Abstract

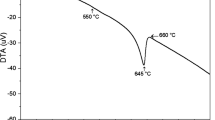

In this paper, the AlMgB14 and AlMgB14–TiB2 composites were synthesized by means of mechanical alloying and the field-activated and pressure-assisted synthesis process. The effect of temperature and pressure on the purity and property of products was discussed. The results show that the process of preparing AlMgB14 bulk materials is optimized as follows: synthesis temperature 1,400–1,500 °C, heating rate 100 °C·min−1, axial pressure 60 MPa, heat preservation 8–10 min, optimum starting powders’ ratio Al: Mg: B = 0.1915:0.1363:0.6722, and adding excessive 3 wt% Al. The abrasion resistance of AlMgB14 composites with varying amounts of TiB2 was studied using single-point diamond scratch tests with loads ranging from 10 to 100 N in 10 N increments. The scratch width increases almost linearly with the applied load and decreases with TiB2 proportion increasing up to 70 wt%. With its advantages of fast heating, short reaction time, energy conservation, and high purity, this method offers a new way to synthesize AlMgB14 and AlMgB14–TiB2 composites.

Similar content being viewed by others

References

Cook BA, Harringa JL, Lewis TL. A new class of ultra-hard materials based on AlMgB14. Scripta Mater. 2000;6(42):597.

Cook BA, Russell AM, Harringa JL. A new fracture-resistant binder phase for use with AlMgB14 and other ultra-hard ceramics. Alloys Compd. 2004;366(1–2):145.

Roberts David J, Zhao JF, Munir Zuhair A. Mechanism of reactive sintering of MgAlB14 by pulse electric current. Refract Metals Hard Mater. 2009;27(3):556.

Okada S, Shishido T, Mori T, Iizumi K, Kudou K, Nakajima K. Crystal growth of MgAlB14-type compounds using metal salts and some properties. J Alloy Compd. 2008;458(1–2):297.

Higashi I, Kobayashi M, Okada S, Hamano K, Lundstrom T. Boron-rich crystals in Al–M–B (M = Li, Be, Mg) systems grown from high-temperature aluminum solutions. Cryst Growth. 1993;128(1–4):1113.

Takeda M, Fukuda T, Domingo F, Miura T. Thermoelectric properties of some metal borides. Solid State Chem. 2004;177(2):471.

Roberts David J, Zhao Jinfeng, Munir Zuhair A. Mechanism of reactive sintering of MgAlB14 by pulse electric current. Int J Refract Metals Hard Mater. 2009;27(3):556.

Meng QS, Fan WH, Chen RX. Thermoelectric properties of Sc- and Y-doped Mg2Si prepared by field-activated and pressure assisted reactive sintering. J Alloy Compd. 2011;509(30):7922.

Munir ZA. The effect of external electric fields on the nature and properties of materials synthesized by self-propagating combustion. Mater Sci Eng, A. 2000;287(2):125.

Kedim OEl, Paris S, Phigini C, Bernard F, Gaffet E, Munir ZA. Electrochemical behavior of nanocrystalline iron aluminide obtained by mechanically activated field activated pressure assisted synthesis. Mater Sci Eng, A. 2004;369(1–2):49.

Zhang N, Chen SP, Liang LJ. In-situ synthesis of (TiC)_pNi/TiAl/Ti functional gradient materials via field-activated process. Rare Metal Mater Eng. 2011;40(4):620.

Chen SP, Meng QS, Zhang N, Xue PF, Munir Zuhair A. In situ synthesis and bonding of TiTiAlTiC/Ni functionally graded materials by field-activated pressure-assisted synthesis process. Mater Sci Eng, A. 2012;538(5):103.

Zhang JC, Fang M, Jin YX, He HB. Design of wideband graded-index antireflection coatings at oblique light incidence. Chin Phys B. 2012;21(1):014202.

Zhang JM, Gao D, Xu KW. The structural, electronic and magnetic properties of the 3d TM (V, Cr, Mn, Fe Co, Ni and Cu) doped ZnO nanotubes: a first-principles study. Sci China-Phys Mech Astron. 2012;55(3):428.

Zhang ZF, Jia XP, Liu XB, Hu MH, Li Y, Yan BM, Ma HA. Effects of aluminum additive on diamond crystallization in the Fe–Ni–C system under high-temperature and high-pressure conditions. Sci China-Phys Mech Astron. 2012;55(5):781.

Su YJ, Dond C, Zhu M, Xu J, Fan PH. Effects of growth temperature on μc-Si: H films prepared by plasma assistant magnetron sputtering. Rare Met. 2012;31(2):193.

Merzhanov AG, Borovinskaya IP. A new class of combustion processes. Combust Sci Technol. 1975;10(5–6):195.

Kevorkijan V, Skapin SD, Jelen M. Cost-effective synthesis of AlMgB14–x TiB2. J Eur Ceram Soc. 2007;27(2–3):493.

Zhang WG, Liu L. Solidification microstructure of directionally solidified superalloy under high-temperature gradient. Rare Met. 2012;31(6):541.

Lewis TL, Cook BA, Harringa JL. Al2MgO4, Fe3O4, and FeB impurities in AlMgB14. Mater Sci Eng. 2003;351(1–2):117.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 50975190).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhuang, L., Miao, Y., Liu, W. et al. Preparation and scratch test of AlMgB14 modified by TiB2 . Rare Met. 34, 101–106 (2015). https://doi.org/10.1007/s12598-013-0181-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0181-3