Abstract

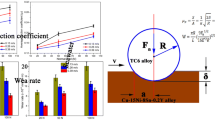

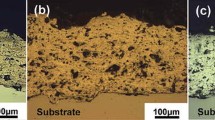

TiCN coatings incorporated with Ti buffer layer were deposited on Ti6Al4V alloy by arc ion plating. The carbon content in TiCN coatings was varied by controlling flow rates of C2H2 in reactive gas. The Ti/TiCN coatings have a typical structure of columnar crystal with a total thickness of about 2 µm. The elements of Ti, C and N are present as TiN and TiC in TiCN coatings. A little free carbon appears with carbon content increasing in TiCN coatings. For the TiCN coatings, the hardness, friction coefficient and wear rate decrease with the increase in carbon content. In seawater, both friction coefficient and wear rate have an obvious decrease at lower carbon content compared with those in atmosphere. However, the friction coefficient and wear rate only have a slight decrease, while the carbon content reaches or exceeds 10 at% in Ti/TiCN coatings.

Similar content being viewed by others

References

Gurrappa I. Characterization of titanium alloy Ti-6Al-4V for chemical, marine and industrial applications. Mater Charact. 2003;51(2–3):131.

Zhou YG, Zeng WD, Yu HQ. An investigation of a new near-beta forging process for titanium alloys and its application in aviation components. Mater Sci Eng A. 2005;393(1–2):204.

Rack HJ, Qazi JI. Titanium alloys for biomedical applications. Mater Sci Eng C. 2006;26(8):1269.

Liu XT, Chu PK, Ding CX. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng R. 2004;47(3–4):49.

Li JL, Sun MR, Ma XX. Structural characterization of titanium oxide layers prepared by plasma based ion implantation with oxygen on Ti6Al4V alloy. Appl Surf Sci. 2006;252(20):7503.

Chen XY, Huang SF, Ma SL, Huang R, Zhang J, Hu HX. Elevated-temperature tribological behavior of TiBCN coatings deposited by reactive magnetron sputtering. Rare Met. 2016;34(12):838.

He ZY, Wang ZX, Wang WB, Fan AL, Xu Z. Surface modification of titanium alloy Ti6Al4V by plasma niobium alloying process. Surf Coat Technol. 2007;201(9–11):5705.

Bloyce A, Qi PY, Dong H, Bell T. Surface modification of titanium alloys for combined improvements in corrosion and wear resistance. Surf Coat Technol. 1998;107(2–3):125.

Li JL, Sun MR, Ma XX. Structure and tribological performance of modified layer on Ti6Al4V by plasma-based ion implantation with oxygen. Wear. 2006;261(11–12):1247.

Shao JZ, Li J, Song R, Bai LL, Chen JL, Qu CC. Microstructure and wear behaviors of TiB/TiC reinforced Ti2Ni/α(Ti) matrix coating produced by laser cladding. Rare Met. 2016. doi:10.1007/s12598-016-0787-3.

Stallard J, Poulat S, Teer DG. The study of the adhesion of a TiN coating on steel and titanium alloy substrates using a multi-mode scratch tester. Tribol Int. 2006;39(2):159.

Ertuerk E, Knotek O, Burgmer W, Prengel HG, Heuvel HJ, Dederichs HG, Stossel C. Ti(CN) coatings using the arc process. Surf Coat Technol. 1991;46(1):39.

Takadoum J, Bennani HH, Allouard M. Friction and wear characteristics of TiN, TiCN and diamond-like carbon films. Surf Coat Technol. 1997;88(1–3):232.

Chen R, Tu JP, Liu DG, Mai YJ, Gu CD. Microstructure, mechanical and tribological properties of TiCN nanocomposite films deposited by DC magnetron sputtering. Surf Coat Technol. 2011;205(21–22):5228.

Li JL, Zhang SH, Li MX. Influence of the C2H2 flow rate on gradient TiCN films deposited by multi-arc ion plating. Appl Surf Sci. 2013;283:134.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51575510), Ningbo International Cooperation Project (No. 2013D10005) and Zhejiang Provincial Natural Science Foundation of China (No. LY14E010005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, JL., Cai, GY., Zhong, HS. et al. Tribological properties in seawater for Ti/TiCN coatings on Ti6Al4V alloy by arc ion plating with different carbon contents. Rare Met. 36, 858–864 (2017). https://doi.org/10.1007/s12598-016-0802-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0802-8