Abstract

High conductive and transparent In-doped ZnO thin films were deposited on glass substrates by radio-frequency (RF) magnetron sputtering at 250 °C. Argon gas was used as the sputtering gas, and its pressure varies from 0.1 to 4.0 Pa. The influences of deposition pressure on the structural, electrical and optical properties of the films were investigated by means of X-ray diffraction (XRD), scanning electron microscope (SEM) and Hall and transmittance measurements. The optical constant of the films was estimated from transmittance data using a nonlinear programming method. It is found that the deposition pressure affects the properties of the films significantly. The film deposited at 2.0 Pa shows the optimal crystal quality with a high transmittance of 85 % in the visible range and a low resistivity of 2.4 × 10−3 Ω·cm and can thus be used as a transparent electrode.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

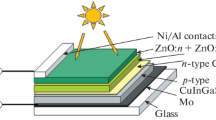

Indium tin oxide (ITO) is used as transparent conductive oxide (TCO) in many kinds of applications such as transparent electrodes, window materials in solar cell and flat panel display. However, high cost of ITO motivated efforts to develop substitutes. ZnO is a promising candidate of ITO in TCO applications due to its high optical transmission in the visible range, low resistivity, low cost, abundant and no toxic [1]. ZnO with a hexagonal structure has a wide optical band gap of 3.3 eV and shows n-type conductivity because of non-stoichiometry. The resistivity of undoped ZnO is not low enough for the use as TCO, so Group III elements such as Al, Ga and In are usually used as dopants to improve the electrical properties and stability of ZnO-based films [1–8]. Owing to its suitable ionic radius (0.062 nm) and electronegativity (1.7) [1], it was reported to be the most promising element as dopant to enhance the photoelectric properties of ZnO thin films.

To use ZnO-based materials in optical and electrical devices with high performance and reliability, it is important to deposit high-quality ZnO films with n-type characteristics. It was reported that n-type ZnO films were prepared by pulsed laser deposition (PLD), radio-frequency (RF) magnetron sputtering, chemical vapor deposition (CVD), etc. As for RF magnetron sputtering, deposition pressure affects the structural, electrical and optical properties significantly. But few reports were found about the influence of deposition pressure on RF magnetron sputtering In-doped ZnO (ZnO:In) films. In this work, ZnO:In thin films were deposited on glass substrates by RF magnetron sputtering, and the deposition pressure dependence of structural, electrical and optical properties of the ZnO:In thin films was studied. Also, a nonlinear programming method was used to estimate the optical constants of the films from only transmittance spectra.

2 Experimental

Powder target (In/(In + Zn) = 5 at%) prepared from high-purity ZnO (99.99 %) and In2O3 (99.99 %) powder was used as sputtering source material. Glass (15 mm × 15 mm × 1 mm) was used as substrate, which was ultrasonically cleaned in acetone, rinsed in alcohol and then dried in hot air. ZnO:In transparent conductive thin films were deposited by 13.56 MHz RF magnetron sputtering. The distance between the target and substrate was 70 mm. In order to avoid contaminating the film, the chamber was evacuated to a base pressure of 6.6 × 10−4 Pa. Argon gas was introduced into the chamber through a mass flow controller. The target was pre-sputtered for 15 min to remove contaminants. The mass flow of argon gas was fixed at 24 ml·min−1, and the total pressure changed from 0.1 to 4.0 Pa. The substrate temperature was maintained at 250 °C, and the deposition lasted 60 min for all the films.

The structure of the films was analyzed by X-ray diffractometer (XRD, MRD-SingleScan) with Cu Kα radiation (λ = 0.154 nm). The surface morphology of the films was investigated by scanning electron microscopy (SEM, Oxford, Nova400). The film thickness was measured by a Dektak II step-measurer. The electrical properties of the films were measured by a Bio-Rad Microscience HL5500 Hall system at room temperature. The transmission spectrum of the film was measured by a double-beam ultraviolet visible (UV–Vis) spectrophotometer in the wavelength range of 300–800 nm at room temperature, and the optical constant of the films was estimated from transmittance spectra by a nonlinear programming method.

3 Results and discussion

The film thickness was measured by a Dektak II step-measurer, and the thicknesses are 662, 393, 286 and 259 nm for the films prepared under the pressures of 0.1, 1.0, 2.0 and 4.0 Pa, respectively. Figure 1 shows the growth rate of ZnO:In thin films as a function of the deposition pressure. The deposition rate decreases from 11.0 to 4.3 nm·min−1 with deposition pressure increasing from 0.1 to 4.0 Pa. A similar result was reported by Assuncao et al. [9] for ZnO:Ga thin films prepared by RF magnetron sputtering. They suggested that with deposition pressure increasing, the mean free path decreases and the sputtered species undergo many collisions, leading to a thermalization of the film-forming particles. The surface mobility of these species decreases, and thus, the growth rate decreases.

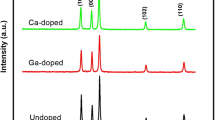

Figure 2 shows the XRD patterns of ZnO:In thin films deposited on glass at different deposition pressures. All the films show a peak at 2θ ≈ 34°, which is attributed to (002) ZnO, indicating good orientation along c-axis almost independence of the deposition pressure. No In2O3 phase is found in the XRD patterns, suggesting that In substitutes Zn in the hexagonal lattice or In segregates to non-crystalline region in the grain boundary and forms In–O bond [10]. The (002) peak becomes more intense with deposition pressure increasing, reaches a maximum at 2.0 Pa and then decreases as the deposition pressure further increases. It can be induced that the ZnO:In film deposited at 2.0 Pa has better crystal quality than others. Figure 3 shows SEM image of ZnO:In thin films deposited at 2.0 Pa, and a smooth surface with dense grain of about 80 nm in size is obtained.

The electrical resistivity of the films depends strongly on the deposition pressure. Figure 4 shows the variation in electrical resistivity (ρ) and carrier concentration (n) as a function of deposition pressure. The electrical resistivity increases slowly from 1.2 × 10−3 to 2.4 × 10−3 Ω·cm with the deposition pressure from 0.1 to 2.0 Pa, and then, it increases sharply with the deposition pressure further increasing. The carrier concentration decreases from 9.2 × 1020 to 2.1 × 1020 cm−3 with the deposition pressure increasing from 0.1 to 4.0 Pa. The lower resistivity of the films deposited at lower pressure is due to higher carrier concentration supplied from the substitution of In by replacement of the host Zn atoms. The substituted In atoms ionize into In3+ so that a free electron can be contributed. At lower pressure, the sputtered species have higher surface mobility on the substrate, which will result in more In substitution, leading to a higher carrier concentration. With deposition pressure increasing, the species kinetic energy decreases, which degrades In substitution, and thus, the carrier concentration decreases and the resistivity increases. A similar phenomenon is also found in the ZnO:Ga films [11], and the mechanism demands further experiment and investigation.

Transmittance of the ZnO:In thin films as a function of wavelength in the range of 300–800 nm is shown in Fig. 5. All the films exhibit a sharp fundamental absorption edge at about 380 nm. The transmittance of the films is affected by the deposition pressure significantly. The film deposited at 0.1 Pa shows lower transmittance because of high thickness. Film deposited at 1.0 Pa or higher pressure shows a high transmittance of about 85 % in the visible range.

To estimate the optical constants of the films using transmittance data only is a very challenging problem with many local non-global solutions. A new method based on nonlinear programming techniques proposed in Refs. [12–14] can successfully estimate the optical constant of thin film only by its transmittance spectra. Figures 6 and 7 show the obtained refractive index and extinction coefficient, respectively. As shown in Fig. 6, the refractive index increases with wavelength decreasing and is in the range of 1.9–2.6 eV, which is in comparison with the ZnO:In thin films prepared by sol–gel method reported by Caglar et al. [15]. From Fig. 7, it can be seen that all the films show a very weak extinction coefficient in the region of 400–800 nm, but below 400 nm, the extinction coefficient increases significantly. From extinction coefficient, the absorption coefficient can be obtained. Using the derived absorption coefficient, the optical band gap of the samples was estimated by extrapolation of the linear portion of square of the absorption coefficient against photon energy. The optical band gap values estimated locate at 3.26–3.48 eV.

From above, it is known that the electrical resistivity deteriorates, but the transmittance gets better with deposition pressure increasing. An optimal pressure should be chosen to deposit ZnO:In thin films as TCO. This work shows that the resistivity increases slowly, but the transmittance increases significantly with deposition pressure of lower than 2.0 Pa. The film deposited at 2.0 Pa with a lower resistivity of 2.4 × 10−3 Ω·cm and a higher transmittance of 85 % in the visible region can be used as a transparent electrode.

4 Conclusion

In-doped ZnO thin films were deposited on glass substrates by RF magnetron sputtering under different pressures from a powder target. The structural, electrical and optical properties of the films were investigated. All the ZnO:In thin films are hexagonal wurtzite with c-axis perpendicular to the substrates. The resistivity of the films increases with deposition pressure increasing, accompanied with a reduction in carrier concentration. The transmittance of the films is affected by the deposition pressure significantly, and the films deposited at a pressure of 1.0 Pa or higher have high transmittance of about 85 % in the visible range. A nonlinear programming method was used to estimate the optical constant of the films. Calculation results show that the refractive index of the films is in the range of 1.9–2.6 eV, a low weak extinction coefficient is in the visible range and the optical band gap is located at 3.26–3.48 eV. The optimal deposition pressure for ZnO:In thin films as TCO is 2.0 Pa, which has a low resistivity of 2.4 × 10−3 Ω·cm and a high transmittance of 85 % in the visible region.

References

Pearson SJ, Norton DP, Heo YW, Steiner T. Recent progress in processing and properties of ZnO. Prog Mater Sci. 2005;50(1):293.

Khranovskyy V, Grossner U, Nilsen O, Lazorenko V, Lashkarev GV, Svensson BG, Yakimova R. Structural and morphological properties of ZnO:Ga thin films. Thin Solid Films. 2006;515(3):472.

Sahu DR, Lin SY, Huang JL. Improved properties of Al-doped ZnO films by electron beam evaporation technique. Microelectron J. 2007;38(1):245.

Zhou Y, Kelly PJ, Postill A, Abu-Zeid O, Alnajjar A. A novel technique for the deposition of aluminium-doped zinc oxide films. Thin Solid Films. 2014;447–448(1):33.

Joseph B, Manoj PK, Vaidyan VK. Studies on the structural, electrical and optical properties of Al-doped ZnO thin films prepared by chemical spray deposition. Ceram Int. 2006;32(6):487.

Musat V, Teixeira B, Fortunato E, Monteriro RCC. Effect of post-heat treatment on the electrical and optical properties of ZnO:Al thin films. Thin Solid Films. 2006;502(1):219.

Gupta RK, Ghosh K, Patel R, Mishra SR, Kahol PK. Band gap engineering of ZnO thin films by In2O3 incorporation. J Cryst Growth. 2013;310(5):3019.

Lucio-Lόpez MA, Luna-Arias MA, Maldonado A, de la Olvera ML. Thickness dependence of ZnO:In thin films doped with different indium compounds and deposited by chemical spray. Sol Energy Mater Sol Cells. 2006;90(2):733.

Assuncao V, Fortunato E, Marques A, Aguas H, Ferreira I, Costa MEV, Martins R. Structural and morphology properties of ZnO:Ga thin films. Thin Solid Films. 2003;421(1):401.

Yu XH, Ma J, Ji F, Wang YH, Zhang XJ, Chang CF, Ma HL. Preparation and properties of ZnO:Ga films prepared by r.f. magnetron sputtering at low temperature. Appl Surf Sci. 2005;245(1):310.

Ma QB, Ye ZZ, He HP, Zhu LP, Zhao BH. Effects of deposition pressure on the properties of transparent conductive ZnO:Ga films prepared by DC reactive magnetron sputtering. Mater Sci Semicond Process. 2007;10(1):167.

Birgin EG, Chambouleyron I, Martinez JM. Determination of the third and fifth-order nonlinear refractive indices in InN thin films. J Comp Physiol. 1999;151(1):862.

Mulato M, Chambouleyron I, Birgin EG, Martinez JM. Determination of thickness and optical constants of amorphous silicon films from transmittance data. Appl Phys Lett. 2000;77(4):2133.

Chambouleyron I, Martinez JM, Morettti AC, Mulato M. Optical constants of thin films by means of a pointwise constrained optimization approach. Thin Solid Films. 1998;317(6):133.

Caglar M, Ilican S, Carlar Y. Influence of dopant concentration on the optical properties of ZnO:In thin films by sol–gel method. Thin Solid Films. 2009;517(6):5023.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 50942021, 50975301).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Peng, LP., He, AL., Fang, L. et al. Structure and properties of indium-doped ZnO films prepared by RF magnetron sputtering under different pressures. Rare Met. 41, 3239–3243 (2022). https://doi.org/10.1007/s12598-015-0661-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0661-8