Abstract

Zn–Fe and Y-modified Zn–Fe coatings were prepared on 42CrMo steel through pack cementation processes at 370, 390 and 410 °C for 4 h. Y modification was achieved through the co-deposition of Zn and Y2O3. The effects of Y modification on microstructure, formation and corrosion behavior of the Zn–Fe coating were investigated. The coating thickness increased with an increase in temperature. The Y-modified Zn–Fe coating was thicker than the plain Zn–Fe coating. Both the Zn–Fe coating and Y-modified Zn–Fe coating showed single-layered structures, but the overall microstructure was improved by Y modification. The activation energies for Zn–Fe coating and Y-modified Zn–Fe coating were 113.15 and 80.65 kJ·mol−1, respectively. The Zn–Fe coating consisted of FeZn13 and Fe11Zn40 phases. The effects of Y modification on the corrosion behavior of the Zn–Fe coating were evaluated through an immersion test and polarization measurements. The results showed that the corrosion resistance was improved by Y modification.

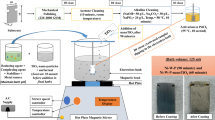

Graphic abstract

Similar content being viewed by others

References

Wang X, Wang H, Liu X, Hou C, Song X. Microstructure and performance of WC-Co-Cr coating with ultrafine/nanocrystalline structures. Rare Met. 2018;37(11):968.

Tachibana K, Morinaga Y, Mayuzumi M. Hot dip fine Zn and Zn-Al alloy double coating for corrosion resistance at coastal area. Corros Sci. 2007;49(1):149.

Barchi L, Bardi U, Caporali S, Fantini M, Scrivani A. Electroplated bright aluminium coatings for anticorrosion and decorative purposes. Prog Org Coat. 2010;67(2):146.

Qiao Y, Shen Z, Guo X. Co-deposition of Si and B to form oxidation-resistant coatings on an Nb-Ti-Si based ultrahigh temperature alloy by pack cementation technique. Corros Sci. 2015;93:126.

Majumdar S, Sengupta P, Kale GB, Sharma IG. Development of multilayer oxidation resistant coatings on niobium and tantalum. Surf Coat Technol. 2006;200(12–13):3713.

Knittel S, Mathieu S, Portebois L, Drawin S, Vilasi M. Development of silicide coatings to ensure the protection of Nb and silicide composites against high temperature oxidation. Surf Coat Technol. 2013;235:401.

Qiao M, Zhou C. Codeposition of Co and Al on nickel base superalloys by pack cementation process. Surf Coat Technol. 2012;206(11–12):2899.

Sánchez L, Bolívar FJ, Hierro MP, Pérez FJ. Effect of Ce and La additions in low temperature aluminization process by CVD-FBR on 12%Cr ferritic/martensitic steel and behaviour in steam oxidation. Corros Sci. 2008;50(8):2318.

Li L, Li H, Lin H, Zhuang L, Wang S, Feng T, Yao X, Fu Q. Comparison of the oxidation behaviors of SiC coatings on C/C composites prepared by pack cementation and chemical vapor deposition. Surf Coat Technol. 2016;302:56.

Michel G, Berthod P, Vilasi M, Mathieu S, Steinmetz P. Protection of cobalt-based refractory alloys by chromium deposition on surface: part I: sub-surface enrichment in chromium by pack-cementation and diffusion. Surface and Coatings Technol. 2011;205(12):3708.

Ebrahimifar H, Zandrahimi M. Mn coating on AISI 430 ferritic stainless steel by pack cementation method for SOFC interconnect applications. Solid State Ion. 2011;183(1):71.

Hamlaoui Y, Tifouti L, Pedraza F. On the corrosion resistance of porous electroplated zinc coatings in different corrosive media. Corros Sci. 2010;52(6):1883.

Marder AR. The metallurgy of zinc-coated steel. Prog Mater Sci. 2000;45(3):191.

Li Y, Xie F, Wu X, Li X. Effects of Y2O3 on the microstructures and wear resistance of Si–Al–Y co-deposition coatings prepared on Ti–Al alloy by pack cementation technique. Appl Surf Sci. 2013;287:30.

Zhang P, Guo X. Y and Al modified silicide coatings on an Nb–Ti–Si based ultrahigh temperature alloy prepared by pack cementation process. Surf Coat Technol. 2011;206(2–3):446.

Mert F, Blawert C, Kainer KU, Hort N. Influence of cerium additions on the corrosion behaviour of high pressure die cast AM50 alloy. Corros Sci. 2012;65:145.

Bouayad A, Gerometta C, Belkebir A, Ambari A. Kinetic interactions between solid iron and molten aluminium. Mater Sci Eng A. 2003;363(1–2):53.

Xiang ZD, Datta PK. Pack aluminisation of low alloy steels at temperatures below 700 °C. Surf Coat Technol. 2004;184(1):108.

Zhao X, Zhou C. Effect of Y2O3 content in the pack on microstructure and hot corrosion resistance of Y-Co-modified aluminide coating. Corros Sci. 2014;86:223.

Tsipas SA, Omar H, Perez FH, Tsipas DN. Boroaluminide coatings on ferritic martensitic steel deposited by low-temperature pack cementation. Surf Coat Technol. 2008;202(14):3263.

Fu X, Shen W, Yao T. Physical chemistry. Beijing: Higher Education Press; 1990. 159.

Cheng J, Yi S, Park JS. Simultaneous coating of Si and B on Nb-Si-B alloys by a halide activated pack cementation method and oxidation behaviors of the alloys with coatings at 1100°C. J Alloys Compd. 2015;644:975.

Hu G, Cai X, Rong Y. Fundamentals of materials science. Shanghai: Profile of Shanghai Jiao Tong University Press; 2000. 144.

Cheng XH, Xie CY. Effect of rare earth elements on the erosion resistance of nitrided 40Cr steel. Wear. 2003;254(5–6):415.

Liu Z, Zhao X, Zhou C. Improved hot corrosion resistance of Y-Ce-Co-modified aluminide coating on nickel base superalloys by pack cementation process. Corros Sci. 2015;92:148.

Peng B, Wang J, Su X, Li Z, Yin F. Effects of zinc bath temperature on the coatings of hot-dip galvanizing. Surf Coat Technol. 2008;202(9):1785.

Stavros AJ. Hot dip coatings: ASM Handbook, vol. 13. New York: ASM International; 1987. 432.

Jordan CE, Goggins KM, Marder AR. Interfacial layer development in hot-dip galvanneal coatings on interstitial free (IF) steel. Metall Mater Trans A. 1994;25(10):2101.

Price GDS, Charles J. Effects of microstructure and of protective coatings on the attack on steel by molten Zn. J Iron Steel Inst. 1973;211(12):871.

Davies JL, Glover CF, Van de Langkruis J, Zoestbergen E, Williams G. The effect of Mg concentration on the resistance of PVD Zn-Mg coatings to corrosion driven organic coating delamination. Corros Sci. 2015;100:607.

Vourlias G, Pistofidis N, Chaliampalias D, Pavlidou E, Patsalas P, Stergioudis G, Tsipas D, Polychroniadis EK. A comparative study of the structure and the corrosion behavior of zinc coatings deposited with various methods. Surf Coat Technol. 2006;200(22–23):6594.

Orjuela GA, Rincón R, Olaya JJ. Corrosion resistance of niobium carbide coatings produced on AISI 1045 steel via thermo-reactive diffusion deposition. Surf Coat Technol. 2014;259:667.

Xing X, Wang H, Lu P, Han Z. Influence of rare earths on electrochemical corrosion and wear resistance of RE-Cr/Ti pack coatings on cemented 304 stainless steel. Surf Coat Technol. 2016;291:151.

Li S, Gao B, Yin S, Tu G, Zhu G, Sun S, Zhu X. The effects of RE and Si on the microstructure and corrosion resistance of Zn–6Al–3Mg hot dip coating. Appl Surf Sci. 2015;357:2004.

Yuan ZX, Yu ZS, Tan P, Song SH. Effect of rare earths on the carburization of steel. Mater Sci Eng, A. 1999;267(1):162.

Lin N, Xie F, Zhong T, Wu X, Tian W. Influence of adding various rare earths on microstructures and corrosion resistance of chromizing coatings prepared via pack cementation on P110 steel. J Rare Earth. 2010;28(2):301.

Wang KL, Zhang QB, Sun ML, Wei XG, Zhu YM. Microstructure and corrosion resistance of laser clad coatings with rare earth elements. Corros Sci. 2001;43(2):255.

Acknowledgements

This work was financially supported by the Natural Science Foundation of Shandong Province of China (No. ZR2017LEM004), the Open Fund of Key Laboratory of Oil & Gas Equipment, Ministry of Education (Southwest Petroleum University) (No. OGE201702-07) and the Fundamental Research Funds for the Central Universities (Nos. 16CX06020A and 18CX02091A).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, L., Yu, SR. & Cao, WA. Zn–Fe and Y-modified Zn–Fe coatings on 42CrMo steel via pack cementation. Rare Met. 40, 2266–2274 (2021). https://doi.org/10.1007/s12598-020-01540-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01540-z