Abstract

Ti(C,N) nanoparticles were added to an Al–0.3Ce alloy by ultrasonic treatment. Further annealing at 570 °C for 4 h afforded the ultimate tensile strength of 79 MPa and electrical conductivity of 64.0% IACS for the Al–0.3Ce alloy with 1.5 vol% Ti(C,N) addition. Both performance parameters were improved by 23.4% and 0.6% IACS, respectively, compared with those of casting refining pure aluminum (64 MPa and 63.4% IACS). This could be explained by the following reasons. The addition of Ti(C,N) nanoparticles could significantly refine the grain of Al–0.3Ce alloy. Notably, most of the coarse strip-shaped second phases distributed at the grain boundaries in Al–0.3Ce were also transformed into spherical microparticles distributed in the grains, with micro–nano hierarchical structures comprising orientated nanosized strip phases with lengths of ~ 400 nm and widths of ~ 100 nm. Moreover, a fine micro–nano hierarchical spherical structure could be obtained after annealing at 570 °C for 4 h. The numbers of micro–nano hierarchical spherical structures also increased due to the precipitation of pseudosolution Ce from the aluminum matrix during the annealing treatment.

Similar content being viewed by others

References

Polmear IJ. Light alloys from traditional alloys to nanocrystals. 4th ed. Amsterdam: Elsevier; 2006. 421.

Sauvage X, Bobruk EV, Murashkin MY, Nasedkina Y, Enikeev NA, Valiev RZ. Optimization of electrical conductivity and strength combination by structure design at the nanoscale in Al–Mg–Si alloys. Acta Mater. 2015;98:355.

Maravić M. A nanostructural design to produce high-strength Al alloys with enhanced electrical conductivity. Scr Mater. 2014;76:13.

Murashkin MY, Sabirov I, Medvedev AE, Enikeev NA, Lefebvre W, Valiev RZ, Sauvage X. Mechanical and electrical properties of an ultrafine grained Ale-8.5wt% RE (RE = 5.4wt% Ce, 3.1wt% La) alloy processed by severe plastic deformation. Mater. Design. 2016;90:433.

Murashkin MY, Sabirov I, Sauvage X, Valiev RZ. Nanostructured Al and Cu alloys with superior strength and electrical conductivity. J Mater Sci. 2016;51(1):33.

Sadler Barry A. Light metals 2013 (sadler, light), development and research of new aluminium alloys with transition and rare-earth metals and equipment for production of wire for electrotechnical applications by methods of combined processing. Hoboken: Wiley; 2013. 443.

Li D, Wang S, Zhao Y. The effect of rare earth to inclusions in Al–Cu alloy. J Spec Cast Nonferrous Alloys. 1989;01:15.

Pan FS, Zhou SZ, Shi GQ, Ding PD. The research and application of rare-earth aluminum alloy. Light Alloy Fabr Technol. 1990;18:1.

Yi He, Xiangjie Yang, Yongbo Zhu, Xiaokai Zhang. Microstructure and refining mechanism of Al–Ce master alloy. Chin J Rare Met. 2018;42(4):350.

Li PF, Wu ZG, Wang YL, Wang XZ, Li ZQ. Effect of cerium on mechanical performance and electrical conductivity of aluminum rod for electrical purpose. J Rare Earth. 2006;24(1):355.

Xu GF, Mou SZ, Yang JJ, Jin TN. Effect of trace rare earth element Er on Al–Zn–Mg alloy. Trans Nonferrous Met Soc China. 2006;16(3):598.

Liao H, Liu Y, Changlã EL, Wang QG. Mechanisms for Ce-induced remarkable improvement of conductivity in Al alloys. J Mater Res. 2016;32(03):566.

Akbari MK, Baharvandi HR, Shirvanimoghaddam K. Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites. Mater Des. 2015;66:150.

Sajjadi SA, Parizi MT, Ezatpour HR, Sedghi A. Fabrication of A356 composite reinforced with micro and nano Al2O3 particles by a developed compocasting method and study of its properties. J Alloy Compd. 2012;511(1):226.

Borodianskiy K, Kossenko A, Zinigrad M. Improvement of the mechanical properties of Al–Si alloys by TiC nanoparticles. Metall Mater Trans A. 2013;44(11):4948.

Nair SV, Tien JK, Bates RC. SiC-reinforced aluminum metal matrix composites. Int Met Rev. 1985;30(1):275.

Wang K, Jiang HY, Wang QD, Ye B, Ding W. A novel method to achieve grain refinement in aluminum. Metall Mater Trans A. 2016;47(10):4788.

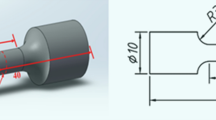

Li WP, Mao J, Feng J. Aluminium grain refinement by Ti(C, N) nanoparticles additions: principles, advantages and drawbacks. Metall Res Technol. 2019;116(2):212.

Tsunekawa Y, Suzuki H, Genma Y. Application of ultrasonic vibration to in situ MMC process by electromagnetic melt stirring. Mater Des. 2001;22(6):467.

Jiang J, Li LC. Ultrasonic-assisted synthesis of core-shell structure Zn0.5Cr0.5Fe2O4/TiO2 nanocomposites in w/o microemulsion. J Alloy Compd. 2008;456(1–2):220.

Inui S, Higashiyama S, Hashimoto K, Higashiyama M, Yoshikawa K, Taniguchi N. Reinforcement fracture and tensile ductility in sphere-reinforced metal-matrix composites. Fatigue Fract Eng Mater Struct. 2010;20(5):689.

Wang TM, Zheng YP, Chen ZN, Zhao YF, Kang HJ. Effects of Sron the microstructure and mechanical properties of in situ TiB2 reinforced A356composite. Mater Des. 2014;64:185.

Wang K, Cui CX, Wang Q, Qi YM, Wang C. Fabrication of in situ AlN–TiN/Al inoculant and its refining efficiency and reinforcing effect on commercially pure aluminum. J Alloys Compd. 2013;547:5.

Wang K, Jiang HY, Wang YX, Wang QD, Ye B, Ding WJ. Microstructure and mechanical properties of hypoeutectic Al–Si composite reinforced with TiCN nanoparticles. Mater Des. 2016;95:545.

Sylwestrowicz W, Hall EO. The deformation and ageing of mild steel. Proc Phys Soc. 2002;64(6):495.

Petch NJ. The cleavage strength of polycrystals. J Iron Steel Inst. 1953;174:25.

Rossiter PL. The electrical re sistivity of metals and alloys. Cambridge: Cambridge University Press; 1987. 6.

Liao HC, Liu Y, Lü CL, Wang QG. Effect of Ce addition on castability, mechanical properties and electric conductivity of Al–0.3Si–0.2Mg alloy. Cast Met. 2015;28(4):213.

Wei F, Mao J, Liu CF, Liu HH. Effect of trace elements La, Ti and homogenization on electrical properties of pure aluminum. Rare Met Mater Eng. 2018;47(11):3257.

Shangguan D, Ahuja S, Stefanescu DM. An analytical model for the interaction between an insoluble particle and an advancing solid/liquid interface. Metall Trans A. 1992;23(2):669.

Cicco MPD, Wang D, Li XC. An investigation of nanoparticle wetting, grain refinement and mechanical property enhancement in aluminum matrix nanocomposites. Hoboken: Wiley; 2011. 2.

Ning YT, Zhou XM, Dai H. Metastable extension of solid solubility of rare earth elements in Al. Acta Metall Sin. 1992;5(11):327.

Hosseinifar M, Malakhov D. Effect of Ce and La on microstructure and properties of a 6xxx series type aluminum alloy. J Mater Sci. 2008;43(22):7157.

Acknowledgements

This study was financially supported by Panxi Strategic Resources Innovation Development Fund of Sichuan Province (No. 1840STC30704/01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, WP., Zhang, YL. & Mao, J. Enhanced strength and electrical conductivity of Al–0.3Ce alloy simultaneously with Ti(C,N) nanoparticle addition. Rare Met. 40, 1890–1896 (2021). https://doi.org/10.1007/s12598-020-01465-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01465-7