Abstract

The irradiation resistance of pre-deformed FeCu alloy was studied using a 3 MeV Fe ion irradiation experiment at room temperature in comparison with that of the as-received sample. Nanoindentation and atom probe tomography (APT) were used to characterize the mechanical properties and solute distribution. The stress–strain curve obtained by nanoindentation shows that the yield strength (σ0.2) of the pre-deformed sample is unexpectedly reduced with an increase in the irradiation dose to five displacements per atom (dpa). We suggest that it results both from the decrease in the dislocation density and the suppression of defects during irradiation. APT shows that the nucleation of the Cu cluster is suppressed; however, its growth is promoted in the pre-deformed sample, resulting in the formation of sparse and coarse clusters at 1 dpa irradiation. These coarse Cu clusters were then unexpectedly refined to finer grains with an increase in the irradiation dose to 5 dpa. Theoretically, the improvement in the resistance to irradiation in the pre-deformed sample is attributed to the dense point-defect sinks, that is, the dislocations and grain boundaries introduced by pre-deformation. In addition, the contributions of the dislocations and grain boundaries to the sink strength are estimated for both the as-received and pre-deformed samples. The results indicate that dislocations, rather than grain boundaries, play a major role after deformation.

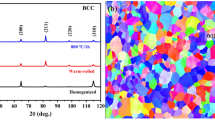

Graphic abstract

Similar content being viewed by others

References

Odette G, Lucas G. Embrittlement of nuclear reactor pressure vessels. JOM. 2001;53(7):18.

Styman PD, Hyde JM, Parfitt D, Wilford K, Burke MG, English CA, Efsing P. Post-irradiation annealing of Ni–Mn–Si-enriched clusters in a neutron-irradiated RPV steel weld using Atom Probe Tomography. J Nucl Mater. 2015;459:127.

Barhate VN, Agrawal KS, Patil VS, Mahajan AM. Post-deposition-annealed lanthanum-doped cerium oxide thin films: structural and electrical properties. Rare Met. 2020. https://doi.org/10.1007/s12598-020-01380-x.

Zhang T, Wang H, Li Z, Schut H, Zhang Z, He M, Sun Y. Positron annihilation investigation of embrittlement behavior in Chinese RPV steels after Fe-Ion irradiation. Acta Metall Sin. 2018;54(4):512.

Lee GG, Jin HH, Chang K, Kwon J. Atom probe tomography analysis of radiation-induced solute clustering in austenite stainless steels. Radiat Eff Defects Solids. 2018;173(7–8):694.

Liu X, Miao Y, Li M, Kirk MA, Maloy SA, Stubbins JF. Ion-irradiation-induced microstructural modifications in ferritic/martensitic steel T91. J Nucl Mater. 2017;490(1):305.

Pascuet MI, Martínez E, Monnet G, Malerba L. Solute effects on edge dislocation pinning in complex alpha-Fe alloys. J Nucl Mater. 2017;494:311.

Was GS. Fundamentals of Radiation Materials Science: Metals and Alloys. New York: Springer; 2016. 230.

Bai XM, Voter AF, Hoagland RG, Nastasi M, Uberuaga BP. Efficient annealing of radiation damage near grain boundaries via interstitial emission. Science. 2010;327(5973):1631.

Ackland G. Controlling radiation damage. Science. 2010;327(5973):1587.

El-Atwani O, Esquivel E, Aydogan E, Martinez E, Baldwin JK, Li M, Uberuaga BP, Maloy SA. Unprecedented irradiation resistance of nanocrystalline tungsten with equiaxed nanocrystalline grains to dislocation loop accumulation. Acta Mater. 2019;165:118.

Shang Z, Fan C, Xue S, Ding J, Li J, Voisin T, Wang YM, Wang H, Zhang X. Response of solidification cellular structures in additively manufactured 316 stainless steel to heavy ion irradiation: an in situ study. Mater Res Lett. 2019;7(7):290.

Song M, Wang M, Lou X, Rebak RB, Was GS. Radiation damage and irradiation-assisted stress corrosion cracking of additively manufactured 316L stainless steels. J Nucl Mater. 2019;513:33.

Zhan ZJ, Li X, Cao HY. Design and properties of new Fe-Cu composites. Chin J Rare Met. 2020;2:153.

Lu Q, Su Q, Wang F, Zhang C, Lu Y, Nastasi M, Cui B. Influence of laser shock peening on irradiation defects in austenitic stainless steels. J Nucl Mater. 2017;489:203.

Miller MK, Sokolov MA, Nanstad RK, Russell KF. APT characterization of high nickel RPV steels. J Nucl Mater. 2006;351(1–3):187.

Miller MK, Russell KF, Sokolov MA, Nanstad RK. APT characterization of irradiated high nickel RPV steels. J Nucl Mater. 2007;361(2–3):248.

Egeland GW, Valdez JA, Maloy SA, McClellan KJ, Sickafus KE, Bond GM. Heavy-ion irradiation defect accumulation in ZrN characterized by TEM, GIXRD, nanoindentation, and helium desorption. J Nucl Mater. 2013;435(1–3):77.

Williamson G, Hall W. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953;1(1):22.

Renzetti RA, Sandim HRZ, Bolmaro RE, Suzuki PA, Möslang A. X-ray evaluation of dislocation density in ODS-Eurofer steel. Mater Sci Eng A. 2012;534:142.

Ungár T, Dragomir I, Révész Á, Borbély A. The contrast factors of dislocations in cubic crystals: the dislocation model of strain anisotropy in practice. J Appl Crystallogr. 1999;32(5):992.

Takebayashi S, Kunieda T, Yoshinaga N, Ushioda K, Ogata S. Comparison of the dislocation density in martensitic steels evaluated by some X-ray diffraction methods. ISIJ Int. 2010;50(6):875.

Odette G, Lombrozo P, Wullaert R. Relationship between irradiation hardening and embrittlement of pressure vessel steels. In: Effects of Radiation on Materials: 12th International Symposium Volume II. West Conshohocken: ASTM International; 1985, 840.

Kalidindi SR, Pathak S. Determination of the effective zero-point and the extraction of spherical nanoindentation stress–strain curves. Acta Mater. 2008;56(14):3523.

Pathak S, Kalidindi SR, Klemenz C, Orlovskaya N. Analyzing indentation stress–strain response of LaGaO3 single crystals using spherical indenters. J Eur Ceram Soc. 2008;28(11):2213.

Sneddon IN. The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int J Eng Sci. 1965;3(1):47.

Oliver WC, Pharr GM. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res. 1992;7(6):1564.

Donohue BR, Ambrus A, Kalidindi SR. Critical evaluation of the indentation data analyses methods for the extraction of isotropic uniaxial mechanical properties using finite element models. Acta Mater. 2012;60(9):3943.

Pathak S, Kalidindi SR, Weaver JS, Wang Y, Doerner RP, Mara NA. Probing nanoscale damage gradients in ion-irradiated metals using spherical nanoindentation. Sci Rep. 2017;7(1):11918.

Pathak S, Kalidindi SR. Spherical nanoindentation stress–strain curves. Mater Sci Eng R Rep. 2015;91:1.

Taylor GI. The mechanism of plastic deformation of crystals. Part I. Theoretical. Proc R Soc Lond Ser A Contain Pap Math Phys Charact. 1934;145(855):362.

Mansur LK. Irradiation creep by climb-enabled glide of dislocations resulting from preferred absorption of point defects. Philos Mag A. 1979;39(4):497.

Heald PT, Speight MV. Steady-state irradiation creep. Philos Mag. 1974;29(5):1075.

van Duysen JC, Meric de Bellefon G. 60th Anniversary of electricity production from light water reactors: historical review of the contribution of materials science to the safety of the pressure vessel. J Nucl Mater. 2017;484:209.

Wolfer WG. The dislocation bias. J Comput Aided Mater Des. 2007;14(3):403.

Acknowledgements

This study was financially supported by the National Key Research and Development Program (Nos. 2016YFB0700401 and 2017YFB0305304) and the Basic Research and Development Program (No. JCYJ20170307153239266).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, H., Li, QL., Xu, B. et al. Improvement in irradiation resistance of FeCu alloy by pre-deformation through introduction of dense point defect sinks. Rare Met. 40, 885–896 (2021). https://doi.org/10.1007/s12598-020-01539-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01539-6