Abstract

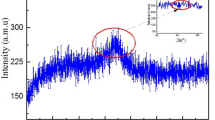

A new Fe-based amorphous–crystalline composite without non-metallic elements, Fe55Cr15Mo15Ni10W5, was prepared by melt-spinning. The formation ability and structure information were investigated by X-ray diffractometer (XRD), energy-dispersive spectrometer (EDS) and scanning electron microscope (SEM). The mechanical properties of the amorphous–crystalline composite were investigated by nanoindentation. A molecular dynamics simulation study was performed to simulate the formation of Fe55Cr15Mo15Ni10W5 amorphous alloy. The mechanical properties were obtained by compression simulations simultaneously. The results indicate that the Fe55Cr15Mo15Ni10W5 ribbon is an amorphous–crystalline composite structure with good ductility, and the hardness of the amorphous–crystalline composite is about 75% higher than that of master ingot. The simulation mechanical properties are in good agreement with the results of nanoindentation at the nanoscale.

Similar content being viewed by others

References

Trexler MM, Thadhani NN. Mechanical properties of bulk metallic glasses. Prog Mater Sci. 2010;55(8):759.

Kim YC, Hwang BC. Effects of metalloid elements on the mechanical properties of Fe-based bulk amorphous alloys. Korean J Mater Res. 2016;26(12):671.

Dong J, Gao M, Huan Y, Feng YH, Liu W, Wang WH. Enhanced tensile plasticity of Zr based bulk metallic glasses by a stress induced large scale flow. J Alloys Compd. 2017;727:297.

Inoue A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000;48(1):279.

Li Q, Liu SS, Wang XH, Yang T, Dong C, Hu JT, Jiang YQ. Mechanical and corrosion properties of Ti–Ni–Cu–Zr metallic glass matrix composites. J Alloys Compd. 2017;727:1344.

Yang S, Li D, Li XC, Zhang ZZ, Zhang SF, He L. Composition dependence of the microstructure and mechanical behavior of Ti–Zr–Cu–Pd–Sn–Nb bulk metallic glass composites. Intermetallics. 2017;90:1.

Zhang N, Liu Y, Yang W, Pang SJ. Formation and properties of a Zr-based amorphous coating by laser cladding. Rare Met. 2018. https://doi.org/10.1007/s12598-018-1113-z.

Niu SZ, Kou HC, Wang J, Li JS. Improved tensile properties. Rare Met. 2017. https://doi.org/10.1007/s12598-016-0860-y.

Zhang GP, Liu Y, Zhang B. Effect of annealing close to Tg on notch fracture toughness of Pd-based thin-film metallic glass for MEMS applications. Scripta Mater. 2006;54(5):897.

Wang G, Guo CX, Pang SJ. Thermal stability, mechanical properties and corrosion behavior of a Mg–Cu–Ag–Gd metallic glass with Nd addition. Rare Met. 2017;36(3):183.

Wang G, Huang YJ, Makhanlall D, Shen J. Resistance spot welding of Ti40Zr25Ni3Cu12Be20 bulk metallic glass: experiments and finite element modeling. Rare Met. 2017;36(2):123.

Chen LY, Hu HT, Zhang GQ, Jiang JZ. Catching the Ni-based ternary metallic glasses with critical diameter up to 3 mm in Ni–Nb–Zr system. J Alloys Compd. 2007;443(1–2):109.

Li J, Wang X, Yang G, Chen N, Liu X, Yao K. Enhanced plasticity of a Fe-based bulk amorphous alloy by thin Ni coating. Mat Sci Eng A. 2015;645:318.

Sun BA, Wang WH. The fracture of bulk metallic glasses. Prog Mater Sci. 2015;74:211.

Wei R, Chang Y, Yang S, Zhang CJ, He L. Strain rate sensitivity variation in CuZr-based bulk metallic glass composites containing B2-CuZr phase. Rare Met Mater Eng. 2016;45(3):542.

Rud AD, Schmidt U, Zelinska GM, Lakhnik AM, Kolbasov GY, Danilov MO. Atomic structure and hydrogen storage properties of amorphous–quasicrystalline Zr–Cu–Ni–Al melt-spun ribbons. J Non-Cryst Solids. 2007;353(32–40):3434.

Zhao K, Xia XX, Bai HY, Zhao DQ, Wang WH. Room temperature homogeneous flow in a bulk metallic glass with low glass transition temperature. Appl Phys Lett. 2011;98(14):141913.

Shen J, Chen QJ, Sun JF, Fan HB, Wang G. Exceptionally high glass-forming ability of an FeCoCrMoCBY alloy. Appl Phys Lett. 2005;86(15):151907.

Eckert J, Das J, Pauly S, Duhamel C. Mechanical properties of bulk metallic glasses and composites. J Mater Res. 2007;22(02):285.

Guo SF, Liu L, Li N, Li Y. Fe-based bulk metallic glass matrix composite with large plasticity. Scripta Mater. 2010;62(6):329.

Xiao ZY, Luo F, Tang CY, Chen L, Ngai TL. Study of amorphous phase in Fe100−x(NbTiTa)x alloys synthesized by mechanical alloying and its effect on the crystallization phenomenon. J Non-Cryst Solids. 2014;385:117.

Wang XY, Gong P, Deng L, Jin JS, Wang SB, Li FW. Sub-Tg annealing effect on the kinetics of glass transition and crystallization for a Ti-Zr-Be-Fe bulk metallic glass. J Non-Cryst Solids. 2017;473:132.

Qiu C, Zhu PZ, Fang FZ, Yuan DD, Shen XC. Study of nanoindentation behavior of amorphous alloy using molecular dynamics. Appl Surf Sci. 2014;305:101.

Zhou XL, Chen CQ. Strengthening and toughening mechanisms of amorphous/amorphous nanolaminates. Int J Plast. 2016;80:75.

Zhang WB, Li Q, Duan HM. Study of the effects of metalloid elements (P, C, B) on Fe-based amorphous alloys by ab initio molecular dynamics simulations. J Appl Phys. 2015;117(10):104901.

Deibler LA, Lewandowski J. Model experiments to mimic fracture surface features in metallic glasses. Mater Sci Eng A. 2010;527(9):2207.

Basu S, Moseson A, Barsoum MW. On the determination of spherical nanoindentation stress–strain curves. J Mater Res. 2006;21(10):2628.

Dean J, Wheeler JM, Clyne TW. Use of quasi-static nanoindentation data to obtain stress–strain characteristics for metallic materials. Acta Mater. 2010;58(10):3613.

Pang JJ, Tan MJ, Liew KM, Shearwood C. Nanoindentation study of size effect and loading rate effect on mechanical properties of a thin film metallic glass Cu49.3Zr50.7. Phys B Condens Matter. 2012;407(3):340.

Uchic Md, Dm Dimiduk, Jn Florando, Nix Wd. Sample dimensions influence strength and crystal plasticity. Science. 2004;305(5686):986.

Safarik DJ, Schwarz RB. Elastic constants of amorphous and single-crystal Pd40Cu40P20. Acta Mater. 2007;55(17):5736.

Johnson WL, Lu J, Demetriou MD. Deformation and flow in bulk metallic glasses and deeply undercooled glass forming liquids—a self consistent dynamic free volume model. Intermetallics. 2002;10(11):1039.

Wang WH. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog Mater Sci. 2012;57(3):487.

Acknowledgements

This research was financially supported by the National Key Research and Development Program of China (No. 2016YFC0801905).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zheng, HW., Shu, XY., Li, Y. et al. Mechanical properties of Fe-based amorphous–crystalline composite: a molecular dynamics simulation and experimental study. Rare Met. 40, 2560–2567 (2021). https://doi.org/10.1007/s12598-018-1183-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1183-y