Abstract

The successful joining of carbon fiber-reinforced aluminum matrix (Cf/Al) composites and TC4 alloy can produce composite structure and meet the demands of lightweight in aerospace field. Up to now, few experimental researches have been reported on the joining of Cf/Al composites and TC4 alloy. In this study, the AgCu foils and Ni–Al–Zr compact were designed for the self-propagating high-temperature synthesis joining of these two materials. Cf/Al composites were joined with a reactive Ti plated on its joining surface. The typical microstructure of TC4/(AgCu/Ni–Al–Zr/AgCu)/Ti/Cf/Al joint was analyzed, and the effects of joining condition on microstructural evolution of the SHS joint were investigated. A thin reaction layer of Ni–Al–Ti intermetallic compounds was formed adjacent to the TC4 alloy. As a result, AgCu foils could reduce the effect of reaction heat on the substrates and improve the joint shear strength. When the thickness of AgCu foils reaches 150 μm, the Ni–Al–Zr interlayer mainly acts as auxiliary heat source. High joining pressure caused the active elements to diffuse into Cf/Al composites and weakened the shear strength of the joint. Finally, the joint shear strength could reach 36.4 MPa when the AgCu foils were 50 μm and the joining pressure was 2 MPa.

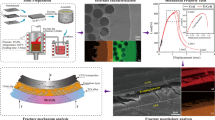

Graphic abstract

Similar content being viewed by others

References

Galyshev S, Gomzin A, Musin F. Aluminum matrix composite reinforced by carbon fibers. Mater Today Proc. 2019;11:281.

Qi LH, Ma YQ, Zhou JM, Hou XH, Li HJ. Effect of fiber orientation on mechanical properties of 2D-Cf/Al composites by liquid–solid extrusion following Vacuum infiltration technique. Mater Sci Eng A. 2015;625:343.

Daguang L, Guoqin C, Longtao J, Ziyang X, Yunhe Z, Gaohui W. Effect of thermal cycling on the mechanical properties of Cf/Al composites. Mater Sci Eng A. 2013;586:330.

Kashaev N, Ventzke V, Riekehr S, Dorn F, Horstmann M. Assessment of alternative joining techniques for Ti–6Al–4V/CFRP hybrid joints regarding tensile and fatigue strength. Mater Des. 2015;81:73.

Pan L, Wang CM, Xiao SF, Chen YG. Hydrogenation behaviors and characteristics of bulk Ti–6Al–4V alloy at different isothermal temperatures. Rare Met. 2019;38:1131.

Zhang LX, Chang Q, Sun Z, Yang ZY, Feng JC. Diffusion bonding of hydrogenated TC4 alloy and GH3128 superalloy using composite interlayers. J Mater Process Technol. 2019;274:1.

Cao J, Song XG, Li C, Zhao LY, Feng JC. Brazing ZrO2 ceramic to Ti–6Al–4V alloy using NiCrSiB amorphous filler foil: interfacial microstructure and joint properties. Mater Charact. 2013;81:85.

Zhou YH, Liu D, Niu HW, Song XG, Yang XD, Feng JC. Vacuum brazing of C/C composite to TC4 alloy using nano-Al2O3 strengthened AgCuTi composite filler. Mater Des. 2016;93:347.

He P, Liu YZ, Liu D. Interfacial microstructure and forming mechanism of brazing Cf/Al composite with Al–Si filler. Mater Sci Eng A. 2006;422(1–2):333.

Lee M, Choi Y, Sugio K, Matsugi K, Sasaki G. Effect of aluminum carbide on thermal conductivity of the unidirectional CF/Al composites fabricated by low pressure infiltration process. Compos Sci Technol. 2014;97:1.

Morsi K. Review: reaction synthesis processing of Ni–Al intermetallic materials. Mater Sci Eng A. 2001;299(1–2):1.

Ma ML, Zhang YZ, Zan X, Liu JQ, Zhu XY, Cheng YC. Status and development of self-propagating high-temperature synthesis of high melting point powders. Chin J Rare Met. 2018;42(11):1210.

Liu LZ, Ying GB, Zhu J, Lin H, Zhu CC. High-temperature compressive properties of TiC–TiB2/Cu composites prepared by self-propagating high-temperature synthesis. Rare Met. 2014;33(1):95.

Li ZR, Feng GJ, Xu K, Zhang X. Microstructure and formation mechanism of SHS joining between Cf/Al composites and TiAl intermetallic with Al–Ni–CuO interlayer. Rare Met. 2015;34(1):17.

Fiedler T, Belova IV, Broxtermann S, Murch GE. A thermal analysis on self-propagating high temperature synthesis in joining technology. Comput Mater Sci. 2012;53:251.

Lin YC, McGinn PJ, Mukasyan AS. High temperature rapid reactive joining of dissimilar materials: silicon carbide to an aluminum alloy. J Eur Ceram Soc. 2012;32(14):3809.

Pascal C, Marin-Ayral RM, Tédenac JC. Joining of nickel monoaluminide to a superalloy substrate by high pressure self-propagating high-temperature synthesis. J Alloys Compd. 2002;337(1–2):221.

Cao J, Wang HQ, Qi JL, Lin XC, Feng JC. Combustion synthesis of TiAl intermetallics and their simultaneous joining to carbon/carbon composites. Scr Mater. 2011;65(3):261.

Rosa R, Veronesi P, Han S, Casalegno V, Salvo M, Colombini E, Leonelli C, Ferraris M. Microwave assisted combustion synthesis in the system Ti–Si–C for the joining of SiC: experimental and numerical simulation results. J Eur Ceram Soc. 2013;33(10):1707.

Feng GJ, Li ZR, Jacob RJ, Yang Y, Wang Y, Zhou Z, Sekulic DP, Zachariah MR. Laser-induced exothermic bonding of carbon fiber/Al composites and TiAl alloys. Mater Des. 2017;126:197.

Feng GJ, Li ZR, Feng SC, Zhang WJ. Microstructure evolution and formation mechanism of laser-ignited SHS joining between Cf/Al composites and TiAl alloys with Ni–Al–Ti interlayer. Rare Met. 2017;36(9):746.

Zeng K, Schmid-Fetzer R, Huneau B, Rogl P, Bauer J. The ternary system Al ± Ni ± Ti Part I: isothermal section at 900°C; experimental investigation and thermodynamic calculation. Intermetallics. 1999;7(12):1337.

Dȩbski A, Gąsior W, Sypień A, Góral A. Enthalpy of formation of intermetallic phases from Al–Ni and Al–Ni–Ti systems. Intermetallics. 2013;42:92.

Simões S, Viana F, Ramos AS, Vieira MT, Vieira MF. Diffusion bonding of TiAl to Ti6Al4V using nanolayers. J Mater Eng Perform. 2018;27(10):5064.

Feng GJ, Li ZR, Zhou Z, Yang Y, Sekulic DP, Zachariah MR. Microstructure and mechanical properties of Cf/Al-TiAl laser-assisted brazed joint. J Mater Process Technol. 2018;255:195.

Feng GJ, Li ZR, Zhou Z, Wang Y. Joining of Cf/Al composites and TiAl intermetallics by laser-induced self-propagating high-temperature synthesis using the Ni–Al–Zr interlayer. Mater Des. 2016;110:130.

Niu GB, Wang DP, Yang ZW, Wang Y. Microstructure and mechanical properties of Al2O3/TiAl joints brazed with B powders reinforced Ag–Cu–Ti based composite fillers. Ceram Int. 2017;43(1):439.

Dai X, Cao J, Wang Z, Wang X, Chen L, Huang Y, Feng J. Brazing ZrO2 ceramic and TC4 alloy by novel WB reinforced Ag–Cu composite filler: microstructure and properties. Ceram Int. 2017;43(17):15296.

Dai X, Cao J, Liu J, Wang D, Feng J. Interfacial reaction behavior and mechanical characterization of ZrO2/TC4 joint brazed by Ag–Cu filler metal. Mater Sci Eng A. 2015;646:182.

Shi JM, Feng JC, Liu H, Tian XY, Zhang LX. Vacuum brazing of the Gr/2024Al composite and TC4 alloy using AgCuTi filler alloy with Ni–Al interlayer as auxiliary heat source. J. Alloys Compd. 2017;694:672.

Li ZR, Feng GJ, Wang S, Feng SC. High-efficiency joining of Cf/Al composites and TiAl alloys under the heat effect of laser-ignited self-propagating high-temperature synthesis. J Mater Sci Technol. 2016;32(11):1111.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51975149 and 51905055) and the Central Universities Project (No. 2019CDXYCL0031).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, L., Li, ZR., Feng, GJ. et al. Self-propagating synthesis joining of Cf/Al composites and TC4 alloy using AgCu filler with Ni–Al–Zr interlayer. Rare Met. 40, 1817–1824 (2021). https://doi.org/10.1007/s12598-020-01520-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01520-3