Abstract

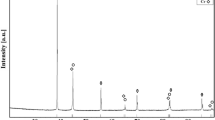

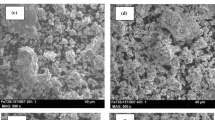

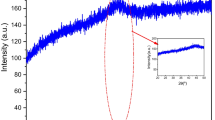

This work synthesized and investigated the amorphous alloy Fe73Si22B5 obtained by high-energy milling. The properties of the amorphous alloy Fe73Si22B5 were investigated by X-ray diffraction (XRD), scanning electron microscopy (SEM) with EDS, Fourier transform infrared spectrometry (FTIR), thermal analysis TGA/DTA, textural analysis by N2 (BET/BJH), and magnetic measurements (VSM). The results confirmed that the Fe73Si22B5 alloy reached the desired amorphization degree and presented IV isotherms with a hysteresis loop for mesoporous materials. The TGA/DTA confirmed that Fe and Si ions are quickly oxidized in the environment with the mass slightly increased to 27.5%. The Fe73Si22B5 exhibited soft magnetic properties with ferromagnetic characteristics. The FTIR spectra exhibit absorption peaks corresponding to the presence of (R)O–H, Fe–O, Si–O, O–Fe–O, and Si–O–Fe groups. This result suggests that the developed high-performance Fe73Si22B5 amorphous alloy has great application potential in various research fields.

Similar content being viewed by others

Availability of Data and Materials

The data supporting the findings of this study are available from the authors on reasonable request.

References

Y. Sakaguchi, S.C. Takata, Y. Kawakita, Y. Fujimura, K. Kondo, Direct observation of concentration fluctuations in Au–Si eutectic liquid by small-angle neutron scattering. J. Phys. Condens. Matter. 35(41), 415403 (2023)

S. Nagireddi, B. Majumdar, S. Bonta, A.B. Diraviam, High-density bulk metallic glasses and their composites for kinetic energy penetrator applications: process, structure and properties. Trans. Indian Inst. Met. 74, 2117–2134 (2021)

S.H. Lee, G.S. Hwang, Structure, energetics, and bonding of amorphous Au–Si alloys. J. Chem. Phys. 127(22) (2007)

T. He, S. Chen, T. Lu, P. Zhao, W. Chen, S. Scudino, High-strength and ductile ultrafine-grained Al–Y–Ni–Co alloy for high-temperature applications. J. Alloy. Compd. 848, 156655 (2020)

A. Singh, P.K. Bijalwan, A. Banerjee, M. Dutta, R.K. Mandal, J. Basu, Structures, interfaces and thermodynamic stability of nanocrystalline phases in rapidly solidified Fe-based amorphous nanocomposite ribbon, powder and coating. Mater. Charact. 186, 111815 (2022)

Q. Wang, M. Chen, L. Shao, Y. Ge, P. Lin, C. Chu, B. Shen, Effects of structural relaxation on the dye degradation ability of FePC amorphous alloys. J. Non-Cryst. Solids 525, 119671 (2019)

A. Kumar, R. Kumar, P. Bijalwan, M. Dutta, A. Banerjee, T. Laha, Fe-based amorphous/nanocrystalline composite coating by plasma spraying: effect of heat input on morphology, phase evolution and mechanical properties. J. Alloy. Compd. 771, 827–837 (2019)

A. Inoue, Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 48(1), 279–306 (2000)

F.L. Kong, C.T. Chang, A. Inoue, E. Shalaan, F. Al-Marzouki, Fe-based amorphous soft magnetic alloys with high saturation magnetization and good bending ductility. J. Alloy. Compd. 615, 163–166 (2014)

S.K. Nayak, A. Kumar, K. Sarkar, A. Pathak, A. Banerjee, T. Laha, A study on the corrosion inhibition of Fe-based amorphous/nanocrystalline coating synthesized by high-velocity oxy-fuel spraying in an extreme environment. J. Therm. Spray Technol. 28, 1433–1447 (2019)

Z. Li, S. Zhou, G. Zhang, W. Zheng, Highly ductile and ultra-thick P-doped FeSiB amorphous alloys with excellent soft magnetic properties. Materials 11(7), 1148 (2018)

S. Yue, H. Zhang, R. Cheng, A. Wang, Y. Dong, A. He, C.T. Liu, Magnetic and thermal stabilities of FeSiB eutectic amorphous alloys: compositional effects. J. Alloy. Compd. 776, 833–838 (2019)

L. Shi, X. Hu, Y. Li, G. Yuan, K. Yao, The complementary effects of Fe and metalloids on the saturation magnetization of Fe-based amorphous alloys. Intermetallics 131, 107116 (2021)

D.W. Zhang, Y. Zhang, Y.F. Cai, B.W. Zang, F. Zhao, Y.C. Wang, R. Umetsu, Z.Z. Li, X. Tong, J.T. Huo, S.L. Che, J.Q. Wang, Magnetic properties evaluation of Fe-based amorphous alloys synthesized via spark plasma sintering. J. Non-Cryst. Solids 613, 122373 (2023)

D. Azuma, N. Ito, M. Ohta, Recent progress in Fe-based amorphous and nanocrystalline soft magnetic materials. J. Magn. Magn. Mater. 501, 166373 (2020)

J. Guan, L. Cheng, M. Li, Microstructure and mechanical properties of Si3N4-Fe3Si composites prepared by gas-pressure sintering. Materials 11(7), 1206 (2018)

S. Fan, Y. Ning, X. Ma, L. Wang, J. Deng, L. Zhang, L. Cheng, Microstructure and mechanical properties of Fe–Si alloy modified C/C–SiC composites. Ceram. Int. 45(17), 21579–21589 (2019)

H. Sun, C. Wang, J. Wang, M. Yu, Z. Guo, Fe-based amorphous powder cores with low core loss and high permeability fabricated using the core-shell structured magnetic flaky powders. J. Magn. Magn. Mater. 502, 166548 (2020)

Y. Jiang, S. Jia, S. Chen, X. Li, L. Wang, X. Han, Theoretical prediction and experimental validation of the glass-forming ability and magnetic properties of Fe-Si-B metallic glasses from atomic structures. Materials 15(9), 3149 (2022)

M.Z. Ibrahim, A.A. Sarhan, T.Y. Kuo, F. Yusof, M. Hamdi, Characterization and hardness enhancement of amorphous Fe-based metallic glass laser cladded on nickel-free stainless steel for biomedical implant application. Mater. Chem. Phys. 235, 121745 (2019)

M.Z. Ibrahim, A. Halilu, A.A. Sarhan, T.Y. Kuo, F. Yusuf, M.O. Shaikh, M. Hamdi, In-vitro viability of laser cladded Fe-based metallic glass as a promising bioactive material for improved osseointegration of orthopedic implants. Med. Eng. Phys. 102, 103782 (2022)

S. Lu, J. Zhang, H. Duan, Effects of B substitution for P on structure and magnetic properties of FePB amorphous alloys by first-principle investigation. Intermetallics 149, 107674 (2022)

S. Ghobrial, D.W. Kirk, S.J. Thorpe, Solid state amorphization in the Ni-Nb-Y system by mechanical alloying. J. Non-Cryst. Solids 502, 1–8 (2018)

K.L. Alvarez, J.M. Martín, N. Burgos, M. Ipatov, L. Domínguez, J. González, Structural and magnetic properties of amorphous and nanocrystalline Fe–Si–B–P–Nb–Cu alloys produced by gas atomization. J. Alloy. Compd. 810, 151754 (2019)

C. Suryanarayana, A.A. Al-Joubori, Z. Wang, Nanostructured materials and nanocomposites by mechanical alloying: an overview. Met. Mater. Int. 28(1), 41–53 (2022)

Y. Zhang, X. Li, Y. Cai, Y. Qi, S. Guo, D. Zhao, Improved hydrogen storage performances of Mg-Y-Ni-Cu alloys by melt spinning. Renew. Energy 138, 263–271 (2019)

H. Liu, R. Han, H. Liu, X. Cui, M. Tang, T. Xiong, Development of hydrogen-free fully amorphous silicon oxycarbide coating by thermal organometallic chemical vapor deposition technique. J. Non-Cryst. Solids 575, 121204 (2022)

H. Han, S. Jin, S. Park, Y. Kim, D. Jang, M.H. Seo, W.B. Kim, Plasma-induced oxygen vacancies in amorphous MnOx boost catalytic performance for electrochemical CO2 reduction. Nano Energy 79, 105492 (2021)

Y. Wang, X. Zhang, B.I. Min, M. Tanaka, T. Watanabe, Synthesis of amorphous Li3BO3 nanoparticles as solid electrolyte for all-solid-state battery by induction thermal plasma. J. Solid State Chem. 318, 123775 (2023)

B.Y. Li, A.C. Li, S. Zhao, M.A. Meyers, Amorphization by mechanical deformation. Mater. Sci. Eng. R Rep. 149, 100673 (2022)

K. Edalati, H.W. Li, A. Kilmametov, R. Floriano, C. Borchers, High-pressure torsion for synthesis of high-entropy alloys. Metals 11(8), 1263 (2021)

B. Mironchuk, G. Abrosimova, S. Bozhko, E. Pershina, A. Aronin, Correlation between phase transformation and surface morphology under severe plastic deformation of the Al87Ni8La5 amorphous alloy. J. Non-Cryst. Solids 577, 121279 (2022)

Z. Msetra, N. Khitouni, J.J. Suñol, M. Khitouni, M. Chemingui, Characterization and thermal analysis of new amorphous Co60Fe18Ta8B14 alloy produced by mechanical alloying. Mater. Lett. 292, 129532 (2021)

C. Suryanarayana, Phase formation under non-equilibrium processing conditions: rapid solidification processing and mechanical alloying. J. Mater. Sci. 53(19), 13364–13379 (2018)

F. Gao, S. Li, K. Li, Formation of non-equilibrium ductile solid solutions and textures in NbCr2 bulks produced by mechanical milling and spark plasma sintering. J. Alloy. Compd. 826, 154130 (2020)

N. Yazdian, F. Karimzadeh, M.H. Enayati, In-situ fabrication of Al3V/Al2O3 nanocomposite through mechanochemical synthesis and evaluation of its mechanism. Adv. Powder Technol. 24(1), 106–112 (2013)

M.G. Ozden, N.A. Morley, Laser additive manufacturing of Fe-based magnetic amorphous alloys. Magnetochemistry 7(2), 20 (2021)

A. Chebli, M. Cesnek, A. Djekoun, J.J. Sunol, D. Niznansky, Synthesis, characterization and amorphization of mechanically alloyed Fe75Si12Ti6B7 and Fe73Si15Ti5B7 powders. J. Mater. Sci. 57(26), 12600–12615 (2022)

L. Yan, B. Yan, Y. Jian, Fabrication of Fe-Si-B based amorphous powder cores by spark plasma sintered and their magnetic properties. Materials 15(4), 1603 (2022)

F. Ahangaran, A. Hassanzadeh, S. Nouri, Surface modification of Fe3O4@SiO2 microsphere by silane coupling agent. International Nano Letters 3, 1–5 (2013)

Z.H. Wang, T. Urisu, H. Watanabe, K. Ooi, G.R. Rao, S. Nanbu, J. Maki, M. Aoyagi, Assignment of surface IR absorption spectra observed in the oxidation reactions: 2H+H2O/Si (1 0 0) and H2O+H/Si (1 0 0). Surf. Sci. 575(3), 330–342 (2005)

V. Rathod, A.V. Anupama, R.V. Kumar, V.M. Jali, B. Sahoo, Correlated vibrations of the tetrahedral and octahedral complexes and splitting of the absorption bands in FTIR spectra of Li-Zn ferrites. Vib. Spectrosc. 92, 267–272 (2017)

J.A. Lopez, F. González, F.A. Bonilla, G. Zambrano, M.E. Gómez, Synthesis and characterization of Fe3O4 magnetic nanofluid. Rev. Latinoam. Metal. Mater. 30(1), 60–66 (2010)

G.H. Du, Z.L. Liu, X. Xia, Q. Chu, S.M. Zhang, Characterization and application of Fe3O4/SiO2 nanocomposites. J. Sol-Gel Sci. Technol. 39, 285–291 (2006)

M. Malekan, R. Rashidi, S.G. Shabestari, J. Eckert, Thermodynamic and kinetic interpretation of the glass-forming ability of Y-containing Cu-Zr-Al bulk metallic glasses. J. Non-Cryst. Solids 576, 121266 (2022)

A. Radoń, P. Włodarczyk, Ł Hawełek, M. Kądziołka-Gaweł, P. Gębara, R. Nowosielski, R. Babilas, Thermodynamic approach for determining chemical composition of Fe-Co based amorphous alloys with high thermal stability and glass forming ability. J. Alloy. Compd. 763, 141–152 (2018)

S.K. Wu, Y. Pan, N. Wang, T. Lu, W.J. Dai, Azo dye degradation behavior of AlFeMnTiM (M= Cr Co, Ni) high-entropy alloys. Int. J. Miner. Metall. Mater. 26, 124–132 (2019)

K.Y. Hou, Q.Y. Dong, L. Su, X.Q. Zhang, Z.H. Cheng, Three-dimensional Heisenberg critical behavior in amorphous Gd65Fe20Al15 and Gd71Fe3Al26 alloys. J. Alloy. Compd. 788, 155–162 (2019)

M.S. Leu, J.S. Jang, C.C. Lin, W.K. Wang, The effect of composition on the crystallization and magnetic transition of Fe-Si-B amorphous alloys. Mater. Chem. Phys. 45(3), 275–279 (1996)

R.A. Parray, K. Ravichandran, Structural, thermal, electrical and magnetic properties of Fe2CrAl FulHeusler alloy prepared by ball milling. Physica B 653, 414665 (2023)

T. Rin, C. Sangwichien, R. Yamsaengsung, T. Reungpeerakul, Hydrogen generation from the hydrolysis of aluminum promoted by Ni–Li–B catalyst. Int. J. Hydrogen Energy 46(56), 28450–28461 (2021)

C. Zhang, X. Zhang, S. Zhang, H. Guo, Ultrafast reductive dechlorination of carbon tetrachloride by amorphous Fe78Si9B13 alloy. Results Phys. 14, 102523 (2019)

Y. Zhu, C. Zhang, X. Liu, X. Kan, S. Feng, Q. Lv, Magnetic properties of phosphoric acid passivated Fe-Si-B amorphous magnetic powder core. Mater. Sci. Eng. B 296, 116673 (2023)

K.L. Alvarez, H.A. Baghbaderani, J.M. Martín, N. Burgos, P. McCloskey, J. González, A. Masood, Novel predictive methodology of amorphisation of gas-atomised Fe-Si-B alloy powders. J. Non-Cryst. Solids 574, 121151 (2021)

Y. Zhu, C. Zhang, X. Liu, X. Kan, S. Feng, Q. Lv, W. Sun, Study on the magnetic property of Fe–Si–B amorphous magnetic powder core coated with Al2O3/phosphoric acid–Al2O3 double layer. J. Mater. Sci. Mater. Electron. 34(4), 292 (2023)

R.M.A. Louvier, R.A. Lopez, F.T. Fernández, P. Urban, F.G. Cuevas, Structure and size distribution of powders produced from melt-spun Fe-Si-B ribbons. Key Eng. Mater. 876, 25–30 (2021)

C. Yang, Z. Liu, X. Pei, C. Jin, M. Yu, Y. Li, Magnetorheological fluid based on amorphous Fe-Si-B alloy magnetic particles. J. Intell. Mater. Syst. Struct. 33(13), 1644–1653 (2022)

Funding

The authors wish to thank CAPES for the financial support of this research.

Author information

Authors and Affiliations

Contributions

Luciano Nascimento: Experiment, analysis and paper writing. Ana Cristina Figueiredo de Melo Costa: Conceptualization, analysis and supervision.

Corresponding author

Ethics declarations

Ethics Approval

This manuscript has not been submitted to any previous journal of this journal. The presented work is original and has not been published elsewhere in any form or language.

Consent to Participate

Not applicable.

Consent for Publication

All authors have read and consented to the published version of the manuscript.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nascimento, L., de Melo Costa, A.C.F. Synthesis by Mechanical Alloying and Characterization Fe73Si22B5 Alloy: Amorphization Evaluation. Braz J Phys 53, 158 (2023). https://doi.org/10.1007/s13538-023-01371-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13538-023-01371-0