Abstract

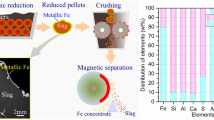

Gold in cyanide tailings from Shandong Province is mainly encapsulated by hematite and magnetite at distribution rates of 76.49 % and 10.88 %, respectively. Chlorination–reduction one-step roasting of cyanide tailings was conducted under the following conditions: calcium chloride dosage of 6 %, bituminous coal dosage of 30 %, calcium oxide dosage of 10 % (all dosages are vs. the mass of cyanide tailings) at 1000 °C of roasting temperature. X-ray diffraction (XRD), scanning electron microscopy (SEM), and chemical-phase analysis were performed to investigate the effects of iron phase transformation on the high-temperature chlorination of gold. Results indicate that the lattice structure of hematite undergoes expansion, pulverization, and reorganization when hematite is reduced to magnetite, which leads to 42.03 % gold exposure, and the high-temperature chlorination rate of gold is 41.17 % at the same time. The structure of wustite formed by the reduction in magnetite is porous and loose, and thus 44.02 % of gold is exposed. The high-temperature chlorination rate of gold is increased by 41.98 percentage points. When wustite is reduced to metallic iron, 4.42 % of gold is exposed, and the high-temperature chlorination rate of gold is increased by 3.38 percentage points. Accordingly, the high-temperature chlorination of gold mainly occurs in two stages, in which Fe2O3 is reduced to Fe3O4, and Fe3O4 is reduced to Fe x O finally.

Similar content being viewed by others

References

Song X. Refractory gold resources and relevant development and utilization technology in China. Gold. 2009;30(7):46.

Sun ZM, Sun CB, Wang JZ, Yin WZ. Optimization and mechanism of gold-bearing sulfide flotation. Rare Met. 2014;33(3):363.

De Michelis Ida, Olivieri Agostino, Ubaldini Stefano, Ferella Francesco, Beolchini Francesca, Vegliò Francesco. Roasting and chlorine leaching of gold-bearing refractory concentrate: experimental and process analysis. Int J Min Sci Technol. 2013;23:709.

Amankwah RK, Pickles CA. Microwave roasting of a carbonaceous sulphidic gold concentrate. Min Eng. 2009;22:1095.

Tang D, Yang C, Wang R. The study of pyrolysis experiment about some refractory gold mine in Guizhou Province. Precious Met. 2013;34(1):51.

Ma YT, Chen DL, Chen ZY, Zhong QS, Huang HJ, Du YJ. Study on the pretreatment technology of refractory gold concentrate containing high arsenic and sulfur. Gold Sci Technol. 2014;22(4):103.

Jiang GH, Liu SM, Zhang Y, Ouyang LA, Zhang YM. Examination on solidification roast and cyanide leaching of gold concentration containing arsenic and sulphur. Chin Hydromet. 2014;23(2):76.

Liu YC, Zhu ZS, Fu JG, Li LF, Lin QQ, Li ZH. Leaching gold ores by lime–sulphur-synthetic-solution with alkali-catalyzed process. Rare Met. 2013;37(1):123.

Liu BL, Zhang Zh, Li LB. Recovery of gold and iron from the cyanide tailings by magnetic roasting. Rare Met Mater Eng. 2013;42(9):1805.

Gao Y, Wang JM, Wu H, Liu TP. Study on comprehensive utilization of cyanidation slags. Mater Res Appl. 2010;4(2):156.

Zhang XP, Yan YY, Sun YF, Wu JJ. Study on gold extraction by roasting, cyanidation and leaching for a gold smelter in Shanxi. Mult Util Min Res. 2014;6:35.

Liu DX, Guo CH, Wang Y, Yuan CX. Gold and silver recovery from residue of roasting-cyaniding process in Tanjianshan of Qinghai. Nonferr Metall Extra Metal. 2011;8:32.

Huang HH, Wang Y, Yuan CX, Li Y. Extraction of gold and silver from gold-extraction residue. Nonferr Metall Extra Metal. 2011;10:37.

Wei QJ, Yuan CX, Liu DX, Xu XH. Experiment of recovery gold from cyanide tailings of a gold mine in Guizhou by high chlorination. Nonferr Metall Eng. 2014;4(3):45.

Shang DX, Chen FF, Zhang YF, Zeng M. Recovery of iron from gold-cyanide residue by reduction roasting and magnetic separation. Min Metall Eng. 2011;31(5):35.

Sun MF, Zang YF, Wang XW. Coal-based reduction-roasting of ferric oxide from a cyanidation slag. Met Min. 2012;3:155.

Wang W, Liu L, Feng AS, Liu HZ. Recovery of iron from gold smelting slag from Henan by direct reduction roasting-low intensity magnetic separation process. Met Min. 2015;12:169.

Ding J, Ye SF. Research on gold recovery from residue of roasting-cyaniding process by chloridizing roast. Gold Sci Technol. 2014;22(4):113.

Chang YC, Xu XH, Wang Y. Chloridizing-roasting test study on gold and silver recovering from cyanidation residue. Min Met. 2015;24(3):42.

Wang J, Chen WL, Jiao ZL, Peng XQ. Research progress on recovering gold and silver from cyanide residues. Conserv Util Min Res. 2014;4:54.

Hager JP, Hill RB. Thermodynamic properties of the vapor transport reactions in the Au–Cl system by a transpiration-mass spectrometric technique. Met Trans. 1970;1:2723.

James SE, Hager JP. High temperature vaporization chemistry in the gold-chlorine system including formation of vapor complex species of gold and silver with copper and iron. Met Trans B. 1978;9(4):501.

Ma HZ, Yang ZX, Guo YS, Jian HS, Zhao B, Wu PX. Magnetization roasting of Fe2O3 in tailings of roasting-cyaniding process. Chin J Rare Met. 2012;36(3):507.

Xie JH, Zhang CH, Li H, Liu SW, Wang X. Experimental researches on comprehensive utilization of roasting-cyanided tailings. Met Min. 2011;1:150.

Liu N, Sun TC, Liu ZZ, Jiang M. Experiment of iron concentration from a cyanided tailing with the process of direct reduction roast-magnetic separation. Met Min. 2012;11:145.

Zhang YL, Yu XJ, Li XB, Zhang LP, Li DG. Thermodynamics analysis of ferric compound during roasting-preparing process of cyanide tailings. J Cent South Univ Technol Nat Sci. 2011;42(12):3623.

Li ZY, Wang WW, Yue K. Recovering gold and iron from cyanide tailings by one-step process of chloridizing volatilization and reduction roasting. Met Min. 2015;10:173.

Sun YS, Peng G, Han YX, Ren D. Reaction behavior of iron minerals and metallic iron particles growth in coal-based reduction of an oolitic iron ore. Ind Eng Chem Res. 2013;52(6):2323.

Jozwiak WK, Kaczmarek E, Maniecki TP, Ignaczak W, Maniukiewicz W. Reduction behavior of iron oxides in hydrogen and carbon monoxide atmospheres. Appl Catal A Gener. 2007;326(1):17.

Luo LQ, Chen M, Yan HT, Cui SS, Zhang YJ. Magnetic reduction roasting and magnetic separation of oolitic iron ore. Chin J Proc Eng. 2014;14(4):593.

Luo LQ, Huang H, Yu YF. Characterization and technology of fast reducing roasting for fine iron materials. J Cent South Univ. 2012;19(8):2272.

Pan BJ. Reduction swellability and pulverization of oxidized pellets iron concentrate pellets at the hematite–magnetite reduction stage. Iron Steel Vanadium Titan. 1983;2:50.

Wang SH. Behavior of gold and silver in high temperature chlorination roasting process. Jiansu Met. 1990;1:15.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51474018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, ZY., Wang, WW., Yue, K. et al. High-temperature chlorination of gold with transformation of iron phase. Rare Met. 35, 881–886 (2016). https://doi.org/10.1007/s12598-016-0804-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0804-6