Abstract

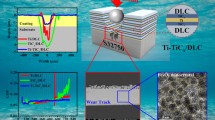

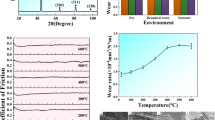

The need for reducing the wear in mechanical parts used in the industry makes self-lubricant films one of the sustainable solutions to achieve long-term protection under different environmental conditions. The purpose of this work is to study the influence of C additions on the tribological behavior of a magnetron-sputtered TiN film in air, water, and seawater. The results show that the addition of C into the TiN binary film induced a new amorphous phase, and the films exhibited a dual phase of fcc (face-centered cubic)-TiN and amorphous carbon. The antifriction and wear-resistance properties were enhanced in air and water by adding 19.1at% C. However, a further increase in the C concentration improved anti-frictional properties but also led to higher wear rates. Although the amorphous phase induced microbatteries and accelerated the corrosion of TiN phases in seawater, the negative abrasion state was detected for all Ti—C—N films due to the adhesion of the tribocorrosion debris on the wear track.

Similar content being viewed by others

References

R. Grinon-Echaniz, P. Refait, M. Jeannin, et al., Study of cathodic reactions in defects of thermal spray aluminium coatings on steel in artificial seawater, Corros. Sci., 187(2021), art. No. 109514.

D.P. Wang, G. Chen, A.D. Wang, et al., Corrosion behavior of single- and poly-crystalline dual-phase TiAl—Ti3Al alloy in NaCl solution, Int. J. Miner. Metall. Mater., 2022. DOI: https://doi.org/10.1007/s12613-022-2513-5

H.S. Wu, G.Z. Shen, R.X. Li, et al, Influence of embedded reduced graphene oxide on the corrosion-wear performance of cold sprayed Zn-rGO/Al coating in NaCl solution, Surf. Coat. Technol., 429(2022), art. No. 127856.

D. Saran, A. Kumar, S. Bathula, D. Klaumünzer, and K.K. Sahu, Review on the phosphate-based conversion coatings of magnesium and its alloys, Int. J. Miner. Metall. Mater., 29(2022), No. 7, p. 1435.

M.D. Zhang, F. Zhou, Y.J. Wu, Q.Z. Wang, and Z.F. Zhou, Microstructure and electrochemical characteristics of CrMoN/Ag nanocomposite coatings in seawater, Surf. Coat. Technol., 441(2022), art. No. 128551.

H.B. Ju, D. Yu, J.H. Xu, et al., Crystal structure and tribological properties of ZrAlMoN composite films deposited by magnetron sputtering, Mater. Chem. Phys., 230(2019), p. 347.

W. Liu, J.X. Li, H.Y. Xu, J. Li, and X.P. Qiu, Stabilized cobalt-free lithium-rich cathode materials with an artificial lithium fluoride coating, Int. J. Miner. Metall. Mater., 29(2022), No. 5, p. 917.

H.B. Ju, D. Yu, L.H. Yu, et al., The influence of Ag contents on the microstructure, mechanical and tribological properties of ZrN—Ag films, Vacuum, 148(2018), p. 54.

H.B. Ju, D. Yu, J.H. Xu, et al., Microstructure, mechanical, and tribological properties of niobium vanadium carbon nitride films, J. Vac. Sci. Technol. A, 36(2018), No. 3, art. No. 031511.

R. Wang, J.X. Deng, Z.H. Zhang, et al., Microstructure and wear performance of electro-sprayed self-lubricating Ni3Al/Cr3C2—MoS2 composite films, Surf. Coat. Technol., 428(2021), art. No. 127862.

H.B. Ju, N. Ding, J.H. Xu, et al., Improvement of tribological properties of niobium nitride films via copper addition, Vacuum, 158(2018), p. 1.

Y.J. Tarzanagh, D. Seifzadeh, and R. Samadianfard, Combining the 8-hydroxyquinoline intercalated layered double hydroxide film and sol—gel coating for active corrosion protection of the magnesium alloy, Int. J. Miner. Metall. Mater., 29(2022), No. 3, p. 536.

R. Zhou, H.B. Ju, S.J. Liu, et al., The influences of Ag content on the friction and wear properties of TiCN—Ag films, Vacuum, 196(2022), art. No. 110719.

Y. Xia, Z.G. Xu, J. Peng, Q. Shen, and C.B. Wang, In-situ formation, structural transformation and mechanical properties CrN coatings prepared by MPCVD, Surf. Coat. Technol., 441(2022), art. No. 128522.

R. Akhter, Z.F. Zhou, Z.H. Xie, and P. Munroe, TiN versus TiSiN coatings in indentation, scratch and wear setting, Appl. Surf. Sci., 563(2021), art. No. 150356.

M. Jafari, L. Rogström, J.M. Andersson, et al., Thermal degradation of TiN and TiAlN coatings during rapid laser treatment, Surf. Coat. Technol., 422(2021), art. No. 127517.

H.B. Ju, R. Zhou, S.J. Liu, et al., Enhancement of the tribological behavior of self-lubricating nanocomposite Mo2N/Cu films by adding the amorphous SiNx, Surf. Coat. Technol., 423(2021), art. No. 127565.

H.B. Ju, N. Ding, J.H. Xu, et al., The tribological behavior of niobium nitride and silver composite films at elevated testing temperatures, Mater. Chem. Phys., 237(2019), art. No. 121840.

C.K. Liu, H.B. Ju, J.H. Xu, et al., Influence of copper on the compositions, microstructure and room and elevated temperature tribological properties of the molybdenum nitride film, Surf. Coat. Technol., 395(2020), art. No. 125811.

H.B. Ju, R. Wang, W.X. Wang, et al., The microstructure and tribological properties of molybdenum and silicon nitride composite films, Surf. Coat. Technol., 401(2020), art. No. 126238.

H.B. Ju, N. Ding, J.H. Xu, et al., The influence of crystal structure and the enhancement of mechanical and frictional properties of titanium nitride film by addition of ruthenium, Appl. Surf. Sci., 489(2019), p. 247.

S.Q. Song, X.F. Cui, G. Jin, et al., Effect of N + Cr ions implantation on corrosion and tribological properties in simulated seawater of carburized alloy steel, Surf. Coat. Technol., 385(2020), art. No. 125357.

Y.Q. Fu, F. Zhou, and M.D. Zhang, The enhancement of individual friction and corrosion properties of CrSiN coatings by Mo doping in seawater, Surf. Coat. Technol., 432(2022), art. No. 128069.

P. Zhang, L. Shan, X.L. Su, et al., Microstructure and tribological performance of CrTiSiCN coatings on 316L and TC4 in seawater, Tribol. Int., 156(2021), art. No. 106832.

J. Takadoum, H.H. Bennani, and M. Allouard, Friction and wear characteristics of TiN, TiCN and diamond-like carbon films, Surf. Coat. Technol., 88(1997), No. 1–3, p. 232.

C.K. Liu, H.B. Ju, P.X. Han, et al., The influence of carbon content on the microstructure, mechanical and frictional property of chromium carbon nitride composite films, Vacuum, 178(2020), art. No. 109368.

X.R. Deng, H. Kousaka, T. Tokoroyama, and N. Umehara, Tribological behavior of tetrahedral amorphous carbon (ta-C) coatings at elevated temperatures, Tribol. Int., 75(2014), p. 98.

G.F. Zheng, Q. Jiao, C. Li, et al., Influence of nitridation on the microstructure and corrosion behavior of reactive plasma sprayed TiCN coatings, Surf. Coat. Technol., 396(2020), art. No. 125954.

H.B. Ju, R. Wang, N. Ding, et al., Improvement on the oxidation resistance and tribological properties of molybdenum disulfide film by doping nitrogen, Mater. Des., 186(2020), art. No. 108300.

Y.H. Cheng, T. Browne, B. Heckerman, and E.I. Meletis, Influence of the C content on the mechanical and tribological properties of the TiCN coatings deposited by LAFAD technique, Surf. Coat. Technol., 205(2011), No. 16, p. 4024.

B. Yi, S.H. Zhou, Z.G. Qiu, and D.C. Zeng, The influences of pulsed bias duty cycle on tribological properties of solid lubricating TiMoCN coatings, Vacuum, 180(2020), art. No. 109552.

H.B. Ju, R. Zhou, J. Luan, et al., Multilayer Mo2N—Ag/SiNx films for demanding applications: Morphology, structure and temperature-cucling tribological properties, Mater. Des., 223(2022), art. No. 111128.

J.G. Qian, S.X. Li, J.B. Pu, et al., Effect of heat treatment on structure and properties of molybdenum nitride and molybdenum carbonitride films prepared by magnetron sputtering, Surf. Coat. Technol., 374(2019), p. 725.

D. Özkan, M.A. Yılmaz, C. Erdem, et al., Wear and friction behavior of CrTiN/TiCN and CrTiN/CrCN multilayer composite coatings, Ceram. Int., 48(2022), No. 10, p. 13732.

H.Q. Wang, Y. Ou, X. Zhang, et al., Tribocorrosion behaviors of TiSiCN nanocomposite coatings deposited by high power impulse magnetron sputtering, Mater. Res. Express, 7(2020), art. No. 076407.

O. Savchuk and A.A. Volinsky, Nonparametric estimation of SiC film residual stress from the wafer surface profile, Measurement, 177(2021), art. No. 109238.

N. Madaoui, N. Saoula, B. Zaid, D. Saidi, and A.S. Ahmed, Structural, mechanical and electrochemical comparison of TiN and TiCN coatings on XC48 steel substrates in NaCl 3.5% water solution, Appl. Surf. Sci., 312(2014), p. 134.

P.B. Mi, J.N. He, Y.F. Qin, and K. Chen, Nanostructure reactive plasma sprayed TiCN coating, Surf. Coat. Technol., 309(2017), p. 1.

J.C. Sánchez-López, M.D. Abad, I. Carvalho, et al., Influence of silver content on the tribomechanical behavior on Ag—TiCN bioactive coatings, Surf. Coat. Technol., 206(2012), No. 8–9, p. 2192.

R. Chen, J.P. Tu, D.G. Liu, Y.J. Mai, and C.D. Gu, Microstructure, mechanical and tribological properties of TiCN nanocomposite films deposited by DC magnetron sputtering, Surf. Coat. Technol., 205(2011), No. 21–22, p. 5228.

X.X. Liu, N. Umehara, T. Tokoroyama, and M. Murashima, Tribological properties of ta-CNx coating sliding against steel and sapphire in unlubricated condition, Tribol. Int., 131(2019), p. 102.

Y.F. Qin, G.F. Zheng, L.Y. Zhu, et al., Structure and wear characteristics of TiCN nanocomposite coatings fabricated by reactive plasma spraying, Surf. Coat. Technol., 342(2018), p. 137.

F.Y. Yan, B.L. Jiang, Z.Y. Wang, et al., Thermal stabilization of nanocrystalline promoting conductive corrosion resistance of TiN—Ag films for metal bipolar plates, Vacuum, 195(2022), art. No. 110631.

H. Cicek, Wear behaviors of TiN/TiCN/DLC composite coatings in different environments, Ceram. Int., 44(2018), No. 5, p. 4853.

H.B. Ju, L.H. Yu, S. He, et al., The enhancement of fracture toughness and tribological properties of the titanium nitride films by doping yttrium, Surf. Coat. Technol., 321(2017), p. 57.

H.B. Ju and J.H. Xu, Microstructure, oxidation resistance, mechanical and tribological properties of Ti—Y—N films by reactive magnetron sputtering, Surf. Coat. Technol., 283(2015), p. 311.

C.K. Liu, H. Ju, L.H. Yu, et al., Tribological properties of Mo2N films at elevated temperature, Coatings, 9(2019), No. 11, p. 734.

A. Erdemir, A crystal chemical approach to the formulation of self-lubricating nanocomposite coatings, Surf. Coat. Technol., 200(2005), No. 5–6, p. 1792.

T.W.B. Riyadi, D. Setiadhi, A.D. Anggono, W.A. Siswanto, and H.H. Al-Kayiem, Analysis of mechanical and thermal stresses due to TiN coating of Fe substrate by physical vapor deposition, Forces Mech., 4(2021), art. No. 100042.

S.G. Ai, H.L. Fu, R.J. He, and Y.M. Pei, Multi-scale modeling of thermal expansion coefficients of C/C composites at high temperature, Mater. Des., 82(2015), p. 181.

J.J. Wang and F.Y. Ouyang, Nanotwinned medium entropy alloy CoCrFeNi thin films with ultra-high hardness: Modifying residual stress without scarifying hardness through tuning substrate bias, Surf. Coat. Technol., 434(2022), art. No. 128191.

Y.H. Lu and Y.G. Shen, Effect of carbon content on thermal stability of Ti—Cx—Ny thin films, J. Mater. Res., 23(2008), No. 3, p. 671.

Y.X. Ou, H.Q. Wang, Q.S. Hua, B. Liao, and X.P. Ouyang, Tribocorrosion behaviors of superhard yet tough Ti—C—N ceramic coatings, Surf. Coat. Technol., 439(2022), art. No. 128448.

R.Z. Li, S.H. Wang, J.B. Pu, et al., Study of NaCl-induced hot-corrosion behavior of TiN single-layer and TiN/Ti multilayer coatings at 500°C, Corros. Sci., 192(2021), art. No. 109838.

I. Dreiling, A. Haug, H. Holzschuh, and T. Chassé, Raman spectroscopy as a tool to study cubic Ti—C—N CVD coatings, Surf. Coat. Technol., 204(2009), No. 6–7, p. 1008.

L. Shan, Y.X. Wang, J.L. Li, et al., Tribological behaviours of PVD TiN and TiCN coatings in artificial seawater, Surf. Coat. Technol., 226(2013), p. 40.

K.L. Ming, Z.H. Zhang, and H.B. Li, In situ growth of NaTiO2 nanotubes on Ti3C2Fx for enhanced sodium ion batteries, Mater. Lett., 309(2022), art. No. 131457.

Y.X. Ou, H.Q. Wang, B. Liao, M.K. Lei, and X.P. Ouyang, Tribological behaviors in air and seawater of CrN/TiN superlattice coatings irradiated by high-intensity pulsed ion beam, Ceram. Int., 45(2019), No. 18, p. 24405.

B. Zhu, G.L. Kelly, and J. Mardel, An investigation of tribological properties of CN and TiCN coatings, J. Mater. Eng. Perform., 13(2004), No. 4, p. 481.

J.M. Lackner, W. Waldhauser, R. Ebner, et al., Room temperature pulsed laser deposited (Ti,Al)CxN1−x coatings—Chemical, structural, mechanical and tribological properties, Thin Solid Films, 468(2004), No. 1–2, p. 125.

J. Liu, S.J. Li, C. Wang, et al., Self-lubricating design strategy for thermally sprayed ceramic coatings by in situ synthesis of carbon spheres, Surf. Coat. Technol., 446(2022), art. No. 128759.

I. Çaha, A.C. Alves, C. Chirico, et al., Improved tribocorrosion behavior on bio-functionalized β-type titanium alloy by the pillar effect given by TiN reinforcements, Surf. Coat. Technol., 415(2021), art. No. 127122.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 52171071, 52172090, 52071159, and 51801081), Portugal National Funds through FCT project (No. 2021.04115), FEDER National funds FCT under the project CEMMPRE-UIDB/00285/2020, Outstanding University Young Teachers of “Qing Lan Project” of Jiangsu Province, Excellent Talents of “Shenlan Project” of Jiangsu University of Science and Technology, and China Merchants Marine Scientific Research and Innovation Fund. Filipe Fernandes acknowledges the funding received in the aim of the projects: MCTool21—ref. “POCI-01-0247-FEDER-045940”, CEMMPRE—ref. “UIDB/00285/2020”, and SMARTLUB—ref. “POCI-01-0145-FEDER-031807”.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Ju, H., Zhou, R., Luan, J. et al. Tribological performance under different environments of Ti—C—N composite films for marine wear-resistant parts. Int J Miner Metall Mater 30, 144–155 (2023). https://doi.org/10.1007/s12613-022-2551-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-022-2551-z