Abstract

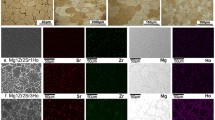

Magnesium alloys exhibit significant potential for use in next-generation biodegradable materials. Implanted magnesium alloys are expected to exhibit good wear resistance. In this work, the effects of rare earth metal Sc on the wear resistance of biodegradable magnesium alloys were studied. The average grain sizes of Mg–1.5Zn–0.6Zr–xSc (ZK21–xSc, x = 0, 0.2, 0.5, 1.0; wt%) alloys decreased with Sc content increasing. Unlike other rare earth metals, the grain refinement mechanism of Sc belongs to the heterogeneous nucleation mechanism. The yield tensile strengths and Vickers hardness of the ZK21–xSc alloys markedly improved with the addition of Sc increasing. This could be due to the grain refinement and enhanced bond energy resulting from Sc addition. Moreover, the friction and wear tests showed that the friction coefficient of the alloys decreased and the weight loss reduced with Sc addition increasing. This implies that Sc addition could enhance the wear resistance of magnesium alloys. With the addition of Sc increasing, the peeling phenomenon weakened gradually and the worn surfaces of samples became smoother. The major wear mechanisms of the as-cast ZK21–xSc alloys were abrasion wear and delamination wear.

Graphic abstract

Similar content being viewed by others

References

Pan H, Qin G, Huang Y, Ren Y, Sha X, Han X, Liu ZQ, Li C, Wu X, Chen H, He C, Chai L, Wang Y, Nie JF. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater. 2018;149:350.

Luo AA. Recent magnesium alloy development for elevated temperature applications. Int Mater Rev. 2004;49(1):13.

Tan L, Zhang XY, Xia T, Huang GJ, Liu Q. Fracture morphology and crack mechanism in pure polycrystalline magnesium under tension-compression fatigue testing. Rare Met. 2020;39(2):162.

Zhao X, Ning Z, Li Z, Zou W, Li B, He K, Cao F, Sun J, Luo AA. In-mold oxidation behavior of Mg–4.32Y–2.83Nd–0.41Zr alloy. J Mater Sci. 2018;53(15):11091.

Wang JL, Wan Y, Ma ZJ, Guo YC, Yang Z, Wang P, Li JP. Glass-forming ability and corrosion performance of Mn-doped Mg–Zn–Ca amorphous alloys for biomedical applications. Rare Met. 2018;37(7):579.

Xie XB, Chen M, Liu P, Shang JX, Liu T. Synergistic catalytic effects of the Ni and V nanoparticles on the hydrogen storage properties of Mg–Ni–V nanocomposite. Chem Eng J. 2018;347:145.

Wan DQ. Strain amplitude-dependent internal friction of as-cast high damping magnesium alloy during cyclic vibration. Rare Met. 2013;32(1):25.

Kim JH, An BM, Lim DH, Park JY. Electricity production and phosphorous recovery as struvite from synthetic wastewater using magnesium-air fuel cell electrocoagulation. Water Res. 2018;132:200.

Liu E, Yu S, Ji Z, Niu Y, Xiong W, Cao N. Preparation, microstructure and properties of fly ash cenosphere/Mg alloy composites for degradable fracturing ball applications. Chin J Rare Met. 2019;43(8):792.

Zheng YF, Gu XN, Witte F. Biodegradable metals. Mater Sci Eng R. 2014;77:1.

Zhao D, Witte F, Lu F, Wang J, Li J, Qin L. Current status on clinical applications of magnesium-based orthopaedic implants: a review from clinical translational perspective. Biomaterials. 2017;112:287.

Chen Y, Xu Z, Smith C, Sankar J. Recent advances on the development of magnesium alloys for biodegradable implants. Acta Biomater. 2014;10(11):4561.

Liu DB, Wu B, Wang X, Chen MF. Corrosion and wear behavior of an Mg–2Zn–0.2Mn alloy in simulated body fluid. Rare Met. 2013;34(8):553.

Haude M, Erbel R, Erne P, Verheye S, Degen H, Böse D, Vermeersch P, Wijnbergen I, Weissman N, Prati F, Waksman R, Koolen J. Safety and performance of the drug-eluting absorbable metal scaffold (DREAMS) in patients with de-novo coronary lesions: 12 month results of the prospective, multicentre, first-in-man BIOSOLVE-I trial. Lancet. 2013;381(9869):836.

Huang L, Su K, Zheng YF, Yeung KWK, Liu XM. Construction of TiO2/silane nanofilm on AZ31 magnesium alloy for controlled degradability and enhanced biocompatibility. Rare Met. 2019;38(6):588.

Zeng RC, Qi WC, Cui HZ, Zhang F, Li SQ, Han EH. In vitro corrosion of as-extruded Mg–Ca alloys—the influence of Ca concentration. Corros Sci. 2015;96:23.

Li T, He Y, Zhou J, Tang S, Yang Y, Wang X. Influence of albumin on in vitro degradation behavior of biodegradable Mg–1.5Zn–0.6Zr–0.2Sc alloy. Mater Lett. 2018;217:227.

Li T, He Y, Wu J, Zhou J, Tang S, Yang Y, Wang X. Effects of scandium addition on the in vitro degradation behavior of biodegradable Mg–1.5Zn–0.6Zr alloy. J Mater Sci. 2018;53(20):14075.

Esguerra-Arce J, Castaneda AB, Esguerra-Arce A, Aguilar Y, Mischler S. Fretting corrosion between bone and calcium phosphate-calcium titanate coatings. Wear. 2018;414:366.

Adetunla A, Akinlabi E. Influence of reinforcements in friction stir processed magnesium alloys: insight in medical applications. Mater Res Express. 2018;6(2):025406.

Shikinami Y, Kawabe Y, Yasukawa K, Tsuta K, Kotani Y, Abumi K. A biomimetic artificial intervertebral disc system composed of a cubic three-dimensional fabric. Spine J. 2010;10(2):141.

Mordike BL, Stulíková I, Smola B. Mechanisms of creep deformation in Mg–Sc-based alloys. Metall Mater Trans A. 2005;36(7):1729.

Mordike BL. Creep-resistant magnesium alloys. Mater Sci Eng A. 2002;324(1):103.

Ma N, Peng Q. Influence of scandium on corrosion properties and electrochemical behaviour of Mg alloys in different media. Int J Electrochem Sci. 2012;7(9):8020.

Li T, He Y, Zhou J, Tang S, Yang Y, Wang X. Microstructure and mechanical property of biodegradable Mg–1.5Zn–0.6Zr alloy with varying contents of scandium. Mater Lett. 2018;229:60.

Brar HS, Ball JP, Berglund IS, Allen JB, Manuel MV. A study of a biodegradable Mg–3Sc–3Y alloy and the effect of self-passivation on the in vitro degradation. Acta Biomater. 2013;9(2):5331.

Li T, He Y, Zhou J, Tang S, Yang Y, Wang X. Effects of scandium addition on biocompatibility of biodegradable Mg–1.5Zn–0.6Zr alloy. Mater Lett. 2018;215:200.

Lachine EE, Noujaim AA, Ediss C, Wieber LI. Toxicity, tissue distribution and excretion of 46ScCl3 and 46Sc-EDTA in mice. Int J Appl Radiat Isot. 1976;27(7):373.

Moghaddam-Banaem L, Jalilian AR, Pourjavid M, Bahrami-Samani A, Mazidi M, Ghannadi-Maragheh M. Preparation and quality control of scandium-46 bleomycin as a possible therapeutic agent. Iran J Nucl Med. 2012;20(1):19.

Li T, Zhang H, He Y, Wang X. Comparison of corrosion behavior of Mg–1.5Zn–0.6Zr and AZ91D alloys in a NaCl solution. Mater Corros. 2015;66(1):7.

Li T, Zhang H, He Y, Wen N, Wang X. Microstructure, mechanical properties and in vitro degradation behavior of a novel biodegradable Mg–1.5Zn–0.6Zr–0.2Sc alloy. J Mater Sci Technol. 2015;31(7):744.

Hort N, Huang Y, Fechner D, Störmer M, Blawert C, Witte F, Vogt C, Drücker H, Willumeit R, Kainer KU. Magnesium alloys as implant materials—principles of property design for Mg–RE alloys. Acta Biomater. 2010;6(5):1714.

Fu P, Peng L, Jiang H, Ma L, Zhai C. Chemical composition optimization of gravity cast Mg–yNd–xZn–Zr alloy. Mater Sci Eng A. 2008;496(1–2):177.

Wan YC, Jiang SN, Liu CM, Wang BZ, Chen ZY. Effect of Nd and Dy on the microstructure and mechanical property of the as extruded Mg–1Zn–0.6Zr alloy. Mater Sci Eng A. 2015;625:158.

Jiang J, Bi G, Liu J, Ye C, Lian J, Jiang Z. Microstructures and mechanical properties of extruded Mg–2Sn–xYb (x = 0, 0.1, 0.5 at%) sheets. J Magnes Alloys. 2014;2(3):257.

Fang D, Bi G, Wang L, Li G, Jiang Z. Microstructures and mechanical properties of Mg–2Y–1Mn–1–2Nd alloys fabricated by extrusion. Mater Sci Eng A. 2010;527(16–17):4383.

Li Q, Wang Q, Wang Y, Zeng X, Ding W. Effect of Nd and Y addition on microstructure and mechanical properties of as-cast Mg–Zn–Zr alloy. J Alloys Compd. 2007;427(1–2):115.

Liu CM, Zhu XR, Zhou HT. Phase Diagrams of Magnesium Alloys. Changsha: Central South University Press; 2006. 49.

Xie ZZ. Analysis on valence electron structure of Mg–Sc alloy. J Taiyuan Univ. 2010;11(4):135.

Archard JF. Contact and rubbing of flat surfaces. J Appl Phys. 1953;24(8):981.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 51174025), the National Key Research and Development Program of China (Nos. 2016YFB0301105 and 2017YFB0103904), Shandong Provincial Natural Science Foundation (No. ZR2017LEM002), the Specialized Fund for Shandong Postdoctoral Innovation Project (No. 201703093) and the Youth Science Funds of Shandong Academy of Sciences (No. 2018QN0034). Thank Yong He and Hai-Long Zhang at University of Science and Technology Beijing and Xi-Wei Liu at Lepu Medical Technology (Beijing) Co., Ltd. for meaningful discussion.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, T., Wang, XT., Tang, SQ. et al. Improved wear resistance of biodegradable Mg–1.5Zn–0.6Zr alloy by Sc addition. Rare Met. 40, 2206–2212 (2021). https://doi.org/10.1007/s12598-020-01420-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01420-6