.201407687

Reboul MC, Baroux B (2011) Metallurgical aspects of corrosion resistance of aluminium alloys. Mater Corros 629(3):215–233. https://doi.org/10.1002/maco.201005650

Funding

The financial support from Department of science and technology of Qinghai province (Grant No. 2016-ZJ-945Q) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Wu, L. Synthesis of self-sacrifice amorphous titanium dioxide-coated aluminum via hydrolysis reaction for anticorrosion application. Ionics 24, 2905–2913 (2018). https://doi.org/10.1007/s11581-017-2400-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2400-7