Abstract

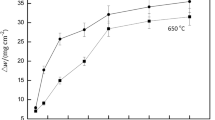

Hot corrosion behavior of FGH96 powder metallurgy (P/M) superalloy in 25 % NaCl + 75 % Na2SO4 molten salts at 650, 700, and 750 °C was investigated in this paper. The methods of mass loss measurement, X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy-dispersive spectroscopy (EDS) were used here. The experimental results show that hot corrosion kinetics follows a square power law at 650 °C, while a linear one at 700 and 750 °C. The corrosion layer is detected to be composed of Cr2O3, NiO, and Ni2S3 at each temperature. The cross-sectional morphologies and corresponding elemental maps indicate that the corrosion layer is a stratified structure of oxide and sulfide. The results and analyses confirm that the hot corrosion mechanism of FGH96 P/M superalloy is a cooperate process of oxidation and sulfidation. Furthermore, the relatively higher concentrations of Cr, Co, and Ti provide better corrosion resistance to the attack of S and Cl−.

Similar content being viewed by others

References

Nie L, Zhang L, Zhu Z, Xu W. Microstructure evolution modeling of FGH96 superalloy during inertia friction welding process. Finite Elem Anal Des. 2014;80:63.

Ning Y, Yao Z, Fu M, Guo H. Dynamic recrystallization of the hot isostatically pressed P/M superalloy FGH4096 in hot working process. Mater Sci Eng A. 2010;527(26):6968.

Fang B, Ji Z, Liu M, Tian G, Jia C, Zeng T, Hu B, Wang C. Study on constitutive relationships and processing maps for FGH96 alloy during two-pass hot deformation. Mater Sci Eng A. 2014;590:255.

Liu J, Liu G, Hu B, Song Y, Qin Z, Zhang Y. Hot deformation behavior of FGH96 superalloys. Int J Miner Metall Mater. 2006;13(4):319.

Ning Y, Yao Z, Guo H, Tao Y, Zhang Y. Effect of multiple forging on microstructure and mechanical properties of powder metallurgy FGH4096 superalloy. Chin J Mech Eng. 2009;22(6):925.

Mingjie Z, Fuguo L, Shuyun W, Chenyi L. Characterization of hot deformation behavior of a P/M nickel-base superalloy using processing map and activation energy. Mater Sci Eng A. 2010;527:6771.

Li FL, Fu R, Feng D, Tian ZL. Hot workability characteristics of Rene88DT superalloy with directionally solidified microstructure. Rare Met. 2015;34(1):1.

Lai GY. Hot Corrosion in Gas Turbines. Ohio: Materials Park, ASM International; 2007. 31.

Zheng L, Maicang Z, Jianxin D. Hot corrosion behavior of powder metallurgy Rene95 nickel-based superalloy in molten NaCl–Na2SO4 salts. Mater Des. 2011;32(4):1981.

Khanna AS. Introduction to High Temperature Oxidation and Corrosion. Ohio: Materials Park, ASM International; 2002. 285.

Mohanty BP, Shores DA. Role of chlorides in hot corrosion of a cast Fe–Cr–Ni alloy. Part I: experimental studies. Corros Sci. 2004;46(12):2893.

Eliaz N, Shemesh G, Latanision R. Hot corrosion in gas turbine components. Eng Fail Anal. 2002;9(1):31.

Rapp RA. Hot corrosion of materials: A fluxing mechanism? Corros Sci. 2002;44(2):209.

Cho SH, Hur JM, Seo CS, Yoon JS, Park SW. Hot corrosion behavior of Ni-base alloys in a molten salt under an oxidizing atmosphere. J Alloys Compd. 2009;468(1):263.

Sahu J, Kumar BR, Das S, Paulose N, Mannan S. Isothermal high temperature low cycle fatigue behavior of Nimonic-263: influence of type I and type II hot corrosion. Mater Sci Eng A. 2015;622:131.

Zhao S, Xie X, Smith GD. The oxidation behavior of the new nickel-based superalloy Inconel 740 with and without Na2SO4 deposit. Surf Coat Technol. 2004;185(2):178.

Liu G, Li M, Zhou Y, Zhang Y. Hot corrosion behavior of Ti3SiC2 in the mixture of Na2SO4–NaCl melts. J Eur Ceram Soc. 2005;25(7):1033.

Liu G, Yu F, Tian J, Ma J. Influence of pre-oxidation on the hot corrosion of M38G superalloy in the mixture of Na2SO4–NaCl melts. Mater Sci Eng A. 2008;496:40.

Bao Z, Wang Q, Li W, Liu X, Gong J, Xiong T, Sun C. Preparation and hot corrosion behaviour of an Al-gradient NiCoCrAlYSiB coating on a Ni-base superalloy. Corros Sci. 2009;51(4):860.

Kameswari S. The role of NaCl in the hot-corrosion behavior of nimonic alloy 90. Oxid Met. 1986;26(1–2):33.

Birks N, Meier GH, Pettit FS. Introduction to the High Temperature Oxidation of Metals. Cambridge: Cambridge University Press; 2006. 205.

Zheng L, Zhang M, Dong J. Oxidation behavior and mechanism of powder metallurgy Rene95 nickel based superalloy between 800 and 1000 C. Appl Surf Sci. 2010;256(24):7510.

Liu F, Zhang M, Dong J, Zhang Y. High-temperature oxidation of FGH96 P/M superalloy. Acta Metall Sin Engl. 2007;20(2):102.

Yan Y, Xu X, Zhou D, Wang H, Wu Y, Liu X, Lu Z. Hot corrosion behaviour and its mechanism of a new alumina-forming austenitic stainless steel in molten sodium sulphate. Corros Sci. 2013;77:202.

Lortrakul P, Trice RW, Trumble KP, Dayananda MA. Investigation of the mechanisms of Type-II hot corrosion of superalloy CMSX-4. Corros Sci. 2014;80:408.

Aung NN, Liu X. Effect of temperature on coal ash hot corrosion resistance of Inconel 740 superalloy. Corros Sci. 2014;82:227.

Clarke DR. Stress generation during high-temperature oxidation of metallic alloys. Curr Opin Solid State Mater Sci. 2002;6(3):237.

Jiang H, Dong J, Zhang M, Zheng L, Yao Z. Oxidation behavior and mechanism of Inconel 740H alloy for advanced ultra-supercritical power plants between 1050 and 1170 °C. Oxid Met. 2015;84(1):61.

Caplan D, Sproule G. Effect of oxide grain structure on the high-temperature oxidation of Cr. Oxid Met. 1975;9(5):459.

Evans H, Lobb R. Conditions for the initiation of oxide-scale cracking and spallation. Corros Sci. 1984;24(3):209.

Liu S, Liu Z, Wang Y, Tang J. A comparative study on the high temperature corrosion of TP347H stainless steel, C22 alloy and laser-cladding C22 coating in molten chloride salts. Corros Sci. 2014;83:396.

Hancock P. Vanadic and chloride attack of superalloys. Mater Sci Technol. 1987;3(7):536.

Hocking M, Sidky P. The hot corrosion of nickel-based ternary alloys and superalloys for gas turbine applications-II. The mechanism of corrosion in SO2/O2 atmospheres. Corros Sci. 1987;27(2):205.

Beltran AM, Shores DA. Hot corrosion. In: Sims CT, Hagel WC editors, The Superalloys. New York: Wiley-Interscience; 1972. 317.

Krupp U, Christ H-J. Selective oxidation and internal nitridation during high-temperature exposure of single-crystalline nickel-base superalloys. Metall Mater Trans A. 2000;31(1):47.

Yuan L, Wang H. Hot corrosion behaviors of a Cr13Ni5Si2-based metal silicide alloy in Na2SO4 + 25 wt% K2SO4 and Na2SO4 + 25 wt% NaCl molten salts. Intermetallics. 2010;18(3):324.

Yang XY, Peng X, Wang FH. Hot corrosion of a novel electrodeposited Ni–6Cr–7Al nanocomposite under molten (0.9Na, 0.1 K)2/SO4 at 900 °C. Scr Mater. 2007;56(10):891.

Acknowledgments

This study was financially supported by the National Basic Research Program of China (No. 2010CB631200).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, H., Dong, JX., Zhang, MC. et al. Hot corrosion behavior and mechanism of FGH96 P/M superalloy in molten NaCl–Na2SO4 salts. Rare Met. 38, 173–180 (2019). https://doi.org/10.1007/s12598-016-0754-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0754-z