Abstract

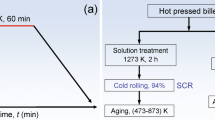

The Cu–10 %Fe–1.5 %Ag in situ composite with high strength, high conductivity and low cost was prepared, and its hot deformation behavior was investigated by isothermal compression test with true strain of 0.69, temperature range of 750–950 °C and strain rate of 0.002–1.000 s−1. The flow stress–strain response shows the characterization of dynamic recrystallization (DRX), and the peak stress increases gradually with deformation temperature decreasing and strain rate increasing. The deformation activation energy of the composite for DRX is calculated as 241.864 kJ·mol−1. The constitutive relation of the composite was got by Arrhenius equation. Furthermore, according to the dynamic material modeling and Kumar–Prasad’s instability criteria, the processing map was constructed and the unsafe regions for hot deformation were analyzed. Based on the processing map and microstructural evolution, the optimal parameter range for hot deformation processing is 750–863 °C at the strain rate of 0.002–0.013 s−1.

Similar content being viewed by others

References

Gao HY, Wang J, Shu D, Sun BD. Microstructure and strength of Cu–Fe–Ag in situ composites. Mater Sci Eng A. 2007;452–453:367.

Wu ZW, Meng L. Influences of different prior heat treatments on the microstructural and mechanical properties of Cu–Fe filamentary composites. J Alloy Compd. 2011;509:8917.

Qu L, Wang EG, Zuo XW, Zhang L, He JC. Experiment and simulation on the thermal instability of a heavily deformed Cu–Fe composite. Mater Sci Eng A. 2011;528:2532.

Sun BD, Gao HY, Wang J, Shu D. Strength of deformation processed Cu–Fe–Ag in situ composites. Mater Lett. 2007;61:1002.

Xie ZX, Gao HY, Lu Q, Wang J, Sun BD. Effect of Ag addition on the as-cast microstructure of Cu–8 wt% Fe in situ composites. J Alloy Compd. 2010;508:320.

Ma X, Li LF, Zhang ZH, Wang H, Wang EZ, Qiu T. Microstructure and melting properties of Ag–Cu–In intermediate-temperature brazing alloys. Rare Met. 2015;34(5):324.

Liu KM, Lu DP, Zhou HT, Chen ZB, Atrens A, Lu L. Influence of a high magnetic field on the microstructure and properties of a Cu–Fe–Ag in situ composite. Mater Sci Eng A. 2013;584:114.

Jia BH, Song WD, Tang HP, Wang ZH, Mao XN, Ning JG. Hot deformation behavior and constitutive model of TC18 alloy during compression. Rare Met. 2014;33(4):383.

Sun HY, Sun YD, Zhang RQ, Wang M, Tang R, Zhou ZJ. Study on hot workability and optimization of process parameters of a modified 310 austenitic stainless steel using processing maps. Mater Des. 2015;67:165.

Yang ZN, Zhang FC, Zheng CL, Zhang M, Lv B, Qu L. Study on hot deformation behaviour and processing maps of low carbon bainitic steel. Mater Des. 2015;66:258.

Liu N, Li Z, Li L, Liu B, Xu GY. Processing map and hot deformation mechanism of novel nickel-free white copper alloy. Trans Nonferr Met Soc China. 2014;24(11):3492.

Liu Y, Zhao RL, Tian BH. Hot deformation behavior and processing maps of W–75 %Cu composite. Rare Met Mater Eng. 2012;41(5):1359.

Momenia A, Dehghania K, Keshmirib H, Ebrahimi GR. Hot deformation behavior and microstructural evolution of a superaustenitic stainless steel. Mater Sci Eng A. 2010;527:1605.

Shibayan R, Satyam S. The influence of temperature and strain rate on the deformation response and microstructural evolution during hot compression of a titanium alloy Ti–6Al–4V–0.1B. J Alloy Compd. 2013;548(25):110.

Jing X, Li CX, Zheng KH. Hot deformation behavior and microstructure of AZ231-1Sm alloy compression at elevated temperature. Rare Met Mater Eng. 2014;43(11):2573.

Li B, Pan QL, Yin ZM. Characterization of hot deformation behavior of as-homogenized Al–Cu–Li–Sc–Zr alloy using processing maps. Mater Sci Eng A. 2014;614:199.

Zeng WD, Zhou YG, Zhou J, Yu HQ, Zhang XM, Xu B. Recent development of processing maps theory. Rare Met Mater Eng. 2006;35(5):674.

Ma X, Zeng WD, Sun Y, Zhao YQ, Wang SL. A comparative study of various flow instability criteria in processing map. Rare Met Mater Eng. 2010;39(5):756.

Hu HE, Wang XY, Deng L. Comparative study of hot-processing maps for 6061 aluminium alloy constructed from power constitutive equation and hyperbolic sine constitutive equation. Mater Sci Technol. 2014;30(11):1321.

Jenab A, Taheri AK. Experimental investigation of the hot deformation behavior of AA7075: development and comparison of flow localization parameter and dynamic material model processing maps. Int J Mech Sci. 2014;78:97.

Zhang JQ, Di HS, Mao K, Wang XY, Han ZJ, Ma TJ. Processing maps for hot deformation of a high-Mn TWIP steel: a comparative study of various criteria based on dynamic materials model. Mater Sci Eng A. 2013;587:111.

Zeng WD, Xu B, He DH, Liang XB, Li SQ, Zhang JW, Zhou YG. Hot deformation characteristics of Ti-22Al-25Nb alloy using processing maps. Rare Met Mater Eng. 2007;36(4):593.

Acknowledgments

This project was financially supported by the National Natural Science Foundation of China (No. 50571035) and the National High-Tech Research and Development Project (No. 2006AA03Z528).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, JQ., Yang, H., Liu, P. et al. Hot deformation characterization and processing map of Cu–10 %Fe–1.5 %Ag in situ composite. Rare Met. 36, 912–918 (2017). https://doi.org/10.1007/s12598-016-0733-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0733-4