Abstract

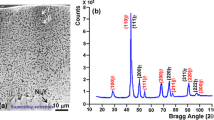

NiCoCrAlY is usually used as the material to bond-coat in thermal barrier coating systems under high temperatures. Using NiCoCrAlY and adding different amounts of the active element Ti (0, 0.1, 0.3, and 0.5; wt%), the relationship between oxide peg size and thermally grown oxide spalling resistance is ascertained by examining specimens subjected to a cyclic oxidation experiment. Oxide pegs, consisting of a Y- and Ti-rich oxide core and an outer Al2O3 sheath, are formed by Ti and Al successively reacting with oxygen after the rapid generation of Y-rich oxide. The size of the oxide pegs with higher Ti concentrations is on average bigger in the alloy. Severe thermally grown oxide spalling occurred in the 0.5 wt% Ti specimen, but in the 0.3 wt% Ti specimen, it displayed the best adherence with the alloy due to the presence of fine pegs. Cavities existed at the interface between the inner oxide core and outer Al2O3 sheath of larger pegs serve as microcrack sources and further induce severe scale failure combined with the initial interface crack between the scale and alloy.

Similar content being viewed by others

References

Pfeil LB. Improvements in heat resistant alloys. UK Patent, 459848; 1937.

Li MS, Zhang YM. A review on effect of reactive elements on oxidation of metals. Corros Sci Protect Technol. 2001;13(6):333.

Allam IM, Whittle DP, Stringer J. Improvements in oxidation resistance by dispersed oxide addition: Al2O3-forming alloys. Oxid Met. 1979;13(4):381.

Whittle DP, Stringer J. Improvements in high temperature oxidation resistance by additions of reactive elements or oxide dispersions. Philos Trans R Soc Lond A. 1980;295(1413):309.

Allam IM, Whittle DP, Stringer J. The oxidation behavior of CoCrAl systems containing active element additions. Oxid Met. 1978;12(1):35.

Mennicke C, He MY, Clarke DR, Smith JS. The role of secondary oxide inclusions (“pegs”) on the spalling resistance of oxide films. Acta Mater. 2000;48(11):2941.

Xu T, Faulhaber S, Mercer C, Maloney M, Evans A. Observations and analyses of failure mechanisms in thermal barrier systems with two phase bond coats based on NiCoCrAlY. Acta Mater. 2004;52(6):1439.

Mumm DR, Evans AG. On the role of imperfections in the failure of a thermal barrier coating made by electron beam deposition. Acta Mater. 2000;48(8):1815.

He MY, Evans AG, Hutchinson JW. Effects of morphology on the decohesion of compressed thin films. Mater Sci Eng A. 1998;245(2):168.

Evans AG, Mumm DR, Hutchinson JW, Meier GH, Pettit FS. Mechanisms controlling the durability of thermal barrier coatings. Prof Mater Sci. 2001;46(5):505.

Salam S, Hou PY, Zhang YD, Wang HF, Zhang C, Yang ZG. Compositional effects on the high-temperature oxidation lifetime of MCrAlY type coating alloys. Corros Sci. 2015;95:143.

Chen LC, Zhang C, Yang ZG. Effect of pre-oxidation on the hot corrosion of CoNiCrAlYRe alloy. Corros Sci. 2011;53(1):374.

Lan H, Yang ZG, Xia ZX, Zhang YD, Zhang C. Effect of dysprosium addition on the cyclic oxidation behaviour of CoNiCrAlY alloy. Corros Sci. 2011;53(4):1476.

Wang HF. Effects of reactive elements on the high temperature oxidation performance of CoNiCrAl alloy. Beijing: Tsinghua University; 2015. 80.

Barrett CA. Effect of 0.1 at% zirconium on the cyclic oxidation resistance of β-NiAl. Oxid Met. 1988;30(5–6):361.

Hamadi S, Bacos MP, Poulain M, Seyeux A, Maurice V, Marcus P. Oxidation resistance of a Zr-doped NiAl coating thermochemically deposited on a nickel-based superalloy. Surf Coat Technol. 2009;204(6–7):756.

Hamadi S, Bacos MP, Poulain M, Zanna S, Seyeux A, Maurice V, Marcus P. Oxidation of a Zr-doped NiAl bondcoat thermochemically deposited on a nickel-based superalloy. Mater High Temp. 2009;26(2):195.

Pint BA. The role of chemical composition on the oxidation performance of aluminide coatings. Surf Coat Technol. 2004;188–189:71.

Haynes JA, Pint BA, More KL, Zhang Y, Wright IG. Influence of sulfur, platinum, and hafnium on the oxidation behavior of CVD NiAl bond coatings. Oxid Met. 2002;58(5–6):513.

Yan K, Guo HB, Peng H, Gong SK. Oxidation behaviour of electron beam physical vapour deposition β-NiAlHf coatings at 1100 °C in dry and humid atmospheres. Rare Met. 2016;35(7):513.

Jedliński J, Mrowec S. The influence of implanted yttrium on the oxidation behaviour of β-NiAl. Mater Sci Eng. 1987;87:281.

Schumann E. The effect of Y-ion implantation on the oxidation of β-NiAl. Oxid Met. 1995;43(1–2):157.

Schumann E, Yang JC, Rühle M, Graham MJ. High-resolution SIMS and analytical TEM evaluation of alumina scales on β-NiAl containing Zr or Y. Oxid Met. 1996;46(1–2):37.

Salam S, Hou PY, Zhang YD, Lan H, Wang HF, Zhang C, Yang ZG. Element accumulation beneath the scale/alloy interface of a CoNiCrAlReY alloy. Corros Sci. 2014;89:318.

Lan H, Zhang WG, Yang ZG. Investigation of Pt-Dy co-doping effects on isothermal oxidation behavior of (Co, Ni)-based alloy. J Rare Earths. 2012;30(9):928.

He J, Zhang Z, Peng H, Gong SK, Guo HB. The role of Dy and Hf doping on oxidation behavior of two-phase (γ′ + β) Ni–Al alloys. Corros Sci. 2015;98:699.

Nijdam TJ, Sloof WG. Effect of reactive element oxide inclusions on the growth kinetics of protective oxide scales. Acta Mater. 2007;55(17):5980.

He J. Study on the mechanisms of reactive elements in the two phase (γ′ + β) Ni–Al alloys. Beijing: Beihang University; 2016. 89.

Chen XC, Shi CB, Guo HJ, Wang F, Ren H, Feng D. Investigation of oxide inclusions and primary carbonitrides in inconel 718 superalloy refined through electroslag remelting process. Metall Mater Trans B. 2012;43(6):1596.

Shi CB, Chen XC, Guo HJ, Zhu ZJ, Sun XL. Control of MgO·Al2O3 spinel inclusions during protective gas electroslag remelting of die steel. Metall Mater Trans B. 2013;44(2):378.

Acknowledgements

This study was financially supported by the Tsinghua University Initiative Scientific Research Program and the National Magnetic Confinement Fusion Energy Research Project of China (No. 2015GB118001). The authors also thank a lot for the discussion with Prof. Peggy Yen Hou from Materials Sciences Division, Lawrence Berkeley National Laboratory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Choi, R., Zheng, Y. et al. Spalling resistance of thermally grown oxide based on NiCoCrAlY(Ti) with different oxide peg sizes. Rare Met. 40, 663–670 (2021). https://doi.org/10.1007/s12598-019-01339-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01339-7