Abstract

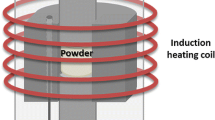

This research is devoted to studying the mechanical characteristics of diamond-drilling-tool matrix. The infiltration method at a temperature of 1100–1150°C for 15 min in hydrogen medium was used for making model diamond-containing and diamond-free samples of 24 × 7 × 8 mm matrices of two types differing in content of nickel and fused tungsten carbide, namely WC-Co-Cu (1) and WC-Co-Cu-Ni + cast tungsten carbide (2). A8K160 (500/400 μm), AC50 (500/400 μm), and SDB1125 (30/40 mesh, i.e., 600/425 μm) diamonds were used as diamond-filling materials with a concentration of 9 vol % in the matrix. The bending strength, hardness, density, porosity, and abrasive resistance of drilling tool matrix samples are measured. It is found that WC-Co-Cu-Ni matrix samples have higher hardness and abrasive resistance when compared with WC-Co-Cu, which is explained by the occurrence of nickel and solid particles of tungsten carbide solids in them. The introduction of diamonds in the matrices results in a substantial increase in their hardness (by 8–10 HRC units), which distorts the hardness measured data of matrices in the diamond layer of drill crowns.

Similar content being viewed by others

References

Budyukov, Yu.E., Vlasyuk, V.I., and Spirin, V.I., Almaznyi instrument dlya bureniya napravlennykh i mnogostvol’nykh skvazhin (Diamond Tool for Drilling the Directionally and Simultaneously Drilled Wells), Tula: ZAO “Grif i K”, 2007.

Polushin, N.I., Laptev, A.I., and Baragunov, E.M., Tsvetn. Met., 2013, no. 2, p. 72.

Osnovy proektirovaniya i tekhnologiya izgotovleniya abrazivnogo i almaznogo instrumenta (Design Foundations and Technology for Making the Abrasive and Diamond Tool), Bakulya, V.N., Eds., Moscow: Mashinostroenie, 1975.

Polushin, N.I., Laptev, A.I., and Baragunov, E.M., Tsvetn. Met., 2013, no. 1, p. 60.

GOST (State Standard) 9206-80. Diamond Powders (Technical Conditions), Moscow: Izd. Standartov, 1989.

Bugakov, V.I., Laptev, A.I., Polushin, N.I., et al., Materialovedenie, 2004, no. 2, p. 24.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © R.Kh. Atabiev, N.I. Polushin, A.I. Laptev, M.N. Sorokin, A.B. Tleuzhev, A.S. Kushkhabiev, 2013, published in Izvestiya VUZ. Poroshkovaya Metallurgiya, 2013, No. 4, pp. 13–18.

About this article

Cite this article

Atabiev, R.K., Polushin, N.I., Laptev, A.I. et al. Composition dependence of mechanical properties of diamond segments. Russ. J. Non-ferrous Metals 56, 73–78 (2015). https://doi.org/10.3103/S1067821215010046

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821215010046