Abstract

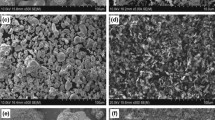

Diamond impregnated Cu-Fe-Co based saw-blade segments are directly processed by vacuum and pressure-assisted sintering at different temperature, with the purpose of reducing the cobalt content in diamond tools. Copper and iron are used as the bonding elements and cobalt-chrome pre-alloyed powder is used as the hardening phase. Effects of sintering temperature on microstructures and mechanical properties of the sintered matrix and diamond graphitization were investigated by X-ray diffraction analysis, electron probe micro-analyzer, universal testing machine, digital Rockwell hardness tester and Raman scattering analyzer. Results showed that microstructures of the sintered matrix were refined and porosities in the sintered matrix were closed to a more spherical-like shape with the increase of the sintering temperature. Densification, hardness and tensile strength of the matrix sintered at 820 °C were 12.75%, 2.72% and 156.38% higher than that of the matrix sintered at 740 °C, respectively. Diamond graphitization was not occurred at 820 °C. The hardness and the tensile strength rose 32.8% and 13.5%, respectively, after 7.5 h ageing treatment. The matrix densification ascent and the dispersed distribution of Co-Cr pre-alloyed powders contributed a hardness improvement and a tensile strength improvement to the Cu-Fe based matrix.

Similar content being viewed by others

References

Viliar M., Muro P., Sanchez J.M., Iturriza I. and Castro F., Consolidation of diamond tools using Cu-Co-Fe based alloys as metallic binders, Powder Metallurgy, 2001, 44(1): 82.

Ilio A.D., and Togna A., A theoretical wear model for diamond tools in stone cutting, International Journal of Machine Tools and Manufacture, 2003, 43(11): 1171.

Zeren M., and Kargoz S., Sintering of polycrystalline diamond cutting tools, Materials & Design, 2007, 28(3): 1055.

Webb S.W., Diamond retention in sintered cobalt bonds for stone cutting and drilling, Diamond and Related Materials, 1999, 8(11): 2043.

Silva S., Mammana V.P., Salvadori M.C., Monteiro O.R. and Brown I.G., WC-Co cutting tool inserts with diamond coatings, Diamond and Related Materials, 1999, 8(9): 1913.

Barbosa A.P., Bobrovnitchii G.S., Skyry A.L., Guimars RS. and Filgueira M., Structure, microstructure and mechanical properties of PM Fe-Cu-Co alloys, Material and Design, 2010, 31(1): 522.

Oliveriar L., Bobrovnitchii G.S., and Figuleira M., Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix, International Journal of Refractory Metals and Hard Materials, 2007, 25(4): 328.

Oliverira H.C., Cabral S.C., Cuimaraes R.S., Bobrovnitchii G.S., and Filgueira M., Processing and characterization of a cobalt based alloy for use in diamond cutting tools, Materials Science and Engineering Technology, 2009, 40(12): 907.

Clark I.E., and Kamphuis B.J., Cobalite HDR-a new prealloyed matrix powder for diamond construction tools, Industrial Diamond Review, 2002, 62(3): 177.

Weber G., and Weiss C., DIAMIX: A family of bonds based on DIABASE-V21, Industrial Diamond Review, 2005, 65(2): 28.

Li W.S., Yuan K.X., Li G.Q., and Lu Y., Investigation on Cu-Fe based diamond composite preparation and properties, Materials Review, 2010, 24(1): 78.

Solin S.A., and Ramadas A.K., Raman spectrum of diamond, Physical Review B, 1970, 1(4): 1687.

Thorat R.R., Brahmankar P.K., and Mohan T.R.R., Consolidation behavior of Cu-Co-Fe pre-alloyed powders, [in] International Symposium of Research Students on Material Science and Engineering, Chennai: Indian Institute of Technology Madras, 2004: 1.

Go Y.S., and Spitzig W.A., Strengthening in deformation-processed Cu-20%Fe composites, Journal of Materials Science, 1991, 26(1): 163.

Ansell G.S., and Lenel F.V., Criteria for yielding of dispersion-strengthened alloys, Acta Metallurgica, 1960, 8(9): 612.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, W., Zhan, J., Wang, S. et al. Characterizations and mechanical properties of impregnated diamond segment using Cu-Fe-Co metal matrix. Rare Metals 31, 81–87 (2012). https://doi.org/10.1007/s12598-012-0467-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-012-0467-x