Abstract

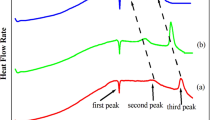

Thermodynamics for reduction of molybdenum oxides by aluminum and silicon were calculated, and the results show that reduction reaction is feasible at a certain temperature region. Compared to the presence of CaO or CaCO3, reduction products of molybdenum trioxide with aluminum and silicon at various temperatures were detected by X-ray diffraction (XRD). Results show that molybdenum trioxide is reduced by aluminum or silicon step by step, and the intermediate product is MoO2. At 1000 °C, molybdenum trioxide could be reduced to metal Mo by aluminum, and in the presence of CaO, metal Mo as the reduction product appears even at 800 °C. In contrast, silicon could barely reduce molybdenum trioxide to metal Mo even at 1200 °C. In the presence of CaO or CaCO3, reducibility of silicon increases significantly, and the reduction products are metal Mo and MoSi2. Altogether, CaO or CaCO3 performs two major roles in reduction process: restraining sublimation of MoO3 and decreasing the temperature of reducing MoO3 to metal Mo.

Similar content being viewed by others

References

An G, Sun J, Liu RZ, Li J, Sun YJ. Mechanical properties of molybdenum products prepared by using molybdenum powders with different micro-morphologies. Rare Met. 2015;34(4):276.

Wang MY, Wang XW, Jiang CJ, Tao CF. Solvent extraction of molybdenum from acidic leach solution of Ni–Mo ore. Rare Met. 2014;33(1):107.

Xiu XW, Zhao WJ. The properties of transparent conducting molybdenum-doped ZnO films grown by radio frequency magnetron sputtering. Chin Phys B. 2012;21(6):066802.

Li CX, Luo YQ, Ren RC, Cheng Q, Man D. Enriching metal elements of carbonaceous molybdenum–nickel ore before leaching. Chin J Rare Met. 2013;37(2):289.

Kennedy MJ, Bevan SC. A kinetic study of the reduction of molybdenum trioxide by hydrogen. J Less-Common Met. 1974;36(1–2):23.

Kim GS, Lee YJ, Kim DG, Kim YD. Consolidation behavior of Mo powder fabricated from milled Mo oxide by hydrogen-reduction. J Alloy Compd. 2008;454(1–2):327.

Kim BS, Kim EY, Jeon HS, Lee HI, Lee JC. Study on the reduction of molybdenum dioxide by hydrogen. Mater Trans. 2008;49(9):2147.

Schulmeyer WV, Ortner HM. Mechanisms of the hydrogen reduction of molybdenum oxides. Int J Refract Met Hard Mater. 2002;20(4):261.

Chaudhury S, Mukerjee SK, Vaidya VN, Venugopal V. Kinetics and mechanism of carbothermic reduction of MoO3 to Mo2C. J Alloy Compd. 1997;261(1–2):105.

Manukyan K, Aydinyan S, Aghajanyan A, Grigoryan Y, Niazyan O, Kharatyan S. Reaction pathway in the MoO3 + Mg + C reactive mixtures. Int J Refract Met Hard Mater. 2012;31(2):28.

Samant MS, Kerkar AS, Bharadwaj SR, Dharwadkar SR. Thermodynamic investigation of the vaporization of molybdenum trioxide. J Alloy Compd. 1992;187(2):373.

Charlu TV, Kleppa OJ. A calorimetric determination of the enthalpy of vaporization of MoO3. J Chem Thermodyn. 1971;3(5):697.

Kirshenbaum AD, Beardell AJ. Thermal analysis of the reaction of molybdenum trioxide with various metals. Thermochim Acta. 1972;4(3):239.

Mehra OK, Bose DK, Gupta CK. Molybdenum metal by the aluminothermic reduction of calcium molybdate. Metall Mater Trans B. 1973;4(3):691.

Jamshidi K, Abdizadeh H, Seyyed Ebrahimi SA, Hanai K. Metallothermic reduction of MoO3 through making Ni–Mo alloys by the ESR method. Int J Refract Met Hard Mater. 2004;22(6):243.

Gupta CK, Jena PK. Reduction of molybdenum trioxide by aluminum. J Less-Common Met. 1968;14(1):148.

Delarco M, Sanfelipe MFM, Rives V, Malet P, Ulibarri MA. Reactivity of molybdenum with silica and alumina. J Mater Sci. 1992;27(11):2960.

Andruszkiewicz R. On the Mo–Ca–O system. J Alloy Compd. 1992;186(2):369.

Acknowledgments

This study was financially supported by Hubei Provincial Natural Science Foundation of China (2015CFC838) and the Open Research Fund of Key Laboratory for Ferrous Metallurgy and Resources Utilization of Ministry of Education, Wuhan University of Science and Technology (No. FMRU201309).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, HY., Gao, R., Jin, WT. et al. Reduction characteristics of molybdenum trioxide with aluminum and silicon. Rare Met. 37, 621–624 (2018). https://doi.org/10.1007/s12598-015-0536-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0536-z