Abstract

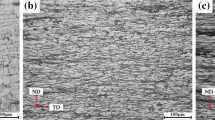

In this paper, 2024 Al alloy and AZ31B Mg alloy were brazed with aid of stirring without flux in air. The effects of the brazing temperature on microstructure and shear strength of the joint were investigated. The diffusion zone is found at joint interface near Al base metal, which consists of Al–Zn–Sn solid solution. At the same time, continuous intermetallic compounds (IMCs) phase and broken ones are found at joint interface near Mg base metal, which mainly consists of the Mg2Sn phase. With the increase of the brazing temperature, the shear strength at the joint interface near Al base metal rises gradually. On the contrary, that of the joint interface near Mg base metal obviously decreases.

Similar content being viewed by others

References

Liu LM, Liu XJ, Liu SH. Microstructure of laser-TIG hybrid welds of dissimilar Mg alloy and Al alloy with Ce as interlayer. Scripta Mater. 2006;55(4):383.

Mofid MA, Abdollah-Zadeh A, Malek Ghaini F. The effect of water cooling during dissimilar friction stir welding of Al alloy to Mg alloy. Mater Des. 2012;36(4):161.

Qi XD, Liu LM. Fusion welding of Fe-added lap joints between AZ31B magnesium alloy and 6061 aluminum alloy by hybrid laser–tungsten inert gas welding technique. Mater Des. 2012;33(1):436.

Joseph Fernandus M, Senthilkumar T, Balasubramanian V, Rajakumar S. Optimising diffusion bonding parameters to maximize the strength of AA6061 aluminium and AZ31B magnesium alloy joints. Mater Des. 2012;21(11):31.

Wang Z, Wang HY, Liu LM. Study on low temperature brazing of magnesium alloy to aluminum alloy using Sn–xZn solders. Mater Des. 2012;39(8):14.

Liu LM, Tan JH, Zhao LM, Liu XJ. The relationship between microstructure and properties of Mg/Al brazed joints using Zn filler metal. Mater Charact. 2007;59(4):1.

Yan JC, Xu ZW, Li ZY, Li L, Yang SQ. Microstructure characteristics and performance of dissimilar welds between magnesium alloy and aluminum formed by friction stirring. Scripta Mater. 2005;53(5):585.

Liu LM, Ren DX. A novel weld-bonding hybrid process for joining Mg alloy and Al alloy. Mater Des. 2011;32(7):3730.

Liu P, Li YJ, Gen HR, Wang J. Microstructure characteristics in TIG welded joint of Mg/Al dissimilar materials. Mater Lett. 2007;61(6):1288.

Yan Y, Zhang DT, Qiu C, Zhang W. Dissimilar friction stir welding between 5052 aluminum alloy and AZ31 magnesium alloy. Trans Nonferrous Met Soc China. 2010;20:619.

Shigematsu I, Kwon YJ, Saito N. Dissimilar friction stir welding for tailor-welded blanks of aluminum and magnesium alloys. Mater Trans. 2009;50(1):197.

Li YJ, Liu P, Wang J, Ma HJ. XRD and SEM analysis near the diffusion bonding interface of Mg/Al dissimilar materials. Vacuum. 2008;82(1):15.

Liu LM, Tan JH, Liu XJ. Reactive brazing of Al alloy to Mg alloy using zinc-based brazing alloy. Mater Lett. 2007;61(11):2373.

Smetana B, Zla S, Kroupa A, Zaludova M, Drapala J, Burkovic R, Petlak D. Phase transition temperatures of Sn–Zn–Al system and their comparison with calculated phase diagrams. J Therm Anal Calorim. 2012;110(1):369.

Meng FG, Wang J, Liu LB, Jin ZP. Thermodynamic modeling of the Mg–Sn–Zn ternary system. J Alloy Compd. 2010;508(2):570.

Ge YM, Song L, Huang JH, Liu CL, Zhang T, Tegus O. Structure and corrosion resistance of composite ceramic coating prepared by EASP/MAO on AZ91D magnesium alloy. Chin J Rare Met. 2013;37(4):543.

Acknowledgments

The work was financially supported by the Natural Science Foundation Project of Chongqing Science and Technology Commission (No. cstc2011jjA50001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, HB., Sun, HB., Yang, H. et al. Microstructure and properties of joint for stirring brazing of dissimilar Al/Mg alloy during heating processes. Rare Met. 34, 245–250 (2015). https://doi.org/10.1007/s12598-014-0391-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0391-3