Abstract

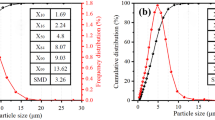

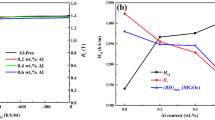

In this paper, the effects of P doping on magnetic properties and microstructure were studied in Nd–Fe–B sintered magnets. With P doping, the grain size gets refined and the distribution of the main phase is optimized due to the reduction of the liquidus temperature. The liquidus temperature for the 0.05 wt% P-doped magnets is 1022 K, while that for the P-free magnets is 1038 K. As P content increases, the liquidus temperature significantly decreases. Clear and continuous grain boundary phases are formed in the P-containing magnets with smaller grain size. The optimized microstructure with average grain size of 8.43 μm is obtained in the 0.05 wt% P-doped magnets, which is approximately 0.69 μm smaller than that of P-free sintered magnets (9.12 μm). Though P is usually thought to be an impurity element, it might be beneficial in Nd–Fe–B sintered magnets with proper addition. The coercivity of the 0.05 wt% P-doped magnets could be increased to 1283 kA·m−1, with slight changes of the remanence and the maximum magnetic energy product. NdPO4 phases in the grain boundary are of hexagonal structure, while those at the triple junctions have monoclinic structure. Activated sintering is achieved by doping proper P element in the Nd–Fe–B sintered magnets.

Similar content being viewed by others

References

Krishna SC, Jha AK, Pant B, George KM. Microstructure and magnetic properties of hot-deformed anisotropic Nd–Fe–B magnets prepared from amorphous precursors with different crystallization proportions. Rare Met. 2017;35(4):263.

Ma Q, Zhu JT, Zhang XF, Zhao ZR, Liu YL, Wang GF, Li YF, Li ZB. Achievement of high performance of sintered R–Fe–B magnets based on misch metal doped with PrNd nanoparticles. Rare Met. 2018;37(3):1.

Cui XG, Wang XH, Cui CY, Yin GC, Xia CD, Fang C. Research progress in grain boundary diffusion modification, microstructures and propertis of sintered Nd–Fe–B magnets. Chin J Rare Met. 2018;42(3):315.

Bance S, Fischbacher J, Schrefl T. Thermally activated coercivity in core–shell permanent magnets. J Appl Phys. 2015;117(17):821.

Liu WQ, Chang C, Yue M, Yang JS, Zhang DT, Zhang JX, Liu YQ. Coercivity, microstructure, and thermal stability of sintered Nd–Fe–B magnets by grain boundary diffusion with TbH3 nanoparticles. Rare Met. 2017;36(9):718.

Yang MN, Wang H, Hu YF, Yang LYM, Maclennan A, Yang B. Relating atomic local structures and curie temperature of NdFeB permanent magnets: an X-ray absorption spectroscopic study. Rare Met. 2017. https://doi.org/10.1007/s12598-017-0918-5.

Wang Z, Liu WQ, Zhang DT, Yue M, Huang XL, Li XL. Enhancement of corrosion resistance in sintered Nd–Fe–B permanent magnet doping with different CuZn5 contents. Rare Met. 2017;36(10):812.

He JZ, Lin T, Shao HP, Zhao LW, Zhao DC. 3D printing of NdFeB rare earth permanent magnet. Chin J Rare Met. 2018;42(6):657.

Loewe K, Brombacher C, Katter M, Gutfleisch O. Temperature-dependent Dy diffusion processes in Nd–Fe–B permanent magnets. Acta Mater. 2015;83:248.

Shi XN, Zhu MG, Han R, Song LW, Li W. Corrosion behavior of dual-main-phased (Nd0.8Ce0.2)2Fe14B magnets with and without annealing process. Rare Met. 2017. https://doi.org/10.1007/s12598-017-0963-0.

Wei HD, Qian Y, Qian H, Zhang B, Xiang BJ, Jia XF. Effect of grain edge region modification on the coercivity of sintered NdFeB magnets. Chin Rare Earth. 2017;38(3):56.

Doser M, Keeler G. Long-term stability of Fe–B–Nd–Dy alloys made by Dy2O3 additions. J Appl Phys. 1988;64(10):5311.

Li WF, Sepehri-Amin H, Ohkubo T, Hase N, Hono K. Distribution of Dy in high-coercivity (Nd, Dy)–Fe–B sintered magnet. Acta Mater. 2011;59(8):3061.

Park SE, Kim TH, Lee SR, Kim DH, Nam-Kung S, Jang TS. Magnetic and microstructural characteristics of Nd–Fe–B sintered magnets doped with Dy2O3 and DyF3 powders. IEEE Trans Magn. 2011;47(10):3259.

Li WF, Ohkubo T, Hono K. Effect of post-sinter annealing on the coercivity and microstructure of Nd–Fe–B permanent magnets. Acta Mater. 2009;57(5):1337.

Mo WJ, Zhang LT, Liu QZ, Shan AD, Wu JS, Komuro M. Dependence of the crystal structure of the Nd-rich phase on oxygen content in an Nd–Fe–B sintered magnet. Scr Mater. 2008;59(2):179.

Kim TH, Lee SR, Namkumg S, Jange TS. A study on the Nd-rich phase evolution in the Nd–Fe–B sintered magnet and its mechanism during post-sintering annealing. J Alloys Compd. 2012;537(19):261.

Jin WK, Lee WS, Byun JM, Kim SH, Kim YD. Grain refinement in heavy rare earth element-free sintered Nd–Fe–B magnets by addition of a small amount of molybdenum. J Appl Phys. 2015;117(17):17B523.

Chu TY, Chin TS, Lin CH, Yao JM. Evidence of domain-wall pinning in W-doped (NdDy)(FeCo)B sintered magnets. J Appl Phys. 1994;76(10):6834.

Cheng WH, Li W, Li CJ, Li XM. The role of Nb addition in Nd–Fe–B sintered magnets with high performance. J Alloys Compd. 2001;319(1):280.

Shen X, Wang Y, Diao Z, Liu X. The effect of molybdenum on the magnetic properties of the Nd–Fe–Co–B system. J Appl Phys. 1987;61(8):3433.

Hu SQ, Peng K, Chen H. Influence of annealing temperature on the Dy diffusion process in NdFeB magnets. J Magn Magn Mater. 2017;426:340.

Fidler J, Bernardi J, Schrefl T. Permanent magnets—new microstructural aspects. Scr Mater. 1995;33(10–11):1781.

Pandian S, Chandrasekaran V, Markandeyulu G, Lyer KJL, Rama-Rao KVS. Effect of Al, Cu, Ga, and Nb additions on the magnetic properties and microstructural features of sintered NdFeB. J Appl Phys. 2002;92(10):6082.

Sasaki TT, Ohkubo T, Une Y, Kubo H, Sawawa M, Hono K. Effect of carbon on the coercivity and microstructure in fine-grained Nd–Fe–B sintered magnet. Acta Mater. 2015;84:506.

Zhang W, Kazahari A, Yubuta K, Makino A, Wang YM, Umetsu R. Effect of P addition on the structure and magnetic properties of melt-spun Fe–Pt–B alloy. J Alloys Compd. 2014;586(4):S294.

Massalski TB. Binary Alloy Phase Diagrams. Ohio: ASM International; 1990. 28.

Huang PY. Powder Metallurgy. Beijing: Metallurgical Industry Press; 1997. 296.

Bae KH, Lee SR, Kim HJ, Lee MW, Jang TS. Effect of WS2/Al co-doping on microstructural and magnetic properties of Nd–Fe–B sintered magnets. J Alloys Compd. 2016;673:321.

Acknowledgements

This study was financially supported by State Key Lab of Advanced Metals and Materials (No. 2018-Z06) and the Fundamental Research Funds for the Central Universities (No. FRF-TP-18-025A1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, F., Dong, GL., Sui, YL. et al. Microstructure and magnetic properties of Nd–Fe–B sintered magnets with P addition. Rare Met. 38, 770–775 (2019). https://doi.org/10.1007/s12598-018-1145-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1145-4